The idea for this project came from two separate project plans:

a) I've wanted to build battery powered, bluetooth speaker for small gatherings (less then 20 people),

b) I wanted to build my first MEH (multy entry horn).

So I almost started with two separate projects, but then I said to my self: "Hmmm, is it possible to combine both things into one project => to build relatively small, portable , battery powered MEH, so I could kill two flies with one blow?"🙂

And then, after couple of months of reading MEH threads on this forum (and outside forum), I've narrowed down my design requirements:

1.) Weight=>when completed, the whole box should be easily grabbed & lifted with one hand,

2.) Size =>the box should be around 350 x 350 x 350mm (so around 45L gross volume),

2.) Sound output =>105db/1m will be sufficient, of course the more headroom the better, but in this particular case I would rather sacrifice output for sound quality,

3.) Frequency range => from 50Hz to 20kHz,

4.) Horn type => design should be based on off-the-shelf plastic horn, with added two woofers on the side and one full range on throat flange.

5.) Lower cut-off frequency => 500 Hz should be sufficient, as it dictates portability,

6.) Loudspeaker drivers selection => initial testing will be done with my existing drivers (two 6.5" woofers & one 2" full range driver).

If the initial concept will be promising, then I will invest into new (better) drivers.

7.) Box material => most probably I will use light 10mm plywood.

8.) Amplification & DSP=> the plan is to use plate amp with DSP , but that can run on batteries (something like "Arylic Up2Stream Plate Amp 2.1").

9.) Batteries & charger => to keep things light, I plan to use Li-Ion batteries, with dedicated battery charger.

When you search MEH threads on this forum, there are plenty interesting projects, and lot of them have similar features as my project, but I couldn't find any specifically built portable MEHs.

The first thing that I wanted to define was which CD horn to choose => so I browsed through catalogues of various manufacturers and in the end I chose "SB Acoustics" H280horn:

https://www.sbaudience.com/index.php/products/horns/horn-h280/

Few reasons:

a) It has 500Hz lower cut-of frequency,

b) The size of the horn is about maximum possible to fit in desired box,

c) It has nice, large, flat areas, for mounting two woofers,

d) The distance between horn mouth and horn throat , and horn cross section allows mounting of two 8" woofers.

a) I've wanted to build battery powered, bluetooth speaker for small gatherings (less then 20 people),

b) I wanted to build my first MEH (multy entry horn).

So I almost started with two separate projects, but then I said to my self: "Hmmm, is it possible to combine both things into one project => to build relatively small, portable , battery powered MEH, so I could kill two flies with one blow?"🙂

And then, after couple of months of reading MEH threads on this forum (and outside forum), I've narrowed down my design requirements:

1.) Weight=>when completed, the whole box should be easily grabbed & lifted with one hand,

2.) Size =>the box should be around 350 x 350 x 350mm (so around 45L gross volume),

2.) Sound output =>105db/1m will be sufficient, of course the more headroom the better, but in this particular case I would rather sacrifice output for sound quality,

3.) Frequency range => from 50Hz to 20kHz,

4.) Horn type => design should be based on off-the-shelf plastic horn, with added two woofers on the side and one full range on throat flange.

5.) Lower cut-off frequency => 500 Hz should be sufficient, as it dictates portability,

6.) Loudspeaker drivers selection => initial testing will be done with my existing drivers (two 6.5" woofers & one 2" full range driver).

If the initial concept will be promising, then I will invest into new (better) drivers.

7.) Box material => most probably I will use light 10mm plywood.

8.) Amplification & DSP=> the plan is to use plate amp with DSP , but that can run on batteries (something like "Arylic Up2Stream Plate Amp 2.1").

9.) Batteries & charger => to keep things light, I plan to use Li-Ion batteries, with dedicated battery charger.

When you search MEH threads on this forum, there are plenty interesting projects, and lot of them have similar features as my project, but I couldn't find any specifically built portable MEHs.

The first thing that I wanted to define was which CD horn to choose => so I browsed through catalogues of various manufacturers and in the end I chose "SB Acoustics" H280horn:

https://www.sbaudience.com/index.php/products/horns/horn-h280/

Few reasons:

a) It has 500Hz lower cut-of frequency,

b) The size of the horn is about maximum possible to fit in desired box,

c) It has nice, large, flat areas, for mounting two woofers,

d) The distance between horn mouth and horn throat , and horn cross section allows mounting of two 8" woofers.

I purchased three pieces of "SB Acoustics" H280 horns:

a) One will be used only for testing/experimentation,

b) The other two will be used in actual design.

Please note that I have plan A and plan B for using two horns:

a) Plan "A" is to simply make two smaller boxes, one for left channel, and one for right channel , within above dimensions.

b) Plan "B" is to try combining both horns in one box, with two horns placed side by side, but with certain angle, to maximize coverage area, but to minimize interference (of course if such arrangement offers good sound),

That way, each horn will have two 8" woofers, and one 2.5" fullrange driver, so the whole box will have four 8" woofers and two 2.5" fullrange drivers.

Of course, this will increase overall volume of the box, and it will be a challenge to make such box light, but it should provide stronger sound output.

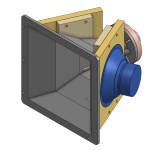

So, first job was to create 3D rendering of the H280 horn => I took some general dimensions from the "SB Acoustics" website drawings, and measured other features directly on physical horn.

Then, I've took my old car woofers (20-year old, "basement specials", poly cone, with little bit rusty frames, but still good rubber surrounds), and took their dimensions and created 3D model as well.

(NOTE: Unfortunately, I don't have T/S parameters for these drivers, but I was using them loooong time ago for my 2-way floorstanding speakers, and if I remember correctly run two of them in approx. 30L closed box, from 50Hz to approx. 3500Hz => I am guessing that Qts is around 0.6-0.7, resonant frequency is around 60Hz, and VAS could be around 14-15L cca.)

After making 3D model of the woofer I played with woofer position, taking into account all basic MEH rules:

a) To place woofer taps as close horn throat as possible,

b) To position woofer taps close to the corners of the horn,

c) To position woofer taps relatively close to woofer membrane center,

d) To make small, elongated slots for woofer taps, which I can enlarge if required,

e) To find position, for mounting woofer where woofer mounting plate will be easily glued/attached.

For fullrange driver, I didn't had any spare 2" or 2.5" drivers around, so I simply took one old PC speaker, took it apart, and took one driver from it => there are no marks on the driver, so I don't have any info about performance - but it is 2" diameter, which should enable simple mounting to horn throat , with simple throat adapter.

I've created model of this fullrange driver as well, plus mounting plate for this driver - and then combined all these 3D parts in one 3D assembly:

a) One will be used only for testing/experimentation,

b) The other two will be used in actual design.

Please note that I have plan A and plan B for using two horns:

a) Plan "A" is to simply make two smaller boxes, one for left channel, and one for right channel , within above dimensions.

b) Plan "B" is to try combining both horns in one box, with two horns placed side by side, but with certain angle, to maximize coverage area, but to minimize interference (of course if such arrangement offers good sound),

That way, each horn will have two 8" woofers, and one 2.5" fullrange driver, so the whole box will have four 8" woofers and two 2.5" fullrange drivers.

Of course, this will increase overall volume of the box, and it will be a challenge to make such box light, but it should provide stronger sound output.

So, first job was to create 3D rendering of the H280 horn => I took some general dimensions from the "SB Acoustics" website drawings, and measured other features directly on physical horn.

Then, I've took my old car woofers (20-year old, "basement specials", poly cone, with little bit rusty frames, but still good rubber surrounds), and took their dimensions and created 3D model as well.

(NOTE: Unfortunately, I don't have T/S parameters for these drivers, but I was using them loooong time ago for my 2-way floorstanding speakers, and if I remember correctly run two of them in approx. 30L closed box, from 50Hz to approx. 3500Hz => I am guessing that Qts is around 0.6-0.7, resonant frequency is around 60Hz, and VAS could be around 14-15L cca.)

After making 3D model of the woofer I played with woofer position, taking into account all basic MEH rules:

a) To place woofer taps as close horn throat as possible,

b) To position woofer taps close to the corners of the horn,

c) To position woofer taps relatively close to woofer membrane center,

d) To make small, elongated slots for woofer taps, which I can enlarge if required,

e) To find position, for mounting woofer where woofer mounting plate will be easily glued/attached.

For fullrange driver, I didn't had any spare 2" or 2.5" drivers around, so I simply took one old PC speaker, took it apart, and took one driver from it => there are no marks on the driver, so I don't have any info about performance - but it is 2" diameter, which should enable simple mounting to horn throat , with simple throat adapter.

I've created model of this fullrange driver as well, plus mounting plate for this driver - and then combined all these 3D parts in one 3D assembly:

Attachments

As this box will be test box, I decided to temporarily fix all plywood boards on the horn, so I can easily change them if required.

So instead epoxy (or some other strong) glue, I used doubly sticky tape (strong type).

With sufficient area, sticky tape can offer quite good holding force, so I applied tape to maximize surface:

So instead epoxy (or some other strong) glue, I used doubly sticky tape (strong type).

With sufficient area, sticky tape can offer quite good holding force, so I applied tape to maximize surface:

When all plywood board for woofer were cut down and temporarily glued to H280 horn, I carefully drilled elongated holes in plastic horn, by using plywood boards as guides.

Then, all holes were sanded smooth, and foam gasket was added on both 6.5" woofers.

Woofers were then attached to both boards, and wires were soldered.

For the fullrange driver board, I also used 18mm birch plywood => as the membrane diameter of my "no-name" driver was around 46mm, and H280 throat was 35.5 mm (1.4"), I decided for this test to simply make conical plywood adapter, without additional compression volume immediately in front of the driver.

Plywood adapter with fullrange driver was then attached to horn, and wires were soldered to driver.

As probably most guys here, I was anxious to hear the whole assembly in free air, without any box => I must admit, I didn't knew what to expect as I was not doing any software simulations/calculations, as I was stubborn, and was trying to see how "forgiving" such MEH design is in real life, if you stick to essential rules.

But on my surprise, sound was quite pleasant even with my 20-years old, rusty woofers and "no-name" fullrange speaker - short video clip is here:

Hm, even with small amount of DSP correction, with randomly chosen drivers, without any box, this MEH sounds very clean and well defined => I would say that it sound much better that it should deserve, considering lack of proper calculations/ simulations.

So, now I was obviously curious, how it would sound with some kind of box, any type of the box => the simplest box I could think of was actually standing right next to my leg => the cardboard box for the H280 horn 🙂

Therefore, by using some masking tape & sharp knife I quickly placed complete horn assembly into cardboard box => it was of course (too) tight fit, and undersized internal volume but for quick tests, who cares😎

Now, with horn placed in improvised cardboard box, I've gain some output in bass region, so I could easily reach 50Hz, or even a little bit lower, but of course this is still far from optimal as box volume is sub-optimal, lot of bass energy is absorbed in box itself, plus box is leaking somewhat.

The sound is still very good & balanced - especially the amount of details when you hear the box from the larger distance (5 to 10meters).

For example, this short video is taken in my office (which is acoustically, far from ideal listening room), with horn simply placed on chair, and from 10m distance (song: Nils Lofgren - Keith Don't Go):

Then, all holes were sanded smooth, and foam gasket was added on both 6.5" woofers.

Woofers were then attached to both boards, and wires were soldered.

For the fullrange driver board, I also used 18mm birch plywood => as the membrane diameter of my "no-name" driver was around 46mm, and H280 throat was 35.5 mm (1.4"), I decided for this test to simply make conical plywood adapter, without additional compression volume immediately in front of the driver.

Plywood adapter with fullrange driver was then attached to horn, and wires were soldered to driver.

As probably most guys here, I was anxious to hear the whole assembly in free air, without any box => I must admit, I didn't knew what to expect as I was not doing any software simulations/calculations, as I was stubborn, and was trying to see how "forgiving" such MEH design is in real life, if you stick to essential rules.

But on my surprise, sound was quite pleasant even with my 20-years old, rusty woofers and "no-name" fullrange speaker - short video clip is here:

Hm, even with small amount of DSP correction, with randomly chosen drivers, without any box, this MEH sounds very clean and well defined => I would say that it sound much better that it should deserve, considering lack of proper calculations/ simulations.

So, now I was obviously curious, how it would sound with some kind of box, any type of the box => the simplest box I could think of was actually standing right next to my leg => the cardboard box for the H280 horn 🙂

Therefore, by using some masking tape & sharp knife I quickly placed complete horn assembly into cardboard box => it was of course (too) tight fit, and undersized internal volume but for quick tests, who cares😎

Now, with horn placed in improvised cardboard box, I've gain some output in bass region, so I could easily reach 50Hz, or even a little bit lower, but of course this is still far from optimal as box volume is sub-optimal, lot of bass energy is absorbed in box itself, plus box is leaking somewhat.

