You have to be pathologically focused on cost reduction to use them in the signal path.

Or space constrained. Otherwise, high value X5Rs are not much cheaper than a common electrolytic, 47u/25V is $1.5 in singles, @DigiKey.

Or space constrained. Otherwise, high value X5Rs are not much cheaper than a common electrolytic, 47u/25V is $1.5 in singles, @DigiKey.

Yep, and the MLCCs are still going in and out of stock due to demand.

By coincidence I'm just finishing up a DIY project that uses AC coupling capacitors. Since the input impedance is 50K I've chosen 2.2 microfarads, and since space and cost are not an issue, I've chosen the Kemet F461 polypropylene film capacitor in 1% tolerance grade.

It's under two dollars at Mouser in (qty=100): link to sales page

It's under two dollars at Mouser in (qty=100): link to sales page

Fresh off the press:

https://www.ti.com/lit/an/slyt796/s...dium=email&utm_source=Eloqua&ts=1601389441251

Nothing really new, although I find fig. 4 quite interesting.

I did suggest to TI that they include the CDE FCA acrylic film cap you had mentioned in the Ikoflexer 1000x thread:

My version of the G = 1000 low noise measurement amp (for Ikoflexer).

I did suggest to TI that they include the CDE FCA acrylic film cap you had mentioned in the Ikoflexer 1000x thread:

My version of the G = 1000 low noise measurement amp (for Ikoflexer).

That looks quite similar to the Rubycon PMLCAP line.

Product Information: PMLCAP Technical Notes/Hybrid, Capacitor, Power Supply Units RUBYCON CORPORATION

Gentlemen, I wish to remind you of other factors such as DA and hysteresis in ceramics, and certainly DA in tant and aluminum caps. These need to be measured with different test methods.

Great quote and conclusion. It all comes down to money and size. ...

That's what she said.

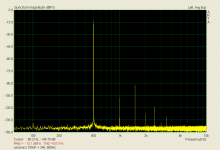

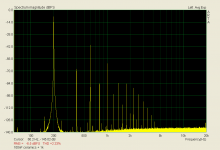

100nF ceramics loaded with 24kohm at 500Hz, and the same capacitor loaded with 1kohm at 200Hz.

Hey buddy,

Great to see ya!

😛

Before we get dragged into another meaningless argument -- does anyone have new insights (no, lets make that good hard, useful data) or just beating a dead horse?

Mark,

Let me know if you get THD of .25% at 20 Hz that then drops.

ES

Did you get an answer? I used NOS TRW PS caps in a Pas Labs style JFET buffer and had -90dB at the -3dB point IIRC somewhere below 20Hz. The distortion was all from the open-loop input amplifier.

I guess not, the phono discussions (including the arguments over the 30-40yr. old circuits) have moved elsewhere.

...does anyone have new insights (no, lets make that good hard, useful data) or just beating a dead horse?

Interesting dichotomy. Nothing in-between, or nothing, say, sorta orthogonal?

I bought a cheap ebay TPA3116 amp for the garage; something to get me by until I stumble upon something else I can use out there. I like to listen to music casually when I'm working on something - or out in the yard after opening the door. I've got a pair of Energy E:XL-15Ws mounted up high at the back end.

When I fired it up, was disappointed - even for $15 - with remote, battery included. Seeing the capacitor article here, made me wonder. I'm fair at tracing PCB routing and found the signal path into the 3116 quickly, which contained a pair of...must've been 402 surface mount ceramic caps - along with a series resistor.

I figured I could land a leaded .33u MKS part there. Got one in, then it turned into a disaster. I just cant work at that pitch without making a mess out of it. Ended up lifting the pins with a sewing needle in a final hail mary pass to make a connection, after cleaning up all the solder bridges. Shortening today's story, no smoke upon power on and both channels work.

Sounds better too. Really. I'll extend myself this way, even for the garage. ;')

When I fired it up, was disappointed - even for $15 - with remote, battery included. Seeing the capacitor article here, made me wonder. I'm fair at tracing PCB routing and found the signal path into the 3116 quickly, which contained a pair of...must've been 402 surface mount ceramic caps - along with a series resistor.

I figured I could land a leaded .33u MKS part there. Got one in, then it turned into a disaster. I just cant work at that pitch without making a mess out of it. Ended up lifting the pins with a sewing needle in a final hail mary pass to make a connection, after cleaning up all the solder bridges. Shortening today's story, no smoke upon power on and both channels work.

Sounds better too. Really. I'll extend myself this way, even for the garage. ;')

jjasniew,

You might want to consider a good soldering microscope. They change everything when working with small parts.

You might want to consider a good soldering microscope. They change everything when working with small parts.

Interesting dichotomy. Nothing in-between, or nothing, say, sorta orthogonal?

When it comes to capacitors, we've run the gamut. My reply was supposed to be under John's, but our dear loquacious ALD hopped in between.

How to explain myself? I bought a cheap amp to have some music in the shop. Then I read "You have to be pathologically focused on cost reduction to use them [ceramics...] in the signal path" and realized what I had purchased probably fits this description exactly. Looking into it, I found this to be true. So, naturally, I took a swag at improving it.

My tools and working conditions were abysmal for the job but I went ahead anyway. As horrible as I did it, now covered in glue, it'll last until something else comes along. If I had to do it again, I'd ask my wife to make the connections; she has more fine pitch SMT component exchange experience that I. We used to have the microscope and SMT hot tweezers at work - dont have those nor access now. I do have a temp controlled heat gun, but the end with the smallest tube would have unsoldered 10 parts around the two I was going after...

I believe the chip, sounds better than the cap that was placed in front of it. Upstream, that is.

My tools and working conditions were abysmal for the job but I went ahead anyway. As horrible as I did it, now covered in glue, it'll last until something else comes along. If I had to do it again, I'd ask my wife to make the connections; she has more fine pitch SMT component exchange experience that I. We used to have the microscope and SMT hot tweezers at work - dont have those nor access now. I do have a temp controlled heat gun, but the end with the smallest tube would have unsoldered 10 parts around the two I was going after...

I believe the chip, sounds better than the cap that was placed in front of it. Upstream, that is.

- Home

- Member Areas

- The Lounge

- The Black Hole......