Hi NWCgrad,

Assuming this is still about the 18" Maelstrom (I guess it has been discontinued), if you can get me clear sideview, frontview and rearview pictures, and accurate dimensions for the driver dimensions, I'll see what I can come up with. Without these dimensions it's just guesswork.

Regards,

Oliver, Unfortunately the driver is discontinued, but since I already own one I can proceed with the build when the navy decides to send me back to the US.

I am attaching data from bjorno (including the driver dimensions) and data from winISD on the driver parameters.

Thanks for all of your assistance, I am having difficulties invisioning the folding - trying to keep the geometry correct using only PowerPoint and Paint is probably futile.

Attachments

Hi NWCgrad,

Let's see what we can do with that. I'm going on the assumption, that the general form factor of the double fold from Post #50 is acceptable; that one came in at 20"W x 32"D x 48"H. I'll see where we end up with bjorno's numbers. It'll probably take a few days until I get to it, let me know if you come up with some idea as to form factor.

Regards,

Let's see what we can do with that. I'm going on the assumption, that the general form factor of the double fold from Post #50 is acceptable; that one came in at 20"W x 32"D x 48"H. I'll see where we end up with bjorno's numbers. It'll probably take a few days until I get to it, let me know if you come up with some idea as to form factor.

Regards,

Hi NWCgrad,

Let's see what we can do with that. I'm going on the assumption, that the general form factor of the double fold from Post #50 is acceptable; that one came in at 20"W x 32"D x 48"H. I'll see where we end up with bjorno's numbers. It'll probably take a few days until I get to it, let me know if you come up with some idea as to form factor.

Regards,

Oliver,

That would be great! I assume it will be deeper than 32" using Bjorno's numbers, I assume you saw his comments in post #57:

It looks like tb46 drawing(.pdf) show an inch less internal dimension behind the driver(without clearance) than whats necessary to fit the driver.

The proposed thickness of wood is ~18mm(0.72"). I suggest at least a 3 times thicker.for the baffle and second of dividers = (~11 cm in total) ~1.88" added for driver clearance.

b🙂

PS: 3" clearance is IMO quite adequate.

I believe a folded design will match nicely witht he 4 LAB-12's that are also in process of being designed by you and Bjorno. I am EXTREMELY grateful for the assistance you are providing, without your help I would be building an LLT (20 cu ft) for Mal-x and sealed cubes for the LAB-12.

These two designs will really maximize the potential of the drivers, I expect that they will sound fantastic!

It'll probably take a few days until I get to it, let me know if you come up with some idea as to form factor.

Oliver, I used Paint to cut and fold a 1:10 scale drawing of bjorno's design (attached). I know it is probably not very accurate, the angles are all off, but it does give an idea of the form factor. My wife liked the look of the double-fold vice the single-fold.

Best, Steve

Attachments

Hi NWCgrad,

I derived a sideview of the driver from the data in Post #61.

Working from bjorno's Hornresp model (Post #61) I ended up with a first try that uses a constant 3 degree angle. This is just a first stab at it (still a little bigger than necessary), but at least you can get an idea of where this goes, and maybe it's just fine as it is, anyway:

My questions right now are:

1. Is the overall size acceptable?

2. Do you want to build up the baffle boards as bjorno described it in Post #57?

3. Do you want to add a center divider to support all the panels (this adds one wood thickness to the interior width, unless you cut a lot of holes/cutouts into the center support)? In this 1st try I added the displaced volume to the duct height.

4. Where do you want the port to be located? Bjorno's Hornresp places the port directly adjacent to the front of the woofer. A round port in that location would also be my preference.

5. I'm drawing with 18mm/0.709" wood thickness, if you want another thickness, this would be the time to change it.

Don't quite know when I'll get back to this, but it won't be too long. 🙂

Regards,

I derived a sideview of the driver from the data in Post #61.

Working from bjorno's Hornresp model (Post #61) I ended up with a first try that uses a constant 3 degree angle. This is just a first stab at it (still a little bigger than necessary), but at least you can get an idea of where this goes, and maybe it's just fine as it is, anyway:

My questions right now are:

1. Is the overall size acceptable?

2. Do you want to build up the baffle boards as bjorno described it in Post #57?

3. Do you want to add a center divider to support all the panels (this adds one wood thickness to the interior width, unless you cut a lot of holes/cutouts into the center support)? In this 1st try I added the displaced volume to the duct height.

4. Where do you want the port to be located? Bjorno's Hornresp places the port directly adjacent to the front of the woofer. A round port in that location would also be my preference.

