surgeon

Hi Luke,

I am about sure if you do a call among forum members, sombody will offer his skills to help you out.

Ed

maybe if your a surgeon. Ryan, is there enough space between components to get an iron in when it starts getting populated? I am nervous about building something this tight with just an iron. What about built modules, is this cost prohibitive or possible?

Hi Luke,

I am about sure if you do a call among forum members, sombody will offer his skills to help you out.

Ed

I use solderpaste as a substitute for regular paste when it's a tight spot and I need one hand free to keep the part in place with ESD safe tweezers.

Haven't tried oven or frying pan method yet.

Haven't tried oven or frying pan method yet.

I feel like a dinosaur😀 Thanks guys for all your posts. I have done SMT chips a very long time ago and can solder pretty well. But I used solder for flux, I have never seen liquid flux pens, or solder paste, or frypan method or oven. I need more videos. I imagine that any oven would work well?

Wlowes, how do you do the other side, wont the components fall off?

Wlowes, how do you do the other side, wont the components fall off?

Last edited:

I feel like a dinosaur😀 Thanks guys for all your posts. I have done SMT chips a very long time ago and can solder pretty well. But I used solder for flux, I have never seen liquid flux pens, or solder paste, or frypan method or oven. I need more videos. I imagine that any oven would work well?

Apart from the flux pen (that are very nice btw) I've been the same until a couple of months ago. I got the solderpaste to try the non-stick frying pan method, but discovered it was the answer to my prayers for a third arm lol

The one I got melts at low temps so it's nice for those heatsensitive parts as well. I still use a very hot iron, been doing that for a long time since I believe the faster I can get a good solder the less risk of damaging the components.

I set my iron to ~385c to 400c depending on what tip I'm using.

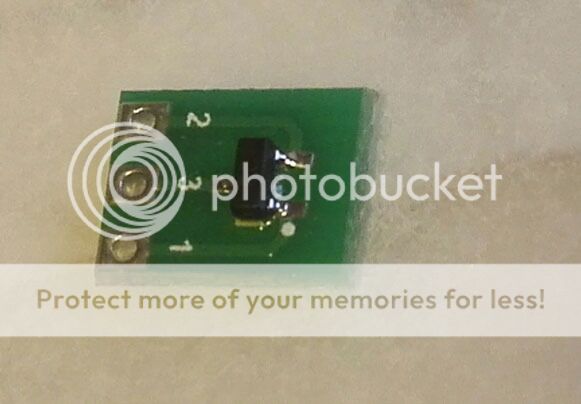

TSSOP soldered

Thanks for everyone's input.

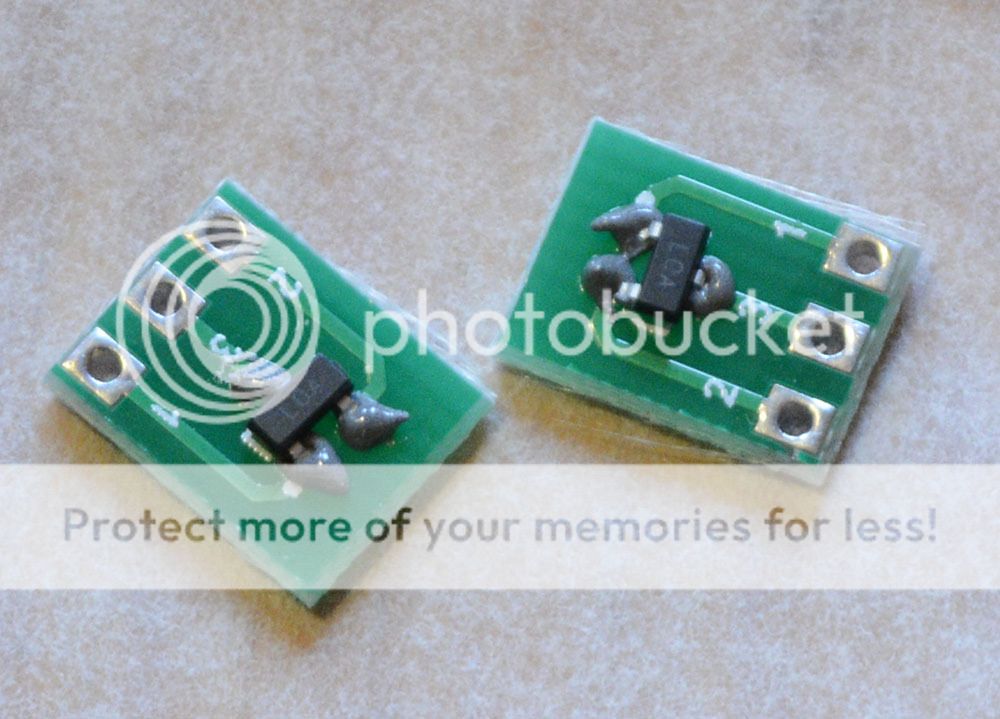

Solder paste with a hot air gun (Mine is a Saike 898d) will be the easiest way to go by far - I had great results tonight. Picture attached.

