I could use some advice on this one. I have everything up and running, recapped pretty well shotgunned the driver board.. replaced VR03,04 with new bourns 1Kohm trimmers. I can get offset down to .001vdc but if I turn the pots for the bias all the way CW and bring up the current as soon as it hit's about 10ma it jumps up to the 300-400ma range and I can't get it to come back down until I turn the unit off and back on... I have been over and over it and can't seem to discern the problem. I am using KSC1845's for the bias transistors... could that be a problem... I know when I pulled the old ones they were not 2SC733 as per the service manual...

Cheers,

Jim

Cheers,

Jim

Hi Jim,

Your amplifier section is oscillating. Try installing the bias transistors again if you want, but I suspect you have changed other parts in there.

-Chris

Your amplifier section is oscillating. Try installing the bias transistors again if you want, but I suspect you have changed other parts in there.

-Chris

Look also for resistors that the body is green or light yellow or even white if there is any this specific type might be drifted or even open ....All the rest resistors should be brown or so ...

Did you made any others changes that you haven't told us yet ?

Did you made any others changes that you haven't told us yet ?

I have made a lot of changes, all using recommended replacements I had found in my research, mainly on here or audiokarma.

It had blown fuses and outputs. Replaced outputs with MJ21193/94's, Drivers with MJE15030/31's. TR05/06 with KSC2073's and TR01-04 with KSA992's. Replaced some resistors that looked iffy with new metal film types.

It had blown fuses and outputs. Replaced outputs with MJ21193/94's, Drivers with MJE15030/31's. TR05/06 with KSC2073's and TR01-04 with KSA992's. Replaced some resistors that looked iffy with new metal film types.

Attachments

Did you match the differential pairs? They must be matched closely. Changing the outputs and drivers probably forces you to work out the compensation again.

In general, I can't recommend that people service their own equipment like this. There are several things you must know in addition to the information you were able to get. Unfortunately, the position you're in requires test equipment and some skill to properly complete your repair job.

I'm going to recommend that you find a really good audio service technician and have him restore your set to proper working condition. You absolutely do need test equipment and an oscilloscope at the bare minimum now.

-Chris

In general, I can't recommend that people service their own equipment like this. There are several things you must know in addition to the information you were able to get. Unfortunately, the position you're in requires test equipment and some skill to properly complete your repair job.

I'm going to recommend that you find a really good audio service technician and have him restore your set to proper working condition. You absolutely do need test equipment and an oscilloscope at the bare minimum now.

-Chris

Did you keep all the original components? if so, put them all in a bag and take the amplifier to a decent technician. It may need to be rebuilt, repaired and then possibly upgraded. Fix the faults before wholesale replacements next time. You say it had blown fuses and outputs. All 4 output transistors- and the drivers? Are the 0.47ohm emitter resistors still good as they often go when you latch-on and kill an output stage?

If the original semis test ok up to the output stage, I'd be rematching the two differential front end trs and re-installing them.

If the original semis test ok up to the output stage, I'd be rematching the two differential front end trs and re-installing them.

Last edited:

Thanks, it seems I'm the only one in these parts that will touch anything this old. Everyone here only does warranty service on new stuff.

I matched the differential pairs.. and think I have found the problem. Had to make a parts order... I took the drivers out and found two bad MJ15030's that I probably took out when I had the bias transistors in backwards... 🙂 The Hfe on them was way low..

I am new to working with audio equipment but I was a radar tech in the USAF.. I'm working my way to getting an scope...

I had tried to get one tech here to look at a Sansui AU-717 and he told me that old stuff was junk and tried to sell me some Sony gear... really!

I matched the differential pairs.. and think I have found the problem. Had to make a parts order... I took the drivers out and found two bad MJ15030's that I probably took out when I had the bias transistors in backwards... 🙂 The Hfe on them was way low..

I am new to working with audio equipment but I was a radar tech in the USAF.. I'm working my way to getting an scope...