5. I'm drawing with 18mm/0.709" wood thickness, if you want another thickness, this would be the time to change it.

Don't quite know when I'll get back to this, but it won't be too long. 🙂

Regards,

Attachments

Hi NWCgrad,

I derived a sideview of the driver from the data in Post #61.

Working from bjorno's Hornresp model (Post #61) I ended up with a first try that uses a constant 3 degree angle. This is just a first stab at it (still a little bigger than necessary), but at least you can get an idea of where this goes, and maybe it's just fine as it is, anyway:

My questions right now are:

1. Is the overall size acceptable? - I like the height, but seems a little deep. I can live with it.

2. Do you want to build up the baffle boards as bjorno described it in Post #57? - I have not seen other builds do so. But with strong bass output down to 10 Hz it is probably a good idea. Can the baffle with the driver be 2 sheets like bjorno originally called for?

3. Do you want to add a center divider to support all the panels (this adds one wood thickness to the interior width, unless you cut a lot of holes/cutouts into the center support)? In this 1st try I added the displaced volume to the duct height. - since the hieght is okay I would leave alone. I had planned on cutting shapes fewm to bracing but it would be less work not to.

4. Where do you want the port to be located? Bjorno's Hornresp places the port directly adjacent to the front of the woofer. A round port in that location would also be my preference. - I thought bjorno indicated that by being as low as possible it maximized low frequency extension. I leave this to the experts.

5. I'm drawing with 18mm/0.709" wood thickness, if you want another thickness, this would be the time to change it. - That is the thickness I would use 3/4 inch).

Don't quite know when I'll get back to this, but it won't be too long. 🙂

Regards,

Thank you for your assistance. I answered the questions within the quote. This will be a beast of an enclosure.

Last edited:

Oliver,

In case you missed my answers to your questions inside the quote:

1. Is the overall size acceptable? - I like the height, but seems a little deep. I can live with it.

2. Do you want to build up the baffle boards as bjorno described it in Post #57? - I have not seen other builds do so. But with strong bass output down to 10 Hz it is probably a good idea. Can the baffle with the driver be 2 sheets like bjorno originally called for?

3. Do you want to add a center divider to support all the panels (this adds one wood thickness to the interior width, unless you cut a lot of holes/cutouts into the center support)? In this 1st try I added the displaced volume to the duct height. - Since the height is okay I would leave alone.

4. Where do you want the port to be located? Bjorno's Hornresp places the port directly adjacent to the front of the woofer. A round port in that location would also be my preference. - I thought bjorno indicated that by being as low as possible it maximized low frequency extension. I leave this to the experts.

5. I'm drawing with 18mm/0.709" wood thickness, if you want another thickness, this would be the time to change it. - That is the thickness I would use (3/4 inch).

Again, I would like thank you and Bjorno for your assistance, without your expertice this design could not happen.

In case you missed my answers to your questions inside the quote:

1. Is the overall size acceptable? - I like the height, but seems a little deep. I can live with it.

2. Do you want to build up the baffle boards as bjorno described it in Post #57? - I have not seen other builds do so. But with strong bass output down to 10 Hz it is probably a good idea. Can the baffle with the driver be 2 sheets like bjorno originally called for?

3. Do you want to add a center divider to support all the panels (this adds one wood thickness to the interior width, unless you cut a lot of holes/cutouts into the center support)? In this 1st try I added the displaced volume to the duct height. - Since the height is okay I would leave alone.

4. Where do you want the port to be located? Bjorno's Hornresp places the port directly adjacent to the front of the woofer. A round port in that location would also be my preference. - I thought bjorno indicated that by being as low as possible it maximized low frequency extension. I leave this to the experts.

5. I'm drawing with 18mm/0.709" wood thickness, if you want another thickness, this would be the time to change it. - That is the thickness I would use (3/4 inch).

Again, I would like thank you and Bjorno for your assistance, without your expertice this design could not happen.

Last edited:

Hi NWCgrad,

"... you all have more important things to do."

Not really, but I gotta eat. 🙂

Regards,

"... you all have more important things to do."

Not really, but I gotta eat. 🙂

Regards,

Hi NWCgrad,

Here is the 2nd attempt at bjorno's T-TQWT for the Maelstrom 18", as we discussed, I tried to get as close as I can to the simulation values (this time not adding any additional volume for braces or stuffing), particularly for the L23 and S2/S3 dimensions, the rest flows from there assuming a constant expansion angle.

I'm also showing a number of suggestions as to stuffing (we still need bjorno's final density and placement calculations), bracing, driver mounting, access plates (for driver and stuffing) and S4 location(s). You should work out how to interconnect the boards, etc., a great example is Danley's DTS-10 kit: Danley DTS-10 "Super Spud" DIY kit .