All I did was smear solder paste on both sides of the footprint, not even worrying about getting any in between the pin pads, aligned the chip, and set my heat gun to 240 degrees celsius. It took about 1 minute to solder. Makes SMD soldering a piece of cake.

Thanks for everyone's input.

Solder paste with a hot air gun (Mine is a Saike 898d) will be the easiest way to go by far - I had great results tonight. Picture attached.

All I did was smear solder paste on both sides of the footprint, not even worrying about getting any in between the pin pads, aligned the chip, and set my heat gun to 240 degrees celsius. It took about 1 minute to solder. Makes SMD soldering a piece of cake.

Attachments

Thanks Nick,

I definitely recommend this approach. Really not too much skill involved compared with using a soldering iron.

Cheers.

I definitely recommend this approach. Really not too much skill involved compared with using a soldering iron.

Cheers.

The biggest mistake I have made is using too much solder paste. Just takes a little.

Hot air is good. Tips on the toaster oven include the obvious... the oven is used only for soldering. This stuff is poison. To do the flip side, just flip it over. The surface tension of the liquid solder hold them in place.

Hot air is good. Tips on the toaster oven include the obvious... the oven is used only for soldering. This stuff is poison. To do the flip side, just flip it over. The surface tension of the liquid solder hold them in place.

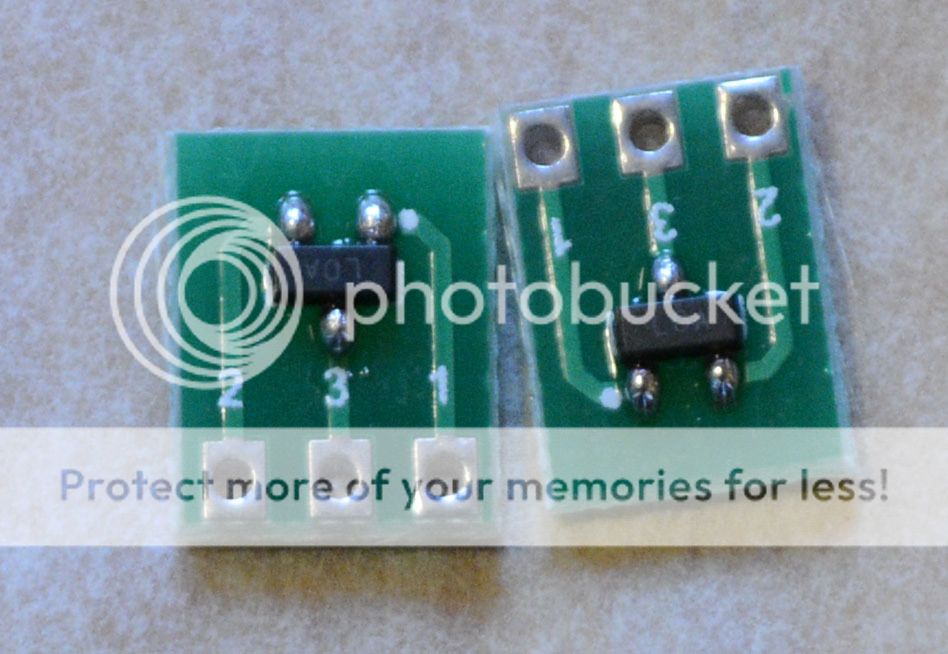

I did two tests with the frying pan method.

Rendering the videos as I type this.

Frying pan method first attempt

Rendering the videos as I type this.

Frying pan method first attempt

Last edited:

