The LOA style lamps..

good site http://www.energydimensions.com/bulbs.html

I'm interested in the 55 Watt Twist Bulb Model #15555

zardoz

good site http://www.energydimensions.com/bulbs.html

I'm interested in the 55 Watt Twist Bulb Model #15555

zardoz

After reading this thread, I must admit that I cam amazed with the knowledge of some of our members, and there ideas for building a projector. I must say that this is a level of design and planning that the advancement of the hobby requires. My reading of your posts remp, I have to say that at points my mind started to hurt! In reading your posts I seems to me that you are seeking two different goals with your concept.

1. Modifying the backlight of a LCD panel to allow for the insertion of a much brighter source, thus allowing projection without removal of the backlight assembly.

2. The collection and focusing of light generated by a LOA light for use as that light source in #1 though light-tunnels.

The issues I have is that it seems that this seems like an awfully difficult ends to a mean. It appears that the results that this while having to potential for spectacular results, in the end it would have been cost competitive with commercially available models, do to the special materials this design requires. Ultimately, I feel that it would be better if these two concepts were developed separately so that the failure of either does not mean the end of these concepts as a whole. I feel that most in the DIY community are seeking the goal of figuring how to use LOA’s in a manner that will allow for focusing the light source. To this end, I feel that the light tunnel idea is a goal that we need to procure to meet this goal, however making such overly complex by using special materials, instead of more orthodox optics will led to a solution to the problem that most will not be able to build on there own. I wish feel that your ideas are without question worth considering, however, lets not go overboard with complex concepts and ideas when even simple goals of using LOA effectively in a projector has not been proven.

1. Modifying the backlight of a LCD panel to allow for the insertion of a much brighter source, thus allowing projection without removal of the backlight assembly.

2. The collection and focusing of light generated by a LOA light for use as that light source in #1 though light-tunnels.

The issues I have is that it seems that this seems like an awfully difficult ends to a mean. It appears that the results that this while having to potential for spectacular results, in the end it would have been cost competitive with commercially available models, do to the special materials this design requires. Ultimately, I feel that it would be better if these two concepts were developed separately so that the failure of either does not mean the end of these concepts as a whole. I feel that most in the DIY community are seeking the goal of figuring how to use LOA’s in a manner that will allow for focusing the light source. To this end, I feel that the light tunnel idea is a goal that we need to procure to meet this goal, however making such overly complex by using special materials, instead of more orthodox optics will led to a solution to the problem that most will not be able to build on there own. I wish feel that your ideas are without question worth considering, however, lets not go overboard with complex concepts and ideas when even simple goals of using LOA effectively in a projector has not been proven.

mikejz84

I think the goal of using LOA's in a "simple/non complex" manner has been examined, maybe not to exhaustion but in-depth at the very least. Our friend remp, I believe is providing us with ways to further the research. We have to get somewhat high tech to achieve better results than we can now achieve. As such we need to educate ourselves in the "current " technology.

zardoz

I think the goal of using LOA's in a "simple/non complex" manner has been examined, maybe not to exhaustion but in-depth at the very least. Our friend remp, I believe is providing us with ways to further the research. We have to get somewhat high tech to achieve better results than we can now achieve. As such we need to educate ourselves in the "current " technology.

zardoz

well my intention are not "non complex" however, i feel that it is possible to do this without the complex parts, however still requiring a complex design, but something were the parts are easyer to come by. I do have been doing some work with loa and have been getting some results. I do however have a question about LOAs, what is the property of the bulb when light is reflected back at it, does it absort it as heat, or reflect it back, or have the light pass though it?

mikejz84

You say my posts are overly complex.

(1) There is a high risk factor in modifying LCD monitors so that the brown flex cable is longer so lighting them via the backlight and not needing to do any risky mods makes a lot of sense to me

(2) Trying to use cheap low heat long life LOA for the backlight or regular straight throught projection seems a good idea.

A way to not damage a perfectly good LCD monitor and trying to use a cheap light source with a low heat content so you dont need noisy fans I dont think is overly complex. Whats overly complex about it.

