Why aren't regulated supplies used in power amps as often as in low level circuits or am I mistaken?

TIA

TIA

One reason is that to do a proper job of regulation with varying load current and input voltage, you need to drop quite a bit of power in the pass devices. So you need a whole second set of transistors and heat sinks.

It's done much more in the DIY world, where nothing is too big or too hot. Pass' Zen updates include a regulated power supply.

It's done much more in the DIY world, where nothing is too big or too hot. Pass' Zen updates include a regulated power supply.

My simplified answer:

It costs more than the consumer is willing to pay for the improvement.

/UrSv

It costs more than the consumer is willing to pay for the improvement.

/UrSv

This is turning into a perfect thread (order of replies):

1. Technical issues

2. Economic issues

3. Personal issues/interpretations

If all DIYaudio threads were like this, it would be awesome!

Petter

1. Technical issues

2. Economic issues

3. Personal issues/interpretations

If all DIYaudio threads were like this, it would be awesome!

Petter

Regulated supplies

To Regulate, or not to regulate........

I agree pretty much with the comments to date. Consumers won't pay for it, a lot of heat is produced, and there are other issues besides.

If you do decide to regulate the rails of a SS power amplifier, you must first choose series or shunt. Since shunt regulation consumes around double the power used by the amp module, most go for series. Of course, with vacuum tubes, where currents are much smaller and usually vary much less, shunt regulation is quite acceptable, though not much used in power stages.

Second, having settled on series regulation, you need to decide whether to use error correction (a feedback circuit) or emitter follower (no error correction at all). The former is complex, usually involves high levels of feedback with attendant problems of speed and overshoot, while the second is simple, but does not give very good regulation because the emitter resistance of the pass element increases with drawn current, giving a non-linear voltage reguation. However, this method has no issues of speed or overcorrection and is fine where current variations are small, for example in a preamplifier.

Like all these issues, design depends on environment and permissible levels of voltage sag. In a power amplifier, the current varies from quiescent, typically 50-100mA per rail, to an all out, head-banging 5A or more, depending on amp rating. This range is quite wide, and the regulation must be pretty good to avoid any kind of signal compression, which is usually audible as the regulation abruptly hits a brick wall. Given that global feedback PP SS amps can effectively compensate gracefully falling rail voltages within their feedback loop, you have to ask yourself if it is really necessary to incorporate an additional layer of complexity using expensive, high current transistors mandating even more expensive heatsinking. Good evidence of this is the perceived difficulty distinguishing sonic differences between a 300VA and a 1000VA transformer, given rectifiers, amp, source, speakers, cabling and filter caps which are identical.

OTOH, there are always exceptions, and in preamplifier circuitry I have found that series pass, emitter follower series regulator circuits give the best all round performance. I am heartened that Elso Kwak finds this too. Here, the sorts of differences I refer to have to do with imaging rather than dynamics; and this I cannot explain, except that the emitter follower series element would clearly offer capacitance multiplication, removing ALL ac from the line, thereby elimininating artefacts which might otherwise blur the delicate phase relationships responsible for good imaging.

I can see no advantage for regulating the rails of a Class A circuit; such amps have almost constant current draw, and a constant, heavy current on even a rudimentary supply gives very little voltage sag.

If you do go for regulation, it is important to design for speed to match the bandwidth of the amp. In this connection, an emitter follower has a natural advantage since it does not suffer Miller or overshoot effects, unlike the common emitter configuration. I liken this situation to a poorly designed power steering system on an automobile; an underrated pump, valving or ram system will not respond quickly enough to steering inputs; in a crisis, this could be fatal. 🙁

Lasty, one cannot overstress the reluctance of the consumer to pay for these electronic trinkets. Like it or not, most commodities in life accrue a dollar value in the eyes of the consumer; go over this, and risk selling nothing. When it is pointed out that in hifi the cost of manufacture is normally between four and six times lower than the retail price, it is obvious that every dollar spent at the factory is highly magnified at the consumer's hip pocket. This is a very powerful drive towards simplicity, no bad thing of itself of course, as long as the money is spent where it really matters. 😀

Cheers,

Hugh R. Dean

www.aksaonline.com

To Regulate, or not to regulate........

