Your post is well intentioned, but the OP’s wallet will just end up $800 lighter if he follows any of the claims in that video, or any other "upgrades" for this speaker found online charging money. Clickbait videos like this only serve the purpose of advertising and I will go on record to call it the audiophile equivalent of a tourist trap.

From the start, GR-Research calls the inductors “steel core inductors”, and the differentiation here is they are soft iron, not steel. An engineer and speaker design knows the difference, but a hobbiest-turned-salesman does not. He also seems to struggle with any challenging drivers. I wouldn't place my faith in someone like that. I anticipated his attempt to cross the tweeters over lower, and sure enough he was aiming for 2 or 3kHz. The salient problem is the JA-0513 was susceptible to broken tinsel leads, even with it's 6kHz crossover point. The wire in the voice coils is like that in earphones. Lowering the crossover to 4kHz, as GR-Research has done, may contribute to a premature failure. When a commenter took him to task over the price (and pointed out DSP could be cheaper), GR responded with “DSP has a lot of bottlenecks.” He uses “poly bypass caps”, yet his kit doesn’t even include the essential backplate. Apparently "caps" are more important.

TL;DR - The whole video was an audiophile grift pushing an $800 crossover, but we don’t find that out until the end.

Yes i am sure.Arez.

Are you sure that is the case? If so I apologise, but the plots that he's showing have the date 8-22-2023. How do you think they compare to the http://www.troelsgravesen.dk/Yamaha-NS1000.htm measurements? I would have thought that the best way forward is to bed them in, take measurements and then refine from there. Otherwise what is one working with?

Burn in or unsettling or whatever to call it will not change the aforementioned things, by any noticeable degree.

Go look at the measurements from both, overlay them on top of each other, and you will find the anomalies (peaks/dips) in the same place in both,, i already tried.

Smoothing and vertical scaling makes all the difference.

Troels uses a lot of smoothing and very different vertical scale.

He likes to show his completed speakers with nice and smooth looking measurements of course, as that is part of what he sells.

Ever notice how little attention is paid to Diffraction in his designs? yet everything looks smooth and mellow, it is not a coincidence🤔

And it is not because Troels defies the laws of physics.

In these graphs the vertical scaling goes up to 20db! in some of them.

Then GR, makes a living of "fixing" other mfg.s speakers partly. There is less smoothing used, and the vertical scale has a very different aspect ratio.

He gains most from showing improvements in his modifications, so from his side, showing anomalies in the response is beneficial, again for sales.

Pretty logical no?

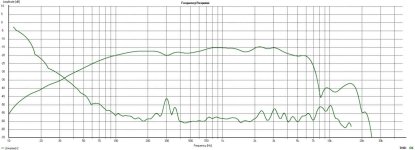

I added 2x, 1m/1W measurements of the same driver.

One from someone that used the "exemplary smooth and extended" behavior in they're marketing. Noticing the 300hz anomaly as a measurements artefact more or less.

And the same measured by someone testing drivers for his own use.

Until you overlay the graphs and mess with the scaling one would maybe not think it is the same driver even.

just a little example.

That driver is loved by many and not a bad 10", but again notice how scaling and smoothing can make you show what is beneficial for your application, for anyone that is not looking too closely.

And i am not trying to convince anyone to spend 800$ on GR research upgrade of the NS-1000M.

just pointing out the differences...

GR Research partly sells snake-oil for a living, and so does most hifi based companies, regardless of name and price.

The NS-1000M is a very nice speaker for it's vintage, and going rate. And the drivers has some good qualities, that is hard to find actually.

Like a fast and clean decay in the mid and upper region, partly due to the BE diaphragms, small clearances - lack of noticeable cavity resonances etc.

Attachments

Last edited:

I hope the OP will forgive me for filling a page here, but being objective-minded I hope to show why upgrades are sometimes a bad idea.

The sincerely wish is that NS-1000M owners will give pause before buying an "upgrade" kit.

Taking some time today, I measured my drivers as a reality check. They don’t have the 1.8kHz ringing mode in GR-Research's video. Nor do any that I have ever measured. Nor do my tweeters have the tall peak at 3kHz or fall off at 12kHz.

The resonance GR shows in that video at 1.8kHz corresponds to the diameter of the midrange's magnetic gap when using the equation 13542/pi/diameter in inches. There is a foam insert behind the voice coil to dampen this cavity resonance and his customer's midrange requires a closer look to determine if something is amiss. Having done my due diligence, I measured many of these midranges and never found a peak in that region, nor found any third-party measurements that recreate what is in GR's video. GR-Reseach's measurements showing poor performance are not representative of normal behavior for those drivers.

Additionally, the speakers I bought don't have the 4kHz dip that Troels Gravesen focused on. In the Yamaha NS-1000M Owner’s Manual we find the speaker was recommended to be listened to at middle height. I investigated by measuring and it can be seen in the impulse response that the tweeter and mid are impulse coincident at that height. You're seeing it first here.

The relevance here is the acoustic slope between the mid and tweeter was an approximate 4th order Butterworth Squared/Linkwitz-Riley, which is often used in time aligned (but not linear phase) speakers; the forward offset of the midrange dome relative to the tweeter dome permits a time coincident impulse response around center baffle; and lastly, the first arrival rules, the impulse of the first driver we hear is perceived as the loudest.

Unsurprisingly, Yamaha was here first. The precise dip Troel's shows was also shown in the manual for the vertical off axis. I was able to cause the same dip shown in the Yamaha graphs and in Troels' graphs at 1 meter, having the calibrated mic at tweeter height. The conclusion is the 4kHz dip that Troels shows was in fact caused by his measuring height. As his crossover was designed using measurements taken at the tweeter level, it implies that his crossover compensated for a response and phase deviation that never existed when the speaker was used at recommended listener ear height. I also noticed his T&S parameters don't match his plotted bass alignment response.