You can knock my posts if you want to. I dont care. I will try and find something real simple in future so its not overly complex.

You say my posts are overly complex.

(1) There is a high risk factor in modifying LCD monitors so that the brown flex cable is longer so lighting them via the backlight and not needing to do any risky mods makes a lot of sense to me

(2) Trying to use cheap low heat long life LOA for the backlight or regular straight throught projection seems a good idea.

A way to not damage a perfectly good LCD monitor and trying to use a cheap light source with a low heat content so you dont need noisy fans I dont think is overly complex. Whats overly complex about it.

You can knock my posts if you want to. I dont care. I will try and find something real simple in future so its not overly complex.

As I see it, complex design is most often made up of high end complex parts.

I think that you might be pre concieving that we can't get or don't allready have some of this stuff available to us. Remp I think mentioned that sample's of some of this high end gear is available...with following samples to the same person getting smaller by every re request. If this is the case...and someone here wants to have an honest try at this I will ask for a sample and send it to them...thus 2 good sized pieces are obtained...then perhaps another member will follow my lead...then another...another...

Now have LOT's of this hard to find material in one place where a dedicated soul can keep us advised on the progress of "THE GREAT SOLLUTION" if this is a do-able thing it would be GREAT indeed. (hmmm anyone want a job?.....anyone want to be famous? (at least amongst us you will be 😉 )

I mean honestly...talk about a good place for "industrial espionage"... R and D man to his boss....jeez boss ya wont believe where I found this tech idea....a forum board on the internet...can you believe it? A bunch of guys putting various pieces of information together just made us a technology leader in our field! And they couldn't do it ..mostly just because they didn't try...

Then we read about it in the paper.."small cold projectors take the world by storm!...say goodbye to expensive short lived lamps!

Me? I'd love to know if this will work and if it comes down to it I will offer to try this on a 10 or 12 inch laptop panel (once I locate another panel of course). If there is one among us that is ready to take the project on and can tell me where to get the sample I will forward my sample to you.

zardoz

I think that you might be pre concieving that we can't get or don't allready have some of this stuff available to us. Remp I think mentioned that sample's of some of this high end gear is available...with following samples to the same person getting smaller by every re request. If this is the case...and someone here wants to have an honest try at this I will ask for a sample and send it to them...thus 2 good sized pieces are obtained...then perhaps another member will follow my lead...then another...another...

Now have LOT's of this hard to find material in one place where a dedicated soul can keep us advised on the progress of "THE GREAT SOLLUTION" if this is a do-able thing it would be GREAT indeed. (hmmm anyone want a job?.....anyone want to be famous? (at least amongst us you will be 😉 )

I mean honestly...talk about a good place for "industrial espionage"... R and D man to his boss....jeez boss ya wont believe where I found this tech idea....a forum board on the internet...can you believe it? A bunch of guys putting various pieces of information together just made us a technology leader in our field! And they couldn't do it ..mostly just because they didn't try...

Then we read about it in the paper.."small cold projectors take the world by storm!...say goodbye to expensive short lived lamps!

Me? I'd love to know if this will work and if it comes down to it I will offer to try this on a 10 or 12 inch laptop panel (once I locate another panel of course). If there is one among us that is ready to take the project on and can tell me where to get the sample I will forward my sample to you.

zardoz

i dont think hes knocking your posts, some people just can't understand genious-ness (if thats a word🙂) your post are very informative,its takes me a while to read em all but the concepts are good. keep up the good work.

-JimmY-

-JimmY-

I think that great results can be obtained currently with knowledge that already exists, but to limit ourselves to just that seems pretty silly. I think that with the use of light guides or other "special" material we may be able to enhance the display quality for only a small increase in price.

I just purchased a Sharp LQ104V1DG11 10.4" display that I hope to be able to use in this way. It was cheaper than any of the 5" displays I could find and has 640x480 resolution and is VGA capable. Once I get it I'm hoping it will work for me. Hopefully by the end of the week 3M will return my email with some pricing and sample availability of their product.. I do not think that it is going to be that expensive and from the product sheets it appears it may be very usable in one way or another.

