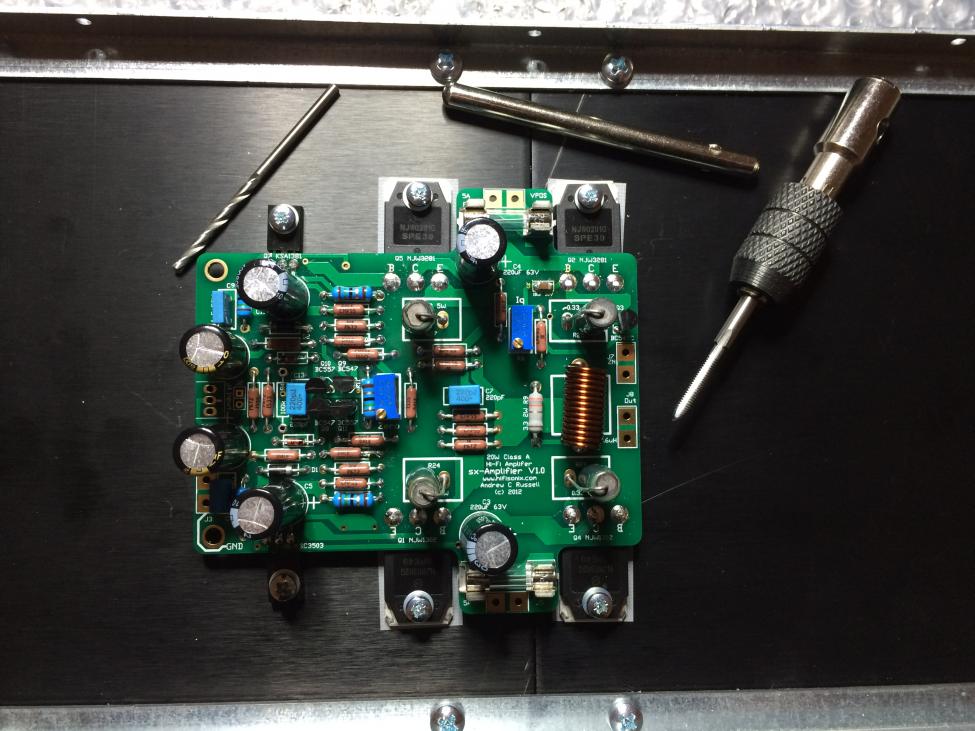

finished PCB's

Sorted the misstakes of the C6 and 120 Ohm.... now for the heatsinks.....

I will not use any connectors on my build, only hard connections. That was a tip from a friend of mine. Not the easiest way, but worth it!

Will post pictures during progress.

Sorted the misstakes of the C6 and 120 Ohm.... now for the heatsinks.....

I will not use any connectors on my build, only hard connections. That was a tip from a friend of mine. Not the easiest way, but worth it!

Will post pictures during progress.

Attachments

Hello everyone, may I ask a couple of questions regarding the SX version of this amplifier?

What is the difference between the version V1 PCB that is for sale at Jims Audio Store and the version V2.09 that is described by Mr. Russell on the Hifisonix web page? ( sorry if this has been asked before )

What are constructors views on the SX after building? Sound quality etc.

Thank you

Alan

What is the difference between the version V1 PCB that is for sale at Jims Audio Store and the version V2.09 that is described by Mr. Russell on the Hifisonix web page? ( sorry if this has been asked before )

What are constructors views on the SX after building? Sound quality etc.

Thank you

Alan

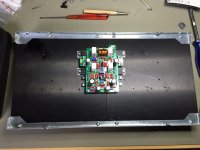

Trying to get the best possible heat dissipation.... This is a puzzle 😀

Any tips are welcome!

You can use a piece of copper heat spender under the transistors.

That would help a lot

6"X 6" min 5 or 6mm thick If copper to expensive you can use aluminium to but copper has superior heat conduct..

Built the sx. Sounds great. In fact it has taken the place as my main amp 🙂

I think Bonsai should answer but there are some minor issues on the Jims Audio pcb that should be sorted out. A couple of differences between the schematics and the pcb.

However there are easy workarounds explained on the first post here.

I have made a writeup on these issues but I am afraid they are in Norwegian.

15 Watt klasse A -> Ovation-SX - Side 4

I think Bonsai should answer but there are some minor issues on the Jims Audio pcb that should be sorted out. A couple of differences between the schematics and the pcb.

However there are easy workarounds explained on the first post here.

I have made a writeup on these issues but I am afraid they are in Norwegian.

15 Watt klasse A -> Ovation-SX - Side 4

Trying to get the best possible heat dissipation.... This is a puzzle 😀

Any tips are welcome!

Mine is placed like this. (SX amp). It doesnt get warm

My heatsinks are huge. I got the 5U big Amp case... bit overkill I think. So I guess just placing the board in the middle, using both heatsinks equally should do it?

Ofcourse I will place the big trannies as low as possible. I will use Keratherm for good heat transfer.

I love the tip about the copper! Would look very good indeed! Could be I will go for that one 🙂

I don't like the idea of the PCB resting on the trannies.... So I will go for spacers.

Ofcourse I will place the big trannies as low as possible. I will use Keratherm for good heat transfer.

I love the tip about the copper! Would look very good indeed! Could be I will go for that one 🙂

I don't like the idea of the PCB resting on the trannies.... So I will go for spacers.

I will try that when I get the new one... No way you can drill out that tap! Much too hardened. Even my cobalt drills won't cut through.... Carma I guess ;-)

Ok, there it is. Number one is on.... But now I have to stop because I broke my M3 tap

It happened several time with me to, especially when I tapped the copper and aluminium together...

We must use proper lubrication and a 1/4 turn forward and back again and again.. No drill driver!!!

Aluminium soft metal and if we tap it faster it will stick and break. When stick does not move neither way..

Incredible hard to remove broken tapper from the soft metal. No drill bit will work because always go to the soft metal when you try it. Not impossible (there is a special tool for that to remove it) but ad rather move the whole PC board a bit and restart the job. 🙂

Thanks for the reply bambadoo. I have built several class A amplifiers, but not an up to date design ( older does not necessarily mean inferior ) so I will be interested in the comparisons. Mr. Russell was very kind to give this design to the DIY community.

Alan

Alan

- Home

- Amplifiers

- Solid State

- SX-Amp and NX-Amp