Hi.

I have a Technics SU-C04 integrated home stereo amp (made in the early '80s).

The left channel is working ok, but on the right channel the output goes dead after about 5 to 10 sec after turning it on.

If it were the power supply then both channels would go out, so it must be afterwards.

I have the service manual and the schematic for this amp.

Any ideas?

I have a Technics SU-C04 integrated home stereo amp (made in the early '80s).

The left channel is working ok, but on the right channel the output goes dead after about 5 to 10 sec after turning it on.

If it were the power supply then both channels would go out, so it must be afterwards.

I have the service manual and the schematic for this amp.

Any ideas?

#1 - every capacitor in it is 34 years old.

You are lucky that the SU-CO4 is a real transistor output (not IC).

Schema - recap - cleaning. new heatsink compound for OPS.

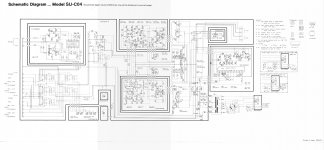

Ahhh , there it is (below) a BJT triple powered by a "blameless".

Full schema is (attached).

OS

http://www.diyaudio.com/forums/solid-state/288674-technics-su-c04-issues.html

You are lucky that the SU-CO4 is a real transistor output (not IC).

Schema - recap - cleaning. new heatsink compound for OPS.

Ahhh , there it is (below) a BJT triple powered by a "blameless".

Full schema is (attached).

OS

http://www.diyaudio.com/forums/solid-state/288674-technics-su-c04-issues.html

Attachments

Os is right, you won't get much sense out of the operation of even the protection circuit, if the electrolytic caps are original. Since you have the schematic, have you checked that voltages shown are reasonably close to correct?

If capacitors inside are all colored light blue then all of them are to be replaced

Then again the problem on this amplifier is tape monitor switches ( all signal passes from there in order to be recorded , monitored and then back inside the amp )

Clean them carefully see how it goes

Kindest regards

Sakis

Then again the problem on this amplifier is tape monitor switches ( all signal passes from there in order to be recorded , monitored and then back inside the amp )

Clean them carefully see how it goes

Kindest regards

Sakis

All caps are colored light grey with dark bluish marking. No light blue ones. Nevertheless, they would have to be switched for new ones, eventually.

I remember that the amp worked fine, until I took the front of the chassis off in order to clean the volume pot.

After reassembling the chassis and putting the cover of the amp back on, the right channel sounded noisy. I then put a piece of carton between the metal shield and the PCB that is mounted verically on the right side of the amp and interferes with the cover. Noise dissapeared but now the right channel fades out after about 5 seconds after turning the amp on.

I remember that the amp worked fine, until I took the front of the chassis off in order to clean the volume pot.

After reassembling the chassis and putting the cover of the amp back on, the right channel sounded noisy. I then put a piece of carton between the metal shield and the PCB that is mounted verically on the right side of the amp and interferes with the cover. Noise dissapeared but now the right channel fades out after about 5 seconds after turning the amp on.

I recapped the whole amp. There are not that much caps, and regarding the NP ones, I made my own.

After turning it on, it sounds nice and clean. Since I finished it last night, I didn't turn up the volume too much.

BUt then after about 5 minutes of use at low volume, it suddenly cut itself out while the amp was still on.

I then turned it off, waited a few seconds and turned it on again and by this time the cut out came after a few seconds.

Maybe it is temperature related?

Anyone had this kind of issue before?

After turning it on, it sounds nice and clean. Since I finished it last night, I didn't turn up the volume too much.

BUt then after about 5 minutes of use at low volume, it suddenly cut itself out while the amp was still on.

I then turned it off, waited a few seconds and turned it on again and by this time the cut out came after a few seconds.

Maybe it is temperature related?

Anyone had this kind of issue before?

Analyse what happens when the output cuts out.

Does the speaker relay open?

Do all sections of the amplifier still have correct power supply voltage?

Is there any DC (> 50mV) across the output terminals or before the relay terminals if it has already opened?

It would appear to be heat related but that may be local rather than heatsink temperature. Recheck caps around IC801 if it is a relay operation problem, since the relay has electrolytic timing caps that can cause wrong or erratic operation.

Note that NP caps are not the same as Bipolar caps (2 reversed caps in series) NP caps are a single elco. with both electrodes coated with the same insulating layer.

Does the speaker relay open?

Do all sections of the amplifier still have correct power supply voltage?

Is there any DC (> 50mV) across the output terminals or before the relay terminals if it has already opened?

