Yes, I could not come up with any seemingly suitable polyurethane products either, I think I don't know the right jargon yet to find any leads...You should ask them what they use. The true test will be if it sticks to the rubber sufficiently, as most water based products don't work well on non-porous surfaces. I've tried PVA on rubber surrounds and it won't stick sufficiently to be a permanent application. Many acordian surround coatings also aren't water based, so they'll also have issues.

PVA is only good on paper and fiber based cones. If it gets any moisture under it, the coating will lift. I'd be curious to try some of that SP355. Polyurethane based products may also be an option, but I'm not aware of anything viscous enough to try, being most PU products are harsh adhesives. Acrylic based substances may also work.

I was told be CP Moyen that the SP-355 cures to a white color.

Yes, the matching of coatings between drivers would be challenging.@duvixan I don't usually watch YT videos, but this guy in the video knows what he's doing. I watched a few of the others he did and so far everything was done to factory standards. The Ecouton LQL150 woofer is a tough driver to replace the surround on, being it has a very tight VC gap. Not removing the DC and using shims makes this a difficult thing to do without ending up with a rubbing VC.

Dynaudio is also hard to refoam due to tight VC gaps. The large VCs on these drivers are very fussy to work with. I refoamed my fair share of Dynaudio and can attest the work done in these videos is superb.

The coating they use on the surround looks to be PVA, but I could be wrong. The ScanSpeak driver they coated was done correctly, but I'd be worried if a pair of drivers would match after this was done. Its incredibly hard to keep the coating the same weight of material for a matched pair of drivers.

I wouldn't hesitate to give this guy my business if he was in the US. Sadly many of these guys are dying off and there's no one to replace them. Pretty soon everyone will be using sound bars and little crappy powered computer speakers. I remember the 80s when people built their own speakers, which was alot of fun and very gratifying. Now we just buy plastic disposable junk.

I need to come up with a rough weight of the damping material used...

My application was for a center channel, so less of an issue for now.

After watching that video, it seems like to get coating consistency, that a good mechanical procedure would be the best approach.

These folks may have some leads in Europe?I came across a Dutch company with cone adhesives, maybe they are a lead? Here is the SDS with contact info https://speakerrepairshop.nl/other/Elastische Contactlijm_EN_2.0.pdf

https://speakerrepairshop.nl/en/glue/g-10

@XtraLateNight They're using an old chuck from a lathe. The adjustable jaw is perfect for holding a driver very centered and the magnet has something to stick to. It takes years of experience to get as good as the guy in the video.

I used an old Lenco turntable for repairing smaller drivers. The 16 rpm speed was perfect for coating surrounds and cones. It had enough torque to spin a 12" pro audio driver.

I used an old Lenco turntable for repairing smaller drivers. The 16 rpm speed was perfect for coating surrounds and cones. It had enough torque to spin a 12" pro audio driver.

I ordered from them for 4 x 6" surrounds for bass speaker last year. I have left half of the the bootle (the one middle priced) after the job. Serious site.

Another possibility in Europe see "butyl Latex treatment for Suspension"The SP-355 is milky white and a litle bit more viscous. Maybe request a sample of that as well

I wish I could too, but don't think they will ship internationally

https://www.reparationhaut-parleur.com/pieces-reparation-haut-parleurs-audax.html

Cool pictures, figure 17 (a) looks like where we are wanting to damp... Some words too https://www.hindawi.com/journals/aav/2017/2792376/

@divixan, seriously, I would gladly pay a little extra for factory coated mid surround when I purchased this driver new. 🤷♂️

Seas knows better and finishes the job at the factory, https://www.seas.no/index.php?optio...&id=592:e0091-08-w12cy006&catid=49&Itemid=246

Seas knows better and finishes the job at the factory, https://www.seas.no/index.php?optio...&id=592:e0091-08-w12cy006&catid=49&Itemid=246

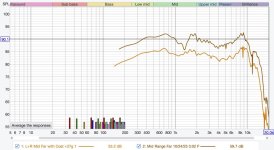

Hi all, any feedback on this result?Well, I am calling this a success...

Orange trace is with edge coating, no smoothing applied to curves.

Impedance sweeps also showed reduction in resonance around 1.3 kHz as well.

I am trying to determine if a second coat may yield additional improvement or stop while I am ahead.

Next, I have some Satori midwoofers, MW16P-8, which also show the ~1.3 kHz edge resonance. These will be used in a 3-way center channel, crossed around 500 Hz. Any benefit by edge coating in this application?

Thanks y'all!

I'm using Mod Podge, Gloss-Lustre-Lustre booth for membrane treatment and edge treatment, its on my speakers for years with no problem, it do the job nice : )

https://modpodgerocksblog.com/what-is-mod-podge/

For coil bonding the best one https://www.hernon.com/voice-coil-bonder-360-2

For magnet Loctite 480

For everything other Scotch Grip EC -1022

https://modpodgerocksblog.com/what-is-mod-podge/

For coil bonding the best one https://www.hernon.com/voice-coil-bonder-360-2

For magnet Loctite 480

For everything other Scotch Grip EC -1022

Last edited:

How to apply Mod Podge. Simply put your speaker on something which is rotating e.g. something like an gramophone, instead of vynil put your speaker there. : ) My speaker magnet don't have hole but an small hole in which I put metall ball and simply rotating speaker on ball I have aplied two layers of Mod Pogde using an fine brush, first layer was thin, when dry I done some fine cleaning by P600 sand, than the next layer is a little thicker, and when it dries it comes out like glass flat and aslo when it dries it will become very thin. You can also speed up drying with a hair dryer. Hope this helped. Note this, this is not reversible! Speakers is a bit dirty and I'm lazy to clean it up

My reference TL speakers, Audax HM170G8 , my faworite 6.5" bass/mid and nice tweeter RAAL 64-10

My reference TL speakers, Audax HM170G8 , my faworite 6.5" bass/mid and nice tweeter RAAL 64-10

Attachments

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Surround coating help?