Would going aperiodic be a way of reducing the size? There is a commercial design that uses a Visaton B200 (which has a high Qts) in a reasonably sized box.

The boffle i mentioned earlier with a somewhat smaller terminus, damped properly, is an aperiodic enclosure.

Rasmussen did a nice aperiodic TL for the B200 and i designed similar for a B200 centre channel.

dave

Rasmussen did a nice aperiodic TL for the B200 and i designed similar for a B200 centre channel.

dave

Sure… for box size i said “as large as you can live with”. If it is smaller it will not go as low (generalization).

dave

dave

Thanks once again, I've been trying to digest all this material.

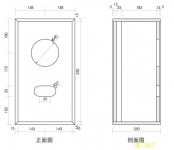

In the meantime, I had asked the supplier to send me a plan for the enclosure but got nothing. So asked another vendor selling the same and here it is attached. However, I noticed that he has a different set of drivers in there, not the ones I purchased. So not sure this wood work.

So based upon the earlier threads this design (attached) seems to have a total volume of about 20 liters, if I'm calculating correctly i.e. External dimension of 560 * 250 * 316 with 15 mm as the thickness of the box. However, the advise was to have a large box i.e. 100 liters and above or the "largest box I can live with" with high dampening/open back (aperiodic boffle ?). Would this work or the sound would be too boomy and not extended down to 60Hz ?

Could you folks comment on the above stated.

P.S.: I've heard in various places that this set of drivers (I bought) is a clone of the Diatone PM610.

In the meantime, I had asked the supplier to send me a plan for the enclosure but got nothing. So asked another vendor selling the same and here it is attached. However, I noticed that he has a different set of drivers in there, not the ones I purchased. So not sure this wood work.

So based upon the earlier threads this design (attached) seems to have a total volume of about 20 liters, if I'm calculating correctly i.e. External dimension of 560 * 250 * 316 with 15 mm as the thickness of the box. However, the advise was to have a large box i.e. 100 liters and above or the "largest box I can live with" with high dampening/open back (aperiodic boffle ?). Would this work or the sound would be too boomy and not extended down to 60Hz ?

Could you folks comment on the above stated.

P.S.: I've heard in various places that this set of drivers (I bought) is a clone of the Diatone PM610.

Attachments

I've heard in various places that this set of drivers (I bought) is a clone of the Diatone PM610.

Not even close.

dave

Given that I use the dimensions in post #25, would there be a difference on which side I put the driver (I'd rather have the driver on the narrowest width). And the vent, can it be located at the bottom/top etc.

Are there (dis)advantages of those design choices (given that the speaker volume/vent area is constant) ?

Are there (dis)advantages of those design choices (given that the speaker volume/vent area is constant) ?

Small sealed box (or aperiodic - sealed box with lots of small holes drilled into the back) plus a subwoofer works for me with this driver. Looks very pretty. I'd still put it on open baffle along with a big woofer but understand you have space limitations.

You can build the ported design and leave the port on the back. This way you can stuff the port with a sock if it's too boomy sounding.

I built this for a 6" Fostex driver and really enjoy it but the specs are totally different from your driver.

https://speakerprojects.wordpress.com/2015/04/27/fostex-168z-projects/

You can build the ported design and leave the port on the back. This way you can stuff the port with a sock if it's too boomy sounding.

I built this for a 6" Fostex driver and really enjoy it but the specs are totally different from your driver.

https://speakerprojects.wordpress.com/2015/04/27/fostex-168z-projects/

Given that I use the dimensions in post #25, would there be a difference on which side I put the driver (I'd rather have the driver on the narrowest width). And the vent, can it be located at the bottom/top etc.

Are there (dis)advantages of those design choices (given that the speaker volume/vent area is constant) ?

The narrower the baffle, the higher in frequency that it rolls off at, so there will be a slight difference in its 'fullness' down low in the speech BW and the cab's dimensions are such that the vent can be anywhere on the cab, though the closer it is to a hard boundary the more it will affect the quality of its bass response if not stuffed.

Not sure what you're asking for, so I'll just note that in a sim using the smallest cab for venting the pioneers concluded would give acceptable performance [25.47 L net tuned to Fs], it has a very strong mid-bass [underdamped] that requires it to be well away from walls, corners unless mounted well up a wall [normally preferably at an odd harmonic of its height, but may sound better at an even one in this case] and if you decided it sounded too 'bottom heavy', then the cab wasn't big enough to hold all the stuffing required to roll it off; so as already noted, a mostly open cab stuffed to 'taste' is the way to go.

Anything smaller and I'd personally build it more open with the sides and back made from pegboard [maybe even the bottom if wall mounted] with just some dowels to brace/tie them all together structurally.

