Should that not be 120V (the strobe light is fed from one 110V coil)? Anyway I have ordered one so we shall have to see.

My TD 124/II restoration

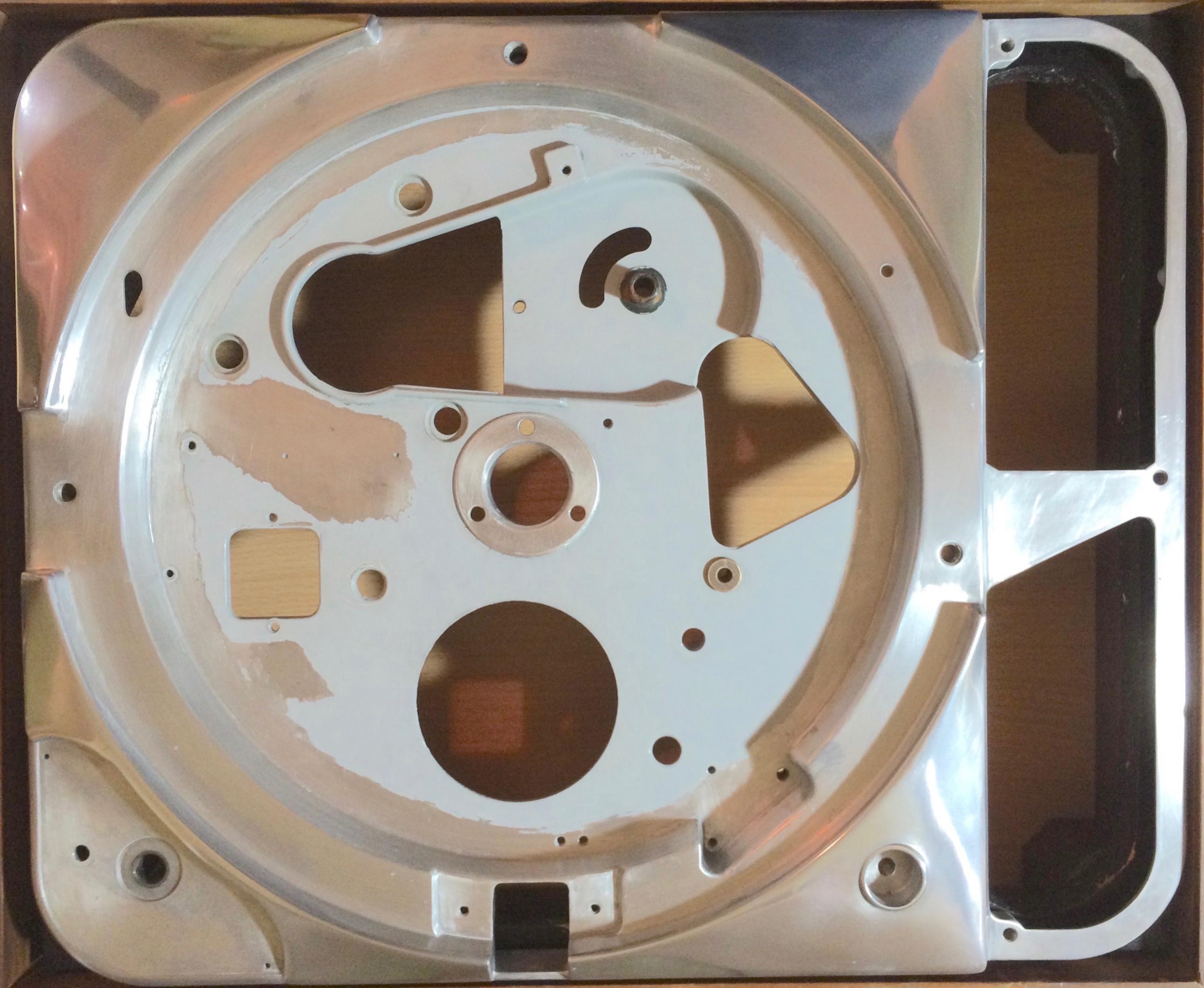

It's been quite awhile since I posted anything here about my own little project, the only TD 124 I've ever worked on. Everyone here, thanks so much for your help. Most of what I learned came from you. The current status is awaiting shipment of the SPU for the SME 3012 arm (payment tomorrow!). A panzerholtz arm board has already been purchased. I have a pair of SUTs, but might not be a good match, so that's got to be resolved. If I could find a set of templates for each "lift" of a birch plywood plinth, I'd work on that right quick, as it's the last piece of the puzzle. Here are some photos of the turntable, still in the service jig I made for the project. The paint is Dupont Aviation blue pearl

