Hi There

I have order a E71/32/33 core and former, I have these now here.

I did wind it and see that the windings are 3.4 mH where it has to be 4.56 mH as it was already wind by somebody.

I did see that the coilformer has a lot of plat around the middle leg of that core, there is a gap of 1.8 mm, and the coilformer is also smaller so 3.3 mm in length has also here a gap.

I think because the windings are 1.8 mm removed around the middle leg of the core this is the reason that the induction is lower.

Do somebody has experience with it.

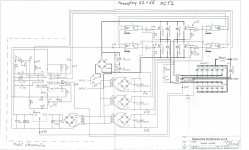

And for the nice ones here a schematic of a smps supply 1000 watts output 2 x 85 volts for 500 watt audio amp.

I have order a E71/32/33 core and former, I have these now here.

I did wind it and see that the windings are 3.4 mH where it has to be 4.56 mH as it was already wind by somebody.

I did see that the coilformer has a lot of plat around the middle leg of that core, there is a gap of 1.8 mm, and the coilformer is also smaller so 3.3 mm in length has also here a gap.

I think because the windings are 1.8 mm removed around the middle leg of the core this is the reason that the induction is lower.

Do somebody has experience with it.

And for the nice ones here a schematic of a smps supply 1000 watts output 2 x 85 volts for 500 watt audio amp.

Attachments

Umm... This is not as easy as you may think...

1kW is maybe for tiny welding... For bigger jobs like 5mm steel I sued to weld at 105A and if i remember the voltage clearly the voltage was near 110V... thats 11 times as much your little transformer can put out. also you need to adjust many things before you can weld...

1kW is maybe for tiny welding... For bigger jobs like 5mm steel I sued to weld at 105A and if i remember the voltage clearly the voltage was near 110V... thats 11 times as much your little transformer can put out. also you need to adjust many things before you can weld...

Hi

The 1 kW is a extra for the people here.

http://www.a-and-t-labs.com/K6_Sw_Amp/art_schematic/k6pwr.pdf

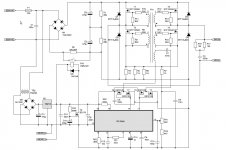

The welder I do make is a 5 to 160 ampere welder from a russian schematic see picture.

The 1 kW is a extra for the people here.

http://www.a-and-t-labs.com/K6_Sw_Amp/art_schematic/k6pwr.pdf

The welder I do make is a 5 to 160 ampere welder from a russian schematic see picture.

Attachments

Last edited:

This is opinion, and just that, but all you need is a transformer with a high current secondary. Say 2 volts, at 100 amps or more.

Well maybe MORE volts but not huge volts. A braizing rig i maintain has a similar output, 0-5v at 50-300 amps.

Well maybe MORE volts but not huge volts. A braizing rig i maintain has a similar output, 0-5v at 50-300 amps.

Last edited:

Thw welding set I saw on site to spot weld a strain guage to a cast iron pipe was all in a medium briefcase sized box and was battery powered.

It mostly contained capacitors to store charge.

The capacitors supplied the welding current for the fraction of a second required to melt the metals and this was done at very low voltage.

The mains connected continuous welding sets also work at low voltage.

It's the current that does the heating.

It mostly contained capacitors to store charge.

The capacitors supplied the welding current for the fraction of a second required to melt the metals and this was done at very low voltage.

The mains connected continuous welding sets also work at low voltage.

It's the current that does the heating.

This is opinion, and just that, but all you need is a transformer with a high current secondary. Say 2 volts, at 100 amps or more.

Well maybe MORE volts but not huge volts. A braizing rig i maintain has a similar output, 0-5v at 50-300 amps.

A welder has a output of 18 to 35 volts, 10 160 ampere of such.

a inverter however give sometimes 70 volts, this keeps the arc going, it is not a spotwelder who is 2 volts and thousends of ampere.

I have a co2 welder who I use for automobile restauration.

The trafo I did wind however did have a coilformer who not fit well on core.

regards

Welding with Audio Amp

Hi:

If memory serves there was an article in the old Audio Magazine about the testers using an audio amp to try welding. The amp was HIGH CURRENT , 20 to 30 amps , about 300 watts and a sort of sawtooth wave was used. The testers thought the sawtooth was better than a sine wave.

Maybe someone with an Audio Magazine collection can find the article.

Ed

Hi:

If memory serves there was an article in the old Audio Magazine about the testers using an audio amp to try welding. The amp was HIGH CURRENT , 20 to 30 amps , about 300 watts and a sort of sawtooth wave was used. The testers thought the sawtooth was better than a sine wave.

Maybe someone with an Audio Magazine collection can find the article.

Ed

Hi There

Can someone help me translate this hungary to english or dutch?

This give also a welding trafo of use, my need is how it has to be wind.

is it not better to use foil copper band? bobbin width and some paralell

it fils the best.

thanks in advance.

kees

Can someone help me translate this hungary to english or dutch?

This give also a welding trafo of use, my need is how it has to be wind.

is it not better to use foil copper band? bobbin width and some paralell

it fils the best.

thanks in advance.

kees

Attachments

Last edited:

The inductance you measure is related to the gap dimension - use a smaller gap if you want a higher inductance, and if the rest of the design is correct for the switchmode requirements.

The inductance you measure is related to the gap dimension - use a smaller gap if you want a higher inductance, and if the rest of the design is correct for the switchmode requirements.

Hi

The version I have do need no gap, I have measure it with no gap at all I have AL 10800 and 3C90 grade as advised.

second post with hungary tekst is a other one who I have schematic from, this schematic is a lot better, have a GAP of 0.1 mm so I need a sheet between the two half of the ferrite? or a other ferrit with a gap only on the middle leg?.

I have wind the primairy now, 8 x 0.8 mm wire.

regards

kees

Attachments

Hi All

Now I have time afain to go on with the welder I have did some research about what kind of supply for what welding, I think it is for audio diy also interesting for small welding tasks like case for amps.

Oke, the welding proces I do is MIG, that is with a wire, buttt, this need a constant voltage source, and the most inverters are constant current sources.

I have includes some schematic photo,s because I think the old one is a constant voltage source but can als do a constant current when put voltage pot complete open and vice versa.

I have copy a schematic who do only current source alone, I have a plan to take the controller schematic and put it on the other, the rest like switching freq is someting I can calculate easely.

In some mig welder is a pulse possibility, with this you can with a pot put the supply on and of quickly, this is for thin metal sheets (like cases ;-)) the pot is adjustable from 0.3 to 10 seconds and I have to inject this in the controller, maybe pin 10 (shutoff pin) can be used. The puls can also be swtich off.

Maybe some people here do now it and have more experience with a smps, and can help me with this.

thanks in advance.

Now I have time afain to go on with the welder I have did some research about what kind of supply for what welding, I think it is for audio diy also interesting for small welding tasks like case for amps.

Oke, the welding proces I do is MIG, that is with a wire, buttt, this need a constant voltage source, and the most inverters are constant current sources.

I have includes some schematic photo,s because I think the old one is a constant voltage source but can als do a constant current when put voltage pot complete open and vice versa.

I have copy a schematic who do only current source alone, I have a plan to take the controller schematic and put it on the other, the rest like switching freq is someting I can calculate easely.

In some mig welder is a pulse possibility, with this you can with a pot put the supply on and of quickly, this is for thin metal sheets (like cases ;-)) the pot is adjustable from 0.3 to 10 seconds and I have to inject this in the controller, maybe pin 10 (shutoff pin) can be used. The puls can also be swtich off.

Maybe some people here do now it and have more experience with a smps, and can help me with this.

thanks in advance.

Attachments

Last edited:

- Status

- Not open for further replies.

- Home

- Amplifiers

- Power Supplies

- Power smps for welding.

discussions about equipment working directly off the mains is not allowed in this board...

discussions about equipment working directly off the mains is not allowed in this board...