I'll apologize in advance if this has been discussed somewhere in the previous 200+ pages. I haven't made it through all of them yet.

I began to notice a rhythmic rumble during quiet passages with my TD 124. The noise is synchronous with each revolution of the idler wheel. The idler wheel is original as far as I know. The noise is present and can be heard with a stethoscope with platter removed. The noise is present using a new idler from Audie Silente. There is no visible sign of wear on the idler spindle. There is one nylon washer present on the idler spindle.

Since the noise is synchronous with the idler movement, I suspect the idler side rather than the step pulley.

Since the noise is present with both idler wheels I suspect either the spindle or the washer. Or perhaps there should be more than just the nylon washer present as my manual suggests a fibre washer or two should be present as well.

Any help would be appreciate.

Thanks

I began to notice a rhythmic rumble during quiet passages with my TD 124. The noise is synchronous with each revolution of the idler wheel. The idler wheel is original as far as I know. The noise is present and can be heard with a stethoscope with platter removed. The noise is present using a new idler from Audie Silente. There is no visible sign of wear on the idler spindle. There is one nylon washer present on the idler spindle.

Since the noise is synchronous with the idler movement, I suspect the idler side rather than the step pulley.

Since the noise is present with both idler wheels I suspect either the spindle or the washer. Or perhaps there should be more than just the nylon washer present as my manual suggests a fibre washer or two should be present as well.

Any help would be appreciate.

Thanks

I think I've answered my own question here. After removing the spindle I see some very slight wear marks. I intend to polish the spindle and reinstall it upside down, then replace the original nylon washer with a teflon washer of the same size. I suspect this will reduce the noise I was hearing.

Let us know whether that resolves the issue. I believe yours is the first comment on this particular issue. Can you snap and post a couple of before and after photos as that may help others to understand what the acceptable wear limit might be.