It's been quite awhile since I posted anything here about my own little project, the only TD 124 I've ever worked on. Everyone here, thanks so much for your help. Most of what I learned came from you. The current status is awaiting shipment of the SPU for the SME 3012 arm (payment tomorrow!). A panzerholtz arm board has already been purchased. I have a pair of SUTs, but might not be a good match, so that's got to be resolved. If I could find a set of templates for each "lift" of a birch plywood plinth, I'd work on that right quick, as it's the last piece of the puzzle. Here are some photos of the turntable, still in the service jig I made for the project. The paint is Dupont Aviation blue pearl

Attachments

It's been quite awhile since I posted anything here about my own little project, the only TD 124 I've ever worked on. Everyone here, thanks so much for your help. Most of what I learned came from you. The current status is awaiting shipment of the SPU for the SME 3012 arm (payment tomorrow!). A panzerholtz arm board has already been purchased. I have a pair of SUTs, but might not be a good match, so that's got to be resolved. If I could find a set of templates for each "lift" of a birch plywood plinth, I'd work on that right quick, as it's the last piece of the puzzle. Here are some photos of the turntable, still in the service jig I made for the project. The paint is Dupont Aviation blue pearl

That looks really nice. Your arm/cartridge plan should result in stunning SQ, I'd think.

re: plinths:

My first TD124 plinth came with the first basket case I bought. (sn 2729). It had one of those really common open box plywood jobs. (3/4" plywood) I tried it with mushrooms and heard a TD124 for the first time in my system. I was impressed with the amount of visceral energy I was getting from records I already thought I knew.

Since then I've tried heavy slate, a variety of birch ply stack-up plinths and now I'm listening again to an open box plinth while using a new set of mushrooms from Audiosilente. Each was a different flavor. But I do like what I hear when using mushrooms in a sturdy open box style plinth. Fwiw, it is the original design from that Thorens designer who dreamed up the TD124 in the first place.

-Steve

Should that not be 120V (the strobe light is fed from one 110V coil)? Anyway I have ordered one so we shall have to see.

I've used the 110-120 vac bulbs with no problem. Because that is the voltage I'm feeding the TD124. Anyone in Europe operating on 240 vac may find they need the higher voltage rated bulb. Intuition.

-Steve

That looks really nice. Your arm/cartridge plan should result in stunning SQ, I'd think.

re: plinths:

My first TD124 plinth came with the first basket case I bought. (sn 2729). It had one of those really common open box plywood jobs. (3/4" plywood) I tried it with mushrooms and heard a TD124 for the first time in my system. I was impressed with the amount of visceral energy I was getting from records I already thought I knew.

Since then I've tried heavy slate, a variety of birch ply stack-up plinths and now I'm listening again to an open box plinth while using a new set of mushrooms from Audiosilente. Each was a different flavor. But I do like what I hear when using mushrooms in a sturdy open box style plinth. Fwiw, it is the original design from that Thorens designer who dreamed up the TD124 in the first place.

-Steve

Thanks, Steve. The plinth I have is one of the original open box plywood jobs. Nice that on mine the mounting board lifts right out, so I can use it as a template. I'm sticking with the mushrooms too - new set - my originals, thanks to Arizona desert heat were totally crushed. I figured stacked birch plywood would do me pretty well for the first try at least. The arm, resting comfortably in a drawer and SPU are courtesy of one of the usual suspects here. He can wave if he wants!

Really itching to get this up and running. It's been years since it made music, so very, very overdue.

Sorry I had a brain infarction and needed to delete my previous post.

I've attached (IIRC) an original Thorens schematic for the neon lamp and motor wiring in the MKII. (It's long out of copyright)

The neon lamp should see approximately 120V in series with a current limiting 33K 1W resistor. Any similar lamp intended for operation on 120V with a series resistor should work fine. (You can change the resistor if required by the lamp you are going to use.)

I've attached (IIRC) an original Thorens schematic for the neon lamp and motor wiring in the MKII. (It's long out of copyright)

The neon lamp should see approximately 120V in series with a current limiting 33K 1W resistor. Any similar lamp intended for operation on 120V with a series resistor should work fine. (You can change the resistor if required by the lamp you are going to use.)

Attachments

Thanks, Steve. The plinth I have is one of the original open box plywood jobs. Nice that on mine the mounting board lifts right out, so I can use it as a template. I'm sticking with the mushrooms too - new set - my originals, thanks to Arizona desert heat were totally crushed. I figured stacked birch plywood would do me pretty well for the first try at least. The arm, resting comfortably in a drawer and SPU are courtesy of one of the usual suspects here. He can wave if he wants!

Really itching to get this up and running. It's been years since it made music, so very, very overdue.

Here's my current setup:

It was down for all of July while I worked on other TD124's and sold off my TD124 #7888. 7888 sold with one of my baltic birch plinths, so that left me with the one seen.

As it is, I'm very happy with my last remaining TD124...sn#13943. It has no paint because.....'it don't need no stinkin' paint'.

There is something to be said for going the 'mushroom route'. 13943 is sounding rather muscular right now. Or maybe I'd had time to forget what a TD124 is supposed to sound like. Anyway, this is the one I keep.

