Erm an Old story There are Far more longer lived 'rubber' surrounds used in drivers. Not all are created equal 🙂 Function of Cost of Mfg basically.

At least those are not ewwww..Foam

Armour All is Garbage... Proven.. years ago to have a reaction with the rubber types used in Car tires. Promoting cracking and deterioration.. enough so that Tire makers will 'reconsider' their warranties if the Swill is detected.

No need to perpetuate the Audio Weenie stereotype

At least those are not ewwww..Foam

Armour All is Garbage... Proven.. years ago to have a reaction with the rubber types used in Car tires. Promoting cracking and deterioration.. enough so that Tire makers will 'reconsider' their warranties if the Swill is detected.

No need to perpetuate the Audio Weenie stereotype

Does anybody know if Butyl rubber is the same as JBL's Lanzaloy? someone at Altec Lansing Heritage web site used a specific brake fluid to soften Lanzaloy surrounds.

I'd be very wary of that. When rubber is cured, it forms cross-links in an irreversible reaction, which causes the rubber to stiffen and stabilize. Over time,with exposure to oxygen and light, the original cross-links break down and new ones form, which causes embrittlement and cracking. The presence of a plasticizer (a solvent, really) will hasten the death.

The main effect of rubber aging and embrittlement (besides impending driver demise) is the increased reflection back from the cone edge. A high resolution impedance curve will show this up- in a Heyser plot, it will appear as a pigtail.

The main effect of rubber aging and embrittlement (besides impending driver demise) is the increased reflection back from the cone edge. A high resolution impedance curve will show this up- in a Heyser plot, it will appear as a pigtail.

Does anybody know if Butyl rubber is the same as JBL's Lanzaloy? someone at Altec Lansing Heritage web site used a specific brake fluid to soften Lanzaloy surrounds.

No.. it is vastly differing. Few drivers use it though.

Really!? Some Moron rubbed brake fluid on his driver surrounds... and bragged about it?

Surprised some twit hasn't yet decided to paper punch 'softening' holes into their speaker surrounds

IMO we can file that bit of genius right in there with sandpapering ones' penis head.

Gives entirely new meaning/scope to what the French call: Idiophiles.

No.. it is vastly differing. Few drivers use it though.

So, what, exactly, is the difference?

Golly Bare, do you really need to practice rudeness? What if brake fluid works on certain stiff old surrounds? We look for informed solutions here. Snarkiness is not that. Clearly there have been many formulations used over the decades. My Polk 10 drivers still measure in the 30s, and my SEAS P17RCYs, mentioned earlier, measured 20 hz above spec when they were new, indicating a problem when they were made. I had a lot of drivers measure out of spec back in the 80s, except for ScanSpeak. And my only leftover SS drivers have failed foam. So oddly enough the best surrounds of the day appear to have been the CTS doped fabric, at least in terms of maintaining both their compliance and seal. And Gefco rubber surrounds are still good after 30 years.

Hmm, I just use black "bumper paint"..

If it comes down to a mechanically faulty surround I'd just replace it.. maybe even make my own out of silicone that the movie makeup industry uses (..and again, use black bumper paint).

..oh, also:

For the most part changes in T/S parameter at least within normal use parameters, have little to do with the surround - rather its mostly about the spider, particularly with "roll" surrounds (rubber or otherwise). The testing for T/S is based off of Impedance around resonance - which the surround really doesn't effect much. You can also get varying numbers based on the amount of voltage used in the test relative to the rest of the motor's performance (..i.e. Impedance at resonance usually "flattens" out some with higher drive levels ..like 5 volts or more depending on the driver). The "DATS" tester can go from .35 to 2 volts (..which is a bit less than your standard 2.83 volts for impulse response measurements at 1 meter.)

If it comes down to a mechanically faulty surround I'd just replace it.. maybe even make my own out of silicone that the movie makeup industry uses (..and again, use black bumper paint).

..oh, also:

For the most part changes in T/S parameter at least within normal use parameters, have little to do with the surround - rather its mostly about the spider, particularly with "roll" surrounds (rubber or otherwise). The testing for T/S is based off of Impedance around resonance - which the surround really doesn't effect much. You can also get varying numbers based on the amount of voltage used in the test relative to the rest of the motor's performance (..i.e. Impedance at resonance usually "flattens" out some with higher drive levels ..like 5 volts or more depending on the driver). The "DATS" tester can go from .35 to 2 volts (..which is a bit less than your standard 2.83 volts for impulse response measurements at 1 meter.)

Last edited:

What can you expect when replacing surrounds?

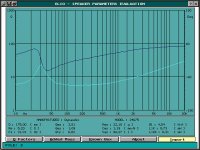

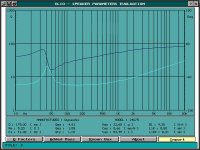

In my case the difference was this.

In my case the difference was this.

Attachments

Last edited:

In my case the difference was this.