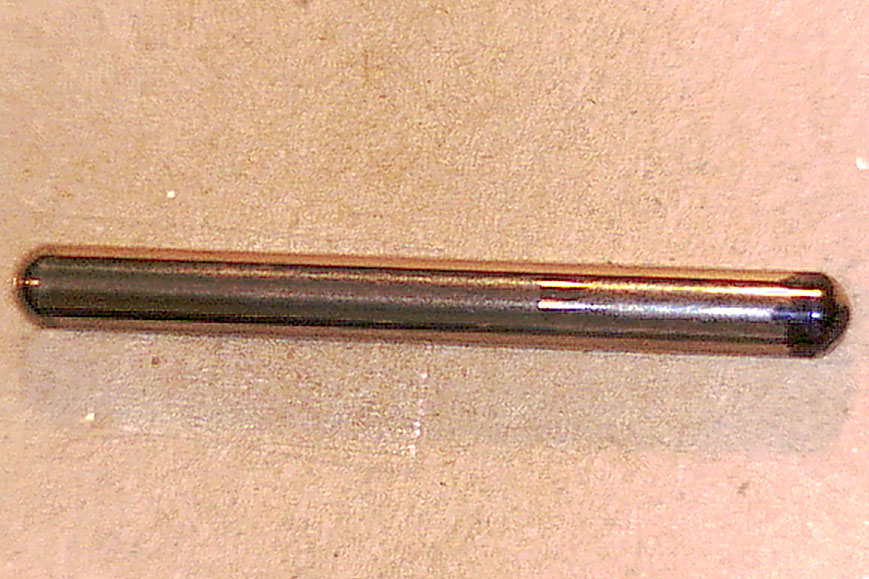

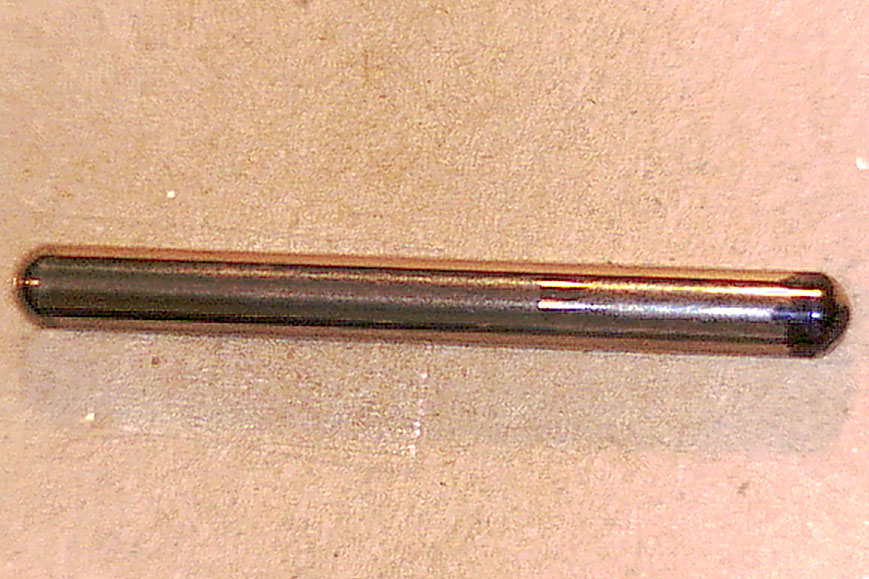

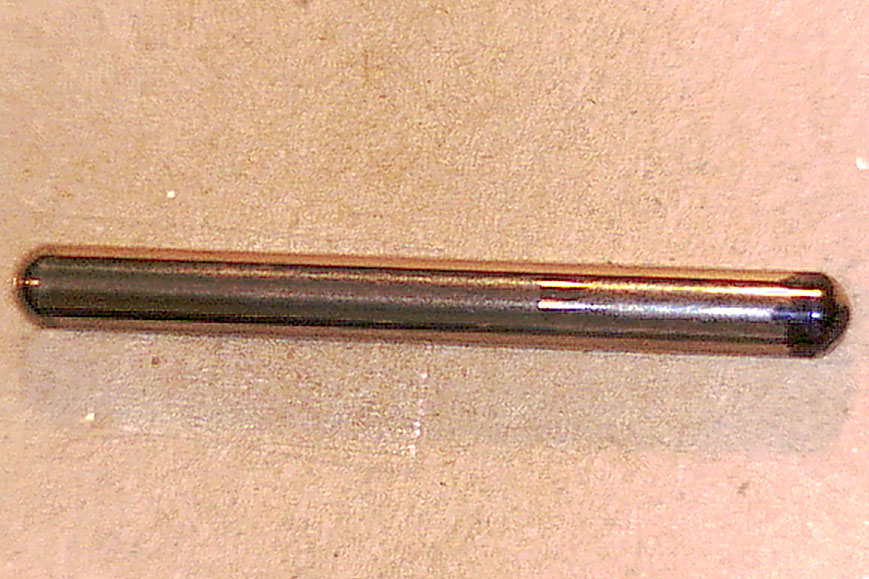

Here are a few photos. Not the best. The first photo shows the entire pin, which is symmetrical, allowing one to flip it over, which I intend to do. You can see the wear marks approximately 17mm from the end. I've marked the tip with felt marker so I know to polish the other end.

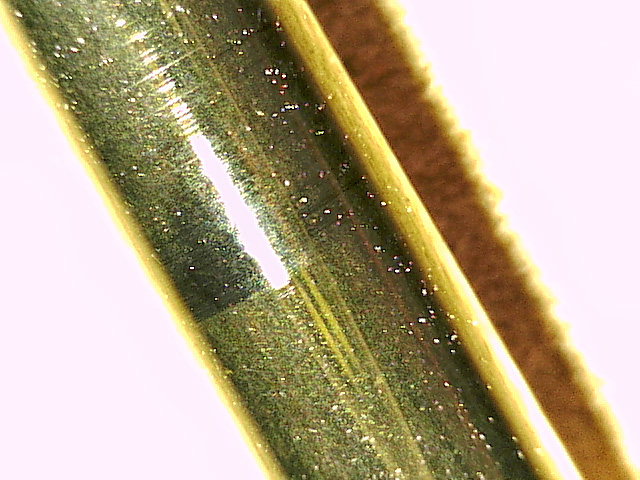

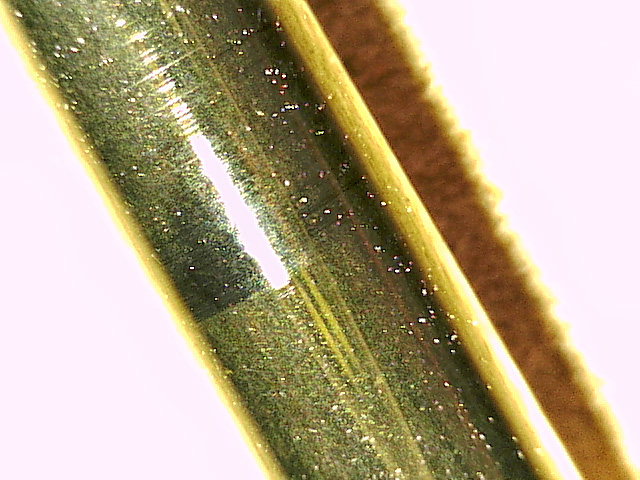

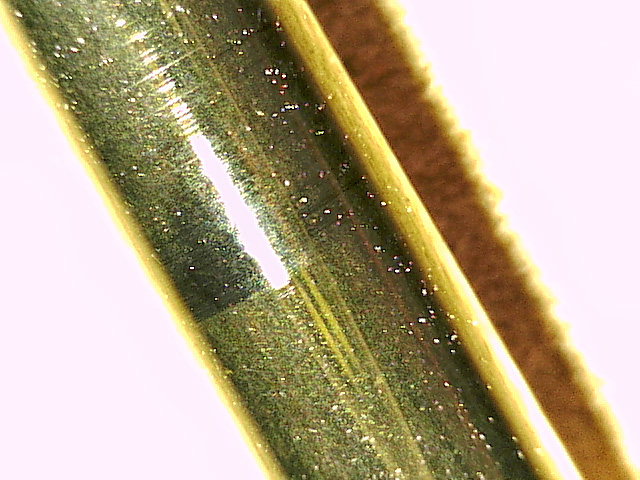

The next two images show a little closer view. Again, not the best photos.

I'm unable to measure this wear accurately with my calipers, but it's obviously present.

The next two images show a little closer view. Again, not the best photos.

I'm unable to measure this wear accurately with my calipers, but it's obviously present.

Here are a few photos. Not the best. The first photo shows the entire pin, which is symmetrical, allowing one to flip it over, which I intend to do. You can see the wear marks approximately 17mm from the end. I've marked the tip with felt marker so I know to polish the other end.

The next two images show a little closer view. Again, not the best photos.

I'm unable to measure this wear accurately with my calipers, but it's obviously present.

I think those photos indicate something symptomatic of a larger issue.

First thing I'd check would be that inner flywheel for eccentricity issues. I bring this up because I've seen that the non-magnetic zamac platter, more commonly seen on the mkII models does not self-align during assembly. They need to be indicated in before tightening the screws all the way.

-Steve

Steve,

Since this is out of a mkII with a zamac platter, I'll be sure to pay close attention to inner flywheel runout during reassembly.

Since this is out of a mkII with a zamac platter, I'll be sure to pay close attention to inner flywheel runout during reassembly.

I meant to respond to your first post ,that I have in quotes above, with regard to the concentricity issue I suggest.I began to notice a rhythmic rumble during quiet passages with my TD 124. The noise is synchronous with each revolution of the idler wheel. The idler wheel is original as far as I know. The noise is present and can be heard with a stethoscope with platter removed. The noise is present using a new idler from Audie Silente. There is no visible sign of wear on the idler spindle. There is one nylon washer present on the idler spindle.

Since the noise is synchronous with the idler movement, I suspect the idler side rather than the step pulley.

Since the noise is present with both idler wheels I suspect either the spindle or the washer. Or perhaps there should be more than just the nylon washer present as my manual suggests a fibre washer or two should be present as well.

As to the wear marks on that idler wheel axle, that is obvious wear and indicates a probable lack of lube during operation for quite some time. The bushings in the idler wheel are suspect. your idea to turn the axle upside down seems fine to me. It will provide a new unworn surface for a new bushing to run on. That said, the wear seen does Indicate that a replacement of the entire wheel is the next step.

For idler wheels there are a few sources to choose from.

A few different sellers are offering silicone O-ring wheels. I'm trying one from AudioSilente shortly when it arrives tomorrow. However for a new oem replacement Schopper has a nice one.

Above is a photo of one of these Schopper wheels I installed to a TD124 last summer. I was impressed with the quality of the wheel. It spun true for concentricity (as needs to be) and also for vertical runout which many oem wheels sometimes do not.

Price was in the "not cheap" category but I think worth it for someone wanting to put one back together as the factory built it.

Included with the 'kit' was their "Idler Wheel Noise Reduction Kit" which is composed of a plastic cup that fits snug over the axle to form a seal and holds a supply of lube beneath the wheel as it operates. And a thrust washer is put in place directly over the axle in the cup. Plus a small vial of Schopper's lube. The negative to that kit is that if you pick the turntable up and tilt it too much the lube will spill out the cup and get oil all over the idler wheel and inner rim of the flywheel. and that is bad, bad, bad. So it goes with a caution. Otherwise the "kit" looks ok to me.

-Steve

Steve,

I already have an idler wheel from Simone on hand. I was tempted by the newly minted Schopper idlers, as well as the oem idlers they still have on hand, but as you know, these are pretty expensive. It may happen yet, but I'm going to give this Audio Silente idler a try first.

My impression is that Simone favors the silicone o-ring over the black rubber o-ring. He described it as resulting in more bass and dynamics. I guess I'll have to decided which one to use soon.

I was assuming after you suggested the lack of concentricity of the flywheel as a source for this wear that it probably happened before I got the table. I have a tool for measuring runout, and I'll make sure I'm particularly particular about this aspect of reassembly.

The spindle has been cleaned, polished, and reinstalled upside down. The nylon washer showed asymmetrical wear on both sides, so I'm going to replace it with a teflon washer, which should arrive in a few days.

I already have an idler wheel from Simone on hand. I was tempted by the newly minted Schopper idlers, as well as the oem idlers they still have on hand, but as you know, these are pretty expensive. It may happen yet, but I'm going to give this Audio Silente idler a try first.

My impression is that Simone favors the silicone o-ring over the black rubber o-ring. He described it as resulting in more bass and dynamics. I guess I'll have to decided which one to use soon.

I was assuming after you suggested the lack of concentricity of the flywheel as a source for this wear that it probably happened before I got the table. I have a tool for measuring runout, and I'll make sure I'm particularly particular about this aspect of reassembly.

The spindle has been cleaned, polished, and reinstalled upside down. The nylon washer showed asymmetrical wear on both sides, so I'm going to replace it with a teflon washer, which should arrive in a few days.

Last edited:

I was assuming after you suggested the lack of concentricity of the flywheel as a source for this wear that it probably happened before I got the table. I have a tool for measuring runout, and I'll make sure I'm particularly particular about this aspect of reassembly.

I did not mean to give that impression. Just to note that when you suggest a synchronous repeating noise, that that is a definite indication to a concentricity issue.

the wear on the axle is from a separate cause; lube being the first thing to check.

-Steve

Okay.

The repeating noise is present with the flywheel removed. I can watch the idler and see that the noise is synchronous with it's movement. I assume and hope this is the same noise I was hearing during playback. It's the same frequency, but obviously the source could also be the idler/flywheel interface.

I'll find out in a few days.

The repeating noise is present with the flywheel removed. I can watch the idler and see that the noise is synchronous with it's movement. I assume and hope this is the same noise I was hearing during playback. It's the same frequency, but obviously the source could also be the idler/flywheel interface.

I'll find out in a few days.

Okay.

The repeating noise is present with the flywheel removed. I can watch the idler and see that the noise is synchronous with it's movement. I assume and hope this is the same noise I was hearing during playback. It's the same frequency, but obviously the source could also be the idler/flywheel interface.

I'll find out in a few days.

Then there is something going on with that idler wheel. Perhaps it is bent?

You could observe it while running and see if there were a flat spot on the tire part of it. or..... observeable runout as it drives against the stepped idler wheel?

-Steve

The noise is present with both the original idler and the Audio Silente idler. The only thing left is the worn spindle and/or the worn washer. Once I have the new washer I'll install the Audio Silente idler and check again with the stethoscope. I'm expecting an improvement because I can't think of anything else it could be.

If this solves the problem, I'll likely abandon the original idler.

If this solves the problem, I'll likely abandon the original idler.

Last edited:

I wonder if end float of the idler, or the drive to the idler, could be the cause of the noise?

I wonder if end float of the idler, or the drive to the idler, could be the cause of the noise?

Yes the steppuley bearing is also suspect for noise same as the belt but this noise you hear as a noisy sound , not a rumbling low freq. sound.

The noise is present with both the original idler and the Audio Silente idler. The only thing left is the worn spindle and/or the worn washer. Once I have the new washer I'll install the Audio Silente idler and check again with the stethoscope. I'm expecting an improvement because I can't think of anything else it could be.

If this solves the problem, I'll likely abandon the original idler.

Is it possible you are expecting too much from an idler wheel deck, they have always been rumbly? That is why many amplifiers of the day had rumble filters.

Is it possible you are expecting too much from an idler wheel deck, they have always been rumbly? That is why many amplifiers of the day had rumble filters.

You are right they are more noisy then belt drives but we try to get them as quiet as possible !

Is it possible you are expecting too much from an idler wheel deck, they have always been rumbly? That is why many amplifiers of the day had rumble filters.

No.

My expectations are reasonable.

Last edited:

I wonder if end float of the idler, or the drive to the idler, could be the cause of the noise?

The noise is synchronous with the rotation of the idler wheel regardless of which speed is chosen. This should rule out the step pulley as the source.

I have several spare vintage idlers, and at least two of them tick, and in one case that it is due to some issue with the rubber hardening locally, possibly the idler left engaged for years - not a classic flat spot, but the it does not run smoothly over it either. Can't see anything obvious, but you can feel a difference in the rubber at that spot.

A very slight warp in the idler such that it hits the step pulley during rotation can also cause this irritating noise. I have one of these too! (Can adjust idler height such that it causes no noise, but I have better ones which I use instead.)

I have one of Simone's idlers and it works quite well.

A very slight warp in the idler such that it hits the step pulley during rotation can also cause this irritating noise. I have one of these too! (Can adjust idler height such that it causes no noise, but I have better ones which I use instead.)

I have one of Simone's idlers and it works quite well.

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII