Hi, just out of curiosity, have you thought of a enclosure less dependant on TS parameters like a tqwt for example.

I have just built a pair to upgrade my existing kef br's. It was certainly worthwhile.

As for material, in my experience a warmth added from a cabinet resonance is far more acceptable than MDF "honk".

I have just built a pair to upgrade my existing kef br's. It was certainly worthwhile.

As for material, in my experience a warmth added from a cabinet resonance is far more acceptable than MDF "honk".

See this thread for some pics.

http://www.diyaudio.com/forums/showthread.php?threadid=80915&perpage=10&pagenumber=2[/URL]

http://www.diyaudio.com/forums/showthread.php?threadid=80915&perpage=10&pagenumber=2[/URL]

Tqwt?? 😕 You've lost me... I'm a newbie in this field. I've only recently taken a serious interest in loudspeaker building. I've learnt a few things since, but I've still only scratched the surface. There's a gazillion things I want to know, and I've no idea where to start. This forum seemed like a good place. 😀

I started with this project just to remake the cabinets, because they look shabby. They're over 20 years old and have taken a few hits. The drivers are in mint condition, though. I've refurbished the filters with new wires, caps and resistors, and that already helped heaps. So now I'd like to go a bit further and build a different cabinet, to find out if that can add more. As stated earlier, I want to tame the peak at around 50 Hz and stretch bandwidth down a little. I think the easiest way to do that is by building a straightforward (vented, in this case) box. I have not very much woodcrafting skills, so I'd like to start simple - this will be my first serious DIY speaker project. But I'd like to do it right; try to get a little more out of the drivers than I get now. I might have to tweak the filters a bit aswell, but there's way too much math there. Math has never been my favourite or best subject...

But can you tell a bit more about Tqwt enclosures? Thanks.

Aslo, is there a place where I can read and learn about crossover networks from scratch? Way back I learned about imaginary numbers (j), but that's far too long ago. I remember nothing of it.

I started with this project just to remake the cabinets, because they look shabby. They're over 20 years old and have taken a few hits. The drivers are in mint condition, though. I've refurbished the filters with new wires, caps and resistors, and that already helped heaps. So now I'd like to go a bit further and build a different cabinet, to find out if that can add more. As stated earlier, I want to tame the peak at around 50 Hz and stretch bandwidth down a little. I think the easiest way to do that is by building a straightforward (vented, in this case) box. I have not very much woodcrafting skills, so I'd like to start simple - this will be my first serious DIY speaker project. But I'd like to do it right; try to get a little more out of the drivers than I get now. I might have to tweak the filters a bit aswell, but there's way too much math there. Math has never been my favourite or best subject...

But can you tell a bit more about Tqwt enclosures? Thanks.

Aslo, is there a place where I can read and learn about crossover networks from scratch? Way back I learned about imaginary numbers (j), but that's far too long ago. I remember nothing of it.

But can you tell a bit more about Tqwt enclosures? Thanks.

Hi

There is a huge wealth of tqwt info on this site, with contributors much more versed in the science than myself.

Check out the full range section in particular, Also well worth a visit is the full range driver ws. Here you can find tqwt projects together with useful calculation software. Another excellent resource is MJK's http://www.quarter-wave.com/

If you can provide the driver fs, and sd, (dia of cone between rubber surround) I can give you typical box dims, if this is of help.

Exactly 145mm.

You really need to obtain the fs or fo (This is the resonant frequency of the driver), this defines the length of the line.

However, if we assume 45 hz, then the following dims are calculated. The calcs are the standard ones you will find if you search around. Box Volume seems divided, John Rutter's spreadsheet (based on DB Weems design) found here:- http://melhuish.org/audio/software.html , suggests a mouth area of 2.5 * Sd, whereas Bob Brines experience suggests 4 *Sd here:- http://www.geocities.com/rbrines1/Pages/Straight_Pipe.html

I have built both versions my latest is base on 4 * Sd, I am really happy with ths results.

Parameter Input

Design Frequency: 45 Hz

Driver SD: 72.5 mm2

Material Thickness: 16 mm

Design Width: 210 mm

Calculated Parameters

Sd: 16512.99639 mm2

Sa: 307 mm

St: 79 mm

Sm: 315 mm

Sp: 126 mm

Drive Unit Height: 890 mm

Design Height: 1109 mm

Design Depth: 315 mm

Line Length 1911 mm

Internal Volume: 70.2 Litres

Please note the above was produced from my own spreadsheet based on the available info as a quick calculator, as such I can offer no guarantee of accuracy or `as built' results either subjective or measured.

For something more advanced I believe MJK produces some calc sheets that are very accurate.

Enjoy!

Addendum - The port length (Sp) given I found you need to play with, the best results were funnily enough the same length as the throat in my case, however this is probably coincidence, or a factor I am unaware of?

