At first there has been a discussion here: http://www.diyaudio.com/forums/solid-state/36422-sony-5-1-output-transistors-repair.html

The unit is a Sony Stereo STR-DA1500ES 2-Channel Audio Receiver (2009/2010 model). This is a 2x100W+ RMS amp.

Now, I get the well known "Protect" mode message. Trying to fix it I referred to a pro. There is no patience to "discover" the real cause of this amp and I have been told to not bother fixing it. So, considering this thing "dead", I have decided to learn some basics to test it myself (very basic following of web instructions and a multimeter).

So here are...

The facts:

🙁 Speakers and headphones receives a noise signal that increases for some seconds (loud enough) until the protect mode circuit activates and shuts it down. It has the same behavior in headphones even if the volume is @ -oo.

When you use the volume control (it is digital I guess) there is a continuous loud clicking sound, like tik-tik-tik ....

This behavior started when I switched off by mistake the UPS instead of the unit. After this, it played ok for about a week and then, has been locked in the protection mode.

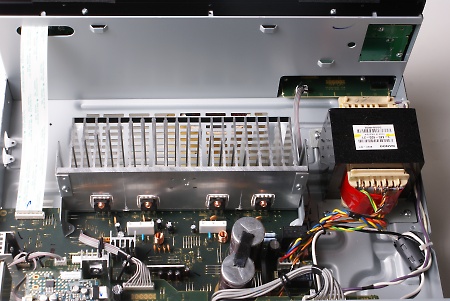

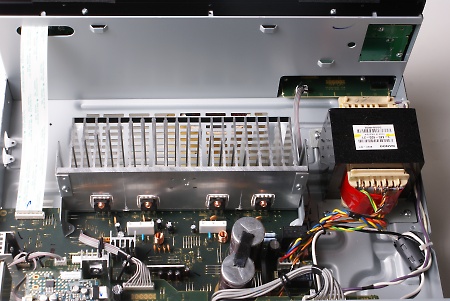

I had the unit disassembled easily, there is some basic pc hardware based experience.

The measurements:

Power transistors: (inside the circuit). In diode mode my very basic multimeter (FERM MMH-930) shows:

(Assuming you see the front of each transistor as it is located in heat sink)

There has been some misleading measurements, it seems that the multimeter is not so accurate, @ the end I conclude those values:

a. MN2488 TRANSISTOR

a1. MN2488 test1

RED(+) @1st pin

BLACK(-) @ 2nd pin

--------VALUE: 585 (both)

RED(+) @1st pin

BLACK(-) @ 3nd pin

--------VALUE: 630 (both)

RED(+) @2nd pin

BLACK(-) @ 3nd pin

--------VALUE: 1 (both)

-------------------------------------------------

a2. MN2488 test2:

BLACK(-) @ 1st pin

RED(+) @2nd pin

--------VALUE: 1 (both)

BLACK(-) @ 1st pin

RED(+) @3nd pin

--------VALUE: 1 (both)

BLACK(-) @ 2nd pin

RED(+) @3st pin

--------VALUE: 450 (both)

====================================

b. MN1620 TRANSISTOR

b1. MN1620 test1

RED(+) @1st pin

BLACK(-) @ 2nd pin

--------VALUE: 1 (both)

RED(+) @1st pin

BLACK(-) @ 3nd pin

--------VALUE: 1 (both)

RED(+) @2nd pin

BLACK(-) @ 3nd pin

--------VALUE: 450 (both)

==================================

b2. MN1620 test2:

BLACK(-) @ 1st pin

RED(+) @2nd pin

--------VALUE: 550 (both)

BLACK(-) @ 1st pin

RED(+) @3nd pin

--------VALUE: 590 (both)

BLACK(-) @ 2nd pin

RED(+) @3st pin

--------VALUE: 1 (both)

=======================================

I had the patience to measure 57V output voltage on those before the unit's activation of protection mode.

But I will not remeasure as it seems risky.

3pin resistors in front of power transistors seem to measure ok @ 1-0.5Ohm

I had measured power transformer @ 40V (main, I guess it splits 40V by 2 as it is a multi pin connector) and 12V and 9V @ secondary wires (seems also ok)

Transformer developed a mechanical hum noise through time, but I think it is independent.

