The problem there isn't really a doppler effect that I can notice, it's just that the speaker's pattern varies just from it being in different locations. Even that is swamped by the flutter that makes it sound like a really bad cassette player. Maybe there's some quaintness in that.Does not reference the hole at all:

YouTube

Yes, the form with onboard speaker has huge wow from Doppler, unless you listen from directly over the center of the orbit.

With all the other problems, I can't imagine a digital link would be any improvement over an analog stereo FM transmitter.And bass and stereo are compromised. But picture a radio link; better, a clocked data stream buffered to another stable clock in the receiver.

It's like the dancing bear. It's amazing that it works at all.

An optical solution using a variation on the CD diffraction grating laser to control a servo. Ideally the groove radius should be a 0.55Hz sawtooth of amplitude one groove pitch

The easy way is to draw a pencil line along the radius that corrects the wow when the record is pushed against the spindle along that path. Tight spindles are inferior by design😛

Would you please elaborate on this, e.g. by means of a drawing? Sorry, I don't get it how a simple pencil line at the platter may correct excentrcities 🙄.

Best regards!

Why should it be different? Remember that both sides of the record are pressed simultaneously and the center hole is drilled afterwards.And what if side A is different from side B?

Best regards!

The eccentricity is a vector. Usually only a mm or two. The pencil mark shows the direction of the vector. If the spindle is undersized then you can have a fixed correction in the right direction, even if the magnitude is uncontrolled.

As regards record pressing each stamper has it's hole cut independently . When the record is pressed the hole is pressed. No drilling.

As regards record pressing each stamper has it's hole cut independently . When the record is pressed the hole is pressed. No drilling.

The eccentricity is a vector. Usually only a mm or two. The pencil mark shows the direction of the vector. If the spindle is undersized then you can have a fixed correction in the right direction, even if the magnitude is uncontrolled.

But you have to align the excentricity with that pencil vector first, right? How do you do that?

Best regards!

Check kaypirinha´s answer:You must realize that will not work except for one side only

We must assume both halves match, they *must*, there is no other way.

Have you ever seen a master pressing plates machine?

Set of machines, actually.

I have not only seen them but actually repaired them, go figure.

Both the one in the RCA plant and the ION Studios one, in Buenos Aires, incredible Lab quality precision machinery, if you ask me.

Google the full process from master tape to master dies to actual pressing, no room for error.

Now the relatively minor operation of drilling the center hole *might* introduce an error and very very few times happens ... but in that case error is same for both sides.

Pity most were sold as scrap a couple years after they were stopped for good, nobody wanted them and machinery plus storage and office space occupy a lot which can be put to better use.

"Sentimentalism" does not pay the bills, rent or salaries 🙁

I have only one record that it does not work on because the hole is too large, a Beatles black market bootleg album.But you have to align the excentricity with that pencil vector first, right? How do you do that?

Best regards!

Your eyes are sufficient to find and correct the eccentricity no problem, the same way you verify the Dragon has corrected it.

You are seriously mistaken here. Not only do they not match, but not a single one is without error, some greater than others. I have hundreds of examples.Check kaypirinha´s answer:

We must assume both halves match, they *must*, there is no other way.

Have you ever seen a master pressing plates machine?

Set of machines, actually.

I have not only seen them but actually repaired them, go figure.

Both the one in the RCA plant and the ION Studios one, in Buenos Aires, incredible Lab quality precision machinery, if you ask me.

Google the full process from master tape to master dies to actual pressing, no room for error.

Now the relatively minor operation of drilling the center hole *might* introduce an error and very very few times happens ... but in that case error is same for both sides.

Pity most were sold as scrap a couple years after they were stopped for good, nobody wanted them and machinery plus storage and office space occupy a lot which can be put to better use.