GM

Folks,

Thanks to all for the suggestions/advise etc. My main objective in this DIY project was to have fun and learn a lot. Of course, I started off on the wrong foot by buying the drivers first (even though I had some (v. minor) knowledge of what I was looking for). Now I have a bigger problem to make this work with some trade-offs (and subsequently learn even more).

What's a readily available material to dampen the box (BTW, I've been looking at all the Home hardware stores for foam, polyfill etc.) ? Any suggestions ? I've been researching this and some say that all the frequencies are not attenuated equally, bass being the hardest to attenuate (which is not good for what I'm doing). Parts express has polyfill but shipping to Canada costs a fortune due to the size.

GM

Could you please clarify your comment i.e. "in the speech BW".

Thanks for the pegboard tip.

Also, just to clarify, what I mean't was that:

Given I can choose any 3 sides of the box to put the driver, I'd rather choose the side with the narrowest width and the highest height. Any implications of this choice ?

Same with the vent placement, top/bottom/front/back, what difference does it make ?

Also, if I were to place the driver off center would that help in attenuating the boominess ?

Thanks in advance again.

Thanks to all for the suggestions/advise etc. My main objective in this DIY project was to have fun and learn a lot. Of course, I started off on the wrong foot by buying the drivers first (even though I had some (v. minor) knowledge of what I was looking for). Now I have a bigger problem to make this work with some trade-offs (and subsequently learn even more).

What's a readily available material to dampen the box (BTW, I've been looking at all the Home hardware stores for foam, polyfill etc.) ? Any suggestions ? I've been researching this and some say that all the frequencies are not attenuated equally, bass being the hardest to attenuate (which is not good for what I'm doing). Parts express has polyfill but shipping to Canada costs a fortune due to the size.

GM

Could you please clarify your comment i.e. "in the speech BW".

Thanks for the pegboard tip.

Also, just to clarify, what I mean't was that:

Given I can choose any 3 sides of the box to put the driver, I'd rather choose the side with the narrowest width and the highest height. Any implications of this choice ?

Same with the vent placement, top/bottom/front/back, what difference does it make ?

Also, if I were to place the driver off center would that help in attenuating the boominess ?

Thanks in advance again.

The narrowest side will mean the baffle step response will occur at at relatively higher frequency, so you need to compensate for that if you want bass extension. However where you position your speakers will also matter, you can get back some bass by using room gain by placing your speaker near the wall. Personally I prefer the wider side, but also place the driver slightly asymmetric

Sent from my XT1575 using Tapatalk

Sent from my XT1575 using Tapatalk

What's a readily available material to dampen the box

I've been researching this and some say that all the frequencies are not attenuated equally, bass being the hardest to attenuate (which is not good for what I'm doing).

GM

Could you please clarify your comment i.e. "in the speech BW".

Thanks for the pegboard tip.

Also, just to clarify, what I mean't was that:

Given I can choose any 3 sides of the box to put the driver, I'd rather choose the side with the narrowest width and the highest height. Any implications of this choice ?

Same with the vent placement, top/bottom/front/back, what difference does it make ?

Also, if I were to place the driver off center would that help in attenuating the boominess ?

Greets!

Not a big fan of open cell foam except for HF smoothing/dispersion/damping, much preferring fiberglass insulation, but a lot of folks worry about potential health issues, so polyfil is the norm, although recycled cotton [jeans] seems to be the 'heir apparent'. Premium carpet [felt] underlayment was common at one time too. In your case you ideally need a fairly dense stuffing material, so the pioneers used blocks of R-30? [ceiling joist] insulation [removed to show cheesecloth over driver, which needs redoing before reinstalling the FG] : http://img0026.psstatic.com/97866022_rare-pair-of-altecheathkit-legato-2-15-horn-driver-ebay.jpg

Also for when heavy damping just needs to be localized: https://s-media-cache-ak0.pinimg.com/236x/54/2f/b5/542fb55f57ec92fb2bc074665c06aadc.jpg

This is true, the lower in frequency, the exponentially more 'massive' a wavelength [WL] is, ergo an exponentially higher damping density required.

The speech band-width [BW] of most importance is the analog telephone one [250-2500 Hz].

You're welcome!

I understood you the first time 😉, but apparently you didn't understand my response 🙁, which by implication of explaining what the difference was between wider and narrower baffles meant yes, you can put it on any side you like, same as the vent since your cab isn't a high aspect ratio one, i.e. one being quite long in one dimension such as a MLTL.

Offsetting a driver in a box assumed to be of ~uniform air mass particle density only changes its inner, outer eigenmodes and since the damping inside is there to damp them down it's of no benefit, though on the outside it can be beneficial by averaging [smoothing] them out to reduce any perceived/audible effect on the driver's output and why some folks put felt, foam or similar on the baffle near/around a driver if not offset in a golden or acoustic ratio.