I get the protect mode only when the main transformer wires are connected. Speaker circuit section seems irrelevant as it is disconnected, I use headphones, same behavior.

I had also measured almost all visible resistors and some capacitors (not sure about 3-4 that I could not follow the voltage "discharge" method I found) they seemed like they do not discharge but I am not sure. No leaks, explosions or anything.

Wiped some dust, searched for pin out problems.

What do you think?

I uploaded the service manual for those who can understand it...:

Zippyshare.com - sony_str-da1500es_ver-1.0_sm.pdf

thanks in advance

The unit is a Sony Stereo STR-DA1500ES 2-Channel Audio Receiver (2009/2010 model). This is a 2x100W+ RMS amp.

Now, I get the well known "Protect" mode message. Trying to fix it I referred to a pro. There is no patience to "discover" the real cause of this amp and I have been told to not bother fixing it. So, considering this thing "dead", I have decided to learn some basics to test it myself (very basic following of web instructions and a multimeter).

So here are...

The facts:

🙁 Speakers and headphones receives a noise signal that increases for some seconds (loud enough) until the protect mode circuit activates and shuts it down. It has the same behavior in headphones even if the volume is @ -oo.

When you use the volume control (it is digital I guess) there is a continuous loud clicking sound, like tik-tik-tik ....

This behavior started when I switched off by mistake the UPS instead of the unit. After this, it played ok for about a week and then, has been locked in the protection mode.

I had the unit disassembled easily, there is some basic pc hardware based experience.

The measurements:

Power transistors: (inside the circuit). In diode mode my very basic multimeter (FERM MMH-930) shows:

(Assuming you see the front of each transistor as it is located in heat sink)

There has been some misleading measurements, it seems that the multimeter is not so accurate, @ the end I conclude those values:

a. MN2488 TRANSISTOR

a1. MN2488 test1

RED(+) @1st pin

BLACK(-) @ 2nd pin

--------VALUE: 585 (both)

RED(+) @1st pin

BLACK(-) @ 3nd pin

--------VALUE: 630 (both)

RED(+) @2nd pin

BLACK(-) @ 3nd pin

--------VALUE: 1 (both)

-------------------------------------------------

a2. MN2488 test2:

BLACK(-) @ 1st pin

RED(+) @2nd pin

--------VALUE: 1 (both)

BLACK(-) @ 1st pin

RED(+) @3nd pin

--------VALUE: 1 (both)

BLACK(-) @ 2nd pin

RED(+) @3st pin

--------VALUE: 450 (both)

====================================

b. MN1620 TRANSISTOR

b1. MN1620 test1

RED(+) @1st pin

BLACK(-) @ 2nd pin

--------VALUE: 1 (both)

RED(+) @1st pin

BLACK(-) @ 3nd pin

--------VALUE: 1 (both)

RED(+) @2nd pin

BLACK(-) @ 3nd pin

--------VALUE: 450 (both)

==================================

b2. MN1620 test2:

BLACK(-) @ 1st pin

RED(+) @2nd pin

--------VALUE: 550 (both)

BLACK(-) @ 1st pin

RED(+) @3nd pin

--------VALUE: 590 (both)

BLACK(-) @ 2nd pin

RED(+) @3st pin

--------VALUE: 1 (both)

=======================================

I had the patience to measure 57V output voltage on those before the unit's activation of protection mode.

But I will not remeasure as it seems risky.

3pin resistors in front of power transistors seem to measure ok @ 1-0.5Ohm

I had measured power transformer @ 40V (main, I guess it splits 40V by 2 as it is a multi pin connector) and 12V and 9V @ secondary wires (seems also ok)

Transformer developed a mechanical hum noise through time, but I think it is independent.

I get the protect mode only when the main transformer wires are connected. Speaker circuit section seems irrelevant as it is disconnected, I use headphones, same behavior.

I had also measured almost all visible resistors and some capacitors (not sure about 3-4 that I could not follow the voltage "discharge" method I found) they seemed like they do not discharge but I am not sure. No leaks, explosions or anything.

Wiped some dust, searched for pin out problems.

What do you think?

