Hi!

Would it be any significant benefits of putting a tiny phono amp super close to the cartridge? (disregard the weight problem).

Would the lower signal impedance from the cartridge and into the amp make an audible difference?

Background for this idea:

I recently bought a opa pre that could easily be made tiny enough to fit inside a tonearm. Power supply and half the filtering would be placed outside the tonearm to reduce the weight.

Any feedback is appreciated!

Would it be any significant benefits of putting a tiny phono amp super close to the cartridge? (disregard the weight problem).

Would the lower signal impedance from the cartridge and into the amp make an audible difference?

Background for this idea:

I recently bought a opa pre that could easily be made tiny enough to fit inside a tonearm. Power supply and half the filtering would be placed outside the tonearm to reduce the weight.

Any feedback is appreciated!

Hi!

Would it be any significant benefits of putting a tiny phono amp super close to the cartridge? (disregard the weight problem).

Would the lower signal impedance from the cartridge and into the amp make an audible difference?

Background for this idea:

I recently bought a opa pre that could easily be made tiny enough to fit inside a tonearm. Power supply and half the filtering would be placed outside the tonearm to reduce the weight.

Any feedback is appreciated!

It is unlikely that the difference in signal impedane makes any difference with the cable what? 10 milliohms, and the cart several 100 ohms?

You say ' disregard the weight problem' but the change in mech resonance frequency might well produce an audible difference, for good or for worse.

Another issue is the hum/noise pickup in the tonearm cable. This could be an issue but not with competent design of the cabling.

Jan

Would it be any significant benefits of putting a tiny phono amp super close to the cartridge? Would the lower signal impedance from the cartridge

and into the amp make an audible difference? I recently bought a opa pre that could easily be made tiny enough to fit inside a tonearm.

Potentially, you would have lower noise/hum/interference by amplifying the signal as closely as possible to the cartridge.

The larger, equalized output would be less fragile on its way down the wiring and cables to the preamp.

You'd want the pcb to be shielded, or at least have a good ground plane.

Last edited:

Member

Joined 2009

Paid Member

I had the same idea last year and thought about a patent even! - why did you have post it in the open like this (just kidding) - I like it a lot, it seems a sensible approach - why put a highly sensitive amp at the end of a long wire when you could place it near the source. My thought was that a simple impedance buffer would be simpler than a full RIAA. I'd use discrete SMD parts. Power would have to be provided and youu'd have to keep this noise free.

I had the same idea last year and thought about a patent even!

Did this in the late '70s with FETs and phantom power. It was even commercialized. Nice gimmick but no real advantage as Jan said. The product died a natural death.

I think that it actually is a good idea to build the phono stage into the plinth, though. Saves cabling, could avoid noise pickup, and makes the phono deck into a flat line-level source just like all the other sources that one might use today.

My turntable has just such a cutout. *REDUCED PRICE* Roksan Artaxerxes phono preamp Photo #310605 - Canuck Audio Mart

It didn't sell well. Linn or Naim also did one that I nearly bought back in the 90s.

@SY do you ever sleep? I have odd diurnal cycles but it was 4AM when you posted!

It didn't sell well. Linn or Naim also did one that I nearly bought back in the 90s.

@SY do you ever sleep? I have odd diurnal cycles but it was 4AM when you posted!

I know it depends on cartridge compliance but have always wondered about ideal tonearm weight. Continumm Cobra tonearms weights almost 1Kg. No matter how good the pivot bearing, doesn't the heavy mass create lateral resistance to inertia of heavy tonearm ? If weight is not an issue a very small battery can be used for Headshell Phono Pre.

Regards

Regards

Tonearm weight is not too important. Tonearm equivalent mass (related to how it moves when subjected to a torque) is very important. The snag is that these two are related via the tonearm geometry. The worst place to add extra mass is at the cartridge, the best is at the pivot.

Signal wires to the tonearm can be thin and flexible. Supply wires may need to be thicker, and in any case there will be more of them.

Signal wires to the tonearm can be thin and flexible. Supply wires may need to be thicker, and in any case there will be more of them.

Thanks for the inputs!