The sound is still very good & balanced - especially the amount of details when you hear the box from the larger distance (5 to 10meters).

For example, this short video is taken in my office (which is acoustically, far from ideal listening room), with horn simply placed on chair, and from 10m distance (song: Nils Lofgren - Keith Don't Go):

Nice little project, Thanks for sharing! It’s amazing to hear that its so forgiving in driver choice and even in tap placement as it seems. Do you plan on following up on this design? Keep us posted on what’s happening!

We should meet up one day when you have the system playing next time 😉

We should meet up one day when you have the system playing next time 😉

2 no name7:

Thanks for your response 🙂

My answers:

1. Regarding MEH as forgiving design:

- Please note that I just stick to the basic MEH building rules, that were covered on this forum many, many times by much more experienced forum members.

They produced vast quantity of measurements, simulations, tests and in the end, they established some basic rules for MEH building.

- I've read lot of threads related to MEH, and tried to note all important things related to actual physical layout of the drivers and horn geometry, because to me it seems that if you do that right, then you are "just" left with crossover & DSP adjustments, testing & measurements 😎

Now, regarding driver choices for 2-way MEH with woofer & fullrange driver, many times members commented that mid-woofer/woofer choice is not so critical as:

a) Driver is working in limited range anyway,

b) Drivers distortion is reduced due acoustic loading (tap points are basically bandpass ports).

That gave me the idea to try MEH with my drivers that were simply laying around for years.🙂

2. Regarding following up on this design:

- Of course, that was the purpose why I started this thread anyway 😎

This is my current workflow:

a) First step => MEH without any box.

I've just tried horn with two 6.5" old drivers and old fullrange driver without box - this test was successful.

b) Second step => MEH inside cardboard box

Considering that horn played nicely even without any box, I was anxious to hear it inside any box => so I placed it in cardboard box, and the results were quite promising.

c) Third step => MEH inside plywood box

I am now in the stage to design & create proper plywood box for my old drivers.

Therefore, I intend to design new plywood box for these old drivers, that will contain speakers & all electronics (batteries, charger, amplifier plate with DSP).

This box will be my first MEH that would be properly measured with REW, and DSP adjustments will be done to extract maximum from these old drivers,

c) Fourth step => MEH with two horns & 6 drivers:

After extracting maximum from old drivers, I will invest into new drivers and try to design new MEH box that will extract maximum from single "Arylic" plate amp.

This new, larger box design will contain:

Btw, I am in Rijeka, so if you are passing by, feel free to come by anytime - I would be glad to demonstrate either this small system, or we can power my larger system if required => https://www.diyaudio.com/community/...-active-tham12-4-fullrange-line-array.399213/

Thanks for your response 🙂

My answers:

1. Regarding MEH as forgiving design:

- Please note that I just stick to the basic MEH building rules, that were covered on this forum many, many times by much more experienced forum members.

They produced vast quantity of measurements, simulations, tests and in the end, they established some basic rules for MEH building.

- I've read lot of threads related to MEH, and tried to note all important things related to actual physical layout of the drivers and horn geometry, because to me it seems that if you do that right, then you are "just" left with crossover & DSP adjustments, testing & measurements 😎

Now, regarding driver choices for 2-way MEH with woofer & fullrange driver, many times members commented that mid-woofer/woofer choice is not so critical as:

a) Driver is working in limited range anyway,

b) Drivers distortion is reduced due acoustic loading (tap points are basically bandpass ports).

That gave me the idea to try MEH with my drivers that were simply laying around for years.🙂

2. Regarding following up on this design:

- Of course, that was the purpose why I started this thread anyway 😎

This is my current workflow:

a) First step => MEH without any box.

I've just tried horn with two 6.5" old drivers and old fullrange driver without box - this test was successful.

b) Second step => MEH inside cardboard box

Considering that horn played nicely even without any box, I was anxious to hear it inside any box => so I placed it in cardboard box, and the results were quite promising.

c) Third step => MEH inside plywood box

I am now in the stage to design & create proper plywood box for my old drivers.