I uploaded the service manual for those who can understand it...:

Zippyshare.com - sony_str-da1500es_ver-1.0_sm.pdf

thanks in advance

Last edited:

Ups have nothing to do with this

Having a back up UPS connected to your amplifier is the most stupid thing to do and farther more a back up UPS has absolutely nothing to offer in this application neither from safety aspect nor from any sound performance improvement .

Expect that the thread will not have much of luck since the measuring procedure you use is wrong and doesn't make much sense

The first and only thing you look if there is an DC present ( even at protection mode ) at the middle point of the dual resistors ..anything above 50-100 mv or full rail voltage simply mean a blown output transistor situation that is extremely common for the type of amplifier series .

Regards

Sakis

Having a back up UPS connected to your amplifier is the most stupid thing to do and farther more a back up UPS has absolutely nothing to offer in this application neither from safety aspect nor from any sound performance improvement .

Expect that the thread will not have much of luck since the measuring procedure you use is wrong and doesn't make much sense

The first and only thing you look if there is an DC present ( even at protection mode ) at the middle point of the dual resistors ..anything above 50-100 mv or full rail voltage simply mean a blown output transistor situation that is extremely common for the type of amplifier series .

Regards

Sakis

final and correct measurement

Thank you Sakis for your quick and informative response on such a misleading topic. First of all excuse my ignorance, as I am not an expert, it seems I could not filter web info about it

e.g. this video: https://www.youtube.com/watch?v=OEmxfNzTnsQ

but this is the success of this forum also 😱. there could be some luck to others also by estimating right this test for a case like this.

UPS is just for safety reasons because I use a notebook/soundcard alongside with the amp that plays only music. I thought it is best to plug everything there. As a mutter of fact I have less radio FM interference using the ups (if I use the pc, the amp has nothing to do with it).

I will find the transistors and replace all of them. Before this...

do you think I can do this measurement you refer to? Can you be more specific when you say "at the middle point of the dual resistors" Do you mean to measure between the middle pins of each couple? (I can see that they work as couples @ each channel)

Protection mode shuts down the unit @ about 10 seconds, do I have to see the measurement before the protection event when the unit is on, am I right? Or there is some kind of voltage leak that is happening to standby also?

Ups have nothing to do with this

Having a back up UPS connected to your amplifier is the most stupid thing to do and farther more a back up UPS has absolutely nothing to offer in this application neither from safety aspect nor from any sound performance improvement.

Expect that the thread will not have much of luck since the measuring procedure you use is wrong and doesn't make much sense

The first and only thing you look if there is an DC present ( even at protection mode ) at the middle point of the dual resistors ..anything above 50-100 mv or full rail voltage simply mean a blown output transistor situation that is extremely common for the type of amplifier series .

Regards

Sakis

Thank you Sakis for your quick and informative response on such a misleading topic. First of all excuse my ignorance, as I am not an expert, it seems I could not filter web info about it

e.g. this video: https://www.youtube.com/watch?v=OEmxfNzTnsQ

but this is the success of this forum also 😱. there could be some luck to others also by estimating right this test for a case like this.

UPS is just for safety reasons because I use a notebook/soundcard alongside with the amp that plays only music. I thought it is best to plug everything there. As a mutter of fact I have less radio FM interference using the ups (if I use the pc, the amp has nothing to do with it).

I will find the transistors and replace all of them. Before this...

do you think I can do this measurement you refer to? Can you be more specific when you say "at the middle point of the dual resistors" Do you mean to measure between the middle pins of each couple? (I can see that they work as couples @ each channel)

Protection mode shuts down the unit @ about 10 seconds, do I have to see the measurement before the protection event when the unit is on, am I right? Or there is some kind of voltage leak that is happening to standby also?

Last edited:

Unless you have a lot of experience testing semiconductor devices in circuit you may need to use the brute force method.Pull the output power devices and test them. If they are Darlington transitors you may need to use a curve tracer to confirm they are fully functional. If they are bad you then need to see what other devices are fried. You may find transitors and bias diodes gone. In the end you may have a hell of a time finding replacement devices. Buy from a reputable vendor especially for the output devices.

Changing all the transistors in hope is a recipe for disaster. east electronics is referring to checking the DC voltage present at each amplifier output. You need to measure this voltage before the speaker relay. Measure from chassis ground to each output.