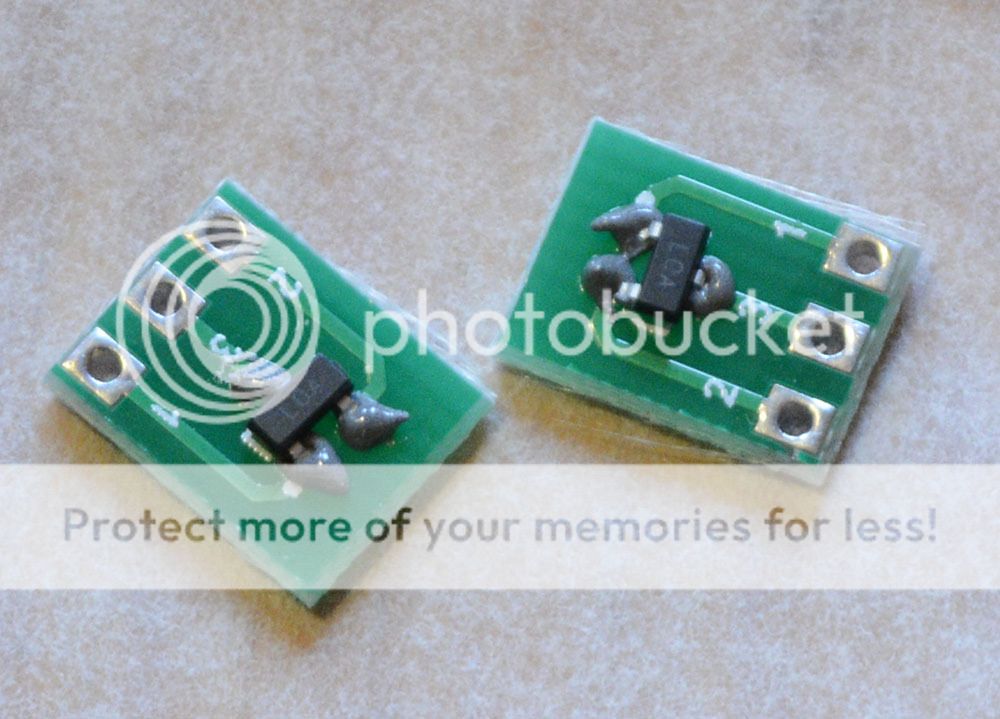

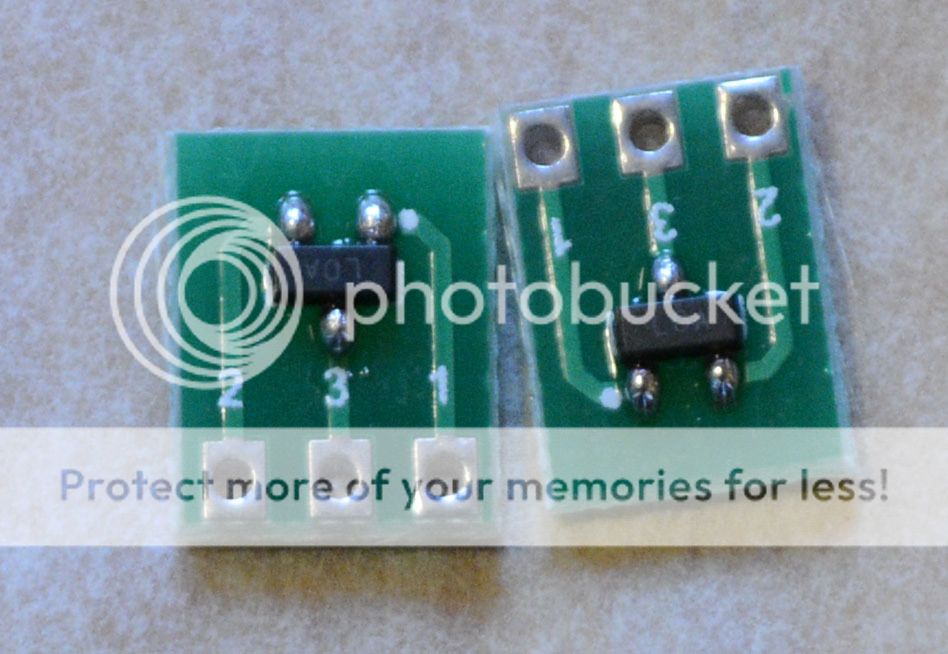

First pic is right out of the frying pan, second pic is after a quick touch up with solder wick

Second attempt with this method

Still going too heavy on the solder paste.

Second attempt

Second attempt with this method

Still going too heavy on the solder paste.

Second attempt

Last edited:

how do you know which parts are sensitive to heat? how long in the oven or under hot air gun is safe and does it vary for different parts?

Last edited:

Luke

There is an optimal heat profile for the SMT soldering. Well covered in the various you tubes. In my toaster oven example you preheat the oven, put in the part, take it up to 350 for x seconds then ramp it up to 450, hold briefly then turn it off and open the door to let the temperature settle back down at a particular rate. The process basically is a rough simulation of how the contract manufacturers tune their ovens for perfect yield.

There is an optimal heat profile for the SMT soldering. Well covered in the various you tubes. In my toaster oven example you preheat the oven, put in the part, take it up to 350 for x seconds then ramp it up to 450, hold briefly then turn it off and open the door to let the temperature settle back down at a particular rate. The process basically is a rough simulation of how the contract manufacturers tune their ovens for perfect yield.