I agree pretty much with the comments to date. Consumers won't pay for it, a lot of heat is produced, and there are other issues besides.

If you do decide to regulate the rails of a SS power amplifier, you must first choose series or shunt. Since shunt regulation consumes around double the power used by the amp module, most go for series. Of course, with vacuum tubes, where currents are much smaller and usually vary much less, shunt regulation is quite acceptable, though not much used in power stages.

Second, having settled on series regulation, you need to decide whether to use error correction (a feedback circuit) or emitter follower (no error correction at all). The former is complex, usually involves high levels of feedback with attendant problems of speed and overshoot, while the second is simple, but does not give very good regulation because the emitter resistance of the pass element increases with drawn current, giving a non-linear voltage reguation. However, this method has no issues of speed or overcorrection and is fine where current variations are small, for example in a preamplifier.

Like all these issues, design depends on environment and permissible levels of voltage sag. In a power amplifier, the current varies from quiescent, typically 50-100mA per rail, to an all out, head-banging 5A or more, depending on amp rating. This range is quite wide, and the regulation must be pretty good to avoid any kind of signal compression, which is usually audible as the regulation abruptly hits a brick wall. Given that global feedback PP SS amps can effectively compensate gracefully falling rail voltages within their feedback loop, you have to ask yourself if it is really necessary to incorporate an additional layer of complexity using expensive, high current transistors mandating even more expensive heatsinking. Good evidence of this is the perceived difficulty distinguishing sonic differences between a 300VA and a 1000VA transformer, given rectifiers, amp, source, speakers, cabling and filter caps which are identical.

OTOH, there are always exceptions, and in preamplifier circuitry I have found that series pass, emitter follower series regulator circuits give the best all round performance. I am heartened that Elso Kwak finds this too. Here, the sorts of differences I refer to have to do with imaging rather than dynamics; and this I cannot explain, except that the emitter follower series element would clearly offer capacitance multiplication, removing ALL ac from the line, thereby elimininating artefacts which might otherwise blur the delicate phase relationships responsible for good imaging.

I can see no advantage for regulating the rails of a Class A circuit; such amps have almost constant current draw, and a constant, heavy current on even a rudimentary supply gives very little voltage sag.

If you do go for regulation, it is important to design for speed to match the bandwidth of the amp. In this connection, an emitter follower has a natural advantage since it does not suffer Miller or overshoot effects, unlike the common emitter configuration. I liken this situation to a poorly designed power steering system on an automobile; an underrated pump, valving or ram system will not respond quickly enough to steering inputs; in a crisis, this could be fatal. 🙁

Lasty, one cannot overstress the reluctance of the consumer to pay for these electronic trinkets. Like it or not, most commodities in life accrue a dollar value in the eyes of the consumer; go over this, and risk selling nothing. When it is pointed out that in hifi the cost of manufacture is normally between four and six times lower than the retail price, it is obvious that every dollar spent at the factory is highly magnified at the consumer's hip pocket. This is a very powerful drive towards simplicity, no bad thing of itself of course, as long as the money is spent where it really matters. 😀

Cheers,

Hugh R. Dean

www.aksaonline.com

If every dollar that might have been put into a regulator was instead put into a better/bigger transformer and more/better output devices you would wind up with a better/more powerful amp.

I don't believe that a regulator relates to quality, only quantity. My view is that a regulator is just another form of limiter.

Someone tell me how a regulator is going to provide better sound, please.

I don't believe that a regulator relates to quality, only quantity. My view is that a regulator is just another form of limiter.

Someone tell me how a regulator is going to provide better sound, please.

Some manufacturers use regulation for the voltage and differential amplifier stages. Since the current used by these stages is typically very low, the cost and complexity of regulation is also very low.