A lot of things can go wrong with these old units.

I had a big old Sony power amp on my bench a couple years ago. I started poking around checking DC voltages like recommended above (you have to be real careful!) and one of the output transistors partially vaporized in a bolt of lightning. I knew I didn't short anything and discovered right away that the driver transistor I had my test lead clipped to was loose. I grabbed it and yanked on it and it pulled right out without desoldering the leads. I grabbed the other driver transistor and it popped right out too. I looked at the bottom of the board and it was pretty fubar. Some of the parts were partially desoldered, and the copper traces were starting to delaminate.

The moral of my story is that if you're careful and observant and do tests in the correct order you might avoid damaging the amplifier. A few loose or cold solder joints can be reflowed and sometimes magic happens and sometimes it's beyond practical repair.

I had a big old Sony power amp on my bench a couple years ago. I started poking around checking DC voltages like recommended above (you have to be real careful!) and one of the output transistors partially vaporized in a bolt of lightning. I knew I didn't short anything and discovered right away that the driver transistor I had my test lead clipped to was loose. I grabbed it and yanked on it and it pulled right out without desoldering the leads. I grabbed the other driver transistor and it popped right out too. I looked at the bottom of the board and it was pretty fubar. Some of the parts were partially desoldered, and the copper traces were starting to delaminate.

The moral of my story is that if you're careful and observant and do tests in the correct order you might avoid damaging the amplifier. A few loose or cold solder joints can be reflowed and sometimes magic happens and sometimes it's beyond practical repair.

Changing all the transistors in hope is a recipe for disaster. east electronics is referring to checking the DC voltage present at each amplifier output. You need to measure this voltage before the speaker relay. Measure from chassis ground to each output.

Unfortunately if he only finds some of the bad parts and replaces them, some of these new parts could blow again when power is reapplied. He needs to know that he has to find every bad part and replace them before turing the unit back on.

Using the "power on method" he should be able to find the "bad" channel. He can then use a DVM to compare the good and bad channels components using the diode test function on the DVM. A better method is a component tetster and ultimately a curve tracer especially for the output Darlington devices. I have seen a leaky device cause this problem. A simple diode test won't work....

The pro I visited proposed a curve tracing for the transistors. I guess this is the last resort before recycling. I will check the surrounding possible failures also, as you suggested.

As I do not want to do "vaporization" experiments, I shall just stop digging further by myshelf. Thanks anyone for the enlightenment and precaution notes. I will came back if I will find something interesting and have the patience to continue. I just feel sad throwing away devices with probably tiny but hard to find problems no mutter the price, too much waste.

As I do not want to do "vaporization" experiments, I shall just stop digging further by myshelf. Thanks anyone for the enlightenment and precaution notes. I will came back if I will find something interesting and have the patience to continue. I just feel sad throwing away devices with probably tiny but hard to find problems no mutter the price, too much waste.

You should find that all clues will be in the voltage measurements. Checking the DC offset of each channel is the basic starting point.

As you can see those are terms that are new to me.

With instructions from:

Amplifier Distortion, DC-Offset, and You! | Audiokarma Home Audio Stereo Discussion Forums

1. Speakers disconnected (or connect the meter to the 'B' speakers and set the front panel speaker control accordingly)

2. Input set to an unusued position (not Phono)

3. Volume control at minimum.

4. Balance in center

5. Tone controls either defeated or set to mid position

6. Set your meter to read DC, and set to a low scale (300mV scale is common) Connect directly to the Pos and Neg of the speaker terminals

7. Give the amp 10 minutes to settle. Report back...I'd like to see how healthy all these old amps are.

Both outputs measurement, starting from 0 with a progressive increase to 100mV, then the protector kicks in.

Both R and L same behavior, I guess this is the voltage value of the increasing noise phenomenon in the headphones/speakers.

