Fresh off the press:

https://www.ti.com/lit/an/slyt796/s...dium=email&utm_source=Eloqua&ts=1601389441251

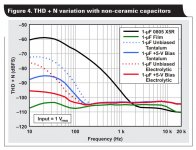

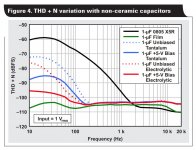

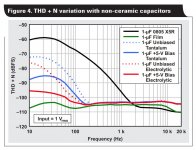

Nothing really new, although I find fig. 4 quite interesting.

https://www.ti.com/lit/an/slyt796/s...dium=email&utm_source=Eloqua&ts=1601389441251

Nothing really new, although I find fig. 4 quite interesting.

I was pleasantly surprised by how well the X7R's did hold up. Certainly not great, but one could do worse (easy enough to go way higher than 4.7 uF, as well to push the corner down).

Still I prefer films for obvious reasons.

Still I prefer films for obvious reasons.

Not to mention that 20k input impedance is still in the low range. For audio small signal applications, IMO the main problem is not distortions, but microphony.

Not to mention that 20k input impedance is still in the low range. For audio small signal applications, IMO the main problem is not distortions, but microphony.

I made the mistake about 15 yrs ago of using a cheap ceramic cap in a EFT damping network. When I tested the amp into a resistive load, the cap ‘sang’ loudly at the test frequency.

Of course. It’s what happens when you’re sloppy about component selection. Great for decoupling DC, not great where you have tens of AC volts swinging across the cap.

Syn, I don't understand the baseline. -105 to -110 dB distortion seems to be the lowest they get. Whereas in real life, I think it should be better than -150 dB for film.

What about NP0/C0G type, is there microphony too?

No. Absolutely nothing and that’s what I’ve gone with (500V 1206).

I use COG/NPO for all filtering, EQ etc.

It is a good thing that some engineer, somewhere, reminds everybody here that most ceramic caps have an awful lot of harmonic distortion, especially when actually dropping some AC signal across them. But this is not the only problem with ceramic or other than the best film caps. There are other serious problems like Dielectric Absorption (DA), vibration sensitivity, and even 'non return to zero' (hysteresis). These other factors can be just as important in cap selection. In the end, usually, the best cap is NO CAP and this is possible much of the time. Why not try it?

Once, back in the 90s, I replaced the non-polar electrolytic capacitors in the preamplifier with military ceramic with palladium plates.

These military capacitors cost a lot of money and are recyclable for the price of gold. However, to my disappointment, the electrolytes sounded much better. Then I remembered that electrolytic capacitors were used in many Japanese tape recorders, even in very expensive models like the Nakamichi. A friend recently bought Energy Veritas speakers from Canada in a brand new condition. Their filters are filled with electrolytic capacitors, but so far these speakers sound worse at midrange than b & w. The midrange drivers are probably not yet warmed up, or electrolytic capacitors in higher voltage speakers still sound worse.

These military capacitors cost a lot of money and are recyclable for the price of gold. However, to my disappointment, the electrolytes sounded much better. Then I remembered that electrolytic capacitors were used in many Japanese tape recorders, even in very expensive models like the Nakamichi. A friend recently bought Energy Veritas speakers from Canada in a brand new condition. Their filters are filled with electrolytic capacitors, but so far these speakers sound worse at midrange than b & w. The midrange drivers are probably not yet warmed up, or electrolytic capacitors in higher voltage speakers still sound worse.

Last edited:

I agree if you can easily avoid a cap then do so. But, good quality caps with zero distortion are now available and we also know, thanks to Cyril Bateman and Douglas Self, how to better apply them, avoiding their worst pitfalls.

Standard XR7 type MLCC’s are great for decoupling power supply rails and that’s where they should remain.

You have to be pathologically focused on cost reduction to use them in the signal path. Well, that’s my take on it.

Standard XR7 type MLCC’s are great for decoupling power supply rails and that’s where they should remain.

You have to be pathologically focused on cost reduction to use them in the signal path. Well, that’s my take on it.

ADJ caps to minimize distortion in audio apps slyt796

Analog Design Journal's Selecting Caps to Minimize Distortion in Audio Apps [slyt796].

View attachment ADJ caps to min dist in audio slyt796.pdf

By Zak Kaye; Applications Engineer; Precision Analog-to-Digital Converters

ADJ 3Q 2020

Some great quotes:

...

The use of capacitors in an audio signal chain is often fraught with mysticism and little quantitative analysis to justify capacitor selection. With many capacitors costing more than the integrated circuits they serve, it is a challenge to determine a solution that balances cost, size and performance.

...

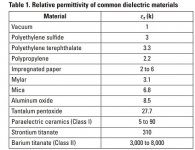

MLCC capacitors are organized into different classes depending primarily on their thermal range and stability over that range. Class II ceramics are often referred to as “high k” because their relative permittivities range from 3,000 (X7R) up to 18,000 (Z5U). By contrast, Class I C0G/NP0 capacitors tend to have relative permittivities in the range of 6 to 200. They are “high-performance” ceramic capacitors because their capacitance is more stable than most other dielectrics.

...

The change in capacitance with applied voltage is known as the capacitor’s voltage coefficient, and it can be the dominant source of distortion in the low-frequency spectrum where capaci-tor impedance is relatively high. Furthermore, as the signal amplitude increases, greater distortion occurs.

...

Minimizing the voltage drop across the capacitor will miti-gate distortion. One approach to do this is to increase the impedance in series with the capacitor to limit the current flowing through it.

...