I just think that simplicity is nice but limited. It is not going to be possible to get near high end projector results without trying out some new lighting possibilities.

I just purchased a Sharp LQ104V1DG11 10.4" display that I hope to be able to use in this way. It was cheaper than any of the 5" displays I could find and has 640x480 resolution and is VGA capable. Once I get it I'm hoping it will work for me. Hopefully by the end of the week 3M will return my email with some pricing and sample availability of their product.. I do not think that it is going to be that expensive and from the product sheets it appears it may be very usable in one way or another.

I just think that simplicity is nice but limited. It is not going to be possible to get near high end projector results without trying out some new lighting possibilities.

What controller are you using to run your Sharp LQ104V1DG11 10.4" display?

zardoz

zardoz

Crash said:I think that great results can be obtained currently with knowledge that already exists, but to limit ourselves to just that seems pretty silly. I think that with the use of light guides or other "special" material we may be able to enhance the display quality for only a small increase in price.

I just purchased a Sharp LQ104V1DG11 10.4" display that I hope to be able to use in this way. It was cheaper than any of the 5" displays I could find and has 640x480 resolution and is VGA capable. Once I get it I'm hoping it will work for me. Hopefully by the end of the week 3M will return my email with some pricing and sample availability of their product.. I do not think that it is going to be that expensive and from the product sheets it appears it may be very usable in one way or another.

I just think that simplicity is nice but limited. It is not going to be possible to get near high end projector results without trying out some new lighting possibilities.

Negative Design

Im glad you read them. Thanks for that.

Just to clarify I do think driving an LCD by replacing the backlight with something much stronger is a good idea and I have said so.

One very obvious thing is it opens up the possibility of using more of the light. Perhaps you guys did not notice the part I wrote about how we only use 50 percent of the light. Thats a very big percentage yet illuminating an LCD via the backlight allows us to get stuck in and use a greater percentage of light as Crash has already posted. And without using any thing complicated just some cleverly designed 3M films.

If we ask them for samples they give them free but first before asking for samples we need to know what samples to ask for.

Does that make sense. In actual fact there are two parts to this.

(1) A modern LCD monitor will have the right stuff already fitted so no samples needed.

(2) Older screens may not have these films fitted

Either way, polarizing films and brightness enhancing films can be obtained even if we have to buy them and each 3M film has been tailored specifically to making more use of the light.

That also brings up a very important point.

With LOA various attempts have been made to use them but not with much success otherwise we would all be using them already.

So if the better light utilisation that 3M can assist us with from their films that could mean that a LOA is now in a stronger position to power the LCD.

Just to clarify that, if the guys who used LOA in the past had been able to use all the light from an LOA instead of having 50 percent of it wasted they might have had a workable light situation. 50 percent of a light wasted is a lot of light.

Now someone is going to say this is overly complex but would you try every means possible to get that extra 50 percent of wasted light to become useful. I would thats for sure.

Its the cheapest modification you can do.

For straight through illumination you need the 3M film as described in their patent 6104536 dated August 2000 but its not listed on their film site or anywhere else that I can find.

Zardoz. Could you look at that patent on the USA patent database, get familiar with its description particularly fig 4 diagram which shows how simple the whole thing is and maybe you can get a sample from 3M.

The film is called....... Plane polarization convertor film.

I cannot get it in New Zealand. They dont know anything about it.

With one of those in your hands I bet your projector will be a lot stronger.

Im glad you read them. Thanks for that.

Just to clarify I do think driving an LCD by replacing the backlight with something much stronger is a good idea and I have said so.

One very obvious thing is it opens up the possibility of using more of the light. Perhaps you guys did not notice the part I wrote about how we only use 50 percent of the light. Thats a very big percentage yet illuminating an LCD via the backlight allows us to get stuck in and use a greater percentage of light as Crash has already posted. And without using any thing complicated just some cleverly designed 3M films.

If we ask them for samples they give them free but first before asking for samples we need to know what samples to ask for.

