In posting #122 I showed the noise of two silent tracks, from an outer track and an inner track having a ratio of almost 1:2 in diameter, and just for the moment only consider the 2 Dry recordings.

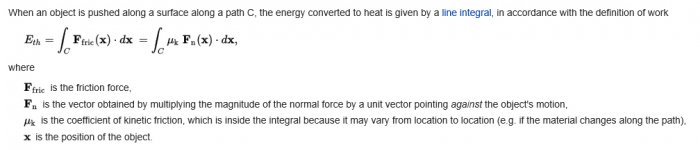

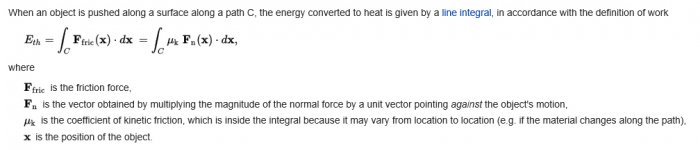

Energy generated when having a certain kinetic friction coeff. and a constant vertical force, is directly dependant on the length of the road that is taken.

In this very case, twice the length has been driven in the same time on the outer track as compared to the inner track.

The Energy generated, converted into heat and into noise transferred to the cart, will be twice as much when the road is twice as long for that reason .

Ergo, with twice as much energy generated in the same time one would expect twice as much noise coming from the outer track, which is definitely not the case as shown in posting #122.

So it seems that energy generated because of friction is not 1:1 correlated to noise, and that just having a friction coeff. is not the holy grail to explain everything.

And that someone in the past has found some correlation between friction and noise is only valid for his specific equipment an test record(s) and cannot be seen as a prove covering all varieties of equipment on the current market.

Exactly the same can be said for Dry/Wet recording. As I said before, one or two swallows do not make a summer. As I have proven that in my very case with my equipment and my test LP, Wet recording gives no bonus, for whatever reason it may be.

Hans

Energy generated when having a certain kinetic friction coeff. and a constant vertical force, is directly dependant on the length of the road that is taken.

In this very case, twice the length has been driven in the same time on the outer track as compared to the inner track.

The Energy generated, converted into heat and into noise transferred to the cart, will be twice as much when the road is twice as long for that reason .

Ergo, with twice as much energy generated in the same time one would expect twice as much noise coming from the outer track, which is definitely not the case as shown in posting #122.

So it seems that energy generated because of friction is not 1:1 correlated to noise, and that just having a friction coeff. is not the holy grail to explain everything.

And that someone in the past has found some correlation between friction and noise is only valid for his specific equipment an test record(s) and cannot be seen as a prove covering all varieties of equipment on the current market.

Exactly the same can be said for Dry/Wet recording. As I said before, one or two swallows do not make a summer. As I have proven that in my very case with my equipment and my test LP, Wet recording gives no bonus, for whatever reason it may be.

Hans

Hans,

This is indeed curious. Now correlation and causality being strange bedfellows it is easy to jump to conclusions, but I have many records with ticks and pops for the first track, then quiet for the rest of the side. I had usually thought this was due to poor storage with dust getting into the jacket by the edge, but it could also be caused by friction.

I do need to get the test record you use and try some things. My problem is that, having toddler proofed the stereo its hard to get at. My fault for too many kids!

This is indeed curious. Now correlation and causality being strange bedfellows it is easy to jump to conclusions, but I have many records with ticks and pops for the first track, then quiet for the rest of the side. I had usually thought this was due to poor storage with dust getting into the jacket by the edge, but it could also be caused by friction.

I do need to get the test record you use and try some things. My problem is that, having toddler proofed the stereo its hard to get at. My fault for too many kids!

What was the time gap between cleaning and friction measurement? You'll understand why I ask that.

edit: also, what are the error bars on the measurement of mu?

SY, well the Pardee article lacks such detail. But otherwise has at least some signs of being reasonable as to method IMO, and does have an Aerospace labs endorsement.

Water/detergent cleaning was the control group. Most of the experiment was testing patent brand cleaning solutions, some of which reduced µ, and there was quite a lot of variance I would say. None of the record brands, nor cleaning agents were identified by name.

I believe the spirit of Pardee's results though, if not the absolute detail.

LD

Thanks to LD I also realise that you can now get MMs with exceeding low compliance (7), albeit only with conical tips. Would be interesting to compare high and low compliance cases for the same generator. For the well heeled of course you could get a line contact tip fitted to the low compliance MM, but I am not in that category!

So for whatever reason LD's recording deviates complete from this, and I'm happy that at least one person in this world recorded the same shape as I did.

This is because yours, and the 3rd party's, intentionally have no audioband programme material in that part of the spectrum, ie above 30Hz or so. Whereas that test of mine intentionally did have audioband programme material in that part of the spectrum above 30Hz, being a pink noise test as I labelled on the plot.

If you just examine the shape of the cart-arm resonant system at frequencies below the audioband, say 30Hz where there is no programme material, the shape of your resonant system is the same as mine, amplitude aside, as expected.

The difference is that your test showed no difference in amplitude of the resonance between wet and dry playback. Whereas mine, and the 3rd party's, clearly did. This is why it's reasonable to deduce you were unsuccessful in reducing friction, for whatever reason, and your result of no noise difference between wet and dry playback follows on from that.

Had you measured friction coefficient, µ, this would have been clear. But it's still reasonable to say µ remained unaltered, because it correlates with amplitude of the cart-arm resonance which did remain unaltered for you but was different for both me and the 3rd party tests. There's no contradiction here, you simply didn't reduce friction, Hans, for reasons unknown.

Ergo, with twice as much energy generated in the same time one would expect twice as much noise coming from the outer track, which is definitely not the case as shown in posting #122.

But your results are odd, Hans, for reasons unknown. Surface crackle-pop-tick noise is well known to be worse on outer tracks. More likely something is wrong, but only you can find why I think.

IME µ stays roughly constant over the surface, but consists of a static element and a dynamic element. The variance of the dynamic element reduces toward inner tracks, and it is the dynamic element which correlates with crackle-pop noise.

LD

A most interesting thread, I get the feeling that most of the contributors were either unborn, or were still peeing their pants during the rapid demise of vinyl? 🙂 This being the case, the object appears to me more about historical reenactment rather than the love of music.

The last new vinyl album that I purchased was Paul Simon's Graceland and that was back in the mid 80's, and from then on I embraced the clean sound and convenience of CD's, as we all did.

Now 30 years on, digital audio has moved on in leaps and bounds, making it possible to store hundreds of albums on a micro SD card and making music even more convenient. I'm slowly ripping my CD collection to mp3 files and storing them on a small tablet and playing them via bluetooth. Why, I do not even have to move from the recliner during a listening session. I did try ripping some vinyl but it just took too long, even though I never attempted a wash cycle as is discussed on this thread, but they did sound pretty good, but that could be a nostalgia component.

The last new vinyl album that I purchased was Paul Simon's Graceland and that was back in the mid 80's, and from then on I embraced the clean sound and convenience of CD's, as we all did.

Now 30 years on, digital audio has moved on in leaps and bounds, making it possible to store hundreds of albums on a micro SD card and making music even more convenient. I'm slowly ripping my CD collection to mp3 files and storing them on a small tablet and playing them via bluetooth. Why, I do not even have to move from the recliner during a listening session. I did try ripping some vinyl but it just took too long, even though I never attempted a wash cycle as is discussed on this thread, but they did sound pretty good, but that could be a nostalgia component.

Last edited:

Well I'm nearly 50. SY and Jan are both ancient. Scott retires in 2 months. LD I believe has a decade on me. From his Bio Hans is also IIRO 60. DPH is a young whipper snapper, but he doesn't play vinyl.

So you are wrong. See you in a week for your next exciting installment.

So you are wrong. See you in a week for your next exciting installment.

Jan is far more ancient than I. When I was a kid and had trouble going to bed, my mother would read me his articles to help me sleep.

Yeah, I think we worked it out that I'm around the age of Scott's kids. 🙂

Yes, the only time I get a chance to play vinyl is when I go up to visit my family, and there my parent's turntable gets put to use. (late-70's mid-level direct drive Technics, don't have the model off the top of my head) And there's definitely a healthy bit of nostalgia going on.

Yes, the only time I get a chance to play vinyl is when I go up to visit my family, and there my parent's turntable gets put to use. (late-70's mid-level direct drive Technics, don't have the model off the top of my head) And there's definitely a healthy bit of nostalgia going on.

I do not own an MM element to test, but these elements usually have a much higher compliance and are terminated with 47K, whereas my MC element has a very low compliance, terminated with several hundreds ohms, so very well damped.

We covered that last time LD was around, taking the energies involved there is no electro-mechanical damping of the major ~10Hz resonance even when shorted certainly not with 100's of Ohms. The tail does not wag the dog.

Hi Scott,We covered that last time LD was around, taking the energies involved there is no electro-mechanical damping of the major ~10Hz resonance even when shorted certainly not with 100's of Ohms. The tail does not wag the dog.

That MM/MC idea came to my mind as a possible cause because the noise spectra around 10 Hz in posting #253 were so totally different.

Now that it turned out that LD recorded pink noise, this is no longer relevant and can be discarded.

Hans

Determination of Sliding Friction Between Stylus and Record Groove, Robert P. Pardee, Ball Corporation, Aerospace Division, Boulder, Co USA. JAES Vol 29 No 12 Dec 1981.

"....The comparison in Table 2 show that thoroughly cleaning a record with detergent solution will, in most cases, cause an increase in friction, sometimes a large increase. And the effect seems to vary from one brand of record to another. For example, cleaning had essentially no effect on µ of brands E and E; caused a slight µ increase on brands F and G, and caused a rather large µ increases on brand C."

Record Manufacturer, side No, µ(mint) µ(after cleaning)

A 1 0.27 0.29

A 2 0.26 0.29

A 1 0.38 0.40

A 2 0.38 0.40

A 1 0.43 0.39

B 1 0.34 0.34

C 1 0.24 0.34

C 1 0.24 0.64

D 1 0.29 0.30

D 1 0.28 0.37

D 2 0.28 0.36

E 1 0.27 0.27

F 1 0.26 0.29

F 1 0.22 0.23

G 1 0.15 0.19 "

LD

We are discussing the possible (detrimental) effects of using fluids on LP's and now only after 256 postings one of the possibly most important and neutral information is shown so far.

May I say that I'm a bit amazed that it took so long?

Friction has of course a relation to noise production, although that relation is not that straightforward.

But when friction does not change, it is very unlikely that noise will change, such as in E and to a slightly lesser degree in F and G.

That makes me suppose that my Adjust+ LP is from the E varyity, because playing Dry, Wet and Again Dry after that, makes no difference at all.

The other important question that SY already placed is: is this a permanent effect or is there a decay over time. Unfortunately the original report does not give any answer to this question.

But it could mean that it be better not clean new LP's anymore, or is the current LP, mostly in 180 grams versions, made from top notch material ??

All in all the given information reinforces my feeling that "playing wet reduces noise" (other than noise from static electricity) cannot be put so generally, because it may largely depend on the chemical compound of the LP.

Hans

The Pardee paper has been referred to several times, so you can excuse LD for not taking the time to hand retype from the paper?

Now that it turned out that LD recorded pink noise....

When examining cart-arm resonance in this test, looking at sub-audio, sub 30Hz LF spectrum, it's best to use a pink noise programme test track. This is because programme spectrum is then effectively a control level, unaffected by the test. Whereas using a 'silent' track, at least in adjacent the LF part of the audio spectrum, is subject to change by the test, it being the noise floor which is known to be affected by the test.

