Hi!

Fore note: This is a forum with a lot of hobbyists who provide a lot of free information. I also understand this request would take someone with knowledge time to come up with results, so I'm happy to compensate if requested. I simply don't have the time in my lifetime to learn the dark arts of audio wizardry 🙁

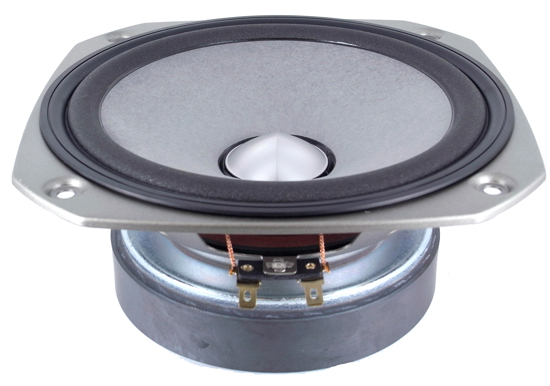

Aim: I would like to rebuild some full range FE168EZ sigmas BLH cabinets. Not like the Fostex recommended cabinets I built a decade ago. Just nice curves and smooooooth surfaces everywhere using CAD & a 4x8ft CNC.

Objectives:

1. Build a Full range BLH unless there's a better recommendation out there for this driver. Down to 50-70hz is good.

2. Have the driver set about 3.5ft/107cm up from the floor

3. I'd prefer having two identical horns come out from the back chamber. One eventually exiting at floor level, the other up top about 7ft/215cm high

4. The total horn mouth area to be less than 0.2sqm

5. Any audio reasons to not build these out of concrete or poured resins?

DATA (in metric or imperial is fine) I am seeking unless you suggest better alternatives:

1. Having a "Back Chamber" volume and shape similar to the B&W Nautilus

- I'd need A cross-sectional curve profile for a straight taper or a shape/equation curve to follow with a recommended volume for this chamber.

2. A suggestion for a good position of the throat/s relative to the back chamber.

- A simple sketch or descriptor

3. Total throat/s area and whether it needs a smooth or sharp transition from the back chamber.

- m^2

4. The length of the horn and either its curve plot or the cross-sectional area at regular intervals

- eg. Total cross-sectional areas at 10cm intervals

5. Is the cross-sectional shape of the horn best circular or eggshell or twisting eggshell to limit standing waves? When it reaches the horn mouth do I taper the cross-section out so it has a flat edge meeting the floor, or do I just continue with the same prior cross-section shape to finish facing forward?

- A simple sketch or descriptor

6. any internal/external features to add at the tip of the horn mouth like a rounded edge or a flat plane?

- A simple sketch or descriptor

7. any external features to add as the driver meets the back chamber such as a flat plane or chamfered surface?

- A simple sketch or descriptor

8. other bits of information that'll be useful?

Thanks for reading!

https://www.fostexinternational.com/docs/speaker_components/pdf/fe168ez.pdfhttps://www.fostexinternational.com/docs/speaker_components/pdf/recom_enclose/168ez_enclrev.pdf

Fore note: This is a forum with a lot of hobbyists who provide a lot of free information. I also understand this request would take someone with knowledge time to come up with results, so I'm happy to compensate if requested. I simply don't have the time in my lifetime to learn the dark arts of audio wizardry 🙁

Aim: I would like to rebuild some full range FE168EZ sigmas BLH cabinets. Not like the Fostex recommended cabinets I built a decade ago. Just nice curves and smooooooth surfaces everywhere using CAD & a 4x8ft CNC.

Objectives:

1. Build a Full range BLH unless there's a better recommendation out there for this driver. Down to 50-70hz is good.

2. Have the driver set about 3.5ft/107cm up from the floor

3. I'd prefer having two identical horns come out from the back chamber. One eventually exiting at floor level, the other up top about 7ft/215cm high

4. The total horn mouth area to be less than 0.2sqm

5. Any audio reasons to not build these out of concrete or poured resins?

DATA (in metric or imperial is fine) I am seeking unless you suggest better alternatives:

1. Having a "Back Chamber" volume and shape similar to the B&W Nautilus

- I'd need A cross-sectional curve profile for a straight taper or a shape/equation curve to follow with a recommended volume for this chamber.