It would appear to be heat related but that may be local rather than heatsink temperature. Recheck caps around IC801 if it is a relay operation problem, since the relay has electrolytic timing caps that can cause wrong or erratic operation.

Note that NP caps are not the same as Bipolar caps (2 reversed caps in series) NP caps are a single elco. with both electrodes coated with the same insulating layer.

The relay does open when protection circuit is engaged.

On the output terminals (with no speaker connected to the R channel which goes down first, and an 8 ohm speaker on the L channel), DC voltage rises up to 8VDC. And after shutting down, there is still between 2.5 and 3VDC present for about 20 sec.

I still have to check if all amp sections have the correct supply voltages present, as soon as I figure out how to connect the probes of my digital volt meter...

I guess supply voltages on IC801 (TA7317P) are pin9 = V+ and pin5 = V-?

I swapped all caps for new ones, even those on the PC-board where IC801 is located.

And as far as I know, german elcaps often use bp = bipolar and other manufacturers use np = non polarised. In fact, I built a few NP or BP caps (2 reversed caps with double uF in series) for some old passive crossovers a while ago that turned out to be working again. But that's just my opinion, and I always have an open mind for learning something new.

On the output terminals (with no speaker connected to the R channel which goes down first, and an 8 ohm speaker on the L channel), DC voltage rises up to 8VDC. And after shutting down, there is still between 2.5 and 3VDC present for about 20 sec.

I still have to check if all amp sections have the correct supply voltages present, as soon as I figure out how to connect the probes of my digital volt meter...

I guess supply voltages on IC801 (TA7317P) are pin9 = V+ and pin5 = V-?

I swapped all caps for new ones, even those on the PC-board where IC801 is located.

And as far as I know, german elcaps often use bp = bipolar and other manufacturers use np = non polarised. In fact, I built a few NP or BP caps (2 reversed caps with double uF in series) for some old passive crossovers a while ago that turned out to be working again. But that's just my opinion, and I always have an open mind for learning something new.

After figuring out how to measure any DC voltage on the output correctly, it gives me 19mV on the L channel and 127 mV on the R channel. This is with 8 ohm speakers connected to each channel.

Sorry it took me a while to come back.

I swapped all electolytic caps for new ones, even the NPs / BPs. Also scrapped and cleaned the circuit bord as far as possible with alcohol. Did the same thing to all selector switches and pots.

Since one channel turns off before the other and not both at the same time, and the relay is 2 SPST switches in parallel, maybe the problem with this amp is that the contacts on the relay are corroded in such way that one switch offers more R that the other, and the unballance on both channels triggers the protection to engage...

Tomorrow I will take a closer look at the relay.

I swapped all electolytic caps for new ones, even the NPs / BPs. Also scrapped and cleaned the circuit bord as far as possible with alcohol. Did the same thing to all selector switches and pots.

Since one channel turns off before the other and not both at the same time, and the relay is 2 SPST switches in parallel, maybe the problem with this amp is that the contacts on the relay are corroded in such way that one switch offers more R that the other, and the unballance on both channels triggers the protection to engage...

Tomorrow I will take a closer look at the relay.

The "problem" is with the relay control circuit if it is triggering and switching the relay, regardless of whether you hear sound or not. You should not have speakers or input connected when testing amplifier operation anyway, as Sakis commented.

The relay is there to protect the speakers and amplifier when there is a serious fault. That is, either excessive current (overload) sensed by the voltage across emitter resistors Z501, 502 or significant DC voltage sensed at the output rail, as it probably will be with >100 mV offset voltage. As you say you have replaced the caps correctly, the more likely remaining problem is an amplifier semiconductor fault - possibly even the input stage dual transistors.

Remember though, you can't measure anything with signal input. Remove input connectors and turn volume right down. A fault in either amplifier has the same protection result and you could isolate the fault channel by removing power to it, to prove the remaining channel is OK. If this is too much to understand, take it to a repair guy now - before you need to bin it due to big mistakes and needing parts like the dual input transistors Q301,302. They will either no longer be available or not genuine quality so look after them.

The relay is there to protect the speakers and amplifier when there is a serious fault. That is, either excessive current (overload) sensed by the voltage across emitter resistors Z501, 502 or significant DC voltage sensed at the output rail, as it probably will be with >100 mV offset voltage. As you say you have replaced the caps correctly, the more likely remaining problem is an amplifier semiconductor fault - possibly even the input stage dual transistors.

