Here is a photo of a Thorens 124 plinth I made for a friend of mine about five years ago. It is made from Panzerholz, which has a very hign damping capacity compared to solid wood and regular plywood.

John

John

Here is a photo of a Thorens 124 plinth I made for a friend of mine about five years ago. It is made from Panzerholz, which has a very hign damping capacity compared to solid wood and regular plywood.

John

You have done a great job there john.

Here is a photo of a Thorens 124 plinth I made for a friend of mine about five years ago. It is made from Panzerholz, which has a very hign damping capacity compared to solid wood and regular plywood.

John

Looks like a very serious piece of kit!

Yes, it was built with another arm board at the rear to supplement the Thorens attachments. It's pretty solid. This plinth and another made for the Garrard 301 were the progenitors of a series of plinths I made for the SP-10 for Albert Porter.

http://cgim.audiogon.com/i/vs/s/f/1284840093.jpg

John

http://cgim.audiogon.com/i/vs/s/f/1284840093.jpg

John

Last edited:

The picture of the capacitor seems to indicate that its value is 10 pF. It looks like the "p" is mangeled to appear like an "n". Correct me if I'm wrong.

Sincerely,

Ralf

As Helmuth has indicated it really is 10nF, I have seen three early 124s (one is a former parts unit I own) with the same cap he snapped a picture of, and it is clearly printed on the case. My newer 124/II also uses 10nF but from a different vendor. (Power switch is different oo)

Uncoupling

Hi

I a now listening to the TD-124 To tweak a bit. The paint job has to wait till the motor had a revision.

with the TT running and the coupling turned on we can lay the needle on the TT. The noise generated by vibration of the motor is now amplified. I can hear the noise is less when I lift the TT and hold it in my hands. So the solid rubber feet do not absorb enough.

Ok I have a good idea to solve this.

I have soft rubber 7mm where seats of supersport bikes made off I call it moosgummi.

Wiht the rubber between two triplex plates i can use the holesaw to drill a nice round pice of 40mm. In the bottem plate of 6mm i drill the same hole.

after that I can screw the assebly to gether again.the rubberfeet loose on a screw so it has suspension. Works really great to absorb the minimum vibration left in the plinth.

Hi

I a now listening to the TD-124 To tweak a bit. The paint job has to wait till the motor had a revision.

with the TT running and the coupling turned on we can lay the needle on the TT. The noise generated by vibration of the motor is now amplified. I can hear the noise is less when I lift the TT and hold it in my hands. So the solid rubber feet do not absorb enough.

Ok I have a good idea to solve this.

I have soft rubber 7mm where seats of supersport bikes made off I call it moosgummi.

Wiht the rubber between two triplex plates i can use the holesaw to drill a nice round pice of 40mm. In the bottem plate of 6mm i drill the same hole.

after that I can screw the assebly to gether again.the rubberfeet loose on a screw so it has suspension. Works really great to absorb the minimum vibration left in the plinth.

Attachments

The first turns. The speed is very good constant I do not hear problems with that rumble is acceptable low my current TT is a Technics sl1700 witch has very low rumble figures and is more quit then the Thorens as long the needle isn't on the record.

The music reproduced by the Thorens with RB301 is more detailed and brighter bass is also good and tight. What is responsible for gain on brightness I think the silver tone arm wiring. And I think the heavy turntable help to be uninfluenced by the sound-pressure of the speakers and therefor doesn't mess up the low frequencies.

For now I am listening to the Grado red greatbudget cartridge it has a wide and big soundstage and and also good bass. The down side it has problems with the "S" compared to other cartridges it sss. When it is finished I will be running my most exspensive cartridge the goldring 1012. It has good detail and brightness witch with some records tents to sound to thin.

When it bothers me then I will switch back to the Shure M97xe really great cartridge very balanced. I have seen it measures very nice and I can hear it doesn't has the level of detail the Grado or Goldring does but it serves you with smooth tonal balance.

