It's the heavyest CD that i ever had in my life and i remember in my young years that it was rebouding very high when it fallen on the floor (always on the side thanks to a huge and heavy glue joint)

This disc would probably last a century if handeled carefully, but :

Teory #1 « dry antiglare »

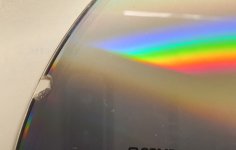

The shocks have breaked the glue joint and delaminated the two layers of polycarbonate and the metalic layer have been « ondulated » on the path of the shockwave dissipation. The farest borders of the metalic layer from the polycarbonate parts have fallen during the corrosion thanks to a better reduction potential and the parts that were still barely flat (lines between bubbles) renowed the contact with the polycarbonate.

Teory #1 « viscous antiglare »

The shocks have breaked the glue joint and delaminated the two layers of polycarbonate and the viscous layer have made bubbles on the path of the shockwave dissipation.

The metalic layer exposed to the air have been eated by corrosion.

This disc would probably last a century if handeled carefully, but :

Teory #1 « dry antiglare »

The shocks have breaked the glue joint and delaminated the two layers of polycarbonate and the metalic layer have been « ondulated » on the path of the shockwave dissipation. The farest borders of the metalic layer from the polycarbonate parts have fallen during the corrosion thanks to a better reduction potential and the parts that were still barely flat (lines between bubbles) renowed the contact with the polycarbonate.

Teory #1 « viscous antiglare »

The shocks have breaked the glue joint and delaminated the two layers of polycarbonate and the viscous layer have made bubbles on the path of the shockwave dissipation.

The metalic layer exposed to the air have been eated by corrosion.

Had a neighbour that was service engineer for CD/DVD production machines. I recall that the fluid used for the final layer was different per area and also that it was one of the quality factors and cost sensitive. He once told of a country where they did not have the required pipes to drain the excess fluid and could not imagine “that poisin” to to through ceramic pipes. He had to fly in the pipes. When I looked surprised he explained that the stuff was pretty bad in fluid condition and the more dangerous ones had best longevity. “Not that anyone cares there, they ditch it in the canal”.

What also surprised is that in many far away areas the majority of produced material was illegal. So he returned home with movies we had not seen yet.

What also surprised is that in many far away areas the majority of produced material was illegal. So he returned home with movies we had not seen yet.

Last edited:

Same thing happened to my CDs which were not coated or printed. That paint like coating does helps to protect the fragile layer underneath

Last edited:

I had a strange thing happen to a Sparklehorse CD about 5 years ago. The coating on the read side bubbled and became sticky. The disc was not readable. This disc was rarely played and so handling was minimal. It was bought new and came in a digipak. I have hundreds of CDs and have never had this issue on any other dics. I put it down to manufacturing fault.

PDO = Philips Dupont Optical. It was the factory in Blackburn that was converted from making Laserdisc (video) to CDs. They used silver rather aluminium as the reflective material. The reflective coating was protected by dropping a measured amount of lacqueur onto the disc whilst spinning and was intended to just go over the edge and seal it. But it didn't quite. Worst, the papers in the associated CD cases were high sulphur and that's why the (unsealed) silver went brown from edge towards middle. I had a couple of CDs do this and they both had PDO stamped in the middle. The OP's CDs have something very odd and entirely different.

By the way, the fragile surface of a CD is the top, not the bottom. Marker pens generally contain solvents, so applying solvent over the edge seal doesn't sound a good idea to me (green pens round the edges).

By the way, the fragile surface of a CD is the top, not the bottom. Marker pens generally contain solvents, so applying solvent over the edge seal doesn't sound a good idea to me (green pens round the edges).

CDs usually "rot" from their edge. It is probably due to incomplete seal of lacquer at the edge. And I heard about a commercial product, a lathe that shaves the edge at 45° in order to improve the ... whatever.