A proud finding or what?😉

With instructions from:

Amplifier Distortion, DC-Offset, and You! | Audiokarma Home Audio Stereo Discussion Forums

1. Speakers disconnected (or connect the meter to the 'B' speakers and set the front panel speaker control accordingly)

2. Input set to an unusued position (not Phono)

3. Volume control at minimum.

4. Balance in center

5. Tone controls either defeated or set to mid position

6. Set your meter to read DC, and set to a low scale (300mV scale is common) Connect directly to the Pos and Neg of the speaker terminals

7. Give the amp 10 minutes to settle. Report back...I'd like to see how healthy all these old amps are.

Both outputs measurement, starting from 0 with a progressive increase to 100mV, then the protector kicks in.

Both R and L same behavior, I guess this is the voltage value of the increasing noise phenomenon in the headphones/speakers.

A proud finding or what?😉

Last edited:

Yes, a finding 🙂

If you are measuring at the speaker terminals then you are measuring the DC up to the point the relay trips out. If you measure the voltage before the relay then you would see it rise further.

This fault sounds a little more obscure tbh. DC offset issues are usually 'hard' faults... hard as in a total failure causing a massive offset instantaneously, and only on one channel (the failed one). DC offset is also silent, it simple pushes the speaker cone out.

Both channels producing a 'noise' suggests something very different and not a failure in the output stages. I'm wondering if this is more deep seated, something much further toward the front end where all the signal processing and so on is done.

Ideally an oscilloscope would be used to see what is going on. I suppose there is a possibility it could be a voltage rail problem somewhere, again that's 'scope territory to quickly check that the rails are clean.

If you are measuring at the speaker terminals then you are measuring the DC up to the point the relay trips out. If you measure the voltage before the relay then you would see it rise further.

This fault sounds a little more obscure tbh. DC offset issues are usually 'hard' faults... hard as in a total failure causing a massive offset instantaneously, and only on one channel (the failed one). DC offset is also silent, it simple pushes the speaker cone out.

Both channels producing a 'noise' suggests something very different and not a failure in the output stages. I'm wondering if this is more deep seated, something much further toward the front end where all the signal processing and so on is done.

Ideally an oscilloscope would be used to see what is going on. I suppose there is a possibility it could be a voltage rail problem somewhere, again that's 'scope territory to quickly check that the rails are clean.

A quick last thought for today... you mentioned a UPS. Those things can produce a really rough sinewave approximation to the mains and that could give the power supply and its capacitors a hard time. Have a really good visual look at the caps in the power supply. Look for any that are bulging or that have the vents on the top splitting open.

Do a Bing or Google image search for 'failed electrolytic capacitors' to see example.

Also, any caps that are hot are suspect.

Do a Bing or Google image search for 'failed electrolytic capacitors' to see example.

Also, any caps that are hot are suspect.

Ok, very useful. The dc-offset/noise is a stereo effect. Both R+L is exactly the same (headphones test).

No visual fails/leaks etc. But as yesterday I had started measurements of resistors and capacitors, all resistors I had access, checked and they seemed good.

Some capacitors though, had a strange behavior.

They had some voltage and resistance but they seem not to discharge the value I get. I'm not sure though because this is the first time I test a capacitor.

The big ones (10000μF 71V) for example discharge OK. This is what I have done: I have measured the resistance and then I've checked the voltage. But some of them do not discharge as others, and I thought that they are some kind of slow discharge components.

![2016-05-11 23_05_07-sony_str-da1500es_ver-1.0_sm.pdf - [00_01-04_STRDA1500_02.indd].jpg 2016-05-11 23_05_07-sony_str-da1500es_ver-1.0_sm.pdf - [00_01-04_STRDA1500_02.indd].jpg](https://www.diyaudio.com/community/data/attachments/511/511817-11a8b74899882c5b20a75621d2a9ae79.jpg?hash=Eai3SJmILF)

Attachment shows the possible capacitors with this behavior.

2x nichicon 3300μF 16v

1x 2200μF 25v

1x 1000uF 25v

...

At least one of those behaved as like not discharging, but no visual fail artifacts. I hope this is not a misleading information as I have to reconfirm.

No visual fails/leaks etc. But as yesterday I had started measurements of resistors and capacitors, all resistors I had access, checked and they seemed good.

Some capacitors though, had a strange behavior.

They had some voltage and resistance but they seem not to discharge the value I get. I'm not sure though because this is the first time I test a capacitor.

The big ones (10000μF 71V) for example discharge OK. This is what I have done: I have measured the resistance and then I've checked the voltage. But some of them do not discharge as others, and I thought that they are some kind of slow discharge components.