If you cant find a drawing showing the different parameters let me know.

If you cant find a drawing showing the different parameters let me know.

Hi,

I'll just add without the driver parameters A TQWT is a bit hit

and miss. Avoiding an upper bass suckout is very difficult IMO.

There is also the MLTWQT (see http://www.quarter-wave.com/)

which in my opinion is a better design approach than a TWQT,

but this to a degree depends on the driver.

🙂/sreten.

I'll just add without the driver parameters A TQWT is a bit hit

and miss. Avoiding an upper bass suckout is very difficult IMO.

There is also the MLTWQT (see http://www.quarter-wave.com/)

which in my opinion is a better design approach than a TWQT,

but this to a degree depends on the driver.

🙂/sreten.

I'll just add without the driver parameters A TQWT is a bit hit and miss

This is really the beauty of `roll your own`, you can build test boxes quickly and easily until you find the technology you prefer.

Having built and played with bass reflex, infinite baffles, TML's, baffles, and tqwt's for over 15 years, my monies on the latter! sure they are not perfect, but what is?

The classic bass `hump' with the br, or 100hz dip of the tqwt, or the rapidly diminishing bass of the baffle, etc, etc.

Bottom line - get the knowledge - apply it - build the things and let your own ears be the judge. If it sounds better it is, oh and of course mostly enjoy the experience!

Just for the record, the pair I am just finishing are the best I have made, so far, incredibly musical, and detailed, with a bottom end to die for IMHO, you really should hear double bass through these babies, dispite the dip.

My CD collection is being re-discovered again.

Thanks for your input and ideas, guys! Really appreciate it.

For now I think I'll just stick with a basic ported box. Since I'm not experienced in building speakers and have yet to develop some woodcrafting skills, I think it will be easiest and safest. Also, The enclosure you suggested, seems quite large for my small room. 70 liters is about twice as large as the 36.5 litres I had in mind. I will dive into it some more, since the concept is quite interesting. Perhaps something for a next project.

The cabinets I will likely build are, by sheer coincidence, about as big (and similar in dimensions and outer looks) as the ProAC Studio 100. I'm not sure about the symmetrically offset tweeter, though. This offset is meant to improve cabinet edge diffraction. Does that also apply to horn tweeters? As far as my knowlegde goes (and that's not very far 😉 ) horn tweeters have a much more controlled dispersion pattern, and are less affected by cabinet design than domes. Is this true?

Thanks!

For now I think I'll just stick with a basic ported box. Since I'm not experienced in building speakers and have yet to develop some woodcrafting skills, I think it will be easiest and safest. Also, The enclosure you suggested, seems quite large for my small room. 70 liters is about twice as large as the 36.5 litres I had in mind. I will dive into it some more, since the concept is quite interesting. Perhaps something for a next project.

The cabinets I will likely build are, by sheer coincidence, about as big (and similar in dimensions and outer looks) as the ProAC Studio 100. I'm not sure about the symmetrically offset tweeter, though. This offset is meant to improve cabinet edge diffraction. Does that also apply to horn tweeters? As far as my knowlegde goes (and that's not very far 😉 ) horn tweeters have a much more controlled dispersion pattern, and are less affected by cabinet design than domes. Is this true?

Thanks!

Hi,

also note I don't disagree with hlj, I've heard a pair of Rega Naos

TL speakers produce stunning in room bass extension and drive.

The design of the Regas appears to be very similar to the Seas Thor :

http://www.seas.no/thor.htm

The woodworking is not particularly diificult. Also see :

http://www.humblehomemadehifi.com/Optimo.html

For the Tannoy drivers edge diffraction is not much of an issue.

🙂/sreten.

also note I don't disagree with hlj, I've heard a pair of Rega Naos

TL speakers produce stunning in room bass extension and drive.

The design of the Regas appears to be very similar to the Seas Thor :

http://www.seas.no/thor.htm

The woodworking is not particularly diificult. Also see :

http://www.humblehomemadehifi.com/Optimo.html

For the Tannoy drivers edge diffraction is not much of an issue.

🙂/sreten.

Right side of cabinet. Front points down. Here you see the brace and the pieces of hardwood slightly recessed, so the baffel sort of slides in to the cabinet. I think this will add some rigidity and better air sealing. The baffle should be able to come out in case I want to modify things.

Attachments

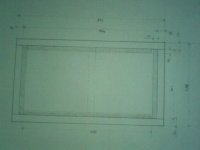

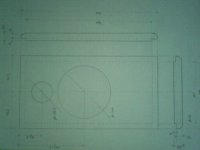

The Baffle. Underneath the woofer will be another hole for the port. I've not determined optimal dimensions yet, but I think 60mm will do best. Port length will still be manageable (about 153mm; might not need a support). I still have to find a suitable flared port in order to determine final dimensions. Top points left.