"Sentimentalism" does not pay the bills, rent or salaries 🙁

"A Simple Matter of Programming" (TM), one could use a Raspberry Pi

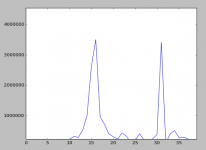

Very simple, RPi should work fine. The cart still has output at .5556Hz the lowest frequency in the system. The frequency spectrum will show a peak there. This is a plot of the low end of a 28sec sample, the signal would be in bin 15.556, you could use a 9sec sample and it would be centered in bin 5. RPi should have no problem with the 864,000 point FFT.

Figuring out a way to start the sample at the same point and the phase of the 0.5556 Hz signal gives you the axis of correction, if it gets below the noise one might argue it no longer matters.

Attachments

Check kaypirinha´s answer:

We must assume both halves match, they *must*, there is no other way.

Nope. The press may be accurate but a man cuts the holes.

Metal Work GZ Vinyl

After the stamper is produced, it is necessary to prepare it for the pressing machines. This process is carried out in several steps. The back side of the stamper is grinded and smoothed. Afterwards, it needs to be precisely centred (according to the sound grooves) before the central hole is cut.

A man looks down the microscope says 'good enough' and clunk. hole is punched.

Essentially what I've outlined. Precision is commensurate to any other degree of acceptable distortion in other ancillary gear.I think a simple gadget like this (link) was posted recently in the forum. Though not terribly precise but should work i guess.

The eccentricity is a vector. Usually only a mm or two. The pencil mark shows the direction of the vector. If the spindle is undersized then you can have a fixed correction in the right direction, even if the magnitude is uncontrolled.

As regards record pressing each stamper has it's hole cut independently . When the record is pressed the hole is pressed. No drilling.

Nope. The press may be accurate but a man cuts the holes.Metal Work GZ Vinyl

A man looks down the microscope says 'good enough' and clunk. hole is punched.

Well, what's the difference here between saying drilling or punching? Anyway, it has to be expected that an eccentricity is the same for both sides of the same record.

I still don't get the use of a pencil drawing. What's it good for if one has to rely on his eyeballs?

Best regards!

Sigh, Lets try again

A record has two sides. Two laquers, two stampers. Each stamper has the hole hand cut with a different error vector. The two stampers are not rotationally aligned in any way. Therefore the error vectors will not align in any way, so each side needs a different correction.

Ref the pencil. put on record. Hand spin to find max and min positions of cartridge. Adjust so that delta is minimal. see which bit of record hole is closest to undersized spindle and put an arrow on. next time you play the record its 2 seconds to get it aligned not 60.

A record has two sides. Two laquers, two stampers. Each stamper has the hole hand cut with a different error vector. The two stampers are not rotationally aligned in any way. Therefore the error vectors will not align in any way, so each side needs a different correction.

Ref the pencil. put on record. Hand spin to find max and min positions of cartridge. Adjust so that delta is minimal. see which bit of record hole is closest to undersized spindle and put an arrow on. next time you play the record its 2 seconds to get it aligned not 60.

How would YOU address the original problem? (and give up on vinyl is NOT an acceptable answer) 🙂

Why not, digital is the only real cure. You accept all the other vinyl inacuracies, Im not listing all of them, as if they make the music sound better, just accept this one also.

Okay, you locate the eccentricity by watching while the record is spinning on the platter. Make a mental note of it. Then turn off the tt. Push/pull the record against the spindle along that radius. Turn on the tt and see if it is now corrected or how close. It will usually take several attempts to find the exact path, trial and error. Now draw a pencil line along that radius. Next time you play that record you simply push it against the spindle along that line. When you do this on the other side you will notice the line needs to be in a different location.Well, what's the difference here between saying drilling or punching? Anyway, it has to be expected that an eccentricity is the same for both sides of the same record.

I still don't get the use of a pencil drawing. What's it good for if one has to rely on his eyeballs?

Best regards!

Okay, you locate the eccentricity by watching while the record is spinning on the platter. Make a mental note of it.

You actually make exact note of it. What's the problem with this process, the USB microscope just helps the eyes and it works? I guess I'm not making my point this is ripe for DIY no $$ gadgets are necessary.

Last edited:

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Speed compensation for off center vinyl