Soldered them on the stand they were supposed to sit on

Right, thanks! Sorry if my quest for details is annoying 😀

Regards

I'm really enjoining reading latest threads 🙂 and I'm sorry to bring you back to our old discussion related to loud popups when we turn off out TTs. I finally got some time and I installed RC snubber on my TT on/off switch. It is parallel to switch lugs and C=0.1uF X1 Rifa with 100R 1W AB resistor is series. I did not even tested if my popups are gone, just because my motor started to vibrate (my pulley is vibratig) when switch is off. BTW, I have AC motor. Any ideas?

In your opinion, what would be the next lower/higher values for that tandem? Thank you.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

If you have connected it the way you say it seems like your motors current need for starting vibrating is low enough for the snubber network to let some AC thru. That is just my guess. Start double/half maybe?

Alexk,

you can move the spark snubber to across the motor L to N, instead of across the switch.

All switch snubbers allow some mains to flow to the load. Not good for very low consumption loads. They end up being part ON !

you can move the spark snubber to across the motor L to N, instead of across the switch.

All switch snubbers allow some mains to flow to the load. Not good for very low consumption loads. They end up being part ON !

I'm really enjoining reading latest threads 🙂 and I'm sorry to bring you back to our old discussion related to loud popups when we turn off out TTs. I finally got some time and I installed RC snubber on my TT on/off switch. It is parallel to switch lugs and C=0.1uF X1 Rifa with 100R 1W AB resistor is series. I did not even tested if my popups are gone, just because my motor started to vibrate (my pulley is vibratig) when switch is off. BTW, I have AC motor. Any ideas?

I have that thump too so I lower the volume before switching off - I know - lazy. But if you guys fix this I promise I will implement it 😀

Regards

Hi Stajo,

How did you get that finish on the larger heat sinks in the mounting area? It's beautiful.

I run through different grades of wet/dry sandpaper with the final a 1200 grit and then the reverse side for the polish. I'm wondering if there is an easier way that you found. It also helps to sand the transistor backs to the same smoothness, then the finest layer of grease and you have about the best thermal transfer possible. Dry mounting may even be possible at this level, it might have lower thermal resistance than the greased mounting.

No, the extra few mm won't affect anything. You're perfectly safe there.

-Chris

How did you get that finish on the larger heat sinks in the mounting area? It's beautiful.

I run through different grades of wet/dry sandpaper with the final a 1200 grit and then the reverse side for the polish. I'm wondering if there is an easier way that you found. It also helps to sand the transistor backs to the same smoothness, then the finest layer of grease and you have about the best thermal transfer possible. Dry mounting may even be possible at this level, it might have lower thermal resistance than the greased mounting.

No, the extra few mm won't affect anything. You're perfectly safe there.

-Chris

Hi Stajo,

How did you get that finish on the larger heat sinks in the mounting area? It's beautiful.

I run through different grades of wet/dry sandpaper with the final a 1200 grit and then the reverse side for the polish. I'm wondering if there is an easier way that you found. It also helps to sand the transistor backs to the same smoothness, then the finest layer of grease and you have about the best thermal transfer possible. Dry mounting may even be possible at this level, it might have lower thermal resistance than the greased mounting.

No, the extra few mm won't affect anything. You're perfectly safe there.

-Chris

Thanks Chris and Stajo!

Long legs aren't a problem - will use 🙂

Any pics on your build?

Regards

Last edited:

Hi Stajo,

How did you get that finish on the larger heat sinks in the mounting area? It's beautiful.

I run through different grades of wet/dry sandpaper with the final a 1200 grit and then the reverse side for the polish. I'm wondering if there is an easier way that you found. It also helps to sand the transistor backs to the same smoothness, then the finest layer of grease and you have about the best thermal transfer possible. Dry mounting may even be possible at this level, it might have lower thermal resistance than the greased mounting.

No, the extra few mm won't affect anything. You're perfectly safe there.

-Chris

Hi anatech, thanks

Those sinks, like many cheap computersinks has a lousy surface. One can see the mill threads in the metal which ends up in that one has like 30-40 % contact metal to metal. Sanding those down is tricky because if you just go on with paper it will get rounded in surface. Even worse contact. You might not see it with the eye but it gets. What you have to do is either machine it properly fixed or build a jig that holds the sink flat to a sandpaper taped on a flat surface. Then, when it's sanded to the finest paper you go over it with paste and fast rotating textile to the finest grain. My fets stick to the metal without screw or paste. The molecules bind.

They hardly get Luke warm.

Hi Stajo and Andrew,

Please see attached pictures.

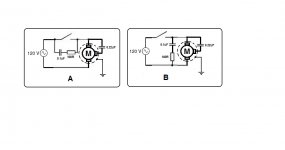

Last picture "A" is when I have switch off vibration. Andrew is right and my motor vibrates due to very small current which bypassing the switch via RC. "B" indicates how I connected RC snubber now based on Andrew's advice.

Will test it tonight and report.

Please advice me if you see something strange on my pictures.

Please see attached pictures.

Last picture "A" is when I have switch off vibration. Andrew is right and my motor vibrates due to very small current which bypassing the switch via RC. "B" indicates how I connected RC snubber now based on Andrew's advice.

Will test it tonight and report.

Please advice me if you see something strange on my pictures.

Attachments

A is a low pass filter. R plus load acts as the comps that determines the frequency getting passed lower then a certain frequency. 15 k or so would be my guess. Totally wrong, you want high pass. B is prolly gonna work but pass some current.

Hi Stajo,

I use a block of fine milled metal and stretch the sand paper across it ~ 6" long. Light pressure gives me a similar surface to yours.

Yes, computer heat sinks are very rough, low cost = low quality.

Do you finish the mounting surfaces of the semiconductors as well?

-Chris

I use a block of fine milled metal and stretch the sand paper across it ~ 6" long. Light pressure gives me a similar surface to yours.

Yes, computer heat sinks are very rough, low cost = low quality.

Do you finish the mounting surfaces of the semiconductors as well?

-Chris

- Home

- Source & Line

- Analogue Source

- Simplistic NJFET RIAA