honestly, I'm not sure about the advantages to look a cutoff over 40kHz if the target is musical fidelity and realism. Perhaps such complex structures may be counterproductive— I say 'perhaps' because I'm not certain. However, I see many wire cuts and subsequent soldering, a real headache.

Now, for me, the greatest concern is figuring out how to achieve 4-ohm and 8-ohm outputs with fairly similar responses. The ideal setup is like Kondo's, a single output. That's what I've been doing to date. Soon I will show different structures I am working on.

The problem is that when we start to have everything under control, we no longer hear or see, and it's possible that we don't even remember our own birthday, but to have the brain busy always is a good anti aging. 🙂

Now, for me, the greatest concern is figuring out how to achieve 4-ohm and 8-ohm outputs with fairly similar responses. The ideal setup is like Kondo's, a single output. That's what I've been doing to date. Soon I will show different structures I am working on.

The problem is that when we start to have everything under control, we no longer hear or see, and it's possible that we don't even remember our own birthday, but to have the brain busy always is a good anti aging. 🙂

Last edited:

To achieve similar responses at 4R and 8R, you'll need to guarantee equal leakage inductance and capacitance for both options.

If you're going after a tapped option, I guess trifiliar winding of each secondary, where each single wire winding equals 1R output impedance is the way to go. You will get the slightest leakage inductance difference. The possible output options will be 1R, 4R and 9R.

You can make the secondaries into a Williamson style output transformer, which means all secondary layers get output terminals, which can allow for a multiple of connections. However, when series connecting, you will usually get degradation that results from a shifting dip resonance lower in frequency. You can achieve eveness by screening the secondary layers, by additional screens or sandwiching series connected layers between always parallel connected secondaries. Like this, for example

Primary // Sec4R , Sec1R, Sec4R // Primary2 // Sec4R, Sec1R, Sec4R // Primary

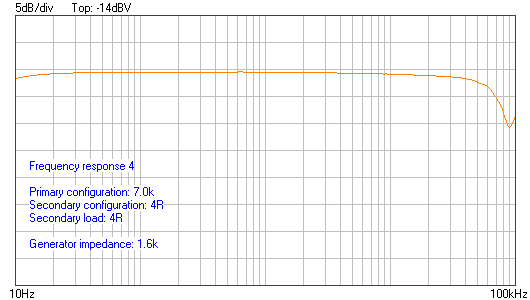

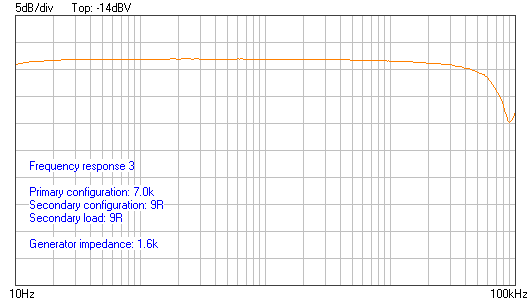

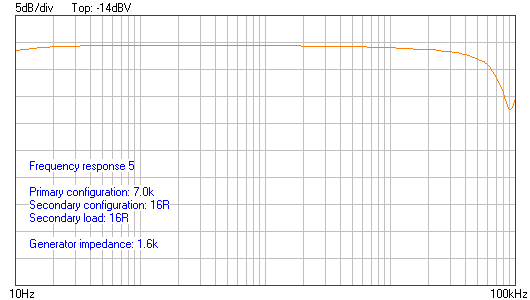

By connecting all Sec4 layers in parallel, you capacitively isolate the Sec1 layers, which can be series or parallel connected by choice with performance eveness. I have tested such strategy. Here is the result: 4R, 9R, 16R secondary options.

If you're going after a tapped option, I guess trifiliar winding of each secondary, where each single wire winding equals 1R output impedance is the way to go. You will get the slightest leakage inductance difference. The possible output options will be 1R, 4R and 9R.

You can make the secondaries into a Williamson style output transformer, which means all secondary layers get output terminals, which can allow for a multiple of connections. However, when series connecting, you will usually get degradation that results from a shifting dip resonance lower in frequency. You can achieve eveness by screening the secondary layers, by additional screens or sandwiching series connected layers between always parallel connected secondaries. Like this, for example

Primary // Sec4R , Sec1R, Sec4R // Primary2 // Sec4R, Sec1R, Sec4R // Primary

By connecting all Sec4 layers in parallel, you capacitively isolate the Sec1 layers, which can be series or parallel connected by choice with performance eveness. I have tested such strategy. Here is the result: 4R, 9R, 16R secondary options.

Wel, the configuration is similar to Sowter, Lundalh or Electra Print transformer, work very good but I would like two simultaneity speaker output 4 and 8 ohm

my thinking go in this way

Primary // Sec4R , Sec8R // Primary2 // Sec4R, Sec8R // Primary

0ohm ------------------ 4 ohm layer 1

0ohm ------------------ 8 ohm layer 2

Before I test with

Primary // Sec4R + Sec4R // Primary2 // Sec4R +Sec4R // Primary

0 ohm ------------ 4 ohm ---- 8 ohm serial in the same layer

8ohm work correctly but 4 ohm is really bad.

But begin to open the Pandora's box. secondary option tends to infinite 🙂

Serial connected work fine and sound fine, but all secondary in parallel work fine and sound fine too.

Sec2R // Primary // Sec2R // Primary2 // Sec2 // Primary // Sec2R

*Sec4R // Primary // Sec2R // Primary2 // Sec2 // Primary // *Sec4R

But will work fine ? 2ohm+2ohm = out 4ohm + // ( *4ohm ) = out 8 ohm

for example: Sec 79turn 4 ohm + 25 turn 8ohm, clearly the most important is the 4ohm ( 76% of the turn ) + where to put the rest 25turn for 8ohm, that do not deteriore the signal.

At the moment seem more coherent double layer one per impedance and the layer that not use always work as screen.

50AE your measures are really very good better than 1500€ Monolith Magnetic OPT

my thinking go in this way

Primary // Sec4R , Sec8R // Primary2 // Sec4R, Sec8R // Primary

0ohm ------------------ 4 ohm layer 1

0ohm ------------------ 8 ohm layer 2

Before I test with

Primary // Sec4R + Sec4R // Primary2 // Sec4R +Sec4R // Primary

0 ohm ------------ 4 ohm ---- 8 ohm serial in the same layer

8ohm work correctly but 4 ohm is really bad.

But begin to open the Pandora's box. secondary option tends to infinite 🙂

Serial connected work fine and sound fine, but all secondary in parallel work fine and sound fine too.

Sec2R // Primary // Sec2R // Primary2 // Sec2 // Primary // Sec2R

*Sec4R // Primary // Sec2R // Primary2 // Sec2 // Primary // *Sec4R

But will work fine ? 2ohm+2ohm = out 4ohm + // ( *4ohm ) = out 8 ohm

for example: Sec 79turn 4 ohm + 25 turn 8ohm, clearly the most important is the 4ohm ( 76% of the turn ) + where to put the rest 25turn for 8ohm, that do not deteriore the signal.

At the moment seem more coherent double layer one per impedance and the layer that not use always work as screen.

50AE your measures are really very good better than 1500€ Monolith Magnetic OPT

Celsius,

Keep in mind impedance increases exponentially. 2R+2R windings mean 2*2^2, so 8R.

To have 4R, 9R and 16R windings, you need at least a set of 4R, and sets of 1R.

4R // 1+1R -> 4R

4R + 1R -> ( SQRT(4) + SQRT(1) )^2 = 9R

4R + 4R -> 4^2 = 16R

The basic ways of winding tapped seccondaries, are either:

-Trifiliar, 1R x3 windings per layer. That way, you can chieve 1R, 4R and 9R. Or if starting with a 4R per winding, that translates to 4R, 16R and 36R

-Or top on top layers. One layer of 1R winding, then a second layer of 4R winding. You will get higher Ls when only using the 4R tap.

Keep in mind I like sharing frequency response for educational purposes only. Not meaning to boast or anything, but my goal is to demonstrate different cause and effect examples, while attempting to back them throughout logical and theoretical explanations. I love building risky* projects, just for the sake of squeezing headroom and study the analysis and behavior behind different frequency behaviors and their relation with the interleaving strategy. There is a lot of interleaving dogma that needs to be taken care of. Neither that I consider frequency response as sound quality factor, but that is another part of the subject.

*risky project = In this case, an audio transformer with hard to achieve goals

Keep in mind impedance increases exponentially. 2R+2R windings mean 2*2^2, so 8R.

To have 4R, 9R and 16R windings, you need at least a set of 4R, and sets of 1R.

4R // 1+1R -> 4R

4R + 1R -> ( SQRT(4) + SQRT(1) )^2 = 9R

4R + 4R -> 4^2 = 16R

The basic ways of winding tapped seccondaries, are either:

-Trifiliar, 1R x3 windings per layer. That way, you can chieve 1R, 4R and 9R. Or if starting with a 4R per winding, that translates to 4R, 16R and 36R

-Or top on top layers. One layer of 1R winding, then a second layer of 4R winding. You will get higher Ls when only using the 4R tap.

Keep in mind I like sharing frequency response for educational purposes only. Not meaning to boast or anything, but my goal is to demonstrate different cause and effect examples, while attempting to back them throughout logical and theoretical explanations. I love building risky* projects, just for the sake of squeezing headroom and study the analysis and behavior behind different frequency behaviors and their relation with the interleaving strategy. There is a lot of interleaving dogma that needs to be taken care of. Neither that I consider frequency response as sound quality factor, but that is another part of the subject.

*risky project = In this case, an audio transformer with hard to achieve goals

Last edited:

yes, I know. I work on the Ratio P/S ( to avoid mistakes ).

79 turn 4 ohm + 25 turn = 8 ohm I say 4R + 4R but only to explain easy.

In all cases congratulation for your fantastic job.

79 turn 4 ohm + 25 turn = 8 ohm I say 4R + 4R but only to explain easy.

In all cases congratulation for your fantastic job.

In the last PP transformer made I disbanded tapped secondary altogether, just single 5 Ohm universal. Speaker impedance is not constantly flat anyway, 16 Ohm tap makes no practical sense, for 4 - 8 Ohm universal 5 Ohm secondary is just fine.

Recalculate, as this is incorrect.79 turn 4 ohm + 25 turn = 8 ohm

To get the proper total amount for an 8R winding, you need to multiply-> 79 * / SQRT(8/4) = 111.7T ; for an 8R winding. Round it to 112. Which is the sum of 79T and 33T.

yes I can....

In your example 79 turns = 4 ohm, and (79+25) 104 turns = 8 ohm.

Example: SE OPT 5k primary, 4 and 8 ohm secondaries.

Number of primary turns related to 8 ohm = 104 x 25 = 2600 turns (25 is winding ratio for 5k:8R).

Winding ratio of your supposed 4 ohm = 2600 : 79 = 32.91.

Then with a real 4 ohm secondary load the primary impedance is not 5k but 4 x 32.91 x 32.91 = 4k33, not 5k.

In your example the number of secondary turns for 4 ohm should have been 73.5 (unlucky half turn....).

In your example 79 turns = 4 ohm, and (79+25) 104 turns = 8 ohm.

Example: SE OPT 5k primary, 4 and 8 ohm secondaries.

Number of primary turns related to 8 ohm = 104 x 25 = 2600 turns (25 is winding ratio for 5k:8R).

Winding ratio of your supposed 4 ohm = 2600 : 79 = 32.91.

Then with a real 4 ohm secondary load the primary impedance is not 5k but 4 x 32.91 x 32.91 = 4k33, not 5k.

In your example the number of secondary turns for 4 ohm should have been 73.5 (unlucky half turn....).

that is right, but for transformer with big load, I change a little de ratio.

4 ohm speaker have less than 88db and move at less three driver: small load = more current

8 ohm speaker are normal for SE two ways and > 90db big load. less distortion and best sound

4 ohm speaker have less than 88db and move at less three driver: small load = more current

8 ohm speaker are normal for SE two ways and > 90db big load. less distortion and best sound

talking with the IA of Google begin to ask different important things, how to have good sex over 50th..... After finish the serious question about the life I begin to ask over dielectric for OPT. I remember older post from 50AE speaking about the dielectric for OPT

parchment paper ( wax paper ) = 2.0 to 2.5 but is too thin 0.05mm

At the end the Perforated toilet paper with Teflon to increase the dielectric strength is the best combination. Therefore, the effective dielectric constant of the material composed of 0.3 mm of toilet paper and 0.18 mm of Teflon with a total thickness of 0.48 mm is approximately k= 2.06.

Well is complicate to sell OPT with the Title: Nanocrystal Core with Perforated toilet paper as Dielactric.

The transformer companies included Lundalh like to use plastic K is low and DS high, Monolith said Teflon ( maybe the best ) but 0,4mm of teflon is a lot of teflon... when I compare the sound of different OPT made with similar P/S is similar to Capacitor MKP sound similar to Copper-PIO. I think the all affect to the sound

Happy Christmas and my best wishes

| Paper | 2.0-2.5 |

| PTFE (Teflon) | 2.1 |

| Silicone | 2.5-3.5 |

| Oil-impregnated paper | 2.5 |

| Perforated toilet paper | 1.5-2.5 |

| Polyethylene (PE) | 2.2-2.5 |

| Polypropylene (PP) | 2.2-2.5 |

| Polystyrene (PS) | 2.5-2.7 |

| Polyvinyl chloride (PVC) | 3.0-3.5 |

| Polytetrafluoroethylene (PTFE) | 2.1 |

| Polyimide (PI) | 3.5-4.0 |

| Polycarbonate (PC) | 2.6-3.2 |

| Acrylonitrile butadiene styrene (ABS) | 2.5-3.0 |

| Kraft paper | 2.2-2.5 |

| Oil-impregnated kraft paper | 2.7-3.0 |

parchment paper ( wax paper ) = 2.0 to 2.5 but is too thin 0.05mm

At the end the Perforated toilet paper with Teflon to increase the dielectric strength is the best combination. Therefore, the effective dielectric constant of the material composed of 0.3 mm of toilet paper and 0.18 mm of Teflon with a total thickness of 0.48 mm is approximately k= 2.06.

Well is complicate to sell OPT with the Title: Nanocrystal Core with Perforated toilet paper as Dielactric.

The transformer companies included Lundalh like to use plastic K is low and DS high, Monolith said Teflon ( maybe the best ) but 0,4mm of teflon is a lot of teflon... when I compare the sound of different OPT made with similar P/S is similar to Capacitor MKP sound similar to Copper-PIO. I think the all affect to the sound

Happy Christmas and my best wishes

Merry Christmas.

Unfortunately, you don't take into account the low density of low epsilon papers, such as toilet paper. They are soft and in practice, pressure from winding tension will squash it, ruining the low epsilon.

If you're after such practices, I'd recommend using polyester flag mesh fabric. Combine it with a finishing wrap of paper.

Unfortunately, you don't take into account the low density of low epsilon papers, such as toilet paper. They are soft and in practice, pressure from winding tension will squash it, ruining the low epsilon.

If you're after such practices, I'd recommend using polyester flag mesh fabric. Combine it with a finishing wrap of paper.

Good point about the impact of squishing soft dielectric, the appearently low Dk is only do to air, and as soon as the airpockets are squished or/and impregnated low Dk is gone.

Same is true for DuPont's low Dk 410, even 411 stuff, as soon as the airpockets get squished or soaked up with impregnation the advertized low Dk is unobtainium.

Hi. I think this is the right thread, so many knowledgeable guys, personnaly I used transformers, don’t make them.

it is about Allnic nickel transformers. They claim nickel make their transformer special. I heard a few Allnic preamp and they sound very good indeed. What is a nickel transformer, nickel in the core laminate steel, pure nickel, simply what some call silicone steel, or is it the same thing as what Lundhall called ‘micro-crystaline core’. Or is it what some call ‘amorphous core’. so many designation and no real clear explanation. Just curious.

Thanks

sB

it is about Allnic nickel transformers. They claim nickel make their transformer special. I heard a few Allnic preamp and they sound very good indeed. What is a nickel transformer, nickel in the core laminate steel, pure nickel, simply what some call silicone steel, or is it the same thing as what Lundhall called ‘micro-crystaline core’. Or is it what some call ‘amorphous core’. so many designation and no real clear explanation. Just curious.

Thanks

sB

Hallo Daan,yes I can....

In your example 79 turns = 4 ohm, and (79+25) 104 turns = 8 ohm.

Example: SE OPT 5k primary, 4 and 8 ohm secondaries.

Number of primary turns related to 8 ohm = 104 x 25 = 2600 turns (25 is winding ratio for 5k:8R).

Winding ratio of your supposed 4 ohm = 2600 : 79 = 32.91.

Then with a real 4 ohm secondary load the primary impedance is not 5k but 4 x 32.91 x 32.91 = 4k33, not 5k.

In your example the number of secondary turns for 4 ohm should have been 73.5 (unlucky half turn....).

Could you give some suggestion for the layering of the 5K OPT? I need a bit more power than an EL84 and i havs SM85B cores.

Thanks

Steven

These are four separate types.Hi. I think this is the right thread, so many knowledgeable guys, personnaly I used transformers, don’t make them.

it is about Allnic nickel transformers. They claim nickel make their transformer special. I heard a few Allnic preamp and they sound very good indeed. What is a nickel transformer, nickel in the core laminate steel, pure nickel, simply what some call silicone steel, or is it the same thing as what Lundhall called ‘micro-crystaline core’. Or is it what some call ‘amorphous core’. so many designation and no real clear explanation. Just curious.

Thanks

sB

Nickel cores

Silicon steel cores

Nanocrystalline cores

Amorphous cores.

Thanks, and does Nickel core having better specs for coupling, output transformer (better freq response, less loss, lower distorsion, etc…

sB

sB

Lams containg nickel are only avaiable in small size, so only output power application migth be headphones.

Gapless microfon, input and interstage transformers are the application where ni content is of advantage because of the very high permeability of ni alloyed cores and corelosses are lower but so is Bmax. Distortion depends on operation condition and the core related distortion depends entirely on those. High nickel content cores are also quite sensitive to electrical and/or mechanical shock. For example a tiny gapless mikrofon transformer can get permanently degraded by only measuring its resistance with a multimeter.

Gapless microfon, input and interstage transformers are the application where ni content is of advantage because of the very high permeability of ni alloyed cores and corelosses are lower but so is Bmax. Distortion depends on operation condition and the core related distortion depends entirely on those. High nickel content cores are also quite sensitive to electrical and/or mechanical shock. For example a tiny gapless mikrofon transformer can get permanently degraded by only measuring its resistance with a multimeter.

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- Show your transformer work (gallery)