After giving up for a couple years, I've again decided to see if I can save the old girl. The problem: the platter spins super fast. I was told here originally to check for bad capacitors. This week, I took everything apart and inspected two caps in the speed circuit that might be involved. They both look fine, but I understand they can just crap out with age. I figured I'd just try and replace both, and see what happens, but I'm having a hard time figuring out replacements. I'm attaching the schematic, and info on the caps in question. To further complicate things, someone suggested recently that it could be a governor failing in the DC motor. That's a whole new wrinkle, and I have no idea how I'd even deal with that or test for it. The dead caps seem to make more sense. Anyone have any thoughts or suggestions? BTW, I'm a novice, not an experienced electronics tinkerer.

Other than their use of mfd instead of µf to mean microfarad, what part of the capacitor replacement has you confused?

Thanks for the reply, mattstat. Thankfully, someone explained that the mfd was the same as uf, so that helped a bit. There seem to be a variety of options, including different life expectancies, etc. Trying to figure out what the best choices would be for my situation. I guess asking someone at Mouser might get me to the right choice. They didn't respond to email, so I'll have to try calling. The bigger concern is whether the 2nd possible issue (governor in motor) could be the culprit. Since I currently have no way of figuring that out, I guess I'll have to try swapping out the caps, and hope for the best.

Instead of replacing capacitors (most often needlessly) I would look at bad solder joints (especially around the controls, connection points and heat generating parts) and breaks of pcb traces. But it would be better to do some measurements first to winnow the problem. The full service manual is available for download at vinylengine.com. E

For general use in typical circuits, most electrolytics are comparable and don't need anything beyond voltage and capacitance specified. Longer life and higher temperature resistance are always a good thing, so those are worth "splurging" for at times. They won't directly affect the performance, but can be a sign of a high quality component. The rest of the differences are likely details that won't affect your circuit either.

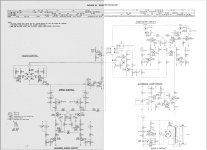

What you attached is a board layout. If you have a schematic, it might be worth posting that too, since it may help others point you in a diagnostic direction. Untangling a board layout can be difficult for those unfamiliar with the circuit.

And given a little more time, someone with experience with your turntable might chime in. Unfortunately, that's not me, so I can't give much guidance on troubleshooting it.

What you attached is a board layout. If you have a schematic, it might be worth posting that too, since it may help others point you in a diagnostic direction. Untangling a board layout can be difficult for those unfamiliar with the circuit.

And given a little more time, someone with experience with your turntable might chime in. Unfortunately, that's not me, so I can't give much guidance on troubleshooting it.

Last edited:

Thanks, mickeymoose. I'll start inspecting solder joints, etc., as you recommended. I don't have any experience in measuring much of anything on a board yet, unfortunately. I have a basic multimeter, and that's about it. I do have a service manual. My vinylengine account got closed, and they weren't accepting new registrations when I tried, for some reason.Instead of replacing capacitors (most often needlessly) I would look at bad solder joints (especially around the controls, connection points and heat generating parts) and breaks of pcb traces. But it would be better to do some measurements first to winnow the problem. The full service manual is available for download at vinylengine.com. E

Okay, I found the schematic in the service manual, and attached it. (tried merging the two pages, for easier reading)What you attached is a board layout. If you have a schematic, it might be worth posting that too, since it may help others point you in a diagnostic direction. Untangling a board layout can be difficult for those unfamiliar with the circuit.

Attachments

Last edited:

I suspect working on this might be outside your comfort zone 🙂

If you can identify and locate parts on the PCB then one worthwhile check is to quickly measure across C and E (collector and emitter) of transistor TS431. The power must be OFF and you should use the diode range on your meter. See if it reads very low or short circuit.

You could also try shorting the base and emitter of TS431 (or lift one end of R538) The platter should not run at all doing that.

All that just proves the motor driver transistor is OK but that type of part is likely to fail in use. Worth checking before getting heavy with it 🙂

If you can identify and locate parts on the PCB then one worthwhile check is to quickly measure across C and E (collector and emitter) of transistor TS431. The power must be OFF and you should use the diode range on your meter. See if it reads very low or short circuit.

You could also try shorting the base and emitter of TS431 (or lift one end of R538) The platter should not run at all doing that.

All that just proves the motor driver transistor is OK but that type of part is likely to fail in use. Worth checking before getting heavy with it 🙂

Well, not so much the comfort zone as the "have a clue zone." 😊 Thanks for the suggestions, Mooly. If I can figure out how to perform those tests with my meter (never used it for electronics testing), I'll have a go at it. Time for some more "homework." I think I ruled out C729, as it appears to be part of the supply circuit, not the speed circuit. Thanks again for your help!I suspect working on this might be outside your comfort zone

If you short these two points together the motor should not run. Its a quick and dirt test that the transistor is basically working OK.

It's the tacho in the motor . The motor has two motors. One for driving and one tacho feedback. They have brushes. The tacho motor wears out first and the circuit gets no feedback anymore and goes 100% power/rpm.

Thanks for the info, Arnolddew. Yet another wrinkle emerges! Is there a way to confirm this (a way a neophyte could handle), and more important, is it something I can repair?

Well, the best thing is to try a second motor. Or you could mesure the voltage the tachomotor is giving when spinning.

- Home

- General Interest

- Everything Else

- Round 2 of attempt to refurb Philips GA 222 turntable - speed issue