I hope this will give you a starting point from which to decide how to put the puzzle together.

Regards,

Here is the 2nd attempt at bjorno's T-TQWT for the Maelstrom 18", as we discussed, I tried to get as close as I can to the simulation values (this time not adding any additional volume for braces or stuffing), particularly for the L23 and S2/S3 dimensions, the rest flows from there assuming a constant expansion angle.

I'm also showing a number of suggestions as to stuffing (we still need bjorno's final density and placement calculations), bracing, driver mounting, access plates (for driver and stuffing) and S4 location(s). You should work out how to interconnect the boards, etc., a great example is Danley's DTS-10 kit: Danley DTS-10 "Super Spud" DIY kit .

I hope this will give you a starting point from which to decide how to put the puzzle together.

Regards,

Attachments

Oliver,

Thanks for the continued assistance, I have printed and studied to design. Does not look like a terribly difficult build.

Because of the angles is is hard to determine the actual length of some of the inner pieces, but I was able to calculate using the printout and ruler. When it is time to build I will ne able to get exact numbers by drawing the design on the side panels and measuring.

Thanks again, hopefully bjorno will weigh in with his comments.

Best, Steve

Thanks for the continued assistance, I have printed and studied to design. Does not look like a terribly difficult build.

Because of the angles is is hard to determine the actual length of some of the inner pieces, but I was able to calculate using the printout and ruler. When it is time to build I will ne able to get exact numbers by drawing the design on the side panels and measuring.

Thanks again, hopefully bjorno will weigh in with his comments.

Best, Steve

Thanks Oliver!!!

Oliver,

Thank you for the dimensions, they really helped with my cutsheet preparation.

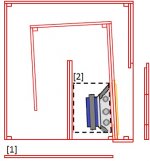

Why is the bottom panel separated and not a solid single piece [1]. Is this to assist with putting this heavy driver into the enclosure?

I added a side panel [2] to allow for two persons to assist with installing the driver, but I am concerned about air leakage.

I will add significant bracing as shown in your earlier attachement, but is 1.5 inches of material on the edges sufficient (see attachement)? This diagram is not the exact scheme I would use, but it shows the general idea. I assume the braces should be 3/4inch plywood.

Thanks,

Steve

Oliver,

Thank you for the dimensions, they really helped with my cutsheet preparation.

Why is the bottom panel separated and not a solid single piece [1]. Is this to assist with putting this heavy driver into the enclosure?

I added a side panel [2] to allow for two persons to assist with installing the driver, but I am concerned about air leakage.

I will add significant bracing as shown in your earlier attachement, but is 1.5 inches of material on the edges sufficient (see attachement)? This diagram is not the exact scheme I would use, but it shows the general idea. I assume the braces should be 3/4inch plywood.

Thanks,

Steve

Attachments

Last edited:

Why not have the whole front panel removable?

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

BP1fanatic,

I followed your build and it looks really good. How are you liking the end product.

I am concerned, probably undue, about air leaks. Will build a frame out of oak that the removable panel bolts into.

I followed your build and it looks really good. How are you liking the end product.

I am concerned, probably undue, about air leaks. Will build a frame out of oak that the removable panel bolts into.

Hi NWCgrad,

In reference to your Post #74: I made the bottom piece removable to provide access to the duct sections that need to be filled with stuffing, and to the back of the driver; the little portion of the bottom panel at the lower right I left fixed to strengthen the box; A side panel (or two) (your #[2]) should be helpful, especially if you decide to mount the driver from behind the driver mounting baffle (the S1/S2 side). For the bracing I would go with about 2" minimum where possible, and maybe round holes or triangular cutouts; 3/4" thickness should be adequate.

Regards,

In reference to your Post #74: I made the bottom piece removable to provide access to the duct sections that need to be filled with stuffing, and to the back of the driver; the little portion of the bottom panel at the lower right I left fixed to strengthen the box; A side panel (or two) (your #[2]) should be helpful, especially if you decide to mount the driver from behind the driver mounting baffle (the S1/S2 side). For the bracing I would go with about 2" minimum where possible, and maybe round holes or triangular cutouts; 3/4" thickness should be adequate.

Regards,

BP1fanatic,

I followed your build and it looks really good. How are you liking the end product.

I am concerned, probably undue, about air leaks. Will build a frame out of oak that the removable panel bolts into.

Thanks guy! I love it!

Thanks guy! I love it!

I am getting excited about the build. Hope it turns out as well as yours.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- TH or T-TQWP or ????