If a paper cap has absorbed a bunch of water over the decades, what does that do to the DC leakage with a plate voltage on one side, and a grounded high value grid leak on the other? A little ionic contamination goes a long way when you’re talking multiple meg ohms - I’m guessing the downstream stage runs at a higher bias than it’s supposed to. That will affect the sound for sure.

Philips consumer is a total different animal from Philips telephone exchanges that I had to put together. You know what they say about accountants running the show but that did not work with telecoms.

Different price point. Telephone network has to be reliable all the time, and parts easily swapped out when they do fail. If a consumer radio receiver fails it’s not likely to inconvenience more than one or two people. We still have standards where it matters, even in the USA, where nobody knows anything and everyone is flying by the seat of their pants.

I don't know if there ever was a standard of "wire wrap before solder" joints.

We have learned to do it that way at the "Deutsche Bundespost Fernmeldewesen" when being educated for a job. This took three and a half years, and this was the usual education time in germany before doing a job. I don't think that such a system have ever existed in the US. It combined schooling in theory and practice training in the company, which pays the sallary in this time. Just to receive perfectly trained people afterwards.

There are industries/companies where this happens. In some places, the unions and companies work together along with the community/technical colleges/trade schools to provide education and on the job training that is a paid apprenticeship like in Germany. Plumbers/carpenters/electricians/welders all get this kind of training in some places. And in other places you get half-arsed training, and people build garbage. Somehow people are ok with that when they don’t know any better? This is why I do most things myself, because if I’m going to have something done poorly, I’d rather not be paying professional wages to someone to do it. Where my moms live, they have people who are much more skilled across the board, and actually get what they pay for. Where I live it’s a little bit of the Wild West in terms of skills/training/smarts/quality of work.

There was me thinking it was something to do with the take over by Chrysler, and moving production to the States.

The Asians make very nice stuff if you want to pay them for that. “Quality” was destroyed by greedy westerners who wanted things for so cheap that they are essentially free. The same is true of companies in the west. Much of what we made for consumers was very poor quality, and broke down quickly. Certain things, maybe not so much. But there is a romance for things that never were in many instances.

One good example is Lucas electrics for cars. Total garbage according to everyone I’ve known who had their budget level stuff in an old enlglish car. But Lucas did make very high quality electrical parts when they were paid enough to do it right. This is the joy of capitalism, and the desire to have everything without working for it.

I’ve always hated when people wrap things to tight when soldering. It’s one thing if the component is on a sturdy binding post, but quite another when trying to remove a component from the little wilder tabs on some of the middle to lesser quality rotary switches in some old gear. Painfully tedious but satisfying to worry a small bit of wire off of something like the rotary switch in an old vtvm without destroying the switch in the process. Most of what we have and repair from the old days was never meant to last as long as it did.

I too have a preference for the high end industrial grade wiring of test equipment and amps that were made for commercial and industrial use, but until that stuff became surplussed due to obsolescence, it would cost half a year of my wages to buy something like that when it was new.

regarding the “solder as glue”, it seems to be what TEK did with their ceramic strips, and it worked just fine for them. Plenty of surface area, and the solder makes a very good glue. I don’t think they had any problems with signal quality due to their wiring methods. I like how easy it is to access parts in the rare instances they need replacing.

I too have a preference for the high end industrial grade wiring of test equipment and amps that were made for commercial and industrial use, but until that stuff became surplussed due to obsolescence, it would cost half a year of my wages to buy something like that when it was new.

regarding the “solder as glue”, it seems to be what TEK did with their ceramic strips, and it worked just fine for them. Plenty of surface area, and the solder makes a very good glue. I don’t think they had any problems with signal quality due to their wiring methods. I like how easy it is to access parts in the rare instances they need replacing.

Or 'Lucas, Prince of Darkness', as the Americans used to say 🙂One good example is Lucas electrics for cars.

Or 'Lucas, Prince of Darkness', as the Americans used to say 🙂

Exactly! I figured people who owned those cars were devil worshipers, or some kind of sadists who like to bother their auto mechanics a lot. 😀

The smart ones all upgraded to Bosch parts.

Yes. But does that really prove the »superior« quality of the bumblebees that has been claimed above? Quite the opposite, I'd say. And I still hold my conviction that the same amp sounded differently when it was new, most probably like it had been equipped with film capacitors (and metal film resistors, btw).If a paper cap has absorbed a bunch of water over the decades, what does that do to the DC leakage with a plate voltage on one side, and a grounded high value grid leak on the other? A little ionic contamination goes a long way when you’re talking multiple meg ohms - I’m guessing the downstream stage runs at a higher bias than it’s supposed to. That will affect the sound for sure.