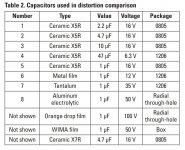

Note that the 47-μF capacitor tested was in a 1206 package, and increasing the package size will also tend to slightly reduce distortion.

...

and the illuminating Fig 4 that was mentioned:

...

THD+N tests were also performed using the TLV320ADC6140 EVM[3] with these capacitor types:

• A standard 1-μF 0805 X5R capacitor.

• 1-μF surface-mount-technology (SMT) tantalum capacitor.

• 1-μF through-hole aluminum electrolytic capacitor.

• A 1-μF SMT film capacitor

...

As expected, the 1-μF SMT film capacitor offers the best performance over the full audio bandwidth, with the electrolytic capacitor as a runner-up. The film capacitor is available in a 1206 surface-mount package with a metallized acrylic dielectric and a 12-V rating.

aaaaannd

When tested, other 1-μF film capacitors with polyester and polypropylene dielectrics and higher voltage ratings did not significantly deviate from the performance shown in Figure 4. The main drawback of film capacitors is their low relative permittivity. Thus, film capacitors tend to be much larger than their MLCC counterparts.

...

PLUS:

Because of this internal bias, +6.5 V was provided at the input of the evaluation module for the +5-V test case. Comparing the two sets of data shows a significant difference in performance when polarized capacitors are not properly biased. High-performance applications must guarantee a positive DC bias or avoid the use of polarized capacitors for AC coupling.

and, in conclusion:

Many factors influence capacitor performance, and capacitors should be chosen carefully based on application needs. There is much debate in the audio community about the best metric to use for a capacitor. This article focuses on how differences in capacitors affect distortion in a real application.

😉

Please discuss!

😱

PS Hows aboot one of you EE types give us an opamp filter with proper biasing using G A S P electrolytics. Figure 4 shows that they're almost as good as film but at a FRACTION of the cost.

Analog Design Journal's Selecting Caps to Minimize Distortion in Audio Apps [slyt796].

View attachment ADJ caps to min dist in audio slyt796.pdf

By Zak Kaye; Applications Engineer; Precision Analog-to-Digital Converters

ADJ 3Q 2020

Some great quotes:

...

The use of capacitors in an audio signal chain is often fraught with mysticism and little quantitative analysis to justify capacitor selection. With many capacitors costing more than the integrated circuits they serve, it is a challenge to determine a solution that balances cost, size and performance.

...

MLCC capacitors are organized into different classes depending primarily on their thermal range and stability over that range. Class II ceramics are often referred to as “high k” because their relative permittivities range from 3,000 (X7R) up to 18,000 (Z5U). By contrast, Class I C0G/NP0 capacitors tend to have relative permittivities in the range of 6 to 200. They are “high-performance” ceramic capacitors because their capacitance is more stable than most other dielectrics.

...

The change in capacitance with applied voltage is known as the capacitor’s voltage coefficient, and it can be the dominant source of distortion in the low-frequency spectrum where capaci-tor impedance is relatively high. Furthermore, as the signal amplitude increases, greater distortion occurs.

...

Minimizing the voltage drop across the capacitor will miti-gate distortion. One approach to do this is to increase the impedance in series with the capacitor to limit the current flowing through it.

...

Note that the 47-μF capacitor tested was in a 1206 package, and increasing the package size will also tend to slightly reduce distortion.

...

and the illuminating Fig 4 that was mentioned:

...

THD+N tests were also performed using the TLV320ADC6140 EVM[3] with these capacitor types:

• A standard 1-μF 0805 X5R capacitor.

• 1-μF surface-mount-technology (SMT) tantalum capacitor.

• 1-μF through-hole aluminum electrolytic capacitor.

• A 1-μF SMT film capacitor

...

As expected, the 1-μF SMT film capacitor offers the best performance over the full audio bandwidth, with the electrolytic capacitor as a runner-up. The film capacitor is available in a 1206 surface-mount package with a metallized acrylic dielectric and a 12-V rating.

aaaaannd

When tested, other 1-μF film capacitors with polyester and polypropylene dielectrics and higher voltage ratings did not significantly deviate from the performance shown in Figure 4. The main drawback of film capacitors is their low relative permittivity. Thus, film capacitors tend to be much larger than their MLCC counterparts.

...

PLUS:

Because of this internal bias, +6.5 V was provided at the input of the evaluation module for the +5-V test case. Comparing the two sets of data shows a significant difference in performance when polarized capacitors are not properly biased. High-performance applications must guarantee a positive DC bias or avoid the use of polarized capacitors for AC coupling.

and, in conclusion:

Many factors influence capacitor performance, and capacitors should be chosen carefully based on application needs. There is much debate in the audio community about the best metric to use for a capacitor. This article focuses on how differences in capacitors affect distortion in a real application.

😉

Please discuss!

😱

PS Hows aboot one of you EE types give us an opamp filter with proper biasing using G A S P electrolytics. Figure 4 shows that they're almost as good as film but at a FRACTION of the cost.

Last edited:

Great quote and conclusion. It all comes down to money and size. When many talk about uncompromising quality, it always makes me laugh 🙂

If you look into the filters of expensive speakers, you can see the cheapest film capacitors from China, Taiwan, or electrolytic capacitors. If you look at amplifiers, you will see other things that have saved money, like output terminals and the like, or reduced capacitors.

If you look into the filters of expensive speakers, you can see the cheapest film capacitors from China, Taiwan, or electrolytic capacitors. If you look at amplifiers, you will see other things that have saved money, like output terminals and the like, or reduced capacitors.

Last edited:

- Home

- Member Areas

- The Lounge

- The Black Hole......