![2016-05-11 23_05_07-sony_str-da1500es_ver-1.0_sm.pdf - [00_01-04_STRDA1500_02.indd].jpg 2016-05-11 23_05_07-sony_str-da1500es_ver-1.0_sm.pdf - [00_01-04_STRDA1500_02.indd].jpg](https://www.diyaudio.com/community/data/attachments/511/511817-11a8b74899882c5b20a75621d2a9ae79.jpg?hash=Eai3SJmILF)

Attachment shows the possible capacitors with this behavior.

2x nichicon 3300μF 16v

1x 2200μF 25v

1x 1000uF 25v

...

At least one of those behaved as like not discharging, but no visual fail artifacts. I hope this is not a misleading information as I have to reconfirm.

Last edited:

Even though you stated an amateur it seems to me that you continue to repost a variety of urban legends and "expert pro opinions" like using a curve tracer to find out if a transistor is broken ....

Excuse my tone but if you don't understand the very very basics of electronics your best chance is to make more damage than already exists in the amplifier.

Posting like that and let us assume for a minute that you do find a shorted transistor then you need to source it which can be a problem since way too many fakes exist on the internet and then you need to replace it which i think that you will not manage ....

At this level remember also that lethal voltage exist in the amplifier meaning that if you don't understand the very basics on electronics i expect that at least you have an idea what i am talking about .

Check all output transistors

conditions:

no signa,l no load,volume down, at any source , power up expect protection to trip and then use your DVM with the black lead to an ground ( preferably attached to a speaker ground) and the red lead to test all the right pins of output transistors one at a time .

All transistors showing a few millivolts should be fine any transistors that show more than that is the broken one Expect there on the right pin as you look to find full rail voltage in this case this is the shorted transistor .

From statistic point of view you might just replace the broken transistor and get away with it Hardly ever in these amps exist more failures ...

still a repair cannot be done like that you expect luck to fix your amp ..even if you replace the broken transistor you need to be able to troubleshoot more problems except that if any and trouble free start up procedures that i expect that you are not familiar with ...

out of curiosity what is your occupation and which place of Greece do you live ?

( i am not trying to offer a repair service as you said you already talked with a pro that suggests a curve tracer

)

)

Excuse my tone but if you don't understand the very very basics of electronics your best chance is to make more damage than already exists in the amplifier.

Posting like that and let us assume for a minute that you do find a shorted transistor then you need to source it which can be a problem since way too many fakes exist on the internet and then you need to replace it which i think that you will not manage ....

At this level remember also that lethal voltage exist in the amplifier meaning that if you don't understand the very basics on electronics i expect that at least you have an idea what i am talking about .

Check all output transistors

conditions:

no signa,l no load,volume down, at any source , power up expect protection to trip and then use your DVM with the black lead to an ground ( preferably attached to a speaker ground) and the red lead to test all the right pins of output transistors one at a time .

All transistors showing a few millivolts should be fine any transistors that show more than that is the broken one Expect there on the right pin as you look to find full rail voltage in this case this is the shorted transistor .

From statistic point of view you might just replace the broken transistor and get away with it Hardly ever in these amps exist more failures ...

still a repair cannot be done like that you expect luck to fix your amp ..even if you replace the broken transistor you need to be able to troubleshoot more problems except that if any and trouble free start up procedures that i expect that you are not familiar with ...

out of curiosity what is your occupation and which place of Greece do you live ?

( i am not trying to offer a repair service as you said you already talked with a pro that suggests a curve tracer

)

)Even though you stated an amateur it seems to me that you continue to repost a variety of urban legends and "expert pro opinions" like using a curve tracer to find out if a transistor is broken ....

Excuse my tone but if you don't understand the very very basics of electronics your best chance is to make more damage than already exists in the amplifier.

Posting like that and let us assume for a minute that you do find a shorted transistor then you need to source it which can be a problem since way too many fakes exist on the internet and then you need to replace it which i think that you will not manage ....

At this level remember also that lethal voltage exist in the amplifier meaning that if you don't understand the very basics on electronics i expect that at least you have an idea what i am talking about .