A nice example from my collection. It is interesting the damage does not reach the part where music pressing is visible, yet I am unable to play the last track until the end.

Attachments

Last edited:

I do not have cd's that rot from the outside. I do however have a few where tiny pinholes have formed all over the surface. All are from the early years of cd production. When you look at a light source through them, it's starry night all over. I have an Otis Redding that is so dotted with holes that it won't even play anymore. No idea what causes this, but since the holes appear everywhere and not only on the outside it can't be an external factor.

Those pin holes were there from new. The metallisation is done by sputtering. You put the CD in a vacuum chamber and fire electrons at the metal target (anode) to produce a metal vapour that condenses on anything within the chamber. Higher voltages give the electrons more energy when they hit the target, allowing more atoms to come off. But the downside is that clumps come off, risking pin holes when those large clumps deposit. Lower voltages dislodge single atoms. Later CDs are nearly translucent but have no pin holes, whereas early CDs have a thicker coating and pin holes. Early CDs assumed that the error correction for burst errors could deal with infrequent pin holes but not with copious smaller errors.

I checked the CD in question and mine is intact, I also have Abacab which is intact, both are of USA origin.

I see. The strange thing is that it seems to get worse over time. They were perfectly playable in the past, but not anymore now.Those pin holes were there from new. The metallisation is done by sputtering.

There is another thing not mentioned - osmosis, as the outside layer can and probably is porous. You can see this all the time in seemingly impenetrable layers of glass fiber boats.

Side delamination or simple chemical activity also can be a reason. Or many more. There is no "longevity" or "reliability" in CD by design.

https://en.wikipedia.org/wiki/Polycarbonate#Environmental_impact

From the chemical and resistance perspective something like Polyethylene could be MUCH better, except the low melting point and the fact, that you can probably set it on fire with laser...

Side delamination or simple chemical activity also can be a reason. Or many more. There is no "longevity" or "reliability" in CD by design.

https://en.wikipedia.org/wiki/Polycarbonate#Environmental_impact

From the chemical and resistance perspective something like Polyethylene could be MUCH better, except the low melting point and the fact, that you can probably set it on fire with laser...

it should be the result of an experiementation of John McAfee...

it should be the result of an experiementation of John McAfee...Effect of fungi

In 2001 a species of fungus in Belize, Geotrichum candidum, was found to consume the polycarbonate found in compact discs (CD). This has prospects for bioremediation. However, this effect has not been reproduced.

Now, that is odd.I see. The strange thing is that it seems to get worse over time. They were perfectly playable in the past, but not anymore now.

I'm planning to backup a 10k+ classical CD collection for a friend.

I wonder how many unplayable samples we will find.

See you all in a few years. 🙂

I wonder how many unplayable samples we will find.

See you all in a few years. 🙂

I'm planning to backup a 10k+ classical CD collection for a friend.

I wonder how many unplayable samples we will find.

See you all in a few years. 🙂

Specialized CD ripping station OR/AND big AT (that is even bigger than ATX) format desktop tower or multiple with as many as possible CD drives in them could be a plus, as the most consuming part will be switching discs by hand. Also software capable handling multiple drives.

Like this?

I've used an accurate ripping software for my disc, it reads the same track many times and compare the extracted data, a single fast reading should be full of errors IMHO

By design all of the digital media has low-level error correction. HDD, optical, MO, tapes, SSD, RAM (ECC) - all of them. Data compact discs and audio discs too. Also the good part - couple or even hundreds of wrong bits in audio disc may be completely inaudible. For some video formats - also. For pure data - single bit is (may be) disaster depending on file type. JPEG and other like it - most likely will be ok. From my experience if the drive does not stuck on some track, does not skip and so on, there is very very very close to 100% chance your rip is ok. Multiple reading and comparing is a more of a gimmick for audio CD, as you still will not know which of multiple copies is the right one.

- Home

- Source & Line

- Digital Source

- Something is eating my CD substrate