Best regards!

People believe they hear a difference. It must therefore be “better”. They may in fact hear a difference. Better? Depends who is on the jury.

And about Philips consumer? People *believe* that it’s in the same league as the ultra reliability telecom stuff, so therefore it must be good. At one time it was. It hasn’t been for a loooooong time.

And about Philips consumer? People *believe* that it’s in the same league as the ultra reliability telecom stuff, so therefore it must be good. At one time it was. It hasn’t been for a loooooong time.

I have a Chinese Philips TV that is working perfectly so far 🙂 Not as bad as modern RCA stuff at least 🙂

Philips has always had good technology, in the execution it could be bettered. The Apple metal look computer screens for instance are 100% Philips.

Hey, guess what. I just cleaned the binding posts of my 46 years old DM2A loudspeakers inside and out, the difference is not subtle. Saves on a couple of fresh HF capacitors I was planning 🙂 Beautiful sealed units by the way, no moisture there and spot on value. Sometimes I see people exchange the internal wiring but I can not imagine these short lengths make a difference if the diameter is sufficient and not corroded.

Hey, guess what. I just cleaned the binding posts of my 46 years old DM2A loudspeakers inside and out, the difference is not subtle. Saves on a couple of fresh HF capacitors I was planning 🙂 Beautiful sealed units by the way, no moisture there and spot on value. Sometimes I see people exchange the internal wiring but I can not imagine these short lengths make a difference if the diameter is sufficient and not corroded.

In audio, first rule is: Everything and every detail is audible.

Rule #2: If rule number one couldn't be applied satisfactionally, level of resolution of the whole audio rig is too low. Improve until you apply for rule #1.

You don't think that small lengths of cable can't make an improvement? For sure that isn't happening when the gear is not high resolution but low quality. If its high resolution, you'll hear that detail.

Rule #2: If rule number one couldn't be applied satisfactionally, level of resolution of the whole audio rig is too low. Improve until you apply for rule #1.

You don't think that small lengths of cable can't make an improvement? For sure that isn't happening when the gear is not high resolution but low quality. If its high resolution, you'll hear that detail.

Last edited:

In audio, first rule is: Everything and every detail is audible.

Rule #2: If rule number one couldn't be applied satisfactionally, level of resolution of the whole audio rig is too low. Improve until you apply for rule #1.

You don't think that small lengths of cable can't make an improvement? For sure that isn't happening when the gear is not high resolution but low quality. If its high resolution, you'll hear that detail.

...provided that you know this »everything« and »every detail«. Otherwise I'd be not too sure of that. Keyword is: Expectation bias.

Best regards!

My wife realizes that big speakers sound better than little ones. That’s why the monkey coffins have been in continuous use for the last 15 years with absolutely no argument about it. She also knows that (point to point wired) 200 watt tube mono blocks are on the horizon, and rightly suspects that speakers to go with them are soon to follow. Dual 15’s, 3 way - loud enough for Who concerts in the house.

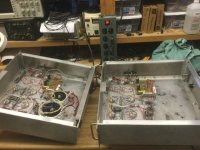

The PA equipment - all of it - must live in the shop. Too easy to let a dog get out while moving 32 cubic foot speakers and amp racks in and out. Not to mention the house isn’t really big enough.

The PA equipment - all of it - must live in the shop. Too easy to let a dog get out while moving 32 cubic foot speakers and amp racks in and out. Not to mention the house isn’t really big enough.

Attachments

Here's a view into one of a pair of Circlotron monophonic amplifiers, featuring PL519's, that I built in 2001. As I don't have the file anymore, I had to borrow the picture from another site:

It's a hybrid construction. Inrush current limiter, bias supply and small signal tubes are on PCB's, while the main PSU, the power tubes and the VU indicator are wired PTP.

Best regards!

It's a hybrid construction. Inrush current limiter, bias supply and small signal tubes are on PCB's, while the main PSU, the power tubes and the VU indicator are wired PTP.

Best regards!

I don't do this myself (yet), but some brands are doing it right and are so proud of it that they publish this kind of pictures on their site. I own an example of this amp, and it sounds like the best. When you open it you see why.

The board is the autobias system, the rest is point to point.

The board is the autobias system, the rest is point to point.

Attachments

- Home

- Amplifiers

- Tubes / Valves

- Point to point wiring