Sounds reasonable to me, I'm almost certain I read it in one of the amplifier books by one of " The Big Two ", been trying to find it but can't.....you know... too many pages 600 to 700 mark.

But did they do any blind AB listening tests comparing against solder joints?

Of course not, they just chose whatever method was most convenient. Still, it shows that screw contacts were apparently not that unreliable under domestic conditions.

How'd yawl build your first project as a kid? bet you didn't use solder. Mine was a crystal set built on a piece of wood using brass wood screws and cup washers

Solder is not glue!

True, but a lot of audio connectors do rely on the solder mechanically

"How'd yawl build your first project as a kid? bet you didn't use solder."

I remember the 1st Xmas gift electronics set I got. It had all the components on yellow plastic strips with plug-board pegs on the bottom. The terminals at each end were single octal tube pins sticking up, with push-on-clip wires for connecting things up.

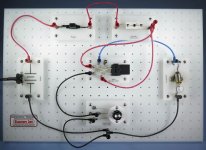

Now there are spring binding posts..., etc:

I remember the 1st Xmas gift electronics set I got. It had all the components on yellow plastic strips with plug-board pegs on the bottom. The terminals at each end were single octal tube pins sticking up, with push-on-clip wires for connecting things up.

Now there are spring binding posts..., etc:

Attachments

Last edited:

Wow, high tech, doesn't sound like it was all that long ago. Mine wasn't a concoction of my own, it was actually described in minute detail as a little project for children in what might have been wireless world magazine.....simpler times ho-hum..

Man! What you described was MY 1st Xmas gift electronics set!! Looong ago....I remember the 1st Xmas gift electronics set I got. It had all the components on yellow plastic strips with plug-board pegs on the bottom. The terminals at each end were single octal tube pins sticking up...

And you know what? I know it still lies hiden somewhere in the depths of some cupboard in the house.

I sure wish I still had that electronics set around, good memories.

But I think the parts got snipped (ripped) off for use in various projects along the way. It was way more sophisticated than the electronics learning kits I see around nowadays. I might appreciate it better now.

Put up a picture of the electronics set and all the parts if you find it. Historical.

I've been looking through some Google pics of old tube related gear, and I just found

Pomona "surface mount tube sockets"!

Not quite what one might expect these days.

http://www.technicalaudio.com/pdf/Electronics_Catalog_Extracts/Pomona_socket_savers_1960_REM_24.pdf

..

But I think the parts got snipped (ripped) off for use in various projects along the way. It was way more sophisticated than the electronics learning kits I see around nowadays. I might appreciate it better now.

Put up a picture of the electronics set and all the parts if you find it. Historical.

I've been looking through some Google pics of old tube related gear, and I just found

Pomona "surface mount tube sockets"!

Not quite what one might expect these days.

http://www.technicalaudio.com/pdf/Electronics_Catalog_Extracts/Pomona_socket_savers_1960_REM_24.pdf

..

Attachments

Last edited:

I was actually referring back to the earlier part of the thread about whether using solder really makes an amplifier sound different. Anyway, those early radios tended to be pretty simple affairs, with few joints to go wrong.Of course not, they just chose whatever method was most convenient. Still, it shows that screw contacts were apparently not that unreliable under domestic conditions.

I again both agree and disagree. True, solder isn't glue, and a joint (not the cannabis kind) must be mechanically robust before soldering. But the molten solder should improve the electrical conductivity of the joint, by melding with the surface of the copper conductors, and also helping prevent air and moisture getting into the joint which would impair conductivity over the long term.The solder is not intended to be a conductor, it's a mechanical thing - if done right. Best practise!

Edit: and it's not glue so you better mount/wire the things to be connected in a way that they can take some force - it should work without solder and withistand some mechanical offence... then solder.