I had tried to get one tech here to look at a Sansui AU-717 and he told me that old stuff was junk and tried to sell me some Sony gear... really!

All 4 outputs were gone.. also the drivers... Someone had done some work on it before I got it.. all the other transistor had been replaced with 2sc1313's, everything from TR01-06. It had two burnt resistors, R37 on board F-2097 and R35 on board F-2092.

Fair enough, it seems it was a mess created by a previous ham-fisted 'tech'.

Use a DBT (dim bulb tester) after the rebuild or use 4 old M205 fuses that are blown and solder 10ohm 1/4 watt resistors over them, then install in the 4x amplifier rail fuse holders. If there is a fault after the rebuild, they will sacrifice themselves and save the drivers/outputs. If it works ok, pull the 10ohm resistors out, replace the fuses and set the bias.

I don't like Sansui's directions to pull a single rail fuse and measure the bias current using an inline DMM or milli amp meter. It's plain stupid, because if your probes slip contact or there is a fault, the amp will latch up and/or trip the DC protector and/or blow itself up and likely take out the low value protection fuse on your DMM for the mA ranges.

Go the tried and true method of measuring the calculated voltage drop you require over the emitter resistor on the outputs.

Use a DBT (dim bulb tester) after the rebuild or use 4 old M205 fuses that are blown and solder 10ohm 1/4 watt resistors over them, then install in the 4x amplifier rail fuse holders. If there is a fault after the rebuild, they will sacrifice themselves and save the drivers/outputs. If it works ok, pull the 10ohm resistors out, replace the fuses and set the bias.

I don't like Sansui's directions to pull a single rail fuse and measure the bias current using an inline DMM or milli amp meter. It's plain stupid, because if your probes slip contact or there is a fault, the amp will latch up and/or trip the DC protector and/or blow itself up and likely take out the low value protection fuse on your DMM for the mA ranges.

Go the tried and true method of measuring the calculated voltage drop you require over the emitter resistor on the outputs.

Hi nadude98,

If you have, or can get a variac, use that instead of a light bulb or resistors in fuse cartridges. That way you can bring it up slowly and stop before you begin to lose parts. It really helps when you have to do some troubleshooting at partial voltages.

Where are you buying your parts from? Do not buy them on Ebay! Buy modern transistors from the usual suspects. That means Digikey, Mouser, Newark or similar. Both Fairchild and On Semi make excellent semiconductors. The JIS numbered parts (2S_xxxx) they have are made under contract, so they are safe to use. Same for the Pro-Electron numbers (BCxxx).

You really should be using an oscilloscope. Often it's the only way to see whats going on. Do you have a good DVM? The cheap ones aren't even accurate enough in mV to use for bias current. Often the last digit is just for show if you work out the error budget, then figure most of those don't even make spec when new. I worked in a calibration lab for a while. Beware of Extech. Junk.

-Chris

If you have, or can get a variac, use that instead of a light bulb or resistors in fuse cartridges. That way you can bring it up slowly and stop before you begin to lose parts. It really helps when you have to do some troubleshooting at partial voltages.

Where are you buying your parts from? Do not buy them on Ebay! Buy modern transistors from the usual suspects. That means Digikey, Mouser, Newark or similar. Both Fairchild and On Semi make excellent semiconductors. The JIS numbered parts (2S_xxxx) they have are made under contract, so they are safe to use. Same for the Pro-Electron numbers (BCxxx).

You really should be using an oscilloscope. Often it's the only way to see whats going on. Do you have a good DVM? The cheap ones aren't even accurate enough in mV to use for bias current. Often the last digit is just for show if you work out the error budget, then figure most of those don't even make spec when new. I worked in a calibration lab for a while. Beware of Extech. Junk.

-Chris

It's unlikely the OP has a Variac and he also doesn't yet have an oscilloscope.

If he goes and buys a oscilloscope, a decent Variac and a 'good' DVM, he will be spending multiple times what the old amp is worth- many hundreds of dollars. Put it into perspective, not everyone has a bench full of test gear, the knowledge to use it and the resources to buy it.

A DBT is a cheap, very effective device and will help save gear from destruction in many cases. Resistors in old fuses are another tried and true (low cost) device for hobbyists when setting up amps they have built or rebuilt.

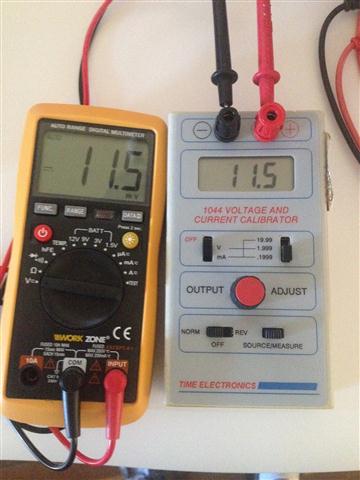

As for DMMs not being accurate, that's pretty much BS. I have a Time Electronics voltage and current calibrator right here and even the $20 meters these days are accurate, across all ranges, particularly the low mV ranges and much better than expensive meters of 10+ years ago. Are you seriously suggesting in line bias current calibration on an amplifier that is clearly latching up is a good idea?

If he goes and buys a oscilloscope, a decent Variac and a 'good' DVM, he will be spending multiple times what the old amp is worth- many hundreds of dollars. Put it into perspective, not everyone has a bench full of test gear, the knowledge to use it and the resources to buy it.

A DBT is a cheap, very effective device and will help save gear from destruction in many cases. Resistors in old fuses are another tried and true (low cost) device for hobbyists when setting up amps they have built or rebuilt.

As for DMMs not being accurate, that's pretty much BS. I have a Time Electronics voltage and current calibrator right here and even the $20 meters these days are accurate, across all ranges, particularly the low mV ranges and much better than expensive meters of 10+ years ago. Are you seriously suggesting in line bias current calibration on an amplifier that is clearly latching up is a good idea?

Last edited:

Hi John,

He isn't fixing this amplifier alone and he mentioned he is working to get an oscilloscope. Go back and read.

As far as cheap meters being accurate, hogwash. Outside the lab I check meters against an HP 34401A and an HP 3457A - calibrated. I have an RFL calibrator as well that I use to transfer the accuracy of the HP meters to others I check.

The main problem cheap meters have is that they use cheap metal film resistors that do drift. Often they are out from range to range so that the one pot can't bring them into tolerance. A real meter uses a single ceramic unit that has the low TC resistors deposited onto it (they now track with temperature) that also has a low and controlled capacitance.

I'm sorry, but I have a very low confidence in your calibrator, or it's use now. Try and do a real error budget for a cheap meter, then you tell me how many digits are effective. Many meters are 2 1/2 digits and "something" that mislead people.

The other equipment a person uses on their bench affects how well they can work. Don't strive to see how little you can spend while claiming any sort of accuracy - or even repeatability. There is a damn good reason why $450 + hand held meters exist. Even more so why $1K + can be spent on a bench meter. They are accurate and they hold their calibration very well. Performance is designed in, not just hoped for as in the cheap meters.

Variacs. If you don't use one, you just can't get it. They can be had for $20 on Ebay, more for better models. I have a few and last year picked up a B&K 1655 for less than $100 in Canada. If you don't have one due to cost, you're only making excuses.

Honestly John, if you are charging for your work, and use cheap instruments and improper test procedures, you maybe should close up shop. I feel very strongly about that since I have to clean up after happy souls who hope they are doing good work.

Last comment. If you charge for work on audio equipment and you don't have a THD analyzer, you are incapable of even knowing if your work is good or not. I hope to heck you have a half decent bench John. You actually do need that stuff, and I do mean need. If you can't see why, you really do need to close up.

-Chris

He isn't fixing this amplifier alone and he mentioned he is working to get an oscilloscope. Go back and read.