Therefore, I intend to design new plywood box for these old drivers, that will contain speakers & all electronics (batteries, charger, amplifier plate with DSP).

This box will be my first MEH that would be properly measured with REW, and DSP adjustments will be done to extract maximum from these old drivers,

c) Fourth step => MEH with two horns & 6 drivers:

After extracting maximum from old drivers, I will invest into new drivers and try to design new MEH box that will extract maximum from single "Arylic" plate amp.

This new, larger box design will contain:

- Two H280 plastic horns,

- Four 8" woofers,

- Two 2.5" fullrange drivers,

- Complete electronics (charger, batteries, amplifier plate with DSP).

Btw, I am in Rijeka, so if you are passing by, feel free to come by anytime - I would be glad to demonstrate either this small system, or we can power my larger system if required => https://www.diyaudio.com/community/...-active-tham12-4-fullrange-line-array.399213/

I didn't get it how do you solve delay which you have to apply on woofers? Does that small amp has that feature? Or you do it in pasive domain?

Congrats on your project anyway.

I've started something simmilar year ago. 2 way MEH with 2,5" fullrange and woofer, but later switched to 3 way MEH with compression driver for tweeter. I power it with Hypex fusion amps. There is some quality to that 2 way which I lack with these 3 way MEH (although it is great in many other ways). It's hard to describe. Maybe because 2,5" fullrange better handles the 1,1kHz crossover than 1" CD.

Congrats on your project anyway.

I've started something simmilar year ago. 2 way MEH with 2,5" fullrange and woofer, but later switched to 3 way MEH with compression driver for tweeter. I power it with Hypex fusion amps. There is some quality to that 2 way which I lack with these 3 way MEH (although it is great in many other ways). It's hard to describe. Maybe because 2,5" fullrange better handles the 1,1kHz crossover than 1" CD.

2 Sealed:

Related to woofer delay:

- I have experience with "Hypex Fusion" plate amps, and compared to that, "Arylic Up2Stream Plate Amp 2.1" is a very simple, low cost 3-channel D-class amp.

But, when compared to "Hypex Fusion" for my application, it has some benefits:

a) It can be powered with batteries, and with quite large range of voltages (from 12-24 VDC),

b) It has Bluetooth, Wi-Fi, ethernet, optical and line-in option for music sources, and it supports USB Audio format,

c) It has Android App, that can be useful for remotely controlling basic functions (volume, source input, folder/files, equalizer, etc.)

c) It is smaller, lighter but of course it has smaller power output.

What is also important, it has internal DSP that can be programmed with "Arylic" ACPWorkbench software - the software is also quite basic, but sufficient for

this purpose, and it has delay for subwoofer (or in my case, woofer) section.

Btw, do you have link for your project? I would like to check it out.

Hm, I also believe that 2-way MEH maybe better solution for low power applications, as you avoid critical crossover range (from 1-4kHz), plus, whenever you add additional driver, you need to sort phase/delay issues, etc.

For last 6 years I enjoy fullrange sound at my home, as my main system is based on fullrange driver and woofer , with crossover at around 700hz (Linkwitz LX-Mini + subs), so maybe I am little bit biased towards 2-way with fullrange driver 😎

Related to woofer delay:

- I have experience with "Hypex Fusion" plate amps, and compared to that, "Arylic Up2Stream Plate Amp 2.1" is a very simple, low cost 3-channel D-class amp.

But, when compared to "Hypex Fusion" for my application, it has some benefits:

a) It can be powered with batteries, and with quite large range of voltages (from 12-24 VDC),

b) It has Bluetooth, Wi-Fi, ethernet, optical and line-in option for music sources, and it supports USB Audio format,

c) It has Android App, that can be useful for remotely controlling basic functions (volume, source input, folder/files, equalizer, etc.)

c) It is smaller, lighter but of course it has smaller power output.

What is also important, it has internal DSP that can be programmed with "Arylic" ACPWorkbench software - the software is also quite basic, but sufficient for

this purpose, and it has delay for subwoofer (or in my case, woofer) section.

Btw, do you have link for your project? I would like to check it out.

Hm, I also believe that 2-way MEH maybe better solution for low power applications, as you avoid critical crossover range (from 1-4kHz), plus, whenever you add additional driver, you need to sort phase/delay issues, etc.

