Thanks for your reply,Dear Julesm,

I am of the "I don't want to use sound absorbing materials" school of thought, so I either don't use them, or if I do, they are made of low density, lightweight polyester.

I do not use high-density felt, and I do not use audio sound-absorbing materials because they are too expensive.

I usually use "quilt padding with mesh" (Photo 1) and "polyester cotton" (Photo 2) for sewing.

We can also substitute quilt batting [100 yen(US$0.75), 75cm x 80cm] and aquarium filters [100 yen, 50g] (Photo 3) available at 100 yen stores in Japan.

I can see your design philosophy focuses the fundamentals of acoustics and geometry over secondary details, and I respect that greatly.

I opted for higher end cabinet materials and driver than in your example, perhaps to negligible performance increase, but ultimately my choice was swayed by the aesthetics.

As a novice keen to learn more, I wondered if hypothetically you would use the 15mm cotton wadding in place of the cotton felt you used if you had it at hand, or would you consider the mass of the additional material detrimental to the design?

I think over the same surface area, it would be double the mass in your design.

Jules

Thanks Dave, hopefully I can compare a few options including the materials that I already have. As a novice I'm pretty much shooting in the dark so it will be interesting to see how it goes.That is what we use.

dave

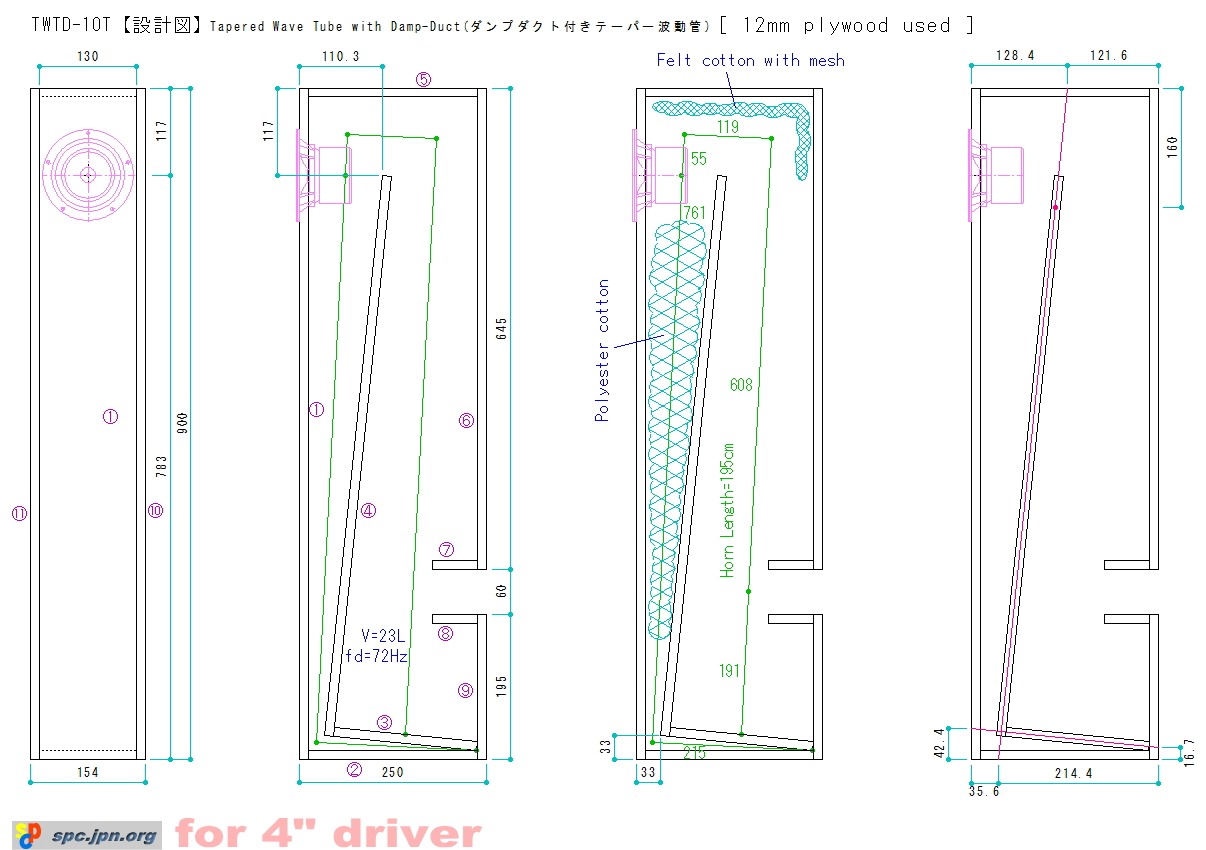

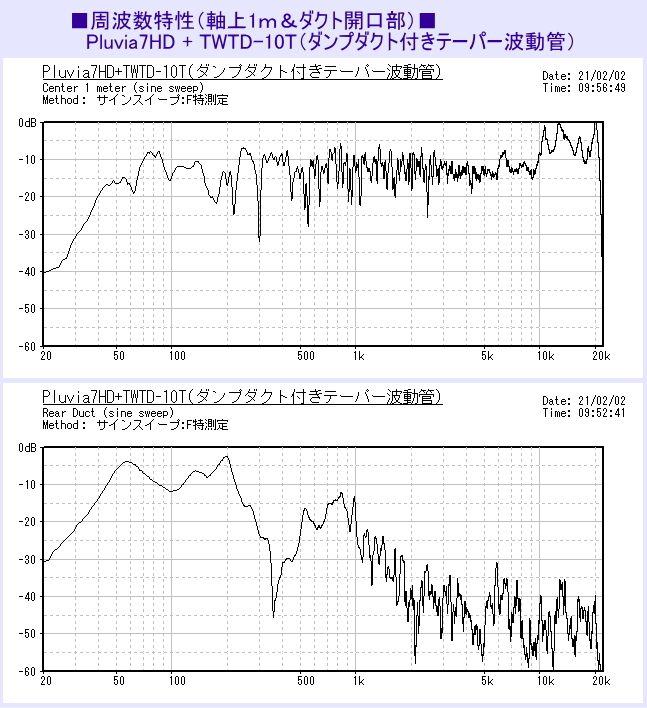

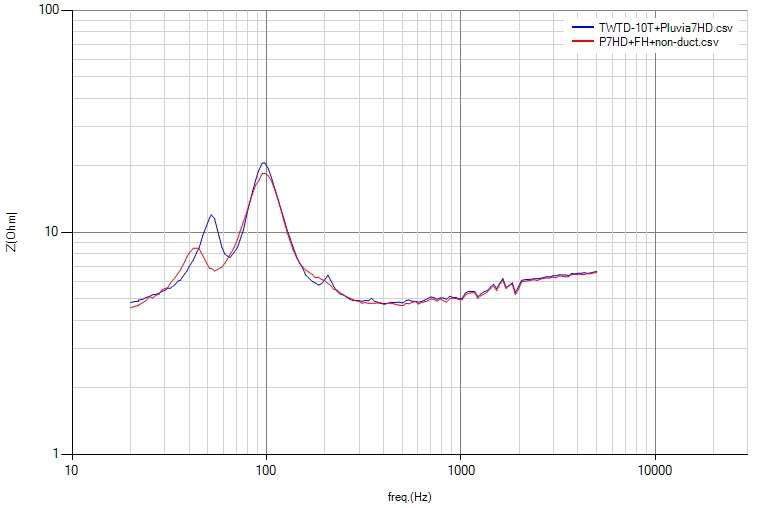

You sure did a nice job on the cabinet. FR graph pretty awesome too. Foster seems to be popular for full range driver for transmission and Voight designs but plenty of other good ones are out there at reasonable prices Seas has one that's supposed to be excellent but pricey. Me a bargain shopper