Wow, what was the drive level? Rubber surround?

Is that "before and after", or "after and before"?

Last edited:

I don't know the exact voltage of drive level, it's the same in both

measurements in the fashion Audiomatica programmed it.

The higher Fs measurement represents the same driver with a

stiffer foam surround I got from a Dutch ebay seller. Funny thing

happened, the bass sounds now tighter. I should also say that modified

driver in the box has Qts approximately about 0,9 without dcr of the

LP coil. The stuffing did that. Before, then after.

measurements in the fashion Audiomatica programmed it.

The higher Fs measurement represents the same driver with a

stiffer foam surround I got from a Dutch ebay seller. Funny thing

happened, the bass sounds now tighter. I should also say that modified

driver in the box has Qts approximately about 0,9 without dcr of the

LP coil. The stuffing did that. Before, then after.

The higher Fs measurement represents the same driver with a

stiffer foam surround I got from a Dutch ebay seller.

..so the newer surround is quite a bit more stiff than it should be - that makes sense, its adding resistance that should only be part of the spider. (..happens all the time with corrugated cloth surrounds in pro drivers, must be pretty tough type of foam.)

I'm guessing it was tested at a lower voltage.

I worry about this in regard to my PSB Stratus Gold-i's. They have some white-ish discoloration of the black midrange surrounds. This seems to be common for this series, as I can see it on other Stratus speakers for sale on eBay and such. They appear to be just fine in terms of flexibility for now but I wonder how they will fare in the future, and if they might have subtly degraded performance that I'm not aware of.

I've seen Ken Kantor comment on Audiokarma that you can't properly replace the surround on a midrange cone. He said at these frequencies the details such as the exact material, shape and even the temperature and amount of the glues applied can greatly change the frequency response.

"Refoaming a midrange": Refoaming a midrange - AudioKarma.org Home Audio Stereo Discussion Forums

I've seen Ken Kantor comment on Audiokarma that you can't properly replace the surround on a midrange cone. He said at these frequencies the details such as the exact material, shape and even the temperature and amount of the glues applied can greatly change the frequency response.

"Refoaming a midrange": Refoaming a midrange - AudioKarma.org Home Audio Stereo Discussion Forums

... must be pretty tough type of foam.)

I'm guessing it was tested at a lower voltage.

The new foam looks really good, only when you touch it,

you know it's not original and it feels tougher allright.

I've looked in the Clio manual and it says that Internal mode

of measuring impedance, which doesn't need external amp,

calculates based upon output impedance of 100 ohm and outputs

sine wave test signals at 0 dB which is 0,775 V rms. The internal

mode is accurate for measuring between 1 and 400 ohms, for the

greater values, the external mode with sensing resistor and an amp

should be used.

I've seen Ken Kantor comment on Audiokarma that you

can't properly replace the surround on a midrange cone.

I can't say I have ever exchanged a midrange surround, I haven't,

I do believe it would be worth trying to do the work yourself,

with an appropriate measuring gear to check things out. Some

of the changes can probably be compensated for.

When the right time comes, you can worry about it.

I've been told that the best product for preserving rubber is Krytox GPL 105. Haven't tried it myself though.

That is not what I used, that is not WD-40, which I think is safe for most rubber compounds. It seems that WD-40 is intended for metals, but the instructions seem to imply that it is safe for most surfaces. It seemed to work well in this application and I don't think I want to risk anything else on the other drivers that I have to do. The rubber really did appear to soak it up, or perhaps there is a component that just evaporates.

Pete B.

Don't use WD40, It's quite good at dissolving glue and might ruin the surround /cone attachment!

Don't use WD40, It's quite good at dissolving glue and might ruin the surround /cone attachment!

Yes, I agree after I used it on some completely unrelated rubber parts that expanded after applying WD-40. Don't use it!

Hmm, I just use black "bumper paint"..

If it comes down to a mechanically faulty surround I'd just replace it.. maybe even make my own out of silicone that the movie makeup industry uses (..and again, use black bumper paint).

..oh, also:

For the most part changes in T/S parameter at least within normal use parameters, have little to do with the surround - rather its mostly about the spider, particularly with "roll" surrounds (rubber or otherwise). The testing for T/S is based off of Impedance around resonance - which the surround really doesn't effect much. You can also get varying numbers based on the amount of voltage used in the test relative to the rest of the motor's performance (..i.e. Impedance at resonance usually "flattens" out some with higher drive levels ..like 5 volts or more depending on the driver). The "DATS" tester can go from .35 to 2 volts (..which is a bit less than your standard 2.83 volts for impulse response measurements at 1 meter.)

This is completely wrong. The surround/edge contributes quite a bit toward the total

compliance. The PSB woofers shifted considerably, and many have noted that if cheap

low compliance foam is used the Fs shifts up quite a bit.

- Home

- Loudspeakers

- Multi-Way

- Rubber Surrounds Hardening With Age