If ripple rejection is the goal, perhaps a capacitance multiplier would be the ticket? Here's a pretty good example:

http://sound.westhost.com/project15.htm

I had intended to experiment with it a little bit, but decided it best to finish my amp before I start tweaking it 😉

Cheers,

Mark Broker

If ripple rejection is the goal, perhaps a capacitance multiplier would be the ticket? Here's a pretty good example:

http://sound.westhost.com/project15.htm

I had intended to experiment with it a little bit, but decided it best to finish my amp before I start tweaking it 😉

Cheers,

Mark Broker

mbroker said:Some manufacturers use regulation for the voltage and differential amplifier stages. Since the current used by these stages is typically very low, the cost and complexity of regulation is also very low.

This is one of the tricks used by the ledgendary NAD3020. The output devices have their own unregulated supply, all the rest runs off a regulated supply (someday, maybe someone can give me an explanation for the asymmetrical rails off the reg).

As to the benefits of regulating the output stage, the regulator is essentially another "amp" the same size or larger than the one you are regulating.

There are some very successful fully regulated amps -- the NAIM NAP250 is a good example. This amp is essentially a NAP 160 or 180 with regulation (& slightly higher rails). There is a decided sonic improvement.

But for most, for an output stage, the same money spent on more inherent regulation in the raw power supply (bigger Trafo, chokes, etc) is probably a more straightforward approach with similar results with a lot less effort.

That said i do plan on trying the Vacuum State SuperReg for all the stages in a differential EL84 amp (total current draw of <300mA/chan).

dave

I have a cyrus amp to which I added the optional regulated psx-r power supply, the result was a significant improvement in sound quality. Whether this is just due to the earlier stages of the amp having more stable cleaner rails I don't know.

It is suprising that more designers don't regulate the supply to the input and driver stages of their power amps. The Pass A75 uses additional voltage doubling rectifier circuits on the main windings which seems a neat way to avoid having to provide extra windings or taps on the trannie.

Why more manufacturers don't provide add-on regulated power supplies is suprising. It would seem to make good commercial sense to provide an easy upgrade path to existing customers.

It certainly works for Naim and their line level power supplies, just look at the prices they charge , £725 for a transformer smoothing caps and a couple of TO3 3 terminal regs and they sell them by the bucket load.

Khush

It is suprising that more designers don't regulate the supply to the input and driver stages of their power amps. The Pass A75 uses additional voltage doubling rectifier circuits on the main windings which seems a neat way to avoid having to provide extra windings or taps on the trannie.

Why more manufacturers don't provide add-on regulated power supplies is suprising. It would seem to make good commercial sense to provide an easy upgrade path to existing customers.

It certainly works for Naim and their line level power supplies, just look at the prices they charge , £725 for a transformer smoothing caps and a couple of TO3 3 terminal regs and they sell them by the bucket load.

Khush

The regulation of the i/p and voltage stages supply brings sonic improvements not because of the inherent principle of regulation, but because it minimises the interstage interactions. As such it is an acceptable commercial comromise but for the ultimate multistage amp the best solution is to have independent power supply for each stage. I've found that a lot of simple amps change dramatically if built with 2 or 3 power supplies. The improvement IMO is larger than building them as monoblocks. Same of course, and maybe to a higher extent, is true of valve designs. Being mostly simple stages with no significant PSRR valve amps show real improvements with many power supplies. And no, multiple series pass regulators do not bring the same improvement.

Amazingly, even opamp circuits improve when each stage has independent supply. Years ago i built an opamp RIAA using split correction and 3 stages of amplification each with their own NiCd supply. The rhytmic abilities of this circuit exceeded everything i've built ever since.

peter

Amazingly, even opamp circuits improve when each stage has independent supply. Years ago i built an opamp RIAA using split correction and 3 stages of amplification each with their own NiCd supply. The rhytmic abilities of this circuit exceeded everything i've built ever since.

peter

General Discussion PSU

Hello Folks,

Anyone wants to put your 2 cents in my pocket?