will settle but you can tweek these designs before final assembly with inexpensive drivers and still get good results. Usually need a surround that is not very compliant ie. Stiff . This design offers so much versitility and fun to try almost any drive. Cheap might surprise! MichaelDriver is mounted 1:1 and damp-duct 1:5.

Sound absorbing material is minimal.

Experiment alot is the key on paper is well on paper. Have fun playing! MichaelThanks for your reply,

I can see your design philosophy focuses the fundamentals of acoustics and geometry over secondary details, and I respect that greatly.

I opted for higher end cabinet materials and driver than in your example, perhaps to negligible performance increase, but ultimately my choice was swayed by the aesthetics.

As a novice keen to learn more, I wondered if hypothetically you would use the 15mm cotton wadding in place of the cotton felt you used if you had it at hand, or would you consider the mass of the additional material detrimental to the design?

I think over the same surface area, it would be double the mass in your design.

Jules

You really are knowledgeable about a variety of audio visual concept. Theory is so important to feed off of for new unconventional ideas. Experience along with experimentation vgo hand in hand with new good STUFF! Keep it up!, MichaelA good horn/TL modeler required. One could easily start with a Pensil, transform it into a Voigt, then fold it. I think i have an unfolded one in my CAD (A10, A10.3, A10p, A10.2 likely not much different), and we have folded versions for FE108e∑ & FF165wk that look like the visualization i posted.

dave

Dear Julesm,

I have tried using needle felt and micron wool, but I just liked regular polyester cotton.

The only thing I preferred over polyester cotton was duck down, but it was too expensive for box.