-Steve

Here's my current setup:

It was down for all of July while I worked on other TD124's and sold off my TD124 #7888. 7888 sold with one of my baltic birch plinths, so that left me with the one seen.

As it is, I'm very happy with my last remaining TD124...sn#13943. It has no paint because.....'it don't need no stinkin' paint'.

There is something to be said for going the 'mushroom route'. 13943 is sounding rather muscular right now. Or maybe I'd had time to forget what a TD124 is supposed to sound like. Anyway, this is the one I keep.

-Steve

Looks great, Steve. Like the plinth. As for no paint, I'd already set things up with a decent shop here by the time I got mine stripped to this point - but did think the same thing. Perhaps a bead blast, but I did like the high polish I had at the time.

Attachments

Looks great, Steve. Like the plinth. As for no paint, I'd already set things up with a decent shop here by the time I got mine stripped to this point - but did think the same thing.

Perhaps a bead blast, but I did like the high polish I had at the time.

Yep. The evidence is pretty much layed bare..😀 It could have worked...but the pearl blue looks trick and will compliment all that silvery metal on the SME.

-Steve

Hello Missouricatman,

I could send you some tracings for the plinth if you want. I also have CAD drawings if you have access to a CNC.

Jim

I could send you some tracings for the plinth if you want. I also have CAD drawings if you have access to a CNC.

Jim

Hello,

I could send you some tracings for the plinth if you want. I also have CAD drawings if you have access to a CNC.

Jim

Jim, that's a great offer. I'm afraid I'm stuck with a trusty jigsaw. Tracings would be a great help. I know I also need to work out the depth for each lift, so I know how many layers to do before switching templates. Are the tracings something you could send to me as files here so I can print out or do need to mail hard copies?

Jim

Hi Jim,

I use Baltic birch plywood-3/4", I think actually 23/32. Using this material I use one layer for each of the four templates. If you go to this site, Free CAD Design Software | eMachineShop, and download the free software I can send you the drawings and you can print 1:1.

Best,

Jim

I use Baltic birch plywood-3/4", I think actually 23/32. Using this material I use one layer for each of the four templates. If you go to this site, Free CAD Design Software | eMachineShop, and download the free software I can send you the drawings and you can print 1:1.

Best,

Jim

Hi Jim,

I use Baltic birch plywood-3/4", I think actually 23/32. Using this material I use one layer for each of the four templates. If you go to this site, Free CAD Design Software | eMachineShop, and download the free software I can send you the drawings and you can print 1:1.

Best,

Jim

Jim

I'm on a Mac & not running any emulation, but in Kansas City there are plenty of places that should be able handle 1:1 printout from your CAD files. if there isn't a way to sent attachments to me via DM here I can send you an addy via DM.

Thanks so much.

Jim

Jim

I'm on a Mac & not running any emulation, but in Kansas City there are plenty of places that should be able handle 1:1 printout from your CAD files. if there isn't a way to sent attachments to me via DM here I can send you an addy via DM.

Thanks so much.

Jim

I don't mind sharing the CAD files so I will try to attach. Exterior dimensions should come out to 16.25" x 13.5". Oh well, it appears that the DXF file extension is not supported here.

Best,

Jim

Hi Jim,

I would certainly also like the cad-files. I can take them to a local stone cutter to have a slate plinth made!!

It is very generous of you, BTW.

I would certainly also like the cad-files. I can take them to a local stone cutter to have a slate plinth made!!

It is very generous of you, BTW.

Hi Jim,

I would certainly also like the cad-files. I can take them to a local stone cutter to have a slate plinth made!!

It is very generous of you, BTW.

I would be happy to send them but I can't seem to find a PM?

Best,

Jim

Are there any of you that have a diagram/picture of the way the fine speed adjustment works? THere's a guy in Denmark that needs, and I am sure that I saw pics of this a year or two ago....

Thanks Volken, Very much appreciated.

But that was not the end we need: We need a picture of the fine adjustment knob and the (disassembled) speed-change mechanism, i.e. the co-axial assembly in the front lefthand corner. My friend's TD124 seems to have all the parts, but it does not push the bar that moves the metal 'wings' under the step-pulley.

But that was not the end we need: We need a picture of the fine adjustment knob and the (disassembled) speed-change mechanism, i.e. the co-axial assembly in the front lefthand corner. My friend's TD124 seems to have all the parts, but it does not push the bar that moves the metal 'wings' under the step-pulley.

Thanks Volken, Very much appreciated.

But that was not the end we need: We need a picture of the fine adjustment knob and the (disassembled) speed-change mechanism, i.e. the co-axial assembly in the front lefthand corner. My friend's TD124 seems to have all the parts, but it does not push the bar that moves the metal 'wings' under the step-pulley.

Ok watch out for the small bronze ring is often overlooked or lost during revision work.

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII