There are lots of very positive reports around from owners of the Townsend Seismic platforms that are used to isolate speakers. My understanding is that the isolation pods utilise a spring which is enclosed in a rubber boot which has a very small hole in the top to allow air in and out. The spring provides the vibration absorption and the boot dampens the spring movement to prevent bouncing.

These are expensive so one naturally thinks of cloning them. There are plenty of companies that make spring based feet for absorbing vibration from industrial machinery, but I haven’t yet found any that also have the rubber boot. Is anybody aware of anything similar that doesn’t have an audiophool price tag?

These are expensive so one naturally thinks of cloning them. There are plenty of companies that make spring based feet for absorbing vibration from industrial machinery, but I haven’t yet found any that also have the rubber boot. Is anybody aware of anything similar that doesn’t have an audiophool price tag?

Best look up some of the properly conducted double-blind ABX tests on speaker isolation before exhausting time and effort on the idea.

I can guarantee that you would achiever better results with room treatment and speaker positioning...

I can guarantee that you would achiever better results with room treatment and speaker positioning...

Sonic Design's Damping Feet work very well and there's no snake oil or mumbo jubo about them, -pure physics. Info: http://www.sonicdesign.co.uk/info.htm Depending on load on top of them, they are made in various dimensions and hardnesses from Getzner's PUR-rubber Sylomer (https://www.getzner.com/en ). These vibration isolators are not costly. I am not sure they can be bought in lets say UK anymore though, as the owner retired a few years ago and sold off his company. I know they are nowadays sold in Sweden, Norway and Finland by several companies. Perhaps email, lets say, https://support.brl.se/hc/sv/ for an answer? Various types: https://www.brl.se/sv/varumarken/sonic-design.html?utm_source=bing&utm_medium=cpc&utm_campaign=[PB] [DSA] [A] - Alla produkter&utm_term=subwoofers&utm_content=Alla Produkter

Last edited:

They sound as though they woud be good for components, but I’m interested in heavy speakers.What about Technics SL1200 feet. They are sprung loaded with hydraulic dampening fluid inside.

Even I would baulk at that in a domestic setting, never mind my wife.Suspend 'em with rubberband threads.

End of game ...

And start of a new One!

Interesting, I will investigate. I have actually previously looked at Sylomer.Sonic Design's Damping Feet work very well and there's no snake oil or mumbo jubo about them, -pure physics. Info: http://www.sonicdesign.co.uk/info.htm Depending on load on top of them, they are made in various dimensions and hardnesses from Getzner's PUR-rubber Sylomer (https://www.getzner.com/en ). These vibration isolators are not costly. I am not sure they can be bought in lets say UK anymore though, as the owner retired a few years ago and sold off his company. I know they are nowadays sold in Sweden, Norway and Finland by several companies. Perhaps email, lets say, https://support.brl.se/hc/sv/ for an answer? Various types: https://www.brl.se/sv/varumarken/sonic-design.html?utm_source=bing&utm_medium=cpc&utm_campaign=[PB] [DSA] [A] - Alla produkter&utm_term=subwoofers&utm_content=Alla Produkter

Vibration isolators are (should be) tuned to the load on top of them. If disturbing frequencies come from a loudspeaker or a machine has no bearing on the function. In general, the isolator should have its own resonating preferably 1 octave or more below below the lowest disturbing frequency. It starts to isolate from root (2) = 1,4 x the disturbing frequency. So, to isolate from 20 Hz and upwards its own resonance should be 14 Hz or lower. If its resonance is 20 Hz, it starts to isolate from 1,4 x 20 = 28 Hz, the higher the frequency the better its isolation. The SD Damping feet can be had for speakers up to 100 kg (220 lbs) / each.

The rubber boot originally came from the steering rack of the Citroen 2CV. Later it was changed to something like a large heat shrink.There are lots of very positive reports around from owners of the Townsend Seismic platforms that are used to isolate speakers. My understanding is that the isolation pods utilise a spring which is enclosed in a rubber boot which has a very small hole in the top to allow air in and out. The spring provides the vibration absorption and the boot dampens the spring movement to prevent bouncing.

These are expensive so one naturally thinks of cloning them. There are plenty of companies that make spring based feet for absorbing vibration from industrial machinery, but I haven’t yet found any that also have the rubber boot. Is anybody aware of anything similar that doesn’t have an audiophool price tag?

Not wife but (actually there are some talks amongst us and friends...)Even I would baulk at that in a domestic setting, never mind my wife.

You gotta see the reaction (oh well, After seeing and hearing the susp.sp. system)when seeing the suspended parts of the crossover ..

You seem to have some inside knowledge 😉. Have you anything else you can share that might assist with cloning them?The rubber boot originally came from the steering rack of the Citroen 2CV. Later it was changed to something like a large heat shrink.

Room tuning, Vibration control, Electrical grid, Transducers, Cabinets, Room cabling, and all other components.

All other; Source, amps, preamps, and equipment racks or platforms.

I listed the importance to ME in their rank and file.

Vibration control and understanding it, is the single transformation that changes HiFi gear from sounding like MidFi at best to the way it can along with room TUNING. Sound without the smear, induced distortion or the FLOOR acting as an out of time driver because of cabinet coupling. There is not a single place things will not improve. From SQ to increasing gear life. When you add all the places you can control vibration vs if you are, spending money on dampening, springs, pods, or air ride is pretty cheap. Compare that to swapping a single piece of my gear vs some of the choices for vibration control. 26.00 for springs and ear plugs is pretty darn cheap.

I had two heavy bass bins on pneumatic tires, you could sure tell when the air went down.

Design helps too. NO downward firing drivers UNLESS they are in a slot. No spikes unless they are on springs.

Decouple everything.

SUB frequencies travel faster through the floor and walls than through the air.

I use a cancelation method for 120hz and below, it helps with unwanted peaks and also VIBRATION control. It's canceling the vibration vs absorbing or dampening the sub peaks. The Helmholtz resonators are on dampened springs with shocks. Again 26-30.00 usd for springs.

Lets face it, you don't hear a sub, you feel it, you hear BASS.

35 years ago I started using heavy tractor inner tubes for bass bins and some other heavy speakers. 250-550lbs.

It stopped the waves in the neighbors pool for one. Second the water quit splashing on my tomato plants.

You know what people do in swimming POOLS? Me neither but I did watch Kaddy Shack, I got an idea. 😎

All other; Source, amps, preamps, and equipment racks or platforms.

I listed the importance to ME in their rank and file.

Vibration control and understanding it, is the single transformation that changes HiFi gear from sounding like MidFi at best to the way it can along with room TUNING. Sound without the smear, induced distortion or the FLOOR acting as an out of time driver because of cabinet coupling. There is not a single place things will not improve. From SQ to increasing gear life. When you add all the places you can control vibration vs if you are, spending money on dampening, springs, pods, or air ride is pretty cheap. Compare that to swapping a single piece of my gear vs some of the choices for vibration control. 26.00 for springs and ear plugs is pretty darn cheap.

I had two heavy bass bins on pneumatic tires, you could sure tell when the air went down.

Design helps too. NO downward firing drivers UNLESS they are in a slot. No spikes unless they are on springs.

Decouple everything.

SUB frequencies travel faster through the floor and walls than through the air.

I use a cancelation method for 120hz and below, it helps with unwanted peaks and also VIBRATION control. It's canceling the vibration vs absorbing or dampening the sub peaks. The Helmholtz resonators are on dampened springs with shocks. Again 26-30.00 usd for springs.

Lets face it, you don't hear a sub, you feel it, you hear BASS.

35 years ago I started using heavy tractor inner tubes for bass bins and some other heavy speakers. 250-550lbs.

It stopped the waves in the neighbors pool for one. Second the water quit splashing on my tomato plants.

You know what people do in swimming POOLS? Me neither but I did watch Kaddy Shack, I got an idea. 😎

The audio product, or the car? 👍You seem to have some inside knowledge 😉. Have you anything else you can share that might assist with cloning them?

You can simply say that every device should be isolated in its working band, which in audio is 20-20000 HzVibration isolators are (should be) tuned to the load on top of them. If disturbing frequencies come from a loudspeaker or a machine has no bearing on the function. In general, the isolator should have its own resonating preferably 1 octave or more below below the lowest disturbing frequency. It starts to isolate from root (2) = 1,4 x the disturbing frequency. So, to isolate from 20 Hz and upwards its own resonance should be 14 Hz or lower. If its resonance is 20 Hz, it starts to isolate from 1,4 x 20 = 28 Hz, the higher the frequency the better its isolation. The SD Damping feet can be had for speakers up to 100 kg (220 lbs) / each.

I think this is incorrect thinking if you have a turntable in the system.You can simply say that every device should be isolated in its working band, which in audio is 20-20000 Hz

When you add a turntable suddenly subsonics well below 20Hz are critical because the turntable can hear those frequencies and it responds with acoustic feedback. Modern systems with lots of fun subwoofers flood the room with low frequency energy that turntables HATE. Must keep those worlds apart, which can be a lot of work.

I was thinking mostly of speakers & associated, but, yes, turntable is another matter -of complexity

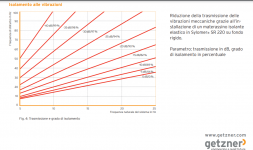

It is enough to "concentrate" on the lowest disturbing frequency which is possible from the system, no need to give a range. If the lowest frequency can be treated well enough, all frequencies above it will be even better isolated. The thick, bold line in the diagram shows the natural resonance frequency of an isolator under load. As can be seen, the isolation improves in % and dB the higher in frequency ones goes above the natural frequency. (In this case it is for a solid piece of rubber = a lot of load is necessary to deflect 6 mm versus 20 Hz, meaning solid rubber is totally useless to isolate 20 Hz to -20 db / 90%. -No usual speaker weigh that much, giving a deflection of 6 mm. Diagrams for cellular rubbers, hollow rubber balls, springs would be similar looking but show another needed deflection for a certain isolation and also dependent on thickness and form factor (like round or square). Thicker are needed for really low frequencies as is shown for Getzner's red Sylomer.

Attachments

I do but that wouldnt be fair. Max Townshend was a good personal friend of mine and he discussed a lot of his developments with me. Sadly he died onYou seem to have some inside knowledge 😉. Have you anything else you can share that might assist with cloning them?

new years eve but his family are keeping the business going. As they don't use the rubber bellows now I didnt think it would harm their business if I told you

about them. Lots of people have cloned them successfully so have a go.

You gotta see the reaction (oh well, After seeing and hearing the susp.sp. system) when seeing the suspended parts of the crossover ..

I didn't bat an eyelid! 😉

Attachments

- Home

- General Interest

- Room Acoustics & Mods

- Speaker isolation