For last 6 years I enjoy fullrange sound at my home, as my main system is based on fullrange driver and woofer , with crossover at around 700hz (Linkwitz LX-Mini + subs), so maybe I am little bit biased towards 2-way with fullrange driver 😎

So we are now at Stage #3 => Building plywood portable test box (for my old, existing drivers).

As portability is the one key issues, I chosen Okume 10mm, 5-layer waterproof plywood.

It is very light, so the weight shouldn't be an issue, and it should be sufficiently stiff, considering that all panels are relatively short (less than 450mm).

So, I created simple box design, with routed grooves on top & bottom panel, to simplify assembly & gluing.

During 3D design, it was obvious that H280 horn can't be installed with both 6.5" woofers attached => so I added two hatch openings on both sides, to install/remove woofers.

The biggest issue was how to mount "Dayton Audio" Li-Ion charger and 6 Li-Ion batteries => the charger has switches and LEDs , which will be invisible if mount PCB inside the box.

Second issue was mounting of "Arylic" plate amp => it has two antennas, which can be damaged if the are protruding too much from behind.

Therefore, I've decided to mount back panel to leave 60mm clearance from the edge of the box, this should give sufficient clearance for electronics.

Here are couple of 3D renedering screenshots:

As portability is the one key issues, I chosen Okume 10mm, 5-layer waterproof plywood.

It is very light, so the weight shouldn't be an issue, and it should be sufficiently stiff, considering that all panels are relatively short (less than 450mm).

So, I created simple box design, with routed grooves on top & bottom panel, to simplify assembly & gluing.

During 3D design, it was obvious that H280 horn can't be installed with both 6.5" woofers attached => so I added two hatch openings on both sides, to install/remove woofers.

The biggest issue was how to mount "Dayton Audio" Li-Ion charger and 6 Li-Ion batteries => the charger has switches and LEDs , which will be invisible if mount PCB inside the box.

Second issue was mounting of "Arylic" plate amp => it has two antennas, which can be damaged if the are protruding too much from behind.

Therefore, I've decided to mount back panel to leave 60mm clearance from the edge of the box, this should give sufficient clearance for electronics.

Here are couple of 3D renedering screenshots:

After initial design was done, it was again time for CNC router => of course, as always , when I generate my initial (very optimistic) G-Code and send it to machine, couple of router bits & plywood boards have to be sacrificed to the Holly God of Audio😀

So after some swearing and cursing, I manage to cut all panels and finally it is time for assembly:

So after some swearing and cursing, I manage to cut all panels and finally it is time for assembly:

Attachments

Btw, do you have link for your project? I would like to check it out.

Haven't posted anything here so far. I have some photos I should take out of my old phone. I still believe it isn't finished, I want to improve it a bit. Contact me when in Zagreb, so you can check them out.

Due the fact that initial testing with existing, old drivers went well, I decided that it is time to order new drivers for my future double (or twin) H280 box.

For fullrange driver, I wanted to use "SB Acoustics" SB65WBAC25-4, which is proven driver in 2-way MEH projects here , but it was out of stock.

Therefore, I searched for similar 2.5" driver but couldn't find anything close, that has similar specs and that has good reviews.

I wanted to have fullrange driver with raising response on the top end (from 10k to 20k), with relatively solid efficiency, and power rating, so I've decided to try "Vifa" TC6FD00-04, and I ordered two drivers => one will be used for each 50W output channel of "Arylic" 2.1 plate amp.

For woofer driver, I've decided to go with "SB Acoustics" SB20PFC30-8, which is low-cost, light weight 8" woofer driver, with relatively low resonant frequency, good X-max, and solid efficiency (89 dB/1W).

I've ordered four of 8 ohm versions => two per each H280 horn, and all four in parallel to get 2 Ohm resistance, in order to extract maximum power from subwoofer channel on "Arylic" 2.1 plate amp.

As I was still in process of building test wooden box for my old drivers, I wanted to test "Vifa" TC6 instead my no-name driver, just to hear what can be expected:

Please note that as this is test box, I temporarily mounted all electronics on rear panel, including batteries & charger.

That way, all SMD LEDs & buttons on charger are accessible, and I can monitor charge process, capacity of batteries, and battery temperature.

On final twin H280 box, I will arrange this differently.

For fullrange driver, I wanted to use "SB Acoustics" SB65WBAC25-4, which is proven driver in 2-way MEH projects here , but it was out of stock.