While I'm at it: does the disance to either sidewall and the distance from the woofer actually matter? Does that affect sound in some way?

While I'm at it: does the disance to either sidewall and the distance from the woofer actually matter? Does that affect sound in some way?

Attachments

Any feedback on this design is welcome, ofcourse. Thanks!

Dimensions (mm) inner/outer:

w: 241/285

h: 494/538

d: 324/354

Woofer cutout: 204

distance to top/side of cabinet: 227.5/120.5

Tweeter cutout: 86.5

distance to top/side of cabinet: 67.5/120.5

Damping: yet to be determined. I have planned to line all insde panels except baffle with bitumen. Then stuff the inside with some absorbant material. I have no clue which and how much... Again, all info/suggestions is wel come.

Dimensions (mm) inner/outer:

w: 241/285

h: 494/538

d: 324/354

Woofer cutout: 204

distance to top/side of cabinet: 227.5/120.5

Tweeter cutout: 86.5

distance to top/side of cabinet: 67.5/120.5

Damping: yet to be determined. I have planned to line all insde panels except baffle with bitumen. Then stuff the inside with some absorbant material. I have no clue which and how much... Again, all info/suggestions is wel come.

Hi,

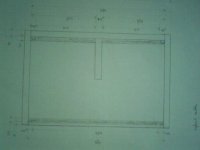

Just some further thoughts on the bracing. What I'd do :

Add vertical braces to the sides offset (~ 0.6) towards the front

of the cabinet say 2" wide. Extend the rear brace to meet these.

The rear brace should be offset to ~ 0.6 of the hieght.

Then add two braces from the baffle either side of the bass

unit extending back to the vertical braces. They will now be

reinforced at 3 points.

Also add front to back 2" braces top and bottom offset ~ 0.6.

Bitumen damping is usually used with thinner ply panels as

it needs to be ~ as thick as the panels. Not used much now.

Driver distance to sidewalls is not really an issue. Reflex designs

generally are not stuffed, you need free airspace around the

port. I'd line them with foam and put 2 pieces of foam directly

behind the driver in the "box" formed by the bracing above.

Also to "spread" resonances the baffle should be thickest e.g.

25mm, followed by the side walls e.g. 19mm x4, followed by

the rear baffle e.g. 16mm (1", 3/4", 5/8" in old money).

🙂/sreten.

Just some further thoughts on the bracing. What I'd do :

Add vertical braces to the sides offset (~ 0.6) towards the front

of the cabinet say 2" wide. Extend the rear brace to meet these.

The rear brace should be offset to ~ 0.6 of the hieght.

Then add two braces from the baffle either side of the bass

unit extending back to the vertical braces. They will now be

reinforced at 3 points.

Also add front to back 2" braces top and bottom offset ~ 0.6.

Bitumen damping is usually used with thinner ply panels as

it needs to be ~ as thick as the panels. Not used much now.

Driver distance to sidewalls is not really an issue. Reflex designs

generally are not stuffed, you need free airspace around the

port. I'd line them with foam and put 2 pieces of foam directly

behind the driver in the "box" formed by the bracing above.

Also to "spread" resonances the baffle should be thickest e.g.

25mm, followed by the side walls e.g. 19mm x4, followed by

the rear baffle e.g. 16mm (1", 3/4", 5/8" in old money).

🙂/sreten.

Hi, Sreten. Thanks.

So you mean to move the horizontal brace a bit upwards and forwards, and then to connect braces from top to bottom to the horizontal brace on both sides? Could you perhaps clarify by means of a simple drawing?

The baffle will be 30 mm thick (22mm +8mm) plywood screwed and glued to eachother. If I want to spread resonances, as the sides will be 22mm, the rear would have to be 18mm?

Bitumen not necessary, just thick acoustic foam would be enough? No stuffing? I remember seeing a box with some "mat" of some sort of synthetic wool folded inside the cabinet. Not really "stuffed" in that there was no more free moving air, but just some extra filling. You know what I mean?

So you mean to move the horizontal brace a bit upwards and forwards, and then to connect braces from top to bottom to the horizontal brace on both sides? Could you perhaps clarify by means of a simple drawing?

The baffle will be 30 mm thick (22mm +8mm) plywood screwed and glued to eachother. If I want to spread resonances, as the sides will be 22mm, the rear would have to be 18mm?

Bitumen not necessary, just thick acoustic foam would be enough? No stuffing? I remember seeing a box with some "mat" of some sort of synthetic wool folded inside the cabinet. Not really "stuffed" in that there was no more free moving air, but just some extra filling. You know what I mean?

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Tannoy Stratford rebuilding and/or retuning