In this way, it is clearer to contrast non-audioband wet/dry LF resonant systems, as per my plot which is thoroughly revealing as to the difference.

Pink or white noise programme fills the audioband spectrum, and can be seen to be unaffected as to level in my plot. I did label it, 'pink noise' FWIW.

Friction has of course a relation to noise production, although that relation is not that straightforward.

But when friction does not change, it is very unlikely that noise will change, such as in E and to a slightly lesser degree in F and G.

Pardee's tests were for cleaning only, not for wet playback. Such effect, if it has the same cause, is significantly amplified by wet playback, IME.

That makes me suppose that my Adjust+ LP is from the E varyity, because playing Dry, Wet and Again Dry after that, makes no difference at all.

Or exposure to the patent fluid you used had a lasting lubricating effect from the 1st test you ran ? You did flood the record. Or something else.

It is an odd result, Hans.

LD

Member

Joined 2009

Paid Member

Jan is far more ancient than I. When I was a kid and had trouble going to bed, my mother would read me his articles to help me sleep.

Then a few questions.Pink or white noise programme fills the audioband spectrum, and can be seen to be unaffected as to level in my plot. I did label it, 'pink noise' FWIW.

1) The noise level in your graph drops ca. 13 dB when going from 100Hz to 1Khz. This conforms exactly to the Riaa curve, so you probably used white noise.

2) What test LP did you use for this recordings having noise in the same order of amplitude/Hz as the noise below 20Hz and how could you possibly know the noise had no content below 20Hz ?

2) When trying to assess the Dry/Wet noise behaviour around 10Hz, why would playing noise of a very low energy level be better than using a 1Khz 0dB tone ?

In both cases you have a reference level and there is no danger in the latter case of interfering with the LF noise.

Hans

(P.S. The graph was called Wet-dryLFSpectrumA and was not identifiable to me as a (pink) noise recording)

It seems to be what we need to do is have a repeat test done by someone and I need an excuse to get off the internet and hook some things up. So I am willing to try and replicate Hans measurements to the best of my abilities if we can agree the setup.

First off test record. Do I need the 7" or 12" Feikert pressing?

second off replay system. MM or MC? MC is possibly quicker as that is in my current working turntable and the Koncrete Kenwood(tm) needs a teeny but of TLC.

3. ripping. Assume as we are not talking down in the weeds noise, will any half decent PC sound card do the job? what rate and bit depth do we need

4. Length of recording for analysis

5. liquid to be used

Sorry for all the questions, but what I would like to plan for is to produce a set of recordings where we all agree the setup and protocol is good, then I can analyse the raw file as can Hans and LD. I want to use the same test record as Hans did initially then I can sacrifice my HFN/RR one. What I don't want to do is mimble off, wet play a record and then we disagree if I did a valid test when I might have already affected the results.

Would love to be able to do friction tests but at the moment have no way of doing this unless I spin the records up by hand which might work but would be a gigantic pain in post processing.

First off test record. Do I need the 7" or 12" Feikert pressing?

second off replay system. MM or MC? MC is possibly quicker as that is in my current working turntable and the Koncrete Kenwood(tm) needs a teeny but of TLC.

3. ripping. Assume as we are not talking down in the weeds noise, will any half decent PC sound card do the job? what rate and bit depth do we need

4. Length of recording for analysis

5. liquid to be used

Sorry for all the questions, but what I would like to plan for is to produce a set of recordings where we all agree the setup and protocol is good, then I can analyse the raw file as can Hans and LD. I want to use the same test record as Hans did initially then I can sacrifice my HFN/RR one. What I don't want to do is mimble off, wet play a record and then we disagree if I did a valid test when I might have already affected the results.

Would love to be able to do friction tests but at the moment have no way of doing this unless I spin the records up by hand which might work but would be a gigantic pain in post processing.

