Your enabling process on the other hand seems right up my alley...I love paper cones and MF domes as found on some of the Philips MF drivers of the late 70s and 80s...which always seem a tad bright in comparison to the later silk dome variants. Hmmm wonder if I should attempt treating them.

Thanks for sharing your particular experiences....

🙂

yeah, I can only handle fairly simple crossovers

which sometimes means the drivers may need some 'rework' instead

I know it was wrong of me to call it 'enabling' 😱

mine is just careless messy coating 😀

but if I had put more on you would not have noticed that 😛

actually I would usually coat much thicker

but it was also to 'test' if this this 'almost nothing' would make any difference

I'm not sure about that midrange coating, and it should probably have a it more

or at least enough to cover that ugly yellow

cheers, and good luck

Yes, I realize the last post is almost exactly 5 years ago, thank you.

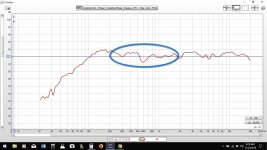

The attached response curve is for a sealed 2 way with 5" woofer and 1" dome tweeter. Crossover is about 3500 Hz. The woofer has a paper cone. I'd like to raise and flatten the woofer's output between 200 and 2,000 Hz. Seems like stiffening the cone might help here and I'm most likely going to Modge Podge it and re-measure. Thought I'd throw it out there beforehand for comment.

The attached response curve is for a sealed 2 way with 5" woofer and 1" dome tweeter. Crossover is about 3500 Hz. The woofer has a paper cone. I'd like to raise and flatten the woofer's output between 200 and 2,000 Hz. Seems like stiffening the cone might help here and I'm most likely going to Modge Podge it and re-measure. Thought I'd throw it out there beforehand for comment.

Attachments

… to Modge Podge...

Very interested.

Use thin layers. Allow 24 hrs to dry. Measure each time. The top should fall off with more coats.

dave

After getting another look at the woofer, it is pretty stiff as is due to its small size. I'm leaning towards thinking it will have no effect.

Perhaps instead of stiffening, you could try the slits with rubberized/flexible glue, aka scan revelatorish. There was a really long thread on this here and on PETT.

I prefer old JBL woofers over newer PA woofer because of their lack of plastic coatings, which surpsingly sound exactly like plastic. If you want to spend some time on it you can cut off the cone, make a mold of it in plaster, and drill many small holes in the mold, then soak some long fiber paper shreds. Swirl the water and lower the mold, and then raise the mold, catching some of those paper fibers. You can also add some ash from burnt wood, and cellulose powder in the water. Then glue a new suspension and reuse the old voice coil.

After getting another look at the woofer, it is pretty stiff as is due to its small size. I'm leaning towards thinking it will have no effect.

I agree. The wiggles are at too low frequency to be cone resonance. They are most likely baffle diffraction or boundary reflections, depending on measurement setup.

I am tinkering about what to do with 4kHz resonance of SEAS MR18 myself. First I will add felt pads on cone edge, then perhapss a hot glue ring. Slicing is out of question because these are coated paper cones.

https://www.diyaudio.com/forums/multi-way/322839-seas-mr18-3-a-2.html#post5608487

you can spray a light wet coat of low gloss Acrylic lacquer this will give you a stiff outer layer, spray the back side of the cone also, make sure to cover the spider.This will stiffen your cone and seal the paper you can add additional layers the first coat has minimal paper penetration. I coated a lot of old cones to test this out it is next to no penetration. This is the lightest means of stiffening your cone PVA layers will add more mass. You can coat PVA over the acrylic and not have to worry about uneven absorption by the cone.

For a pressed paper cone, cyanoacrylate (super glue) is the best way to stiffen a cone. If you want to dampen the cone, you can try something like PVA instead. But don't do this to a speaker that is precious to you, as there is no guarantee that the results will be better for your intended use

You already have an incredibly smooth curve; specially in the area that worries you.

If anything, you have a slight bump between 120 and 280 Hz.

I bet increasing cabinet volume by some 40% would both move it lower by 1/3 octave or so, flatten it in line with the rest of the curve and extend LF response downwards by the same amount.

If anything, you have a slight bump between 120 and 280 Hz.

I bet increasing cabinet volume by some 40% would both move it lower by 1/3 octave or so, flatten it in line with the rest of the curve and extend LF response downwards by the same amount.

My experiment wilt felt pads today, sort of success! Just have to find black or grey pads! The 4kHz peak of SEAS MR18 was attenuated 6dB with 6 pads, 3dB with 3 pads.