Therefore, I searched for similar 2.5" driver but couldn't find anything close, that has similar specs and that has good reviews.

I wanted to have fullrange driver with raising response on the top end (from 10k to 20k), with relatively solid efficiency, and power rating, so I've decided to try "Vifa" TC6FD00-04, and I ordered two drivers => one will be used for each 50W output channel of "Arylic" 2.1 plate amp.

For woofer driver, I've decided to go with "SB Acoustics" SB20PFC30-8, which is low-cost, light weight 8" woofer driver, with relatively low resonant frequency, good X-max, and solid efficiency (89 dB/1W).

I've ordered four of 8 ohm versions => two per each H280 horn, and all four in parallel to get 2 Ohm resistance, in order to extract maximum power from subwoofer channel on "Arylic" 2.1 plate amp.

As I was still in process of building test wooden box for my old drivers, I wanted to test "Vifa" TC6 instead my no-name driver, just to hear what can be expected:

Please note that as this is test box, I temporarily mounted all electronics on rear panel, including batteries & charger.

That way, all SMD LEDs & buttons on charger are accessible, and I can monitor charge process, capacity of batteries, and battery temperature.

On final twin H280 box, I will arrange this differently.

Wow you’re making good progress, looks much nicer in the wooden box now! I would advise against wiring all 4 mids in parallel as you will loose stereo capabilities and put more strain on amplifier.. but since it’s a 3 channel board you’re options are limited I guess if you don’t want to buy another one like the 4 channel tiny sine or wondom jab line amplifier boards with Bluetooth..

do you plan on pairing these with your tham subwoofers? Would like to hear that combination one day!

do you plan on pairing these with your tham subwoofers? Would like to hear that combination one day!

2 noname 7:

Thanks, yes, it definitely looks nicer in wooden box 🙂

Regarding your advice:

Yes, I was thinking a lot about various wiring combinations with my 2.1 plate amp, but in the end I decided that all 8" woofers will be connected in parallel , when I complete double H280 box.

There are couple of reasons:

1. To extract maximum output:

- "Arylic" 2.1 plate amp has 3 outputs , as they are designed for mounting on subwoofer box, and then connect two small satellite boxes to plate amp outputs.

According to specs, power output for two satellites is 50W per 4 Ohm each , and power output for subwoofer is 100W per 2 Ohm.

- As I will have 6 drivers total (four 8" woofers + two 2.5" fullrangers), my plan was to:

a) Connect all 8" woofers in parallel (each 8 ohm impedance), to get 2 Ohm total impedance => this is important to raise low frequency level to cope with horn output of 2.5" fullrangers,

b) Connect each 2.5" fullrange driver to dedicated output for satellites =>with 50W per 4 ohm, I will have to reduce power output to be inline with woofer output, as mid frequencies will be too loud.

2. Beacuse of application:

- This project is about exploring possibility to use MEH as portable bluetooth speaker, for covering small events where my other, larger system is not practical.

That said, true stereo effect is not very important in that application, and it would be very hard to properly implement it, unless I make two separate MEH boxes, each box for one stereo channel.

For example, if I decided to go in stereo mode, with double H280 box, the physical distance between each horn will be limited, so there would be minimum stereo separation between channels.

Then, subwoofer channel is mono summed L+R, and in my case , cross-over frequency is much higher then typical sub/sat combo.

Such high cross-over frequency (600Hz) wouldn't work good if I had classic sub/sat combination that is few meters apart (due localization issue) ...but all woofers are mounted in horn together with fullrange driver, so integration/coherence is much better.

In any case, I can easily try mono/stereo combinations, and then decide based on listening tests what is better in the end.

Regarding pairing with THAM subwoofers:

I could pair this MEH with THAMs (or even Keystone sub), but this was not main intention.

The general idea is to have portable MEH that runs on batteries, and that could be transported to remote/difficult-to-reach locations.

Also, portable MEH should sound smoother in smalller spaces (less than 30-50m2), as THAMs have too much output, causing lot of notches/cancellations in low frequencies, too much rattling & vibrations of internal wall surfaces , so they sound best in large , open spaces.

