Horn Response is primarily a low frequency modeling program. It is too limited to accurately model the response of a compression driver. In addition, you'll have to measure and derive your own T/S parameters for the compression driver. There is not a single manufacturer that publishes the full T/S parameters for a compression driver. Akabak is a more capable program to simulate the response of a compression driver. However, it has a steep learning curve.

Hi JLH,

Jean-Michel Le Cléac'h used the following parameter values in Hornresp to specify a TAD TD2001 compression driver. I understand that his simulations compared quite favourably to measured results.

Sd = 18.10

Bl = 7.20

Cms = 1.60E-04

Rms = 2.72

Mmd = 1.60

Le = 0.06

Re = 6.30

Nd = 1

Vrc = 0.14

Lrc = 2.70

Fr = 40000.00

Tal = 1.00

Vtc = 0.81

Atc = 18.10

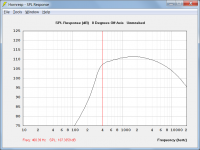

The attachment shows the on-axis far-field pressure response of a 320 Hz Le Cléac'h horn (T = 0.80) with TAD TD2001 driver, using data provided by Jean-Michel.

Kind regards,

David

Attachments

Last edited:

Trying to do the maths for a conical horn that will be turned to form a OSWG.

Hi Studio Au,

You could always just specify the required OSWG in Hornresp, and then export the horn data 🙂.

Kind regards,

David

Attachments

Found a nice guide on Home Theatre, managed to get it to start designing the horn, however Radian pdf's contain none of the parameters I need to enter.

Can anyone help?

Hi Studio Au,

Set Eg = 0 to give the driver diaphragm a constant rms velocity of 10 cm/sec. It then doesn't matter what the actual driver parameter values are.

Kind regards,

David

Hi JLH,

Jean-Michel Le Cléac'h used the following parameter values in Hornresp to specify a TAD TD2001 compression driver. I understand that his simulations compared quite favourably to measured results.

Sd = 18.10

Bl = 7.20

Cms = 1.60E-04

Rms = 2.72

Mmd = 1.60

Le = 0.06

Re = 6.30

Nd = 1

Vrc = 0.14

Lrc = 2.70

Fr = 40000.00

Tal = 1.00

Vtc = 0.81

Atc = 18.10

The attachment shows the on-axis far-field pressure response of a 320 Hz Le Cléac'h horn (T = 0.80) with TAD TD2001 driver, using data provided by Jean-Michel.

Kind regards,

David

I already had that data. In no way I'm I knocking your program (I love Horn Response), but Akabak is better for modeling compression drivers. Of course we both know how difficult Akabak can be to learn and use.

I have found the OS WG .xls and the Gedlee version,

Now trying to work out how best to plot the thousands of points into CNC readable file.

Using a Mac and installing plugins for sketchup is being a pain.

I remember reading some code for illustrator to plot lines.

Guess I need the exit angle for the 850pb to proceed...

Will try and invest some time in Hornresp, seems like a good program once you get to grips with what seems like an abstract concept at first.

Now trying to work out how best to plot the thousands of points into CNC readable file.

Using a Mac and installing plugins for sketchup is being a pain.

I remember reading some code for illustrator to plot lines.

Guess I need the exit angle for the 850pb to proceed...

Will try and invest some time in Hornresp, seems like a good program once you get to grips with what seems like an abstract concept at first.

Right David, possible you can walk me through, creating a OSWG?

This is what I have worked out so far:

So set all S & L values to 0. Selecting L12 lets me choose OSWG

S1 is the mouth of the horn, 1" = 12.7mm radius....

If I want a 15" mouth, set S2 to 15" or 381mm.

What next?

This is what I have worked out so far:

So set all S & L values to 0. Selecting L12 lets me choose OSWG

S1 is the mouth of the horn, 1" = 12.7mm radius....

If I want a 15" mouth, set S2 to 15" or 381mm.

What next?

Found someones else's screen shots for a 1" driver, and copied that, and hey-presto an OSWG.

Next dillema how to transcribe the data to the CNC for template cutting.

Next dillema how to transcribe the data to the CNC for template cutting.

but Akabak is better for modeling compression drivers.

Hi JLH,

While it is possible to specify the acoustic pathways of the compression driver in greater detail in AkAbak, the problem remains of obtaining suitable electro-magnetic-mechanical parameter values to use in the simulations. I suspect that the end result may not be much different to that obtained by entering the same values in Hornresp - with the airways approximated using the standard throat chamber and throat adaptor elements.

Kind regards,

David

Right David, possible you can walk me through, creating a OSWG?

This is what I have worked out so far:

So set all S & L values to 0. Selecting L12 lets me choose OSWG

S1 is the mouth of the horn, 1" = 12.7mm radius....

If I want a 15" mouth, set S2 to 15" or 381mm.

What next?

Hi Studio Au,

S1 is the horn throat area in sq cm, S2 is the horn mouth area in sq cm, and L12 is the horn axial length in cm.

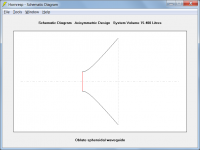

The Horn Segment Wizard can be used to specify a design using different input parameters. The attached example shows a OSWG given a throat area S1 of 20 sq cm, a cutoff frequency F12 of 500 hertz, a throat entry half-angle AT of 2 degrees, and a mouth circumference Cir equal to one wavelength at the cutoff frequency.

Kind regards,

David

Attachments

Thanks David, I will investigate more when I have some free time.

The Radian 850pb's are here, my they are big and so heavy. Will have to rethink my mounting ideas.

I think I will try conical first, as this can be produced pretty quickly and with not too much material. The JMLC 350Hz

Better get started on the big horns. Bass cabinets are made which should handle <800Hz. Pic below

The Radian 850pb's are here, my they are big and so heavy. Will have to rethink my mounting ideas.

I think I will try conical first, as this can be produced pretty quickly and with not too much material. The JMLC 350Hz

Better get started on the big horns. Bass cabinets are made which should handle <800Hz. Pic below

An externally hosted image should be here but it was not working when we last tested it.

Started work on the conicals, template CNC'd, cherry machined down, just need a new bandsaw blade to deep the timber.

More soon

More soon

Sounds awesome Studio Au! I've been looking to make a set of 500Hz conicals as well, wanting to try some polygonal units similar to the Ah! ones but possibly with fewer sides. Curious how an odd side count (i.e. - 5, 7, or 9 sided polygon) would affect the performance?

I asked Gedlee the same thing (regarding OSWG's), he simply said a circle is the best, so the more petals the better.

12 Sided made for what I thought was easy angles as they are all at 15*. Glueing up the most recent one this isn't true and basic maths has failed me somewhere.

Worked out the mounting approach. Pics soon, when the birch version is finished.

12 Sided made for what I thought was easy angles as they are all at 15*. Glueing up the most recent one this isn't true and basic maths has failed me somewhere.

Worked out the mounting approach. Pics soon, when the birch version is finished.

In addition to turning larger round horns I've also made a number of polygonal horns. There was no audible difference between the round horns and polygonal horns. ( 9 sided and 12 sided) I don't know if there would be a difference between even or odd number of sides, but if I was doing it I would go for odd to help avoid any possibility of reflections causing wavy upper frequency response.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Radian 850pb & Wooden horns.