2. A suggestion for a good position of the throat/s relative to the back chamber.

- A simple sketch or descriptor

3. Total throat/s area and whether it needs a smooth or sharp transition from the back chamber.

- m^2

4. The length of the horn and either its curve plot or the cross-sectional area at regular intervals

- eg. Total cross-sectional areas at 10cm intervals

5. Is the cross-sectional shape of the horn best circular or eggshell or twisting eggshell to limit standing waves? When it reaches the horn mouth do I taper the cross-section out so it has a flat edge meeting the floor, or do I just continue with the same prior cross-section shape to finish facing forward?

- A simple sketch or descriptor

6. any internal/external features to add at the tip of the horn mouth like a rounded edge or a flat plane?

- A simple sketch or descriptor

7. any external features to add as the driver meets the back chamber such as a flat plane or chamfered surface?

- A simple sketch or descriptor

8. other bits of information that'll be useful?

Thanks for reading!

https://www.fostexinternational.com/docs/speaker_components/pdf/fe168ez.pdfhttps://www.fostexinternational.com/docs/speaker_components/pdf/recom_enclose/168ez_enclrev.pdf

Scottmoose (Scott Lindgren) could probally do that, but he charges a fee for that (it's his profession).

A design he did for that driver is this: http://wodendesign.com/Victor.html

That site is also his website, but he is very active here also.

A design he did for that driver is this: http://wodendesign.com/Victor.html

That site is also his website, but he is very active here also.

Just nice curves and smooooooth surfaces everywhere

Some comments: This approach may look pretty but it is counterproductive.

How low the horn can go will depend on the horn mouth size. 2m2 is a 0.8m circle (max extention) > 5m circumference > 70 Hz. So if on the floor, 35 Hz, pushed against the wall, <20 Hz. Hope i got that right.

The current leading exising designs are Victor and Dallas II. Right on the edge, but FHXL works too. The Fostex recommended horns tend to be mediocre at best. The 1st 2 are horns are end-loaded with an initial air-cavity, the FHXL a tapped horn.

Do note that this driver wants to see a high Rout amplifier… what do you plan to use.

To expand on what waxx said, Scott (Woden) will do a custom design. This is by donations, and so far, only once has the donation covred all the work so Scott retains rights to the design. I will tell you that a “smmothly curved) BLH is not something he would tackle willingly.

dave

Hi Dave.Some comments: This approach may look pretty but it is counterproductive.

How low the horn can go will depend on the horn mouth size. 2m2 is a 0.8m circle (max extention) > 5m circumference > 70 Hz. So if on the floor, 35 Hz, pushed against the wall, <20 Hz. Hope i got that right.

The current leading exising designs are Victor and Dallas II. Right on the edge, but FHXL works too. The Fostex recommended horns tend to be mediocre at best. The 1st 2 are horns are end-loaded with an initial air-cavity, the FHXL a tapped horn.

Do note that this driver wants to see a high Rout amplifier… what do you plan to use.

To expand on what waxx said, Scott (Woden) will do a custom design. This is by donations, and so far, only once has the donation covred all the work so Scott retains rights to the design. I will tell you that a “smmothly curved) BLH is not something he would tackle willingly.

dave

thanks for the speedy reply.

- mouth size 0.2m^2 +/- some as yet undefined amount. If it were 2m^2 I’d need an auditorium to put it in!

- I’ve got a Cheap and simple SMSL D-class amp. I’ll maybe look to upgrade this only once I’ve upgraded the cabinets

- I’ll take a look over the weekend at the designs you’ve mentioned. What im hoping to find is the design both as the theoretical schematic showing the horn curve cross section, alongside a wooden cabinet plan that got built from that concept data.

- I work in CAD, rapid prototyping and surface modelling so once I have some numerical data and direction, the rest for me will be actually quite straightforward. If it ends up sounding good (or bad) at least I’ll have enjoyed the process.

- I did contact Scott some years ago but life things got in the way and my project concept got put on pause. Quite happy to open up another chat with him once I have a more succinct plan and hopefully constraints so I don’t unleash millions of new variables.