But for the fun purposes, of course it could be done 😎

Thanks, yes, it definitely looks nicer in wooden box 🙂

Regarding your advice:

Yes, I was thinking a lot about various wiring combinations with my 2.1 plate amp, but in the end I decided that all 8" woofers will be connected in parallel , when I complete double H280 box.

There are couple of reasons:

1. To extract maximum output:

- "Arylic" 2.1 plate amp has 3 outputs , as they are designed for mounting on subwoofer box, and then connect two small satellite boxes to plate amp outputs.

According to specs, power output for two satellites is 50W per 4 Ohm each , and power output for subwoofer is 100W per 2 Ohm.

- As I will have 6 drivers total (four 8" woofers + two 2.5" fullrangers), my plan was to:

a) Connect all 8" woofers in parallel (each 8 ohm impedance), to get 2 Ohm total impedance => this is important to raise low frequency level to cope with horn output of 2.5" fullrangers,

b) Connect each 2.5" fullrange driver to dedicated output for satellites =>with 50W per 4 ohm, I will have to reduce power output to be inline with woofer output, as mid frequencies will be too loud.

2. Beacuse of application:

- This project is about exploring possibility to use MEH as portable bluetooth speaker, for covering small events where my other, larger system is not practical.

That said, true stereo effect is not very important in that application, and it would be very hard to properly implement it, unless I make two separate MEH boxes, each box for one stereo channel.

For example, if I decided to go in stereo mode, with double H280 box, the physical distance between each horn will be limited, so there would be minimum stereo separation between channels.

Then, subwoofer channel is mono summed L+R, and in my case , cross-over frequency is much higher then typical sub/sat combo.

Such high cross-over frequency (600Hz) wouldn't work good if I had classic sub/sat combination that is few meters apart (due localization issue) ...but all woofers are mounted in horn together with fullrange driver, so integration/coherence is much better.

In any case, I can easily try mono/stereo combinations, and then decide based on listening tests what is better in the end.

Regarding pairing with THAM subwoofers:

I could pair this MEH with THAMs (or even Keystone sub), but this was not main intention.

The general idea is to have portable MEH that runs on batteries, and that could be transported to remote/difficult-to-reach locations.

Also, portable MEH should sound smoother in smalller spaces (less than 30-50m2), as THAMs have too much output, causing lot of notches/cancellations in low frequencies, too much rattling & vibrations of internal wall surfaces , so they sound best in large , open spaces.

But for the fun purposes, of course it could be done 😎

To continue with project:

After completing new box, I've created initial DSP settings, and performed couple of tests outside, couple of things were noted:

a) Even after some larger distance (>10m listening distance) , there are still lot of details present,

b) High end coming from small fullrange driver is more than sufficient => I was afraid that there would be lack of high frequency extension, bit this is not the case,

c) Bass from my old 6.5" woofers goes to about 50-60Hz, which is sufficient extension, but I can hear some low frequency distortion on higher volume, which seems like membrane is out of control (excessive stroke under bass reflex tuning frequency).

I'll try to sort this with different high-pass filters and/or different bass reflex tuning,

d) Woofer ports are maybe little bit too restrictive, as chuffing noise can be heard => but these holes could be easily enlarged if required,

e) Thin okume plywood (10mm) is sufficient for box of this size, as there are no excessive vibrations/ringing.

Here is first test outdoors, after initial DSP settings were done:

(Song used: Brian Bromberg - My Bass)

After completing new box, I've created initial DSP settings, and performed couple of tests outside, couple of things were noted:

a) Even after some larger distance (>10m listening distance) , there are still lot of details present,

b) High end coming from small fullrange driver is more than sufficient => I was afraid that there would be lack of high frequency extension, bit this is not the case,

c) Bass from my old 6.5" woofers goes to about 50-60Hz, which is sufficient extension, but I can hear some low frequency distortion on higher volume, which seems like membrane is out of control (excessive stroke under bass reflex tuning frequency).

I'll try to sort this with different high-pass filters and/or different bass reflex tuning,

d) Woofer ports are maybe little bit too restrictive, as chuffing noise can be heard => but these holes could be easily enlarged if required,

e) Thin okume plywood (10mm) is sufficient for box of this size, as there are no excessive vibrations/ringing.

Here is first test outdoors, after initial DSP settings were done:

- Home

- Loudspeakers

- Multi-Way

- Portable Bluetooth MEH project (based on "SB Acoustics" H280 horn)