I read somewhere that the cable resistance from cartridge cables quickly could be

0.4 ohms. Series resistance is usally bad..

I too were thinking discrete point to point wiring! I assume I could utilize high gain since the noise from the pickup would probably be really low. I can't stand a high noise floor!

I think the opamp part in the tonearm would probably weigh 3-4 grams. It would consist of input pull down resistor and loading cap, opamp and small smd ceramic psu filtering cap. All these components could be super small! With +-15V driving opamp, the cables to the opamp could be really thin and light. The signal cables from opamp to the amp could also be light. And the best thing is that it would fit inside a carbon tube

I read somewhere that the cable resistance from cartridge cables quickly could be

0.4 ohms. Series resistance is usally bad..

I too were thinking discrete point to point wiring! I assume I could utilize high gain since the noise from the pickup would probably be really low. I can't stand a high noise floor!

I think the opamp part in the tonearm would probably weigh 3-4 grams. It would consist of input pull down resistor and loading cap, opamp and small smd ceramic psu filtering cap. All these components could be super small! With +-15V driving opamp, the cables to the opamp could be really thin and light. The signal cables from opamp to the amp could also be light. And the best thing is that it would fit inside a carbon tube

Was about to post my own thread, but saw this one.

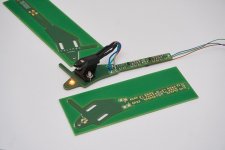

I have wondered about this and designed a PCB 7.5mm wide with RIAA stages and 4-pole rumble filter. So far one of them has seen service inside a diecast box rather than a tonearm, since building or altering a tonearm is a more daunting prospect for me.

One thing that strikes me is that mounting such a long thin pcb inside a metal tube using foam inserts might act as effective damping of tonearm resonances, and keep the signal wires short enough that they cannot rattle around inside (is this an issue?)

Of course one downside is changing the cartridge (type) means having to change the arm too.

I used SMT NE5532's and OPA1612's in a couple of copies of the board, the picture doesn't show the PPS RIAA capacitors and decoupling caps which are on the underside. Mass is a couple of grams or so.

This brings up another thought of mine - could the tone arm itself be made from FR4 PCB material? Its tough glass fibre composite after all.

I have wondered about this and designed a PCB 7.5mm wide with RIAA stages and 4-pole rumble filter. So far one of them has seen service inside a diecast box rather than a tonearm, since building or altering a tonearm is a more daunting prospect for me.

One thing that strikes me is that mounting such a long thin pcb inside a metal tube using foam inserts might act as effective damping of tonearm resonances, and keep the signal wires short enough that they cannot rattle around inside (is this an issue?)

Of course one downside is changing the cartridge (type) means having to change the arm too.

I used SMT NE5532's and OPA1612's in a couple of copies of the board, the picture doesn't show the PPS RIAA capacitors and decoupling caps which are on the underside. Mass is a couple of grams or so.

This brings up another thought of mine - could the tone arm itself be made from FR4 PCB material? Its tough glass fibre composite after all.

Last edited:

Yes we discussed this in another thread a couple of weeks ago. Mainly focussed on phantom powered to allow connection straight to the mic inputs on the common USB audio interfaces used today, but the principle would work with seperate power wires as well.

There are two 'active headshell' products on the market but not what I would call mass market friendly.

There are two 'active headshell' products on the market but not what I would call mass market friendly.

A problem is that the loading is very different for MC and MM cartridges, one circuit cannot do both without some sort of switching (which itself can be a noiseI wonder if it would be an idea to just have a pair of unity gain buffers, instead of a complete phone stage? A bit more flexibility with being able to change phono stages, etc..

issue).

And you always want to lift out of the noise floor in the first stage with these signal levels - especially MC which is already very low impedance and has no need of buffering to transmit a signal, a buffer would just add more noise.

The earlier you apply the RIAA eq the less sensitivity to mains hum, RIAA boosts mains frequencies a lot if they get into the signal path.

A small radioactive source to ionize the air perhapsAlso maybe some kind of device to dissipate static attract dust?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Putting a super light phono amp inside the tonearm?