I think it is correct that the wood used, sound-absorbing materials, etc. should ultimately be selected based on the user's budget and preferences. Please try it out and make your decision.

I have tried using needle felt and micron wool, but I just liked regular polyester cotton.

The only thing I preferred over polyester cotton was duck down, but it was too expensive for box.

I think it is correct that the wood used, sound-absorbing materials, etc. should ultimately be selected based on the user's budget and preferences. Please try it out and make your decision.

Good advice. Do the best with a minimal budget. That's half the fun. Made some crescent shaped pillow cases with zippers filled with Kapok. Tree pod fiber. A pound goes a long way so make an awesome pillow for cheap and use some for sound absorbing. Forget real down pillows, Kapok fill is delightful. Squishable delectible, you get it so get it. Bean Products or DIY Bedding. Michael

The 'name of the game' is to have no reflections back to the driver at high enough amplitude to modulate it, i.e. 'comb filter' its radiation output, so the pioneers originally made cab shapes to randomize the box's internal eigenmodes, leaving only a pad needed on the back wall opposite the driver(s) just big/dense enough to lower them to below audibility at the design minimum listening distance and for consumer versions the ornate grill cloth were often designed/chosen to do it and in some cases the whole grill system was designed to shape its in room response since there were no tone controls per se.As a novice keen to learn more

These drivers, cabs were large, so the eigenmodes were low/strong enough to require considerable density, though 8" (smallest) were usually in acoustically tiny cabs, so had considerably more damping since these were typically for high speech intelligibility with a limited BW (AM radio).

Nowadays, most DIYers only understand how to use a T/S box calculator at best, so typically need to not just line, but stuff, often quite heavily whether they really need to or not 🙁, whereas the pioneers proved that a typical well done rectangular box only needs a modest amount on the top, one side and back, covering ~70 % of each panel and only with rare exception on the bottom where the vent normally is.

BLHs, some TLs OTOH really requires a bit of knowledge as to how (ideally) continuous the air mass 'plug' is whipping back n' forth along its axial path length at the SoS, so friction/stiction plays a (significant) role in the horn's HF response, hence the need for keeping lossy damping to a minimum when trying to get the right hand-off for best blend to the driver's forward radiation at smoothest response (a tall order!), though if a bass horn the acoustic XO will be low enough that we just want to quell as much HF coming out of the horn as practical, so damping is somewhat more dense and in different locations from the wide range, so to a great extent each differing BLH horn design is ~unique, ergo IME no easy 'rules-of-thumb'.

Yes ,. The rules need to be violated some depending on what you think depends. Well I imagine the driver compliance should have considerable weight in design parameters.. Good old critical unbiased listening should help. As most of us that build and experiment often think what we create is actually better than it really is. Michael

Thanks for your response, that's very interesting 🙂. I will definitely have to do a lot of testing, the 15mm wadding feels quite thick for this application but I guess I won't know until I run some tests.The 'name of the game' is to have no reflections back to the driver at high enough amplitude to modulate it, i.e. 'comb filter' its radiation output, so the pioneers originally made cab shapes to randomize the box's internal eigenmodes, leaving only a pad needed on the back wall opposite the driver(s) just big/dense enough to lower them to below audibility at the design minimum listening distance and for consumer versions the ornate grill cloth were often designed/chosen to do it and in some cases the whole grill system was designed to shape its in room response since there were no tone controls per se.

These drivers, cabs were large, so the eigenmodes were low/strong enough to require considerable density, though 8" (smallest) were usually in acoustically tiny cabs, so had considerably more damping since these were typically for high speech intelligibility with a limited BW (AM radio).

Nowadays, most DIYers only understand how to use a T/S box calculator at best, so typically need to not just line, but stuff, often quite heavily whether they really need to or not 🙁, whereas the pioneers proved that a typical well done rectangular box only needs a modest amount on the top, one side and back, covering ~70 % of each panel and only with rare exception on the bottom where the vent normally is.

BLHs, some TLs OTOH really requires a bit of knowledge as to how (ideally) continuous the air mass 'plug' is whipping back n' forth along its axial path length at the SoS, so friction/stiction plays a (significant) role in the horn's HF response, hence the need for keeping lossy damping to a minimum when trying to get the right hand-off for best blend to the driver's forward radiation at smoothest response (a tall order!), though if a bass horn the acoustic XO will be low enough that we just want to quell as much HF coming out of the horn as practical, so damping is somewhat more dense and in different locations from the wide range, so to a great extent each differing BLH horn design is ~unique, ergo IME no easy 'rules-of-thumb'.

Understood. I wanted a good starting point as I have so little experience but I think I have that now, thanks again!Dear Julesm,

I have tried using needle felt and micron wool, but I just liked regular polyester cotton.