Remember though, you can't measure anything with signal input. Remove input connectors and turn volume right down. A fault in either amplifier has the same protection result and you could isolate the fault channel by removing power to it, to prove the remaining channel is OK. If this is too much to understand, take it to a repair guy now - before you need to bin it due to big mistakes and needing parts like the dual input transistors Q301,302. They will either no longer be available or not genuine quality so look after them.

I ran the amp with one preamp board removed at a time and the problem is definitely on the "R" channel. Unfortunately (as far as I can tell) the 2 preamp boards are not exactly the same so I cannot just switch them from one side to the other to to see if the problem is on the preamps or the main board...

I don't know if you've checked already, but this sounds like a classic case of a dirty speaker relay. The relay is certainly old enough. The relay contacts can become oxidized if the contact material is not inert like Gold. The contacts can also just get pitted and damaged by years of use connecting fairly high current, inductive (speakers) loads.

What often happens to speaker relays is that when they connect the load, the contacts bounce. When the contacts bounce, the connected, inductive load, is breaking/making contact. When an inductive load loses contact, the inductance attempts to keep the current flowing and raises the voltage, creating an arc at the relay contacts. This arc is very high temperature and creates melted metal features and carbon on the relay contacts........ ......making them not work so well. The tell tale sign of a poor relay contact is drop out at low volume settings, restored by cranking the volume.

You can get a burnishing tool to resurface the relay contacts, best done by dismantling the relay. After spray a deoxidizing chemical for best results. Something like D5 spray. A replacement relay guarantees results.

What often happens to speaker relays is that when they connect the load, the contacts bounce. When the contacts bounce, the connected, inductive load, is breaking/making contact. When an inductive load loses contact, the inductance attempts to keep the current flowing and raises the voltage, creating an arc at the relay contacts. This arc is very high temperature and creates melted metal features and carbon on the relay contacts........ ......making them not work so well. The tell tale sign of a poor relay contact is drop out at low volume settings, restored by cranking the volume.

You can get a burnishing tool to resurface the relay contacts, best done by dismantling the relay. After spray a deoxidizing chemical for best results. Something like D5 spray. A replacement relay guarantees results.

Took out the relay today and cleaned the contacts.

Same result.

Maybe I could put the 2 on/off switches of the relay directly (always on) but chances are that this might blow a few transitors...

Same result.

Maybe I could put the 2 on/off switches of the relay directly (always on) but chances are that this might blow a few transitors...

I cleaned both of them with a syringe and alcohol. And then I pushed them in and out for at least a dozen times.

Are you working from the schematic to isolate where the break in the chain is?

Cleaning and all that won't fix a truly broken part. I've had push switches that wouldn't clean, because they were broken. In the Alps and Schadow types of push switches, they have a sliding U shaped contact that slides over the contacts that solder to the board. I've seen where the "spine" of the U shaped contact gets fatigued and loses it's contact pressure. No amount of cleaning will fix that.

Also, using Alcohol to deoxidize a contact will probably have a very limited affect. Best to use something like De-Oxid, or D-5 spray to really strip the oxide off. Your probably making more headway in cleaning a contact with the scraping that occurs when exercising the control rather than anything that Alcohol would do. Don't get me wrong, I love Alcohol. It's just not a good application to clean switch contacts.

Rather than stab around, see if you can isolate the affected area. Do you have a scope? An audio generator and an ACVM??

Cleaning and all that won't fix a truly broken part. I've had push switches that wouldn't clean, because they were broken. In the Alps and Schadow types of push switches, they have a sliding U shaped contact that slides over the contacts that solder to the board. I've seen where the "spine" of the U shaped contact gets fatigued and loses it's contact pressure. No amount of cleaning will fix that.

Also, using Alcohol to deoxidize a contact will probably have a very limited affect. Best to use something like De-Oxid, or D-5 spray to really strip the oxide off. Your probably making more headway in cleaning a contact with the scraping that occurs when exercising the control rather than anything that Alcohol would do. Don't get me wrong, I love Alcohol. It's just not a good application to clean switch contacts.

Rather than stab around, see if you can isolate the affected area. Do you have a scope? An audio generator and an ACVM??

I dont' have a scope. I do have a tone generator (Quad Eight Electronics, used in 1970's consoles). What is an ACVM? If you mean an AC volt meter, I do have a Digital volt meter with an A/C scale (200 and 600V), but I think that would not be sensitive enough.

I cleaned both of them with a syringe and alcohol. And then I pushed them in and out for at least a dozen times.

You need to push it for several minutes straight.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Technics SU-C04 issues