As far as cheap meters being accurate, hogwash. Outside the lab I check meters against an HP 34401A and an HP 3457A - calibrated. I have an RFL calibrator as well that I use to transfer the accuracy of the HP meters to others I check.

The main problem cheap meters have is that they use cheap metal film resistors that do drift. Often they are out from range to range so that the one pot can't bring them into tolerance. A real meter uses a single ceramic unit that has the low TC resistors deposited onto it (they now track with temperature) that also has a low and controlled capacitance.

I'm sorry, but I have a very low confidence in your calibrator, or it's use now. Try and do a real error budget for a cheap meter, then you tell me how many digits are effective. Many meters are 2 1/2 digits and "something" that mislead people.

The other equipment a person uses on their bench affects how well they can work. Don't strive to see how little you can spend while claiming any sort of accuracy - or even repeatability. There is a damn good reason why $450 + hand held meters exist. Even more so why $1K + can be spent on a bench meter. They are accurate and they hold their calibration very well. Performance is designed in, not just hoped for as in the cheap meters.

Variacs. If you don't use one, you just can't get it. They can be had for $20 on Ebay, more for better models. I have a few and last year picked up a B&K 1655 for less than $100 in Canada. If you don't have one due to cost, you're only making excuses.

Honestly John, if you are charging for your work, and use cheap instruments and improper test procedures, you maybe should close up shop. I feel very strongly about that since I have to clean up after happy souls who hope they are doing good work.

Last comment. If you charge for work on audio equipment and you don't have a THD analyzer, you are incapable of even knowing if your work is good or not. I hope to heck you have a half decent bench John. You actually do need that stuff, and I do mean need. If you can't see why, you really do need to close up.

What the hell are you talking about now? I was very clear when I said you can take measurements at partial line voltages before things go to pot. Read the post.Are you seriously suggesting in line bias current calibration on an amplifier that is clearly latching up is a good idea?

-Chris

Here's a cheap, $20 at Aldi meter. More than good enough for setting the bias current. This meter was very accurate on the DC ranges.

Even on AC, it was accurate to 3kHz. Amazing for the price.

Dropped over the 0.47ohm emitter resistors in the AU-6600, you'd want 11.7mV. There is a range Sansui quote that corresponds to 7mV to 16.5mV, so it's not at all critical.

Oh, go read the specs on the Time unit. It's perfect for the job and RS does a good job on the periodic calibrations.

Even on AC, it was accurate to 3kHz. Amazing for the price.

Dropped over the 0.47ohm emitter resistors in the AU-6600, you'd want 11.7mV. There is a range Sansui quote that corresponds to 7mV to 16.5mV, so it's not at all critical.

Oh, go read the specs on the Time unit. It's perfect for the job and RS does a good job on the periodic calibrations.

Attachments

Hi John,

You have got to be kidding me!

Portable calibration instruments aren't that accurate. We calibrated those as well. A Fluke 787 is more accurate (really) and costs a great deal more, for a reason.

A calibration generator has to be on and running for at least 1/2 hour after it reaches room temperature. They use ovenized DC references and have an auto-calibration cycle that runs during use. A 9V battery can't even begin to power the voltage reference, never mind the rest of it. I have a little DC reference that I play with. It is far more accurate than that meter you show. It's still a toy. There is no ambient temperature correction going on, nor is there any gain correction happening.

If you open that little calibrator up, have a look at the reference and note what the multiplier resistors are. Look up the chip and understand that the limits that are published are under optimum conditions. That unit you have doesn't qualify as optimum. Now for the resistors. For a transistor matcher I designed, I used 0.1%, low thermal TC metal film resistors. All that circuit does is look for a null, not scaling any quantity like your unit there does. If you see trimmers, beware! They should be restricted in adjustment range and be low TC types (read bloody expensive). Somehow I strongly doubt your calibrator is actually as accurate as you might think it is. For sure the meter isn't.

