I can remain in this welcoming tread 🙂 . I'll be back in a few minutes.

Of course you can. What you have done is shown that it is possible to use an off the shelf tractrix (?) with a 3in full range. The next step is to add bandpass injection holes for the bass and you have a plastic horn Trynergy. I built it out of foam core but if you can buy a plastic one and don't mind cutting some holes in it, that is just fine also.

Currency British Pound.....How much do one of these PH-2380 sell for?.....

P. Audio PH-2380 link to dealer P-Audio PH-2380 2" Throat Horn Flare 90 x 40 Dispersion 24.98

JBL 2380A link to dealer JBL 2380A 2" Bolt On Flat Front Bi-radial Horn Flare 90 x 40 Dispersion from JBL 155.00

P. Audio website P-Audio UK

P.Audio PH2380 2" horn. The P.Audio PH2380 2" horn is a JBL 2380 copy. - mine bought locally 5 years ago.

prototype 😀 data http://www.jblpro.com/pub/components/2380a.pdf

Ukrainian clone H-7 ????? 2" ???????? ????-???????? . ?????? ?? ???? ????????????? ? ?????????? ????????? ?? ??????? - $30+, made out of plastic trash.

Tread about 2380 was at multiway recently.

prototype 😀 data http://www.jblpro.com/pub/components/2380a.pdf

Ukrainian clone H-7 ????? 2" ???????? ????-???????? . ?????? ?? ???? ????????????? ? ?????????? ????????? ?? ??????? - $30+, made out of plastic trash.

Tread about 2380 was at multiway recently.

Yes, I thinked about this also.... add bandpass injection holes for the bass..

I purchased drivers (2*4550 and 10*3fe) for coventional unity\synergy.

And at one moment bolted spare 3fe to not using 2380.. 🙂

Flaesh,

Thanks for pointing out the actual one you use - ABS with fiberglass reinforcement.

P.Audio PH2380 2" horn. The P.Audio PH2380 2" horn is a JBL 2380 copy.

The size is actually very similar to my Trynergy...

$120 from US Speaker for a 2in throat 400Hz horn is a very reasonable price. Certainly the labor involved in making your own from foam core or wood is comparable if not more.

Are you brave enough to drill holes in it? I suppose it can always be patched with sheets of black ABS and ABS cement they use for ABS plumbing.

If you want to do it with any sort of predictability, you will need to measure the profile of the horn at least 7 or 10 points along the axial distance (internal width, height and distance from throat flange). Put that in an Akabak model and then play with where the bandpass injection should go. OTOH, the bass injection ports are relatively insensitive to location and can go approximately 75% of the way down the axial distance and should work well. As Kees noted, there is no bass gain so you will have to specify the driver and quantity of driver based on sensitivity and excursion to match the sensitivity of the 3FE22 - which is probably circa 105dB+ at 2.83v and 1m. You will need to fit at least two 99dB 8ohm pro audio woofers on top and bottom to get 105dB sensitivity at 2.83v.

A couple of Eminence Deltalite 12in drivers (100dB) should be able to handle your bass needs from 50Hz to 500Hz. The dia is 12.4in, smaller than the 17.4in width of the main horn so theoretically can all fit in a similar width enclosure. You can make it vented with four bass reflex vents re-entering into the corners near the mouth exit. This will be needed to get the 50Hz bass extension. It doesn't have to re-enter the horn - can just go out straight along front face in corners, just looks cooler the other way. 🙂

http://www.parts-express.com/eminence-deltalite-ii-2512-neo-12-speaker-driver--290-593

Thanks for pointing out the actual one you use - ABS with fiberglass reinforcement.

P.Audio PH2380 2" horn. The P.Audio PH2380 2" horn is a JBL 2380 copy.

The size is actually very similar to my Trynergy...

$120 from US Speaker for a 2in throat 400Hz horn is a very reasonable price. Certainly the labor involved in making your own from foam core or wood is comparable if not more.

Are you brave enough to drill holes in it? I suppose it can always be patched with sheets of black ABS and ABS cement they use for ABS plumbing.