My experiment wilt felt pads today, sort of success! Just have to find black or grey pads! The 4kHz peak of SEAS MR18 was attenuated 6dB with 6 pads, 3dB with 3 pads.

you want to try some acoustical wool felt like F11 which has the widest effective absorption coefficient. acrylic felt is a waste of time as it has a very narrow bandwidth of absorption. Pure wool is critical.

^I don't think that absorption has anything to do with this, it is just the added mass on the edge of the cone that prevents edges from wobbling. Wool felt pads are heavier than these acrylics, which is nice.

^^ eBay is fine but if a strip of pads costs only some 1-2€ but shipping might be 10-15€. I will check local stores when I pass by - minimal cost of expedition!

^^ eBay is fine but if a strip of pads costs only some 1-2€ but shipping might be 10-15€. I will check local stores when I pass by - minimal cost of expedition!

Impressive result! Especially the fact that it only affected the desired part of the frequency respone 🙂 Except maybe the dip at 600 Hz.My experiment wilt felt pads today, sort of success! Just have to find black or grey pads! The 4kHz peak of SEAS MR18 was attenuated 6dB with 6 pads, 3dB with 3 pads.

/Anton

Actually I lost 1dB of efficiency below 1kHz. Not significant to me.

Please let me remind of this paper that I linked in this thread already in Nov 27th 2013... Then I tried this same trick with Peerless NE95 aluminium cones, with much less success.

http://www.klippel.de/fileadmin/kli...ture/Papers/KLIPPEL_Cone_Vibration_Poster.pdf

This Peter Larsen's video is good too YouTube

Please let me remind of this paper that I linked in this thread already in Nov 27th 2013... Then I tried this same trick with Peerless NE95 aluminium cones, with much less success.

http://www.klippel.de/fileadmin/kli...ture/Papers/KLIPPEL_Cone_Vibration_Poster.pdf

This Peter Larsen's video is good too YouTube

Last edited:

Very interesting tread.

I have been experimenting a bit with a pair of JBL LE111H woofers which have smooth paper cones with "Aquaplas" coating on the backside.

The LE111H woofers are no longer aviable new, and cone kits are obsolete. Basically leaving me with aftermarket parts as the only option if I want to build more of these woofers from suitable frames or blown woofers aviable on ebay.

Aftermarket cones have no "Aquaplas" coating and are because of this probably lighter, and less stiff than the original cones. The last part are what worries me the most, a db or 2 higher sensitivity and a a bit less extension down would not be a problem for my intended application, but a flimsy cone can be a problem. so some kind of coating on the rear of the cone seems like a good idea.

But with what? Thinned PVA? Cyanoacrylate? or Epoxy, I am not after a thin hard shell but something that's liquid enough to soak into the cone.

I have been experimenting a bit with a pair of JBL LE111H woofers which have smooth paper cones with "Aquaplas" coating on the backside.

The LE111H woofers are no longer aviable new, and cone kits are obsolete. Basically leaving me with aftermarket parts as the only option if I want to build more of these woofers from suitable frames or blown woofers aviable on ebay.

Aftermarket cones have no "Aquaplas" coating and are because of this probably lighter, and less stiff than the original cones. The last part are what worries me the most, a db or 2 higher sensitivity and a a bit less extension down would not be a problem for my intended application, but a flimsy cone can be a problem. so some kind of coating on the rear of the cone seems like a good idea.

But with what? Thinned PVA? Cyanoacrylate? or Epoxy, I am not after a thin hard shell but something that's liquid enough to soak into the cone.

Very interesting tread.

I have been experimenting a bit with a pair of JBL LE111H woofers which have smooth paper cones with "Aquaplas" coating on the backside.

The LE111H woofers are no longer aviable new, and cone kits are obsolete. Basically leaving me with aftermarket parts as the only option if I want to build more of these woofers from suitable frames or blown woofers aviable on ebay.

Aftermarket cones have no "Aquaplas" coating and are because of this probably lighter, and less stiff than the original cones. The last part are what worries me the most, a db or 2 higher sensitivity and a a bit less extension down would not be a problem for my intended application, but a flimsy cone can be a problem. so some kind of coating on the rear of the cone seems like a good idea.

But with what? Thinned PVA? Cyanoacrylate? or Epoxy, I am not after a thin hard shell but something that's liquid enough to soak into the cone.

"The Wet Look" by Parts Express.

- Home

- Loudspeakers

- Multi-Way

- Stiffening Paper woofer cones.