One cheap meter brand was good. It was called Escort. Agilent bought them and used their great manufacturing to produce great hand-held meters. Of course, Escort got Agilent's great accuracy engineering out of the deal. I think they are part of Keysight now (modern Agilent is now Life Sciences only). Now those are meters you should consider buying. I have some old HP 974A meters, and a new Keysight U1273A. No Hfe function, but it does extremely well on the functions it does have.

The basic DC accuracy of the meters I listed is 0.05%. Other functions are not as good, as you might expect. The old 974A is good to 100 KHz (specified to), so keep your eyes peeled for these if they come up for sale.

-Chris

You have got to be kidding me!

Portable calibration instruments aren't that accurate. We calibrated those as well. A Fluke 787 is more accurate (really) and costs a great deal more, for a reason.

A calibration generator has to be on and running for at least 1/2 hour after it reaches room temperature. They use ovenized DC references and have an auto-calibration cycle that runs during use. A 9V battery can't even begin to power the voltage reference, never mind the rest of it. I have a little DC reference that I play with. It is far more accurate than that meter you show. It's still a toy. There is no ambient temperature correction going on, nor is there any gain correction happening.

If you open that little calibrator up, have a look at the reference and note what the multiplier resistors are. Look up the chip and understand that the limits that are published are under optimum conditions. That unit you have doesn't qualify as optimum. Now for the resistors. For a transistor matcher I designed, I used 0.1%, low thermal TC metal film resistors. All that circuit does is look for a null, not scaling any quantity like your unit there does. If you see trimmers, beware! They should be restricted in adjustment range and be low TC types (read bloody expensive). Somehow I strongly doubt your calibrator is actually as accurate as you might think it is. For sure the meter isn't.

One cheap meter brand was good. It was called Escort. Agilent bought them and used their great manufacturing to produce great hand-held meters. Of course, Escort got Agilent's great accuracy engineering out of the deal. I think they are part of Keysight now (modern Agilent is now Life Sciences only). Now those are meters you should consider buying. I have some old HP 974A meters, and a new Keysight U1273A. No Hfe function, but it does extremely well on the functions it does have.

The basic DC accuracy of the meters I listed is 0.05%. Other functions are not as good, as you might expect. The old 974A is good to 100 KHz (specified to), so keep your eyes peeled for these if they come up for sale.

-Chris

Hi John,

That model is not sold in North America, but I can see it isn't cheap either. It is better to use it with the inexpensive meters as you are. What you should do is work out what the calibration errors will be at the temperature that you are using it at before taking important readings until you become familiar with the meter you're using. You should buy at least one good meter for your bench. A used 34401A would be ideal.

For what that cost you, you could have bought a Keysight U1273A, or even a bench meter. That would probably have been a better use of the $$.

Now back to the Sansui thread. Sorry for the OT.

-Chris

That model is not sold in North America, but I can see it isn't cheap either. It is better to use it with the inexpensive meters as you are. What you should do is work out what the calibration errors will be at the temperature that you are using it at before taking important readings until you become familiar with the meter you're using. You should buy at least one good meter for your bench. A used 34401A would be ideal.

For what that cost you, you could have bought a Keysight U1273A, or even a bench meter. That would probably have been a better use of the $$.

Now back to the Sansui thread. Sorry for the OT.

-Chris

Prices here in Oz are nothing like NA. Heavy items are not so easy to import and Variacs are not cheap or common anywhere in Oz - even products that are identical other than in voltage rating, to those sold in your stores. No one has to make excuses over this, because we pay a lot more and whilst variacs are certainly part of the repair culture in NA, they have long been frowned on by authorities here. In the past, auto-transformers were denied to retail customers at least, which set the pattern.

You seldom see more than a few Variacs available on Ebay, Australia wide and $80-120 is more like the price asked for 250-2,000VA rating. Freight could be as much as the goods are worth so that makes the idea a non-starter for the few repairs that Joe Average ever needs to do. 0-260VAC Variable Laboratory Autotransfomer (Variac) - 500VA - Shop Online in Australia

A problem for Variac users is that most of the cheapo products are auto-transformers and the casing may not be fully sealed so there are a shipload of safety issues that have never in my lifetime been addressed properly and few handyman buyers will have any idea of them. It may be a subject of little concern in a 115V country but 230V+ calls for rapt attention and concerns are rightly with that rather than the insistence on test procedures that have developed to take advantage of a variable line voltage.