1) The noise level in your graph drops ca. 13 dB when going from 100Hz to 1Khz. This conforms exactly to the Riaa curve, so you probably used white noise.

Pink or white noise, or any colour in between, it really doesn't matter. The elephant in the room is the profound change to the sub-audio LF cart-arm resonance spectrum, not the programme material which is unaltered between wet/dry tests.

IIRC, exact noise colour was not correct on that record: it was a BBC test record from the 60s and IIRC this had cropped up before and so I'd decided it was fit to ruin in wet/dry tests. So long as programme spectrum occupies the LF audioband, any differences in the LF cart-arm resonance, which by definition doesn't occupy the LF audioband, become clear. If that makes sense. It's pretty obvious from the plot I think.

2) What test LP did you use for this recordings having noise in the same order of amplitude/Hz as the noise below 20Hz and how could you possibly know the noise had no content below 20Hz ?

You've missed the point, Hans. ALL vinyl programme content has applied steep high pass filter at c 30Hz or thereabouts, for obvious reasons. There is no intentional programme content cut below 20Hz, even in the pink/white/rose noise track. There is no significant stimulus of the cart-arm resonance from programme material, nor the noise track, and that is certainly not the point of using a noise track for the test. The purpose is to fill the audioband spectrum so that it can be identified and separated clearly from the LF cart-arm resonance. Programme material stays constant, LF cart-arm resonance alters in the test. I think this is obvious from the plot.

When trying to assess the Dry/Wet noise behaviour around 10Hz, why would playing noise of a very low energy level be better than using a 1Khz 0dB tone ?

See above. A 1kHz monotone would effectively have no intentional programme content in the audioband decade above 10Hz. There would just be the noise floor, and that is subject to be altered by the wet/dry test. Whereas intentional programme noise track fills the audioband spectrum and remains unaltered by the test. The benefit is in clarity when seperating the LF cart-arm resonance from the audioband noise floor. Again I think the plot is clear.

But actually, just about any record is capable of showing the effect of reduced friction in suppressing the LF spectrum IME. Just that noise tracks make it very clear and obvious.

LD

Last edited:

What I don't want to do is mimble off, wet play a record and then we disagree if I did a valid test when I might have already affected the results.

Suggest start small by getting familiar with wet playback. Expect to ruin a few records, perhaps the cartridge, and possibly the carpet (!) Start with a classical LP you never want to play dry again, one that shows characteristic crackle-pop-tick surface noise but is otherwise clean and not obviously damaged or abused. Philips label from the 70s are good candidates IME, and piano sonatas have enough space to hear the noise.

Doesn't matter whether MM or MC, but MM will be cheaper and easier to replace the stylus should it all end in tears.

Use 10% IPA in distilled water with a drop or two of surfactant, or rinse aid. Make up about a litre in a clean glass container with a glass stopper.

Play and record your record dry. Listen. Flood the record, trying to keep the fluid out of TT electrics and mechanics. Play and record your record wet. Listen and be amazed. Analyse ad nauseum. Spend the best part of three years trying to work out how on earth what you've just heard and measured is even possible........😉

If you aim to reproduce Hans' test, best to use his fluid which is a commercial brand he did post.

It would seem a real pity not to measure friction coefficients this time, Bill, because that probably holds the key to further understanding. The most likely outcome of your re-test should be confirmation of Hans' result I think, unless there was some mistake which has to be possible I suppose.

LD

I know nothing of how records are produced, so I take your point on that.ALL vinyl programme content has applied steep high pass filter at c 30Hz or thereabouts, for obvious reasons. There is no intentional programme content cut below 20Hz, even in the pink/white/rose noise track. LD

Steep filtering means large phase distortion that is not compensated for in the Riaa curve, so I hope it is still below perception level.

Hans

- Home

- Source & Line

- Analogue Source

- Reducing Record Surface Noise - I want to know all Approaches