Yes, I also built some Crystal sets, and even added audio amplifier stages, with various screw or spring connectors. Then I built a battery valve Short wave radio, and did some DXing, which was huge fun. But I couldn't wait to be allowed by my parents to do real soldering. I never realized at the time, that the audio quality would suffer 🙂How'd yawl build your first project as a kid? bet you didn't use solder. Mine was a crystal set built on a piece of wood using brass wood screws and cup washers

Sent from my phone with Tapatalk. Please excuse any typpos.

> reading somewhere recently by a very well respected audio bod

US Navy, basic e-tech training course--- yes, respected audio bod.

He works in the Swedish army also, I see.

I heard it from NASA training.

Every organization solder training touches on this.

> first have mechanical integrity then be soldered, the solder's primary function being to preserve the mechanical connection.

Lead is mechanically terrible. It "creeps" with pressure/tension, and never stops creeping. Old leaded-glass windows, and old lead pipes, sag.

Therefore we first make a mechanical wrap that will NOT move.

Unless it is an engineered Wire-Wrap connection, we can not trust it to be or stay electrically good. Tarnish never sleeps. Terminal wraps are not gas-tight (WireWraps are). Therefore we clean the tarnish and solder the joint for a lasting electrical contact.

This is debatable (but not with your navy/army instructor!). Early high-reliability PCBs had leads bent or crimped so the parts WERE solid-support before solder. Most later PCBs omit this. Many SMT parts are only held-on by solder. Turns out that tin-lead has a low-low threshold below which it does not creep. May be 1% of the breaking strength measured with a few-seconds pull. However parts are small, and their mass is getting smaller faster than their leg-areas shrink. Obviously we don't have cellfones with loose SMTs inside. (Also we keep cellfones a year, not centuries like church windows or some pipes.)

______________

> solder is not intended to be a conductor, it's a mechanical thing

No, the solder IS the reliable conductor. But NOT a reliable mechanical joint.

US Navy, basic e-tech training course--- yes, respected audio bod.

He works in the Swedish army also, I see.

I heard it from NASA training.

Every organization solder training touches on this.

> first have mechanical integrity then be soldered, the solder's primary function being to preserve the mechanical connection.

Lead is mechanically terrible. It "creeps" with pressure/tension, and never stops creeping. Old leaded-glass windows, and old lead pipes, sag.

Therefore we first make a mechanical wrap that will NOT move.

Unless it is an engineered Wire-Wrap connection, we can not trust it to be or stay electrically good. Tarnish never sleeps. Terminal wraps are not gas-tight (WireWraps are). Therefore we clean the tarnish and solder the joint for a lasting electrical contact.

This is debatable (but not with your navy/army instructor!). Early high-reliability PCBs had leads bent or crimped so the parts WERE solid-support before solder. Most later PCBs omit this. Many SMT parts are only held-on by solder. Turns out that tin-lead has a low-low threshold below which it does not creep. May be 1% of the breaking strength measured with a few-seconds pull. However parts are small, and their mass is getting smaller faster than their leg-areas shrink. Obviously we don't have cellfones with loose SMTs inside. (Also we keep cellfones a year, not centuries like church windows or some pipes.)

______________

> solder is not intended to be a conductor, it's a mechanical thing

No, the solder IS the reliable conductor. But NOT a reliable mechanical joint.

Yes, if you keep hitting an amp with a piece of wire you may eventually degrade the sound quality of the amp via mechanical damage. Do some audiophiles do this? If so, why? Is it like the way some antiques are 'stressed' in order to raise the price?

hahahahahaaha square heads, but why many things internally wrapped amps spekers as bose three ou one, why nobody thought on copper welded sot welded contacts as seen exactly laser cils ,hu hu

http://i.ebayimg.com/images/i/182188071946-0-1/s-l1000.jpg

look at this contacts, noticed on failed cdp ..marantz, new one laer that has been replaced and worked some months.

look at this contacts, noticed on failed cdp ..marantz, new one laer that has been replaced and worked some months.

- Home

- Amplifiers

- Tubes / Valves

- solderless amplifier?