The stripes and the mcu is connected from labor power supply.Do you mean too much with Meanwell?

its a siglent SPD3303X-E.

You could try feeding the MCU board with a 5V power bank and use Siglent (or Mean Well) for the led stripes. Do you have any spec for the LED stripes?

How is the ground wiring of the LED stripes done? Any common resistance between the loop supply-LED stripe-ground and the ground wiring between the LT3045, microphone board and microcontroller analogue ground?

If the microphone with MCU has low noise without the LED stripes adding a 74HCT125 (or similar) between the GPIOs and the LED stripes is one option.

I would like to thank you again for your help.Do you have any spec for the LED stripes?

The data sheet is attached.

If I supply the data line of the LED with 3.3V. Sometimes it happens that the first or the last LED is not controlled correctly.

All grounds are together connect without any resistor or capacitor.How is the ground wiring of the LED stripes done?

i dont use the LT3045 because i cant use it without a good pcb desing :-(Any common resistance between the loop supply-LED stripe-ground and the ground wiring between the LT3045, microphone board and microcontroller analogue ground?

Attachments

Any wire has resistance (except superconductors), self-inductance, capacitance, and mutual inductance and capacitance to wires nearby. Not a lot, but maybe the wires' own resistance is enough to cause crosstalk from the LED stripes to the microphone.

if no data is sent to the led strips via spi. then the noise is on rms -60dBIf the microphone with MCU has low noise without the LED stripes adding

i have 9x sn74ahct125n from tiadding a 74HCT125 (or similar) between the GPIOs and the LED stripes is one option.

https://www.ti.com/lit/ds/symlink/s...48640&ref_url=https%3A%2F%2Fwww.google.com%2F

i use 4 data connection parallel.

If you use 5V as power supply to 74AHCT125 it also acts as a level shifter (3V-5V) so it should also solve your issue with the first LED not controlled correctly.

If you use 5V as power supply to 74AHCT125 it also acts as a level shifter (3V-5V)

is the connection fine? or i need any resistor or capacitor?

Attachments

You need a decoupling capacitor (100nF) for the power supply (between VCC and GND) and all output-enable pins tied to GND.

thanksYou need a decoupling capacitor (100nF) for the power supply

Attachments

i have a little current problem.

how much current need the sn74ahct125n for an logic input?

how much current can it handle as output?

how much current need the sn74ahct125n for an logic input?

how much current can it handle as output?

According to the datasheet input current is typically +-1ua. Max output current is +-25mA. Max power dissipation is 500mW.

Input current of the data lines on your LED stripes is only +-1uA so should not be a problem for 74AHCT125.

Input current of the data lines on your LED stripes is only +-1uA so should not be a problem for 74AHCT125.

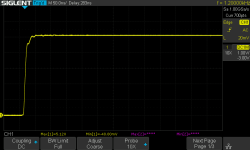

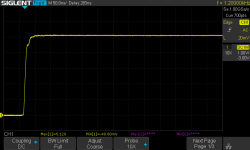

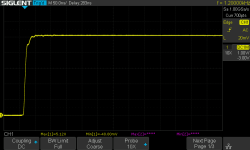

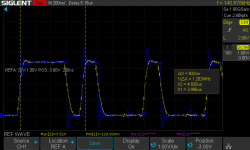

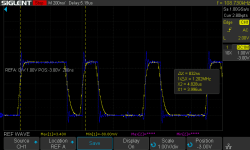

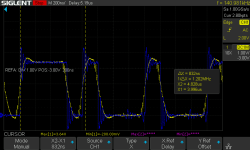

Here is a picture to show the SPI_0 direct comes out from the microcontroller.

Blue is without a cap.

yellow is with a ceramic cap and the GPIO port current is limited.

i played with different sizes.

what do you say?

Blue is without a cap.

yellow is with a ceramic cap and the GPIO port current is limited.

i played with different sizes.

what do you say?

Attachments

If you are worried about the overshoot my recommendation is to use series termination resistors.

This covers common termination techniques for transmission lines:

https://www.ti.com/lit/an/scaa045a/scaa045a.pdf

This covers common termination techniques for transmission lines:

https://www.ti.com/lit/an/scaa045a/scaa045a.pdf

So is this the situation?

- MCU+mic without data lines -> no noise

- MCU+mic with data lines running but not connected to leds -> no noise

- MCU+mic with data lines controlling leds -> noise

Assuming the crosstalk comes from the LED strip's ground current, this would be one way to lay the wiring out. Star connection at the supply to minimize the mutual impedance, twisting to avoid magnetic coupling as much as possible, capacitor reduces efficacy of the star connection, but provides a return path for the data signal close to the data wire. Value of the capacitor to be determined experimentally, you could try 0, 1 nF and 100 nF to get an idea what works best.

I have just noticed that. Meanwell power supply is connected to the strips and to the microcontroller. The microphone is connected to the lab power supply and the microphone is connected to my usb sound card. this is enough to turn on the meanwell power supply and send led data. only when sending, there is again a strong noise on the mic. what is happening? i don't understand it.So is this the situation?

- MCU+mic without data lines -> no noise

- MCU+mic with data lines running but not connected to leds -> no noise

- MCU+mic with data lines controlling leds -> noise

could be difficult. see my picture. please dont fire me...twisting to avoid magnetic coupling

i did it. see my pdf.Value of the capacitor to be determined experimentally, you could try 0, 1 nF and 100 nF to get an idea what works best.

Attachments

- Home

- Design & Build

- Construction Tips

- Strong noise floor when the mic is connected to the microcontroller