If you want to do it with any sort of predictability, you will need to measure the profile of the horn at least 7 or 10 points along the axial distance (internal width, height and distance from throat flange). Put that in an Akabak model and then play with where the bandpass injection should go. OTOH, the bass injection ports are relatively insensitive to location and can go approximately 75% of the way down the axial distance and should work well. As Kees noted, there is no bass gain so you will have to specify the driver and quantity of driver based on sensitivity and excursion to match the sensitivity of the 3FE22 - which is probably circa 105dB+ at 2.83v and 1m. You will need to fit at least two 99dB 8ohm pro audio woofers on top and bottom to get 105dB sensitivity at 2.83v.

A couple of Eminence Deltalite 12in drivers (100dB) should be able to handle your bass needs from 50Hz to 500Hz. The dia is 12.4in, smaller than the 17.4in width of the main horn so theoretically can all fit in a similar width enclosure. You can make it vented with four bass reflex vents re-entering into the corners near the mouth exit. This will be needed to get the 50Hz bass extension. It doesn't have to re-enter the horn - can just go out straight along front face in corners, just looks cooler the other way. 🙂

http://www.parts-express.com/eminence-deltalite-ii-2512-neo-12-speaker-driver--290-593

Last edited:

Having seos24, coax in process and highs and mids for synergy I thik nice 2380 's plastic [can] remains undrilled.

4*6.5 like in Trynergy seems more convenient.

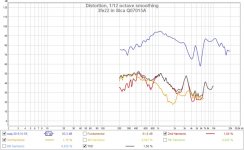

2.83 V at 0.5 m in another horn (only for sensitivity evaluation; even 1.4" throat is unsuitable and your 2*2 seems better than 2" round at 3-6k region).

As similar color old automobile in this tread is a good reason for slow speaker building - mine attached 😀

4*6.5 like in Trynergy seems more convenient.

2.83 V at 0.5 m in another horn (only for sensitivity evaluation; even 1.4" throat is unsuitable and your 2*2 seems better than 2" round at 3-6k region).

As similar color old automobile in this tread is a good reason for slow speaker building - mine attached 😀

Attachments

Last edited:

Nice Car!! i go busy with the Rover 2200TC from 1973 soon, but first the equipment for making the horn, I have made a router so I can make the flare more precise and easy, this works perfectly after make a model.

I maybe go make a apart horn vor bass 80 Hz to 225 Hz, but need thinking about that.

go on with the search to perfect audio, I keep informing you guys when I go experiment with analog filtering.

regards

kees

I maybe go make a apart horn vor bass 80 Hz to 225 Hz, but need thinking about that.

go on with the search to perfect audio, I keep informing you guys when I go experiment with analog filtering.

regards

kees

Attachments

So quit here so I go post some things about how far I am now, I have so much other work in health care I have not much time, but soon I have it again.

I have make a mold for the flare, pressing it in to get a nice shape who is very stiff.

regards

I have make a mold for the flare, pressing it in to get a nice shape who is very stiff.

regards

Attachments

Another thing done, the horn flare is glued so it has a very stiff bent of itselfs.

I am almost ready now to put it together and test it on the hybrid amp in photo three.

Nice work Kees! You will have to explain in detail to us how you accomplished this as I am lost how you did it. You glued two thinner pieces together and while the glue was drying, you clamped and bent it to the proper shape?

Anyhow, looks very nice.

I used the very same technique (minus the cool DIY clamps 😉 ) when I built the curved reflector panel for my Karlson SK8's. I used two sheets of 3/16" oak ply - perhaps not the best choice in retrospective, a softer wood would have been much easier to bend. Once the glue had set, it was extremely rigid. Imageshack has lost the pictures of the gluing process, but here's the assembled result:

Attachments

Good job! Those horn flares certainly turned out well. What type of glue did you use? Nice Rover too. Will the horns go in the back?? 🙂 😉

I kind of like urea-formaldehyde for laminations, but PVA and epoxy work too.