Check all output transistors

conditions:

no signa,l no load,volume down, at any source , power up expect protection to trip and then use your DVM with the black lead to an ground ( preferably attached to a speaker ground) and the red lead to test all the right pins of output transistors one at a time .

All transistors showing a few millivolts should be fine any transistors that show more than that is the broken one Expect there on the right pin as you look to find full rail voltage in this case this is the shorted transistor .

From statistic point of view you might just replace the broken transistor and get away with it Hardly ever in these amps exist more failures ...

still a repair cannot be done like that you expect luck to fix your amp ..even if you replace the broken transistor you need to be able to troubleshoot more problems except that if any and trouble free start up procedures that i expect that you are not familiar with ...

out of curiosity what is your occupation and which place of Greece do you live ?

( i am not trying to offer a repair service as you said you already talked with a pro that suggests a curve tracer)

I thought this is not an expert only forum. I will not force anyone to tech me the basics, I can withdraw in piece if this level of guidance makes confusion.

Please accept my apologies, and close the topic.

To tell the truth, I've learned some stuff and took the fundamental info I wanted. I thank all participants and you for this.

You are right about the possibility to damage the amp further, so we can stop here.

Last edited:

Check all output transistors

conditions:

no signa,l no load,volume down, at any source , power up expect protection to trip and then use your DVM with the black lead to an ground ( preferably attached to a speaker ground) and the red lead to test all the right pins of output transistors one at a time .

All transistors showing a few millivolts should be fine any transistors that show more than that is the broken one Expect there on the right pin as you look to find full rail voltage in this case this is the shorted transistor

For the history, this test gives on all transistors a value of about 250 in the DVM scale of 2000mV

Last edited:

Before abandoning this topic I would like also to correct the "curve tracing" term. As those words are new to me in english, the corect word ment is "oscilloscope", this concerns some replies above.

Last edited:

Before abandoning this topic I would like also to correct the "curve tracing" term. As those words are new to me in english, the corect word ment is "oscilloscope", this concerns some replies above.

Google is your friend. Use it.

A semiconductor "curve tracer" is a special type of test equipment that very few would own. They are used to "actively" test diodes, transistors and a bunch of other two and three terminal semiconductor devices. They used to be standard piece of equipment in any lab but are rarely seen anymore. Mine was built in the 1970's. The only cheap ones today with an integrated CRT display are made in China and are close to $1K. You can buy a simple one on eBay that works in conjunction with an oscilloscope in X-Y mode. You can build your own for cheap if you are handy. Unless it can test a device at 100 volts at a reasonably high current it will not fully stress a power device.

A simpler piece of equipment would be a "two lead" component tester. These are very simple to make but only measure current versus an applied voltage. You mate these to an oscilloscope in X-Y mode. They are woefully inadequate by themselves to fully test a three terminal device like a transistor but are 100X better than a DVM in diode mode.

Measuring components “in circuit” with any accuracy requires a lot of experience and an idea of how the surrounding components will alter the measurement.

A quick correction with a clearer mind, the last test gives this:

0.1 to 0.5 in the DVM scale of 200mV but it could be inaccurate. The right test equipment will be used in the next step. I will refer to what I have found even if it is wrong or inaccurate. No more tests from me.

Thanks for your kind support.

0.1 to 0.5 in the DVM scale of 200mV but it could be inaccurate. The right test equipment will be used in the next step. I will refer to what I have found even if it is wrong or inaccurate. No more tests from me.

Thanks for your kind support.

Ok, very useful. The dc-offset/noise is a stereo effect. Both R+L is exactly the same (headphones test).

No visual fails/leaks etc. But as yesterday I had started measurements of resistors and capacitors, all resistors I had access, checked and they seemed good.

Some capacitors though, had a strange behavior.

You will find that attempting to check parts in circuit can give very misleading results due to interaction with all the other components connected around them. That applies to resistors, caps and semiconductors. Slight residual charge remaining on capacitors can wildly affect resistance readings as the voltage 'confuses' the DVM.

What kind of noise is it you hear ? Is it a hum/buzz (which would tend to point to a power supply problem) or is it much higher in pitch which could point to a problem around the front end signal processing area.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Sony 2.0 receiver "protect" mode test/repair