Does that make sense. In actual fact there are two parts to this.

(1) A modern LCD monitor will have the right stuff already fitted so no samples needed.

(2) Older screens may not have these films fitted

Either way, polarizing films and brightness enhancing films can be obtained even if we have to buy them and each 3M film has been tailored specifically to making more use of the light.

That also brings up a very important point.

With LOA various attempts have been made to use them but not with much success otherwise we would all be using them already.

So if the better light utilisation that 3M can assist us with from their films that could mean that a LOA is now in a stronger position to power the LCD.

Just to clarify that, if the guys who used LOA in the past had been able to use all the light from an LOA instead of having 50 percent of it wasted they might have had a workable light situation. 50 percent of a light wasted is a lot of light.

Now someone is going to say this is overly complex but would you try every means possible to get that extra 50 percent of wasted light to become useful. I would thats for sure.

Its the cheapest modification you can do.

For straight through illumination you need the 3M film as described in their patent 6104536 dated August 2000 but its not listed on their film site or anywhere else that I can find.

Zardoz. Could you look at that patent on the USA patent database, get familiar with its description particularly fig 4 diagram which shows how simple the whole thing is and maybe you can get a sample from 3M.

The film is called....... Plane polarization convertor film.

I cannot get it in New Zealand. They dont know anything about it.

With one of those in your hands I bet your projector will be a lot stronger.

I apologies if my post seemed to have to goal of knocking a new idea, that was not my intent. To say the least your idea if it works would be revolutionary. I was simply trying to perform a slight act of ‘peer review’ posing possible problems that might arise with this project; it was not my intent of coming off mean or saying that it was a bad idea. I can think of no reason why your idea would not work, and it is a very interesting idea, in fact the only issue I can raise with your idea is heat, LOA do get somewhat warm, and I have managed to melt a plastic reflector with mine. I am not saying we should not use new products, or items that may be hard to come by, but that this is an issue that needs to be consider, and nothing more.

In a related matter, I have been getting positive results today with an idea I am testing with my LOA, instead of trying to focus the light that is been emitted by the entire bulb. I am working with the concept of placing a reflective cone into the middle of the bulb and using it to reflect the internal light into a set a lens I got from a slide projector to get the light into focus. Results are mixed, but positive, have managed to get a clear but dark image projected—my reflective cone is somewhat crude and I am only using a about ½ of the LOAs light, but this idea seems somewhat promising.

In a related matter, I have been getting positive results today with an idea I am testing with my LOA, instead of trying to focus the light that is been emitted by the entire bulb. I am working with the concept of placing a reflective cone into the middle of the bulb and using it to reflect the internal light into a set a lens I got from a slide projector to get the light into focus. Results are mixed, but positive, have managed to get a clear but dark image projected—my reflective cone is somewhat crude and I am only using a about ½ of the LOAs light, but this idea seems somewhat promising.

mikejz84

I was simply trying to perform a slight act of ‘peer review’ posing possible problems that might arise with this project;

Thats a darn good idea. I have a habbit of wandering off into no-mans land quite often and its good you look at things from a practical point.

So one more man added to looking at the LOA problem. Excellent.

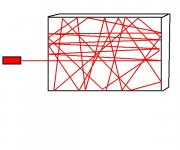

You are thinking there is some light in the middle that is being wasted and you are trying to get hold of it.

Heres the problem with any light using phosphers including LOA or any flourescents. Inside the tube is coated with phosphers like microscopic grains of sand. Along comes the UV light from the arc inside the tube and hits one of the grains of phospher. The grain then radiates white light in all directions, not straight ahead.

You end up with millions of little source lights all radiating in different directions.

Thats the problem because it then becomes harder to gather that light from all directions and make it go where we want.

Using a reflector will gather some and by using a highly polished well shaped reflector improves the chances of a certain number of light rays going in the right direction but compared to a single source light such as a Metal Halide we are well down.

The only way I see any possibility of getting all the light from a LOA is to surround it by a collection device, and then having collected as much as possible to get it to the LCD.