'Boominess' is due to the cab alignment being too acoustically small and/or tuned too high [underdamped], so short of making it larger and/or tuned lower depending on the driver's 'effective' specs [Vas, Qts' = Qts + any added series resistance], some form of EQ is required, with heavy stuffing being the most common used by DIYers and some manufacturers.

GM

Sent from my XT1575 using Tapatalk

aoc, please turn off the Tapatalk advertisement.

dave

Dave,

How do I do that

Sent from my XT1575 using Tapatalk

How do I do that

aoc, please turn off the Tapatalk advertisement.

dave

Sent from my XT1575 using Tapatalk

Thanks to all for your help and responses, too many names to mention.

Based upon all the information I've gleaned from this thread and other readings, I'm settling on the following (impatient and don't want to succumb to "paralysis through analysis"). Please advise if I'm in the ballpark, of any "faux pas" or if I'm totally off:

I'm settling on the below:

Construction:

Questions:

If I have a perforated back, do I need a vent/port as the diagram in post #25 suggests ? Are they mutually exclusive ?

Based upon all the information I've gleaned from this thread and other readings, I'm settling on the following (impatient and don't want to succumb to "paralysis through analysis"). Please advise if I'm in the ballpark, of any "faux pas" or if I'm totally off:

I'm settling on the below:

- Volume of about 25-35 liters due to size limitations (against a suggested 100L and up)

- I'll be using a perforated back (pegboard)

- Heavy damping on the inside i.e. mostly ceiling insulant, and car noise damping material that I have already

- Driver will be on the broadest width (to improve the bass, albeit a little) and may be off center (any way to calculate optimum placement ?)

Construction:

- Mostly 15mm thick MDF with melamine finish (I have some pieces of MDF and an old cabinet that can be salvaged)

- Front baffle will be 30mm thick or so (was toying around putting this instead APTITLIG Butcher block - IKEA)

- Minor bracing

- Looked into the finishing of the box, since the MDF looks so drab i.e. painting, vinyl sheets, veneer, wallpaper etc., yet have to settle on something easy. Thinking about wallpaper, hehehe !!!

Questions:

If I have a perforated back, do I need a vent/port as the diagram in post #25 suggests ? Are they mutually exclusive ?

No, the entire back is a vent, so if more is needed, then start converting sides to pegboard.

Offset drivers using a golden or acoustic ratio [two out three of an acceptable room ratio].

Thick baffles require the driver cutouts for to be heavily chamfered [>45 deg] for all but bass alignments with a low XO point.

For lossy cab construction, only the baffle need be rigid/braced with the driver mass loaded to it, i.e. build like an OB and tack on a lossy back box that's only there to hold the insulation.

FWIW, most of the consumer cabs [kitchen/whatever], inexpensive furniture, bookshelves, etc., I've built or help [re]finish were wallpapered with vinyl paste or wood glue, be it wood grain, bamboo, marble, textured/whatever or just to give it a good seal for painting. With the better [read thicker] wallpapers, I've fooled quite a few, having to show them the [near] invisible seams one can do with a steady hand, sharp exacto knife.

Properly done, they withstand the test of time too as witnessed by what I did in my bathroom in '82. Nary a lifted seam even on the walls above the one piece 'drop-in' tub/shower unit or on the DIY cheap plywood overhead recessed light 'bar' cum shelving 'L' unit. Ditto the main wall's super thin [not cheap] foil paper [I can't see any seams and can only feel one by running my fingers over the walls because it's on a peaked wallboard joint].

GM

Offset drivers using a golden or acoustic ratio [two out three of an acceptable room ratio].

Thick baffles require the driver cutouts for to be heavily chamfered [>45 deg] for all but bass alignments with a low XO point.

For lossy cab construction, only the baffle need be rigid/braced with the driver

FWIW, most of the consumer cabs [kitchen/whatever], inexpensive furniture, bookshelves, etc., I've built or help [re]finish were wallpapered with vinyl paste or wood glue, be it wood grain, bamboo, marble, textured/whatever or just to give it a good seal for painting. With the better [read thicker] wallpapers, I've fooled quite a few, having to show them the [near] invisible seams one can do with a steady hand, sharp exacto knife.

Properly done, they withstand the test of time too as witnessed by what I did in my bathroom in '82. Nary a lifted seam even on the walls above the one piece 'drop-in' tub/shower unit or on the DIY cheap plywood overhead recessed light 'bar' cum shelving 'L' unit. Ditto the main wall's super thin [not cheap] foil paper [I can't see any seams and can only feel one by running my fingers over the walls because it's on a peaked wallboard joint].

GM

GM,

Thanks for the input, you've been really helpful. Will start putting together the materials. BTW, please explain what this means "two out three of an acceptable room ratio".

Thanks for the input, you've been really helpful. Will start putting together the materials. BTW, please explain what this means "two out three of an acceptable room ratio".

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Speaker enclosure build - 6.5" full range drivers