Luke

There is an optimal heat profile for the SMT soldering. Well covered in the various you tubes. In my toaster oven example you preheat the oven, put in the part, take it up to 350 for x seconds then ramp it up to 450, hold briefly then turn it off and open the door to let the temperature settle back down at a particular rate. The process basically is a rough simulation of how the contract manufacturers tune their ovens for perfect yield.

I didn't care about temp curves when doing the frying pan method yesterday. I figured that the faster I got the solder to flow the better.

Less time on the heatsoutce = less risk of damaging the IC was my thought behind that.

Since my fiancé wouldn't let me use the good non-stick frying pans, I used "baking paper" to protect the part being soldered.

I am less than a novice to this type of soldering so if I am doing it wrong or my way of reasoning about it is wrong, please let me know.

Luke

There is an optimal heat profile for the SMT soldering. Well covered in the various you tubes. In my toaster oven example you preheat the oven, put in the part, take it up to 350 for x seconds then ramp it up to 450, hold briefly then turn it off and open the door to let the temperature settle back down at a particular rate. The process basically is a rough simulation of how the contract manufacturers tune their ovens for perfect yield.

Thanks Wlowes, I will read up on this, or maybe watcha couple of vids. It is something I need to start learning to do, through hole is dyeing.

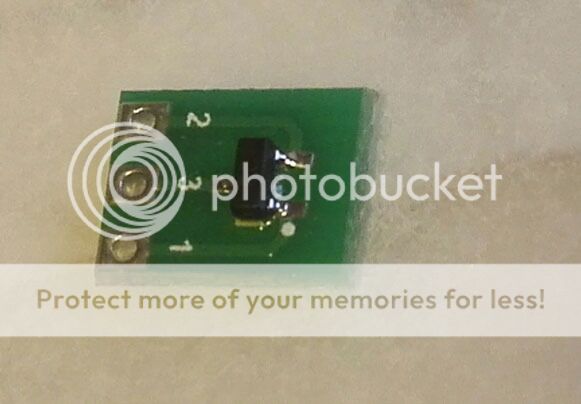

Progress.

Hi Guys,

Thanks to those who posted their advice/help on how to solder smd, i'm sure it will help many people out.

Just thought I'd post a pic of my progress. All going well, only minor hiccups so far. Unfortunately the 10uF film caps (C28, C20, and C34) are on backorder and won't arrive until early November. I might put a 10uF X7R there for the time being for testing - which is not too far off. Almost every part this far has been soldered using solder paste and hot air.

Up until now I haven't done much work to organise the prereg supply so i'm going to test run from batteries until I do.

Some good reading related to this project:

Cap multiplier with info on the TDA1541A.

Ryan

Hi Guys,

Thanks to those who posted their advice/help on how to solder smd, i'm sure it will help many people out.

Just thought I'd post a pic of my progress. All going well, only minor hiccups so far. Unfortunately the 10uF film caps (C28, C20, and C34) are on backorder and won't arrive until early November. I might put a 10uF X7R there for the time being for testing - which is not too far off. Almost every part this far has been soldered using solder paste and hot air.

Up until now I haven't done much work to organise the prereg supply so i'm going to test run from batteries until I do.

Some good reading related to this project:

Cap multiplier with info on the TDA1541A.

Ryan

Attachments

Last edited:

Interesting project.

Nah, not really but this is just my opinion.

I can think of a thousand colours but how many have names?

Elvis - "In the Ghetto", I love that song.

Thanks for listening, and I suspect he might also - but who really knows?

And, so - who really knows?. Those who say that they do, or those that pretend that they do not.

Add them together and divide by two?

Good luck.

Anyway - carry on… (if you must) as you will …

Oh, sorry.. yeah interesting project that you have here.. or did I say that already?.

🙂

LH/S

Nah, not really but this is just my opinion.

I can think of a thousand colours but how many have names?

Elvis - "In the Ghetto", I love that song.

Thanks for listening, and I suspect he might also - but who really knows?

And, so - who really knows?. Those who say that they do, or those that pretend that they do not.

Add them together and divide by two?

Good luck.

Anyway - carry on… (if you must) as you will …

Oh, sorry.. yeah interesting project that you have here.. or did I say that already?.

🙂

LH/S

Last edited:

Hi xaled,

I don't have a video camera capable of good close up macro recording.

Dave Jones from EEVblog has some good videos on this subject.

SMD Stencil Reflow Soldering Tutorial

Heaps of other videos on youtube. I hope this helps.

Ryan

I don't have a video camera capable of good close up macro recording.

Dave Jones from EEVblog has some good videos on this subject.

SMD Stencil Reflow Soldering Tutorial

Heaps of other videos on youtube. I hope this helps.

Ryan

Last edited:

- Home

- Source & Line

- Digital Line Level

- TDA1541A Diy Pcb - "Distinction-1541 v2"