Think about it. In a backlite LCD they put a high efficiency light down the side of a light pipe which spreads the light across the LCD and makes the light go forward.

If you can reverse that process by pretending the LCD is the light source you see that light instead of going forward, goes back into the light guide and comes out where the backlite is.

Lighting systems are reversible. If it works going forward it also works going backwards.

So if we then bend the light guide around an LOA we should be able get a lot of the light.

Lightguides can be glass, plexiglass, lexan or polycarbonate. Glass is too hard to work with but any of the others can be bent. Stick it in the oven until you can make an indentation with a pin then it will bend around a wooden former or a paint tin.

To persue this we have to get a better grasp of what sort of scoring patern would be needed on the material to make it work.

One way to do that is to closely examine the lightguide that is in an LCD. Thats the patern for regular flourescent cold cathode backlights and LOA are fluorescent so it should work.

Quick rub over one side with sandpaper might be OK.

But before that we really need to understand a bit about lightguides so we can make our own.

mikejz84

I honestly don't know if your idea would work or not but the main thing is you are having a go and that is the most important thing.

Keep posting.

I was simply trying to perform a slight act of ‘peer review’ posing possible problems that might arise with this project;

Thats a darn good idea. I have a habbit of wandering off into no-mans land quite often and its good you look at things from a practical point.

So one more man added to looking at the LOA problem. Excellent.

You are thinking there is some light in the middle that is being wasted and you are trying to get hold of it.

Heres the problem with any light using phosphers including LOA or any flourescents. Inside the tube is coated with phosphers like microscopic grains of sand. Along comes the UV light from the arc inside the tube and hits one of the grains of phospher. The grain then radiates white light in all directions, not straight ahead.

You end up with millions of little source lights all radiating in different directions.

Thats the problem because it then becomes harder to gather that light from all directions and make it go where we want.

Using a reflector will gather some and by using a highly polished well shaped reflector improves the chances of a certain number of light rays going in the right direction but compared to a single source light such as a Metal Halide we are well down.

The only way I see any possibility of getting all the light from a LOA is to surround it by a collection device, and then having collected as much as possible to get it to the LCD.

Think about it. In a backlite LCD they put a high efficiency light down the side of a light pipe which spreads the light across the LCD and makes the light go forward.

If you can reverse that process by pretending the LCD is the light source you see that light instead of going forward, goes back into the light guide and comes out where the backlite is.

Lighting systems are reversible. If it works going forward it also works going backwards.

So if we then bend the light guide around an LOA we should be able get a lot of the light.

Lightguides can be glass, plexiglass, lexan or polycarbonate. Glass is too hard to work with but any of the others can be bent. Stick it in the oven until you can make an indentation with a pin then it will bend around a wooden former or a paint tin.

To persue this we have to get a better grasp of what sort of scoring patern would be needed on the material to make it work.

One way to do that is to closely examine the lightguide that is in an LCD. Thats the patern for regular flourescent cold cathode backlights and LOA are fluorescent so it should work.

Quick rub over one side with sandpaper might be OK.

But before that we really need to understand a bit about lightguides so we can make our own.

mikejz84

I honestly don't know if your idea would work or not but the main thing is you are having a go and that is the most important thing.

Keep posting.

what I am trying to figure out is how a loa reacts when you reflect light back at the bulb. An LOA is hollow in the center and my idea is to encase the light is a reflective circle where the light from the outside of the loa is reflected back at the bulb, and hopefully is passes down to the center where a cone reflects though serveral small len and out though another lens. I have only proven at this point that the center cone reflector somewhat works, however I don't think the bulb behaves as I had wanted when I reflect light back at it, it appears to just absorb it to some degree.

Attachments

remp

on the job...here's a little teaser so far."BACKGROUND OF THE INVENTION

The present invention relates to a polarization converter that efficiently converts substantially normally incident unpolarized light into linearly polarized light. More specifically, the present invention relates to a relatively thin lenticular polarization converter and to liquid crystal display (LCD) projection system designs including the novel thin polarization converter, for example, full-color LCD projection systems."

