Anyone know a fix for any of these issues with an old Rotel.

1. Randomly seems to cut out, almost like a skip, can hear the cd do something funny.

2. When selecting random playback, always starts with track #6. I haven't paid attention to see if the whole order is always the same.

I downloaded the service manual but it doesn't seem too complete (for a service manual). Does anyone have a manual with more than 9 pages? There must be some diagnostic / test modes but the manual doesn't mention any kind of trouble shooting.

Thanks!

__________________

Infinity IRS-Beta, ADS 1230, ADS 880

Rotel 971

NAD 1130

NAD 2200, Crown PSA-2

1. Randomly seems to cut out, almost like a skip, can hear the cd do something funny.

2. When selecting random playback, always starts with track #6. I haven't paid attention to see if the whole order is always the same.

I downloaded the service manual but it doesn't seem too complete (for a service manual). Does anyone have a manual with more than 9 pages? There must be some diagnostic / test modes but the manual doesn't mention any kind of trouble shooting.

Thanks!

__________________

Infinity IRS-Beta, ADS 1230, ADS 880

Rotel 971

NAD 1130

NAD 2200, Crown PSA-2

Majority of problems are mechanical. What laser mechanism does this model use. eg Philips CDM12.1 or KSS210 etc ?

As for test modes etc, what you need to do is confirm the signal quality from the pickup (the RF or "eye" pattern) to make sure it is clean, of correct amplitude, and with no jitter. Most skipping problems are down to dried grease and lubrication problems, other common problems are worn spindle motors.

As for test modes etc, what you need to do is confirm the signal quality from the pickup (the RF or "eye" pattern) to make sure it is clean, of correct amplitude, and with no jitter. Most skipping problems are down to dried grease and lubrication problems, other common problems are worn spindle motors.

(Unfortunately) This player uses the Sony KSS-213B laser with 2 x PCM63P and PMD100 and is not one of the earlier Philips clones.

Having said that, a replacement laser is both cheap and easy.

Andy

.

Having said that, a replacement laser is both cheap and easy.

Andy

.

Yesterday I disconnected / reconnected everything. Issue #2 seemed to be fixed but as soon as I put the case back together the problem returned. Did some more disconnecting, poking / pressing on boards and components w/o success. Also did a close exam for cold solder joints and didn't see any. I was surprised at how dust free the interior of the unit was.

Its still apart so I took a quick look at the laser, its a KSS-213C.

I can see how problem #1 might be laser / transport related, but doesn't #2 seem more likely to be circuit related?

Any suggestions as to cleaning the lens? Q-tip and alcohol? I'll clean and re-grease. What's the suggested lube, white lithium?

Thanks for the help!!

Its still apart so I took a quick look at the laser, its a KSS-213C.

I can see how problem #1 might be laser / transport related, but doesn't #2 seem more likely to be circuit related?

Any suggestions as to cleaning the lens? Q-tip and alcohol? I'll clean and re-grease. What's the suggested lube, white lithium?

Thanks for the help!!

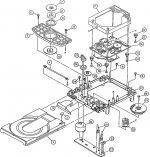

Ok, the lens looked clean but I gave it a wipe anyway. Connected it up to the stereo with the case still apart and it started out with the common tray in/out leaf switch problem. I've never had that problem :-( Anyway got it to load and part way through the first track it skipped. I'm still on the same disc and it hasn't skipped again yet. I did notice the yoke (#7 in picture) seems to have a very slight wobble.

I'll see if I can find a disc that skips more frequently to see if the yoke wobbles more.

I'll see if I can find a disc that skips more frequently to see if the yoke wobbles more.

Attachments

The wobble is be normal as it's a magnetic clamp that centres loosely on the disc.

Problems with grease can be hardening in the teeth of the gears. You need a grease that's compatable with metals and plastics, everyone seems to have their favourites, mine was always,

ELECTROLUBE|SPG35SL|SPECIAL PLASTICS GREASE 35ML | CPC

Always starting on track 6 is down to the player electronics... you would have to ask other users if they do this or not. Electronics are supremely reliable so wouldn't like to say that is a fault at all.

Problems with grease can be hardening in the teeth of the gears. You need a grease that's compatable with metals and plastics, everyone seems to have their favourites, mine was always,

ELECTROLUBE|SPG35SL|SPECIAL PLASTICS GREASE 35ML | CPC

Always starting on track 6 is down to the player electronics... you would have to ask other users if they do this or not. Electronics are supremely reliable so wouldn't like to say that is a fault at all.

Although it is pretty rare on that mech, you should check that the final drive gear to the laser has no broken/bent teeth. On the earlier mechs for KSS210/150, the gear teeth that mate with the laser gear rack would break, due to the spring tension from the upper gear rack over-stressing them. Quick & effective fix, with just a slight sacrifice to 'bump resistance', is to simply remove the upper rack & spring from the laser. While you have the final drive gear off, you should check that the laser moves freely & easily all the way up & down the rails. If you encounter unusual resistance at any point, that'll be a problem to address.

The other & more likely cause for the skipping is carbon build-up in platter and/or sled motor, which can be easily & pretty darn near permanently cured with (specifically)silicone spray lub. You just have to access the slots in the bottom end of each motor to spray the lub into, which, I believe, in your case, means de-soldering the small pcb from the two motors' terminals. One you have slots access, just give a healthy shot of silicone lub into each motor, re-assemble & then play a disc, doing a lot of first to last track skipping to excersize the sled motor. Once each motor has a few minutes of fast running, you're good to go for years.

The other & more likely cause for the skipping is carbon build-up in platter and/or sled motor, which can be easily & pretty darn near permanently cured with (specifically)silicone spray lub. You just have to access the slots in the bottom end of each motor to spray the lub into, which, I believe, in your case, means de-soldering the small pcb from the two motors' terminals. One you have slots access, just give a healthy shot of silicone lub into each motor, re-assemble & then play a disc, doing a lot of first to last track skipping to excersize the sled motor. Once each motor has a few minutes of fast running, you're good to go for years.

Played several CD's today with the case open and it never skipped. A few times it did make a grind noise when play was first pressed.

I did notice that split rack on the laser when I was poking around. Wouldn't it be better to epoxy the two racks for more surface area rather than removing the upper? I didn't see any damaged teeth on the rack or gear.

How hard is it to find a new transport? Or at least some kind of rebuild kit? I'll clean off all the grease and lube it again. I just need to find someone locally that has the appropriate grease.

Thanks

I did notice that split rack on the laser when I was poking around. Wouldn't it be better to epoxy the two racks for more surface area rather than removing the upper? I didn't see any damaged teeth on the rack or gear.

How hard is it to find a new transport? Or at least some kind of rebuild kit? I'll clean off all the grease and lube it again. I just need to find someone locally that has the appropriate grease.

Thanks

If that 'grinding' noise before play was more like a creeking, it's pretty much proof positive that you just need to silicone spray the platter motor, which is what I considered the most likely cause. So, if you just go to an auto-parts store, you should find a silicone spray lub that will fix it right up. The creeking noise is a classic symptom of a platter motor having difficulty starting up.

Although I have never seen one of those mechs actually need replacing, I am fairly sure it's entirely just a stock Sony KSM213CCM, or a slightly different number. Been too long since I've worked on that series of Rotel players to remember specifically, but your exploded view looks exactly like the above number. Should be available pretty cheaply, including laser, from dalbani.com or dalbani.co.uk, or other oem suppliers. But doing the silicone treatment to the motors will make replacement a non-issue, anyway, I am quite sure.

As for the gear rack, the counter-sprung upper is just for the sake of reducing skips from the player getting bumped, and is a 'vestigial organ' from Sony's old discmans. There's no need for the extra gear width, and the player will work perfectly fine without it, although, as you have now observed, it hasn't done any harm to the drive gear and probably won't.

Although I have never seen one of those mechs actually need replacing, I am fairly sure it's entirely just a stock Sony KSM213CCM, or a slightly different number. Been too long since I've worked on that series of Rotel players to remember specifically, but your exploded view looks exactly like the above number. Should be available pretty cheaply, including laser, from dalbani.com or dalbani.co.uk, or other oem suppliers. But doing the silicone treatment to the motors will make replacement a non-issue, anyway, I am quite sure.

As for the gear rack, the counter-sprung upper is just for the sake of reducing skips from the player getting bumped, and is a 'vestigial organ' from Sony's old discmans. There's no need for the extra gear width, and the player will work perfectly fine without it, although, as you have now observed, it hasn't done any harm to the drive gear and probably won't.

It definitely was the gears grinding.

I thought it would be easier to just replace the whole mechanism. After some internet searching, it appears the ksl2130CCM mechanism is no longer manufactured. Prices from the few places that have them are crazy. Hopefully the lube job will keep it together for a few more years.

I thought it would be easier to just replace the whole mechanism. After some internet searching, it appears the ksl2130CCM mechanism is no longer manufactured. Prices from the few places that have them are crazy. Hopefully the lube job will keep it together for a few more years.

if by platter motor, you mean the motor that spins the disc (some of us also know it as spindle motor), best to just replace now while the machine is open if it's misbehaving. it will only get worse - lubricating would only temporarily mask the symptoms. it's probably a cheap mabuchi motor with worn down brushes.

the RCD-971 is a nice sounding machine and deserves to be well treated.

🙂

mlloyd1

the RCD-971 is a nice sounding machine and deserves to be well treated.

🙂

mlloyd1

Only reason I can think of to hear actual gear grinding on play start is if the EF balance is far enough off to cause the laser to back track while searching for track start so abruptly that it runs into home position. See my posts under 'cd alignments' about that. Improper ef balance can also cause intermittent skipping, since the slightest disturbance to the tracking will cause the laser to inaccurately hunt for it's previous location. If, however, the 971 uses a philips servo controller, rather than a Sony controller, there may not be any servo adjustments, so laser replacement is the only cure for such minor issues.

Dalbani.com is showing stock on the KSM213CCM, for only $8.25 each, but doesn't say it includes the laser, and I doubt it does, but they also have the lasers really cheap.

As for motor lubrication, in answer to mlloyd, you are not correct. I have been servicing cd players since 1984, and silicone-treated probably well over a thousand platter & sled motors of exactly this sort, and never ONCE had one give a problem ever again. The action is that the solvent/oil base of the silicone spray helps the motor dislodge it's tiny carbon deposits from the commutator & then leaves behind a silicone film to prevent further buildup. There are some motors that don't respond well to this, like the nylon-back motors used in the Yamaha players, but every one of the metal-back motors of the sort used by Sony, Pioneer & etc. have uniformly been permanently cured by silicone treatment. Works wonderfully well for Nakamichi tape deck mode drive motors, too, though not on the reel drive motors.

Dalbani.com is showing stock on the KSM213CCM, for only $8.25 each, but doesn't say it includes the laser, and I doubt it does, but they also have the lasers really cheap.

As for motor lubrication, in answer to mlloyd, you are not correct. I have been servicing cd players since 1984, and silicone-treated probably well over a thousand platter & sled motors of exactly this sort, and never ONCE had one give a problem ever again. The action is that the solvent/oil base of the silicone spray helps the motor dislodge it's tiny carbon deposits from the commutator & then leaves behind a silicone film to prevent further buildup. There are some motors that don't respond well to this, like the nylon-back motors used in the Yamaha players, but every one of the metal-back motors of the sort used by Sony, Pioneer & etc. have uniformly been permanently cured by silicone treatment. Works wonderfully well for Nakamichi tape deck mode drive motors, too, though not on the reel drive motors.

I'll check your balance postings. Ran it all day today (case is still open) and no skipping or grinding. I'm afraid to touch it now 🙂

According to the service manual the transport is KSL-2130CCM but I'll see if there's anything on the unit itself. The laser is a KSS-213C and they are relatively cheap.

Thanks

According to the service manual the transport is KSL-2130CCM but I'll see if there's anything on the unit itself. The laser is a KSS-213C and they are relatively cheap.

Thanks

I've replaced several 971 laser assys recently. KSM-2130CCM is the correct unit, and includes the laser. Most all of the replacement assys are Chinese which is not a big problem, but the QC is not very good. One replacement had a disc platter with so much runout that the laser could not keep up. Another one had physical interference problems towards the outer travel limits of the laser. Easy enough to fix but worth noting. MCM Electronics still lists the OEM Sony assy as being in stock for around $40. The Chinese units usually go for around $15.

Of the ones I worked on, two had spindle motor bearing problems, basically just worn out.

Of the ones I worked on, two had spindle motor bearing problems, basically just worn out.

KSM-2130, really? Guess the service manual is wrong. Not unheard of though, I just started going through my PSA-2 and the service manual is so far off on some of the voltages its just not funny.

I must be doing something wrong. I just searched MCM and can't find the KSM-2130. They do show KSM-213. Is the 213 the same as 2130? I'd prefer OEM, but in case I can't find it, where do you get the Chinese version?

Thanks

I must be doing something wrong. I just searched MCM and can't find the KSM-2130. They do show KSM-213. Is the 213 the same as 2130? I'd prefer OEM, but in case I can't find it, where do you get the Chinese version?

Thanks

Last edited:

ok, I just took apart the mechanism. It IS the KSM213CCM. Thats what stephensank has been saying all along!

I see there seem to be several flavors of the KSM213. Should I only get the CCM or is there an updated unit?

Thanks!

I see there seem to be several flavors of the KSM213. Should I only get the CCM or is there an updated unit?

Thanks!

If the disc platter's runout is high, is that fixable? I got a MCM "OEM" KSS213CCM that seems to have a lot of runout. Could be a bad unit.

Just to pipe up and mention that my RCD-971 was recently repaired by Bill Fuss and he did a fantastic job, especially since my ham-fisted initial efforts at repairing it had made things considerably worse. I had the leaf switch problem amongst others and Bill replaced them as well as the laser assembly, switches, belt and also modded it. It now sounds wonderful and works perfectly.

A great job and really appreciated!

I'll go back to lurking now........

A great job and really appreciated!

I'll go back to lurking now........

KSM-2130, really? Guess the service manual is wrong. Not unheard of though, I just started going through my PSA-2 and the service manual is so far off on some of the voltages its just not funny.

I must be doing something wrong. I just searched MCM and can't find the KSM-2130. They do show KSM-213. Is the 213 the same as 2130? I'd prefer OEM, but in case I can't find it, where do you get the Chinese version?

Thanks

You are right, I put in the zero for some unknown reason. Google will give you plenty of hits for the imports.

The disc platter can be damaged pretty easy if you lay the assy upside down on the bench and apply any amount of weight to it. The steel will separate from the plastic slightly, causing the disc to wobble. If it's not too bad you can usually tweak it back into shape if you are patient.

- Status

- Not open for further replies.

- Home

- Source & Line

- Digital Source

- Rotel RCD-971 Issues