Power supply parts list

Transformer - PLITRON 300VA 22-0-22

Positive rail –

Bridge rectifier – MIC KBPC2504, not heat sink mounted, just suspend in air by transformer secondary output wires

PSU capacitors - 3 times BHC Aerovox ALT22A 15,000uF 63V bypassed with

ACROTRONICS KP1.72 100nF polypropylene each

Voltage regulator - LM388K, mounted on 0.5C/W heat sink

Negative rail –

Bridge rectifier – MIC KBPC2504, not heat sink mounted, just suspend in air by transformer secondary output wires

PSU capacitors - 3 times BHC Aerovox ALT22A 15,000uF 63V bypassed with

ACROTRONICS KP1.72 100nF polypropylene each

Voltage regulator - LM388K, mounted on 0.5C/W heat sink

Connects to amprefier PCB with

Quiescent Voltage set at 20V

Quiescent Current set at 4A

Power consumes approx. 200W at idle

After 1 hour power on:

What temperature would one expects the bridge rectifiers get to?

What temperature would one expects with the transformer?

What causes the temperature to rise with the rectifiers and transformer?

What is the life expectancy for such a power supply unit?

Besides mounting bridge rectifiers on heat sink or utilizing fans, any other options to lower the PSU temperature?

Regards,

Chris

Hello Folks,

Anyone wants to put your 2 cents in my pocket?

Power supply parts list

Transformer - PLITRON 300VA 22-0-22

Positive rail –

Bridge rectifier – MIC KBPC2504, not heat sink mounted, just suspend in air by transformer secondary output wires

PSU capacitors - 3 times BHC Aerovox ALT22A 15,000uF 63V bypassed with

ACROTRONICS KP1.72 100nF polypropylene each

Voltage regulator - LM388K, mounted on 0.5C/W heat sink

Negative rail –

Bridge rectifier – MIC KBPC2504, not heat sink mounted, just suspend in air by transformer secondary output wires

PSU capacitors - 3 times BHC Aerovox ALT22A 15,000uF 63V bypassed with

ACROTRONICS KP1.72 100nF polypropylene each

Voltage regulator - LM388K, mounted on 0.5C/W heat sink

Connects to amprefier PCB with

Quiescent Voltage set at 20V

Quiescent Current set at 4A

Power consumes approx. 200W at idle

After 1 hour power on:

What temperature would one expects the bridge rectifiers get to?

What temperature would one expects with the transformer?

What causes the temperature to rise with the rectifiers and transformer?

What is the life expectancy for such a power supply unit?

Besides mounting bridge rectifiers on heat sink or utilizing fans, any other options to lower the PSU temperature?

Regards,

Chris

Pwer amp regulation

http://www.users.zetnet.co.uk/avondale/

NAPRegulator2.jpg towards bottom of page.

http://www.passdiy.com/pdf/zen-ver3.pdf

Zen Variations - Part 3: Active Supply Regulation

http://www.users.zetnet.co.uk/avondale/

NAPRegulator2.jpg towards bottom of page.

http://www.passdiy.com/pdf/zen-ver3.pdf

Zen Variations - Part 3: Active Supply Regulation

Re: Pwer amp regulation

Thank you for that URL. Very interesting stuff.

dave

HarryHaller said:

Thank you for that URL. Very interesting stuff.

dave

Regulated supplies etc

Hey HH,

Neat setup. Slap on a couple of opamps and you would really have a winner...😀 😀

Jan Didden

"If you don't know where you're going, any road will take you there" - Anonymous the Younger

Hey HH,

Neat setup. Slap on a couple of opamps and you would really have a winner...😀 😀

Jan Didden

"If you don't know where you're going, any road will take you there" - Anonymous the Younger

Forgot one

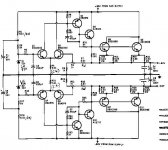

The schematic is from:

“A Power Supply Regulator For the Adcom GFA-555,” Kit Ryan, The Audio Amateur4/89

"Slap on a couple of opamps and you would really have a winner..."

If you can find on op amp with +/- 35 volts rails!

The schematic is from:

“A Power Supply Regulator For the Adcom GFA-555,” Kit Ryan, The Audio Amateur4/89

"Slap on a couple of opamps and you would really have a winner..."

If you can find on op amp with +/- 35 volts rails!

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Regulated Power supplies