Last edited:

Altough that's a reasonable good amp, it's the type of amp you don't want for this or any fostex driver. Fostex drivers are build with high Rout amplifiers in mind, and those are class A or tube amps, not class D. It will make sound, but not the sound you expect as the damping is affected by the low Rout of the amplifier.

- I’ve got a Cheap and simple SMSL D-class amp. I’ll maybe look to upgrade this only once I’ve upgraded the cabinets

A cheaper good solution is the ACA kit from the shop on this site (but it requieres self assembly and knowledge about electronics).

I only have a moment, and what I'll quickly say more or less follows some of the above. However, for what it's worth:

- As Dave notes, smooth curves, while beneficial for midrange & HF horns, are in many ways counterproductive for bass horns, since they promote maximum efficiency at shorter wavelengths, i.e. the frequencies you don't want, while leaving the LF relatively unaffected.

- In a similar vein, given the terminus CSA limits and tunings noted, you're going to be using more resonant action over the operating BW than anything else, so the concerns over parallel surfaces, rounded lips to the termini &c. that would apply to an uncompromised / impedance matched horn don't really factor as significantly in this instance.

- The notes about the amplifier are fine; you can correct for that by using a high resistance speaker wire however. Thin (24ga - 30ga) is one solution, or you can move from the usual material suspects for the wire & shift to a higher resistance alternative. A power-resistor or resistor grid also works, but resistive wire is arguably a more elegant solution, and one Fostex themselves pulled 20 years ago at least one show.

it's the type of amp you don't want for this or any fostex driver.

To clarify. The most common Fostex drivers used arE168e∑. Personally i prefer it. It can use some simple tweaks (many the same as you do to FE168e∑ as well).

dave

mouth size 0.2m^2 +/- some as yet undefined amount.

Oops.

0.2m2 > 215 Hz. So if on the floor, 110 Hz, pushed against the wall, <55 Hz. 30 Hz if you push it into a corner.

This is an ideal situation.

dave

I work in CAD, rapid prototyping and surface modelling so once I have some numerical data and direction, the rest for me will be actually quite straightforward. If it ends up sounding good (or bad) at least I’ll have enjoyed the process.

Getting the numbers for the horn is part 1, and you need a proper modeler to get into the ballpark. But it is just a tool, and some experience really helps. The curve will also not give the whole story. The bends in the horn need to be modeled in to know what they do. A good designer will use them to their advantage.

dave

Good stuff. I’ll check it out and get a kit. I already like the sound of that other amp so if it is to get much better i can’t wait!

i work in subsea robotics so I don’t think assembly will be a big deal. The problem is having millions of options and not knowing where to start

i work in subsea robotics so I don’t think assembly will be a big deal. The problem is having millions of options and not knowing where to start

To raise or dampen certain frequencies? I can parametrise the model to try have flexibility in editing this aspect. Might get a bit messy but definitely possible

Another option is to replicate the curves as when they occur in the wooden cabinets, whilst changing the pathways from rectangular to circular/elliptical/egg?

Another option is to replicate the curves as when they occur in the wooden cabinets, whilst changing the pathways from rectangular to circular/elliptical/egg?

Last edited by a moderator:

In a bass horn a waste of time and could actually make things worse for the reasons Scott mentioned. Lose the idea of smooth curves. Those are useful in a front horn, a problem in a BLH.whilst changing the pathways from rectangular to circular/elliptical/egg

Youmay be able to do that in your CAD modeler, but they need to be in a TL Modeler and they do not support parametrization.I can parametrise the model

dave

I like solutions! going to order an ACA kit or two now! thanksAltough that's a reasonable good amp, it's the type of amp you don't want for this or any fostex driver. Fostex drivers are build with high Rout amplifiers in mind, and those are class A or tube amps, not class D. It will make sound, but not the sound you expect as the damping is affected by the low Rout of the amplifier.

A cheaper good solution is the ACA kit from the shop on this site (but it requieres self assembly and knowledge about electronics).

- Home

- Loudspeakers

- Full Range

- Requesting assistance for a Fostex FE168e∑ cabinet design

Thread moved to Full Range.

Thread moved to Full Range.