You seldom see more than a few Variacs available on Ebay, Australia wide and $80-120 is more like the price asked for 250-2,000VA rating. Freight could be as much as the goods are worth so that makes the idea a non-starter for the few repairs that Joe Average ever needs to do. 0-260VAC Variable Laboratory Autotransfomer (Variac) - 500VA - Shop Online in Australia

A problem for Variac users is that most of the cheapo products are auto-transformers and the casing may not be fully sealed so there are a shipload of safety issues that have never in my lifetime been addressed properly and few handyman buyers will have any idea of them. It may be a subject of little concern in a 115V country but 230V+ calls for rapt attention and concerns are rightly with that rather than the insistence on test procedures that have developed to take advantage of a variable line voltage.

The 1044 calibration unit I use and keep here is a 0.05% guaranteed accuracy and does not drift. It wasn't cheap, but wasn't expensive either, and it is an incredibly useful little unit. It is an extremely useful reference to check multiple meters. I can confirm basic DC and DC current accuracy of any multimeter, DVM panel meter in situ or in a remote location ie, it is very portable. That has its advantages.

At 0.05% it is the same basic accuracy as my bench meters and the better Flukes I use. I am a sucker for DMMs and have had perhaps 40 over the years, ranging from nixie-tube vintage units to all type of newer ones. With that single calibrator, I know which ones are accurate. It's always useful to check them after an 'event' (you know what I mean)

My points are these:

1:Cheap DMMs are more than good enough for setting the bias. I use more expensive meters as you no doubt do- because I can, but the OP does not need one to measure an 11.7mV drop over a 0.47ohm resistor- any meter will do that well enough.

2:Measuring current on the mA setting across fuse clips (as per Sansui's AU-6600 S/M) in a possibly unstable amplifier is unwise. I'm sure you'd agree with that too. The low current ranges on DMMs are usually only protected by some oddball value fuse and nobody needs to kill their meter.

3:A DBT is a useful thing for someone getting into vintage restoration. It is not a substitute for a Variac and I never said it was. My variac is an ancient 1kVA thing I bought in 1980 from a retired TV tech. It's had its fair share of warm moments over the years. To be honest, I hardly use it- big amplifiers would cook the low end voltage windings if you have a major fault. Over the years, on major rebuilds, the output stage is kept out of circuit until I have a confirmed functioning VAS right through to the drivers.

Variacs don't play well with RCDs and you can't safely use them in conjunction with a isolation transformer either- your RCD will esentially become useless. Variacs cost a stack of money here due to the economies of scale for 240/250v- they have twice as much copper and steel or they use stacked 120v units (I have an old powerstat dual stacked one I built years ago). Authorities had pretty much outlawed autoformers over here for years and years. Remember, we are 240v and our earthing requirements and insulation standards are high enough to make metal encased autoformers a bit of a no-no. The cheap ones sold in this country ($230 or so) are made in India. Seriously.

Anyway, peace out, it's Friday night and I'm gonna have a beer.

At 0.05% it is the same basic accuracy as my bench meters and the better Flukes I use. I am a sucker for DMMs and have had perhaps 40 over the years, ranging from nixie-tube vintage units to all type of newer ones. With that single calibrator, I know which ones are accurate. It's always useful to check them after an 'event' (you know what I mean)

My points are these:

1:Cheap DMMs are more than good enough for setting the bias. I use more expensive meters as you no doubt do- because I can, but the OP does not need one to measure an 11.7mV drop over a 0.47ohm resistor- any meter will do that well enough.

2:Measuring current on the mA setting across fuse clips (as per Sansui's AU-6600 S/M) in a possibly unstable amplifier is unwise. I'm sure you'd agree with that too. The low current ranges on DMMs are usually only protected by some oddball value fuse and nobody needs to kill their meter.

3:A DBT is a useful thing for someone getting into vintage restoration. It is not a substitute for a Variac and I never said it was. My variac is an ancient 1kVA thing I bought in 1980 from a retired TV tech. It's had its fair share of warm moments over the years. To be honest, I hardly use it- big amplifiers would cook the low end voltage windings if you have a major fault. Over the years, on major rebuilds, the output stage is kept out of circuit until I have a confirmed functioning VAS right through to the drivers.

Variacs don't play well with RCDs and you can't safely use them in conjunction with a isolation transformer either- your RCD will esentially become useless. Variacs cost a stack of money here due to the economies of scale for 240/250v- they have twice as much copper and steel or they use stacked 120v units (I have an old powerstat dual stacked one I built years ago). Authorities had pretty much outlawed autoformers over here for years and years. Remember, we are 240v and our earthing requirements and insulation standards are high enough to make metal encased autoformers a bit of a no-no. The cheap ones sold in this country ($230 or so) are made in India. Seriously.

Anyway, peace out, it's Friday night and I'm gonna have a beer.

Last edited:

you may kiss the amplifier BB .... It will eventually produce some sound but this will have nothing to do with how the amplifier worked in the original condition ....

Regards

Sakis

Regards

Sakis

Thanks guys, I always use a DBT and I have a variac. I actually prefer powering up with the DBT since it gives a visual clue right away if there is an issue. I almost always get parts from mouser, though I have bought from Digikey or Michael Percy Audio.

I have gotten a few, very few off of ePray, however I did some research on the seller. For example I bought several SVT-4's from a seller in Germany that had been vouched for on AK..

I'm using a Fluke 189 and I have a Simpson 260 I am trying to find new leads for.. I'm trying to save some money towards getting a scope. I'm retired on disability pension so I have limited means. I'm hoping to make a small business of doing some restorations, though I am no EW by any means.. I was one of the top techs on the FPS-27a receiver section, but that was years ago. I actually wanted to service audio after I got out of the Air Force but there was no money in it and I got hired by the Post Office.. I started getting back into audio equipment and got my vinyl out of storage about 10 years ago.. I have been doing a little work for myself in that time period and now I am feeling a little more confident in my abilities so I'm getting more serious in my endeavors, and hopefully with good help I can get better.. that's why I'm here! It is DIY audio, lol!

I use On Semi almost exclusively for outputs.

I matched the pre-drivers in each channel, do they need to be matched so both channels are equal? I can see why it would be good if they were but it shouldn't affect operation or generate oscillation, correct? Again I don't have the means to buy 100 or so transistors at a time when I to other parts too..

I have gotten a few, very few off of ePray, however I did some research on the seller. For example I bought several SVT-4's from a seller in Germany that had been vouched for on AK..

I'm using a Fluke 189 and I have a Simpson 260 I am trying to find new leads for.. I'm trying to save some money towards getting a scope. I'm retired on disability pension so I have limited means. I'm hoping to make a small business of doing some restorations, though I am no EW by any means.. I was one of the top techs on the FPS-27a receiver section, but that was years ago. I actually wanted to service audio after I got out of the Air Force but there was no money in it and I got hired by the Post Office.. I started getting back into audio equipment and got my vinyl out of storage about 10 years ago.. I have been doing a little work for myself in that time period and now I am feeling a little more confident in my abilities so I'm getting more serious in my endeavors, and hopefully with good help I can get better.. that's why I'm here! It is DIY audio, lol!

I use On Semi almost exclusively for outputs.

I matched the pre-drivers in each channel, do they need to be matched so both channels are equal? I can see why it would be good if they were but it shouldn't affect operation or generate oscillation, correct? Again I don't have the means to buy 100 or so transistors at a time when I to other parts too..

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Sansui AU-6600 Bias