I remember that SK8 IG. 1/8" ply is a lot easier to bend. That one turned out perfectly anyway.

I kind of like urea-formaldehyde for laminations, but PVA and epoxy work too.

I remember that SK8 IG. 1/8" ply is a lot easier to bend. That one turned out perfectly anyway.

Nice work Kees! You will have to explain in detail to us how you accomplished this as I am lost how you did it. You glued two thinner pieces together and while the glue was drying, you clamped and bent it to the proper shape?

Anyhow, looks very nice.

Yes I did make a mold by first drawn the horn in sketchup and print it on multiply pages for the form of the flare, and cnc it with the form as a model cnc see post 508 to make the mold, get three 0.3 mm plywood and put with white woodglu all together and clamp them on the mold with self made clamps. Two 0.3 mm plywood was to thin, three was a better one and really stiff looks good.

Whay concern use them in the rover car, no it is for home and high end audio, as far it will give that high end. I have to see and measure with ears and equipment.

It was not very difficult at all, with the mold I can make horns fast and precise, see the part on the throat the important smaller part is also in it.

PS for the rover, I get work like welding with it, however parts is not so easy to get.

regards

kees

Attachments

Last edited:

Yes I did make a mold by first drawn the horn in sketchup and print it on multiply pages for the form of the flare, and cnc it with the form as a model cnc see post 508 to make the mold, get three 0.3 mm plywood and put with white woodglu all together and clamp them on the mold with self made clamps. Two 0.3 mm plywood was to thin, three was a better one and really stiff looks good.

Whay concern use them in the rover car, no it is for home and high end audio, as far it will give that high end. I have to see and measure with ears and equipment.

It was not very difficult at all, with the mold I can make horns fast and precise, see the part on the throat the important smaller part is also in it.

PS for the rover, I get work like welding with it, however parts is not so easy to get.

regards

kees

Kees,

Did you ever finish this speaker?

Btw, for anyone interested in getting the buyout 6.5in woofers I used - they are back in stock for $4.88ea. Great units to have around for experimentation - they actually sound decent too. A simple 7liter sealed box with stuffing gets you 62Hz. So dead simple to get an 88dB speaker with clean impulse response and low group delay not possible with bass reflex. Add a tweeter or a TC9FD mid tweet and XO at 500Hz and you are set for some excellent sound.

6-1/2" Poly Cone Midbass Woofer 4 Ohm

Kees,

Did you ever finish this speaker?

Btw, for anyone interested in getting the buyout 6.5in woofers I used - they are back in stock for $4.88ea. Great units to have around for experimentation - they actually sound decent too. A simple 7liter sealed box with stuffing gets you 62Hz. So dead simple to get an 88dB speaker with clean impulse response and low group delay not possible with bass reflex. Add a tweeter or a TC9FD mid tweet and XO at 500Hz and you are set for some excellent sound.

6-1/2" Poly Cone Midbass Woofer 4 Ohm

Good question, I have help mother, was sick, and holiday after, I go soon put it together en work at it.

regards

Did start with the speaker measurement jigg who has a class b 6 watt amp on it and works for get thiele small parameters.

So I go work further on it to sdee what happens with this horn.

i did see hornresp can do also nice things with senergy horn design.

regards

So I go work further on it to sdee what happens with this horn.

i did see hornresp can do also nice things with senergy horn design.

regards

Attachments

Are you testing the tractrix now or still building it? Hope your mother is feeling better.

He is almost ready however I did have no time for a while, now mother is better I can start again, like the jigg was needed for the work, otherwise I have go to judge because a nabure has a 8 watts wifi mast on roof, and did disturb everything here, Onw I have won it is replaced somewhere further, but still it is strong and so, I go let remove it.

Who want 15 km reach with a wifi? I have just cable, so I have no interference myself.

regards

I am started with the horn build, it looks already nice the full wood horn, but it is also some work but fun. the wood file I have make myself to flatten the horn flare connection, this is some heavy work.

regards

regards

Attachments

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Presenting the Trynergy - a full range tractrix synergy.