One day I want to upgrade to the DL103 But my kids play with my equipment and already broke two cartridges. And that would be to expensive with the dl103.

It would complete the color scheme of the TT and the gils will say the color of the TT looks very nice.

The music reproduced by the Thorens with RB301 is more detailed and brighter bass is also good and tight. What is responsible for gain on brightness I think the silver tone arm wiring. And I think the heavy turntable help to be uninfluenced by the sound-pressure of the speakers and therefor doesn't mess up the low frequencies.

For now I am listening to the Grado red greatbudget cartridge it has a wide and big soundstage and and also good bass. The down side it has problems with the "S" compared to other cartridges it sss. When it is finished I will be running my most exspensive cartridge the goldring 1012. It has good detail and brightness witch with some records tents to sound to thin.

An externally hosted image should be here but it was not working when we last tested it.

When it bothers me then I will switch back to the Shure M97xe really great cartridge very balanced. I have seen it measures very nice and I can hear it doesn't has the level of detail the Grado or Goldring does but it serves you with smooth tonal balance.

One day I want to upgrade to the DL103 But my kids play with my equipment and already broke two cartridges. And that would be to expensive with the dl103.

An externally hosted image should be here but it was not working when we last tested it.

It would complete the color scheme of the TT and the gils will say the color of the TT looks very nice.

Attachments

Last edited:

The switch capacitor is listed in the TD124 service manual as .01 uf.

Although the manual calls it a "condensor". At any rate, I've been using .01 uf value switch caps on my td124 projects and that value does prevent the speakers from popping as you swtich the unit on/off.

The conversion between uf and pf: .01 uf = 10 pf. So the 10pf value would be per spec in the service manual.

That's a nice looking setup.

-Steve

Although the manual calls it a "condensor". At any rate, I've been using .01 uf value switch caps on my td124 projects and that value does prevent the speakers from popping as you swtich the unit on/off.

The conversion between uf and pf: .01 uf = 10 pf. So the 10pf value would be per spec in the service manual.

That's a nice looking setup.

-Steve

Hi steve you are making a fault of 1000 there 10pF =0,00001uF.The switch capacitor is listed in the TD124 service manual as .01 uf.

Although the manual calls it a "condensor". At any rate, I've been using .01 uf value switch caps on my td124 projects and that value does prevent the speakers from popping as you swtich the unit on/off.

The conversion between uf and pf: .01 uf = 10 pf. So the 10pf value would be per spec in the service manual.

The capacitor has to be 10nF=01uF , in europe we call a capacitor a condensator and that in the manual will be a translation fault.

That's a nice looking setup.

-Steve

Thanks steve you are very nice , it will get a paint job the wood transparent and the white parts going to be semi gloss-black. Then it will have a professional look to it I hope. First the motor must be upgraded and to prevent scratches I will wait till that is ready.

Last edited:

Hi steve you are making a fault of 1000 there 10pF =0,00001uF.

The capacitor has to be 10nF=01uF , in europe we call a capacitor a condensator and that in the manual will be a translation fault.

Right:

.01 uf = 10nf

10nf = 10,000 pf

At any rate, using the service manual it was possible to source a replacement using the exact value stated in that manual. .01 uf Fortunately they are sold with the "uf" value inked on the body of the cap.

btw, I heard that that Faraday guy died.🙂

I see a few others got here ahead of me, hence the post edit.

Anyway as general guide:

1nF = 0.001uF or 1000pF

10nF= 0.01uF or 10000pF

100nF = 0.1uF or 100000pF

Anyway as general guide:

1nF = 0.001uF or 1000pF

10nF= 0.01uF or 10000pF

100nF = 0.1uF or 100000pF

Last edited:

Motor rebuild kit installed

The kit:

And the plinth inside.

Bottom.

The kit:

And the plinth inside.

Bottom.