..out of a big body of patent data found here.

http://patft.uspto.gov/netacgi/nph-...0&s1=6104536.WKU.&OS=PN/6104536&RS=PN/6104536

more to follow

zardoz

on the job...here's a little teaser so far."BACKGROUND OF THE INVENTION

The present invention relates to a polarization converter that efficiently converts substantially normally incident unpolarized light into linearly polarized light. More specifically, the present invention relates to a relatively thin lenticular polarization converter and to liquid crystal display (LCD) projection system designs including the novel thin polarization converter, for example, full-color LCD projection systems."

..out of a big body of patent data found here.

http://patft.uspto.gov/netacgi/nph-...0&s1=6104536.WKU.&OS=PN/6104536&RS=PN/6104536

more to follow

zardoz

remp if that page is not accessable to you let me know and I will Email it in zip format to you if you wish.

zardoz

zardoz

Zardoz

Thanks. I can access the patent information ok its just that 3M in New Zealand have not heard of that product because its not listed in their catalogue.

I hope it is available.

mikejz84

Remember the reversibility of light. What comes out of a tube can go back in. I think most of your refected light is going back into the tubes. Watch for overheating. Safety glasses.

You are on the right track. Collect the outward going light in a collector then its yours.

Thanks. I can access the patent information ok its just that 3M in New Zealand have not heard of that product because its not listed in their catalogue.

I hope it is available.

mikejz84

Remember the reversibility of light. What comes out of a tube can go back in. I think most of your refected light is going back into the tubes. Watch for overheating. Safety glasses.

You are on the right track. Collect the outward going light in a collector then its yours.

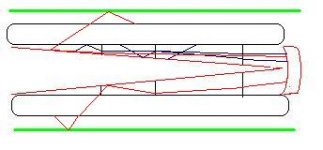

This drawing is what I think happens with a light guide.

Take a piece of plexiglas, lexan or polycarbonate panel.

No scratches anywhere and perfectly smooth edges polished

Inject light and none will come out. Its all reflected back inside.

By a process known as TIR. Total Internal Reflection.

Then if you scratch a patern on one of the sides the light comes out.

Thats what the lightguides in LCD's do.

I have to see it. I have some plastic in the shed. I will try a small piece.

Take a piece of plexiglas, lexan or polycarbonate panel.

No scratches anywhere and perfectly smooth edges polished

Inject light and none will come out. Its all reflected back inside.

By a process known as TIR. Total Internal Reflection.

Then if you scratch a patern on one of the sides the light comes out.

Thats what the lightguides in LCD's do.

I have to see it. I have some plastic in the shed. I will try a small piece.

Attachments

zardoz

I am not sure what controller is coming with the LCD, reportedly has one with it. Will see when it arrives next week or whatever.

I am not sure what controller is coming with the LCD, reportedly has one with it. Will see when it arrives next week or whatever.

remp

You have it right..I'm looking at two different lightguides now from two different LCD screens. The etching is on the side AWAY from the LCD, thus the light is sent back (away from the lcd) to an "ultrawhite" high reflectance sheet. Where it makes the ultrawhite GLOW, emitting difused light back at the panel. This light that makes it finally all the way through the lightguide still has to go through 2 layers of "polarization" material. If that lightguide were to be installed backwards it would shove the light at the LCD and be too bright too comfortably view IMHO.

zardoz (the answer might be easier than we think)

You have it right..I'm looking at two different lightguides now from two different LCD screens. The etching is on the side AWAY from the LCD, thus the light is sent back (away from the lcd) to an "ultrawhite" high reflectance sheet. Where it makes the ultrawhite GLOW, emitting difused light back at the panel. This light that makes it finally all the way through the lightguide still has to go through 2 layers of "polarization" material. If that lightguide were to be installed backwards it would shove the light at the LCD and be too bright too comfortably view IMHO.

zardoz (the answer might be easier than we think)

- Status

- Not open for further replies.

- Home

- General Interest

- Everything Else

- The Moving Image

- DIY Projectors

- Step into the Light.....