The only thing I preferred over polyester cotton was duck down, but it was too expensive for box.

I think it is correct that the wood used, sound-absorbing materials, etc. should ultimately be selected based on the user's budget and preferences. Please try it out and make your decision.

Looks like it's a very good material for acoustic damping, I was worried about the moths but apparently they don't like taste. Think I might try that along side standard polyesterGood advice. Do the best with a minimal budget. That's half the fun. Made some crescent shaped pillow cases with zippers filled with Kapok. Tree pod fiber. A pound goes a long way so make an awesome pillow for cheap and use some for sound absorbing. Forget real down pillows, Kapok fill is delightful. Squishable delectible, you get it so get it. Bean Products or DIY Bedding. Michael

Julesm, Hi appreciate your concern for details. I'm like that too. Experimented with pillow fills for a year and have narrowed it down. I personally like a creasent shaped case. Easy just buy zipper case at Walmart cotton and poly both nice and just inverter and sew a curve.Done. This resign is popular for lots of reasons. Shoulder support for me. Tried all sorts of fill and mad a few for my customers as a gift. A combination of real shredded latex not synthetic and Kapok. More latex =bouncy and firmer. More Kapok softer squishy. Play till you get what is awesome because it is. Mix well and fluff if needed . The shape kind of cradles soon for me. Hey hate on me administration if I'm waaay off topic but audio aholics even need a break. Not as important as an awesome pillow for cheap. Avacodo Pillow Co inspired the idea I just stole it. Not even look at my pillow.! Michael Bean products and DIY Bedding good sources.Looks like it's a very good material for acoustic damping, I was worried about the moths but apparently they don't like taste. Think I might try that along side standard polyester

Michael, I'm a bit confused. Do you use kapok as volume fill in your cabinets or just pillows? I'm thinking about moths getting into my speaker cabinet once I finally glue the sides on as it as it'll be harder to access the fill. I'm considering casing the stuffing in a nylon mesh to keep bugs out and just in case I decide to replace it I future. I'm guessing some people here would welcome the opportunity to build a new case and swap out the drivers but for this build I hope to find the sweet spot and keep the units closed until obsession drives me to build a new set. I'm living in Germany currently, most birch comes through Russia so not looking forward to replacing the cabinets any time soonJulesm, Hi appreciate your concern for details. I'm like that too. Experimented with pillow fills for a year and have narrowed it down. I personally like a creasent shaped case. Easy just buy zipper case at Walmart cotton and poly both nice and just inverter and sew a curve.Done. This resign is popular for lots of reasons. Shoulder support for me. Tried all sorts of fill and mad a few for my customers as a gift. A combination of real shredded latex not synthetic and Kapok. More latex =bouncy and firmer. More Kapok softer squishy. Play till you get what is awesome because it is. Mix well and fluff if needed . The shape kind of cradles soon for me. Hey hate on me administration if I'm waaay off topic but audio aholics even need a break. Not as important as an awesome pillow for cheap. Avacodo Pillow Co inspired the idea I just stole it. Not even look at my pillow.! Michael Bean products and DIY Bedding good sources.

Hey Julesm, Kapok has been used for different stuffing material for centuries. Also called silk cotton because so silky feeling. It is inert and does not support any insect or microbial life. Moths included. That's why it's so great as pillow stuffing. A pound really goes a long way when you draw it out into bulk. DIY Bedding is cheapest for a pound . 2 lb will do a regular pillow. Should work perfect as sound absorbing material because of long fibers. Good luck Michael

I'll give it a go, thank you!Hey Julesm, Kapok has been used for different stuffing material for centuries. Also called silk cotton because so silky feeling. It is inert and does not support any insect or microbial life. Moths included. That's why it's so great as pillow stuffing. A pound really goes a long way when you draw it out into bulk. DIY Bedding is cheapest for a pound . 2 lb will do a regular pillow. Should work perfect as sound absorbing material because of long fibers. Good luck Michael

So ... will my old cotton T shirt work well as damping material?That is what we use.

dave

Maybe. Lots of variables. Cotton fabric has been successfully used by others.

dave

dave

Last edited:

Hey All, damping materials are not all that much different. Slowing down the speed of sound a bit and absorbing a bit. T shirt? Why not. Free and volume used might be just as important as materials.Over stuff then reduce if necessary with critical listening. Maybe none. Totally driver selection dependent. More of us should JUST enjoy the music and the total atmosphere and experience. That is what you will keep with you. Not how f ing fancy or expensive system you played it on. Lighten up and just enjoy. Michael

- Home

- Loudspeakers

- Full Range

- Tapered Wave Tube with Damp-Duct (TWTD) + Pluvia7HD