Attachments

Last edited:

The unveiling.

What do think of the result.🙂

The new dustcover. Made by GLORIOUS.

Badge Thorens inox.

Neutrik terminals.

The classic Thorens TD124 MK1 Swiss made up to 1966.

Goldring 1012GX fineline good bass and dynamics in the RB301 tonearm and Thorens TD124 MK1 turntable.

Van den Hul silver tone arm wiring. MCS-150M

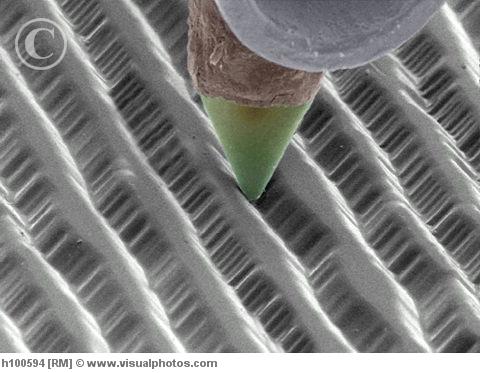

Close up. 😀

What do think of the result.🙂

The new dustcover. Made by GLORIOUS.

Badge Thorens inox.

Neutrik terminals.

The classic Thorens TD124 MK1 Swiss made up to 1966.

Goldring 1012GX fineline good bass and dynamics in the RB301 tonearm and Thorens TD124 MK1 turntable.

Van den Hul silver tone arm wiring. MCS-150M

An externally hosted image should be here but it was not working when we last tested it.

Close up. 😀

Attachments

-

Schermafbeelding 2011-06-11 om 16.16.37.jpg41.2 KB · Views: 474

Schermafbeelding 2011-06-11 om 16.16.37.jpg41.2 KB · Views: 474 -

Schermafbeelding 2011-06-11 om 16.29.44.jpg48.2 KB · Views: 457

Schermafbeelding 2011-06-11 om 16.29.44.jpg48.2 KB · Views: 457 -

Schermafbeelding 2011-06-11 om 16.18.07.jpg61.8 KB · Views: 443

Schermafbeelding 2011-06-11 om 16.18.07.jpg61.8 KB · Views: 443 -

Schermafbeelding 2011-06-11 om 16.31.23.jpg47.2 KB · Views: 830

Schermafbeelding 2011-06-11 om 16.31.23.jpg47.2 KB · Views: 830 -

Schermafbeelding 2011-06-11 om 16.57.31.jpg39.6 KB · Views: 456

Schermafbeelding 2011-06-11 om 16.57.31.jpg39.6 KB · Views: 456 -

stylus_in_groove_of_lp.jpg35.6 KB · Views: 498

stylus_in_groove_of_lp.jpg35.6 KB · Views: 498

Last edited:

Thanks steve,very nice looking results.

bravo

-Steve

Just bin enjoying music that I got for free of my neighbors there where a lot of nice collector albums in the gift.

Works great the Goldring 1012 on the RB301.

I hope I can shoot better pictures of the turntable outside in daylight.

Last edited:

Thorens orignal belt

Hi

I did buy a new belt because the old one seemed a bit tight to me.

On the pictures we can see the differences.

The trapped pulley did sing when running with the small aftermarket one now with the higher original one it is much quitter.

The after market one will eventually damage the bearings of the motor where I payed more then 100Euro for. Because it is shorter it pulls the axes to one side and will wear the new bearings that way. So spend a other 25 on the belt.

Hi

I did buy a new belt because the old one seemed a bit tight to me.

On the pictures we can see the differences.

The trapped pulley did sing when running with the small aftermarket one now with the higher original one it is much quitter.

The after market one will eventually damage the bearings of the motor where I payed more then 100Euro for. Because it is shorter it pulls the axes to one side and will wear the new bearings that way. So spend a other 25 on the belt.

Attachments

Last edited:

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- TD124 mk1 RB301 new plinth and service