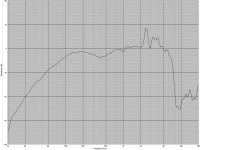

I will leave you with some quick measurements taken in my room with lots of reflections. Does this "need" a crossover upgrade? Well, the stock NS-1000M power response was good enough in fact that Floyd Tool chose it as an example, though I cannot recall which book/page but there was also a photo of it. I know what Harold Callahan would say.

On axis in room at 2.5 meters:

Impulse response near center of baffle. Time-aligned tweeter-midrange. Woofer appears later at 1.55ms and is more visible in step response.

Contains room reflections at 2ms onward (mic was on a chair).

Midrange and tweeter:

Midrange waterfall:

The sincerely wish is that NS-1000M owners will give pause before buying an "upgrade" kit.

Taking some time today, I measured my drivers as a reality check. They don’t have the 1.8kHz ringing mode in GR-Research's video. Nor do any that I have ever measured. Nor do my tweeters have the tall peak at 3kHz or fall off at 12kHz.

The resonance GR shows in that video at 1.8kHz corresponds to the diameter of the midrange's magnetic gap when using the equation 13542/pi/diameter in inches. There is a foam insert behind the voice coil to dampen this cavity resonance and his customer's midrange requires a closer look to determine if something is amiss. Having done my due diligence, I measured many of these midranges and never found a peak in that region, nor found any third-party measurements that recreate what is in GR's video. GR-Reseach's measurements showing poor performance are not representative of normal behavior for those drivers.

Additionally, the speakers I bought don't have the 4kHz dip that Troels Gravesen focused on. In the Yamaha NS-1000M Owner’s Manual we find the speaker was recommended to be listened to at middle height. I investigated by measuring and it can be seen in the impulse response that the tweeter and mid are impulse coincident at that height. You're seeing it first here.

The relevance here is the acoustic slope between the mid and tweeter was an approximate 4th order Butterworth Squared/Linkwitz-Riley, which is often used in time aligned (but not linear phase) speakers; the forward offset of the midrange dome relative to the tweeter dome permits a time coincident impulse response around center baffle; and lastly, the first arrival rules, the impulse of the first driver we hear is perceived as the loudest.

Unsurprisingly, Yamaha was here first. The precise dip Troel's shows was also shown in the manual for the vertical off axis. I was able to cause the same dip shown in the Yamaha graphs and in Troels' graphs at 1 meter, having the calibrated mic at tweeter height. The conclusion is the 4kHz dip that Troels shows was in fact caused by his measuring height. As his crossover was designed using measurements taken at the tweeter level, it implies that his crossover compensated for a response and phase deviation that never existed when the speaker was used at recommended listener ear height. I also noticed his T&S parameters don't match his plotted bass alignment response.

Quick and Dirty Measurements

I will leave you with some quick measurements taken in my room with lots of reflections. Does this "need" a crossover upgrade? Well, the stock NS-1000M power response was good enough in fact that Floyd Tool chose it as an example, though I cannot recall which book/page but there was also a photo of it. I know what Harold Callahan would say.

On axis in room at 2.5 meters:

Impulse response near center of baffle. Time-aligned tweeter-midrange. Woofer appears later at 1.55ms and is more visible in step response.

Contains room reflections at 2ms onward (mic was on a chair).

Midrange and tweeter:

Midrange waterfall:

Skepticism is a good thing, but, TRUE measurements don't lie.I’m very skeptical of a "reviewer" who tests long time stored speakers without a re-bedding in process of a least a couple of hundred hours and who makes dramatic criticisms and changes based on those. Then to ask nearly $1000 to put them “right” shows a possible condflict of interests. After 200 hours they will sound nothing like they did initially, with no mods at all, then clean the pots, change rear connectors first and go from there.

The "reviewer" actually measured each driver disconnected from the crossover and "rear connectors" >

you should perhaps pay more attention to exact details. The NS-1000 mids actually RING in their mid-band.

PS.

I actually re-designed the crossover of my YAMAHA NS-50T's to solve a 2Khz problem.

Don't just assume that Yamaha can't make mistakes (or) cost cutting measures.

( the NS-10's really got some things right - FLUKE ??? )

I actually re-designed the crossover of my YAMAHA NS-50T's to solve a 2Khz problem.

Don't just assume that Yamaha can't make mistakes (or) cost cutting measures.

( the NS-10's really got some things right - FLUKE ??? )

After 200 hours they will sound nothing like they did initially, with no mods at all, then clean the pots, change rear connectors first and go from there.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

WELL > after 200 hours, speakers will in fact sound very much like they did before. (unless you have damaged them)

The sound SIGNATURE of speakers doesn't actually change much over time - unless there is a problem.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

WELL > after 200 hours, speakers will in fact sound very much like they did before. (unless you have damaged them)

The sound SIGNATURE of speakers doesn't actually change much over time - unless there is a problem.

Prompted by all the different opinions I've taken 5 mins to check up on this. My experience, is that it does happen. Others are saying otherwise. I'm happy to learn, I suppose the best way forward is a set of before and after measurements, at different elapsed times, conducted under similar conditions, but in the absence of that here’s some stuff from Mr Google.

https://hub.yamaha.com/audio/a-how-to/how-to-burn-in-speakers/

https://mynewmicrophone.com/do-speakers-need-to-be-broken-in-burned-in-fact-fiction/

But here is a good post (with some measurements) that seems to say otherwise.

https://www.audiosciencereview.com/forum/index.php?threads/do-audio-speakers-break-in.11898/

So now I'm more undecided, I would say that less than five hours is not a very long time. But I'm not so invested as to get tired checking, I would say that after being stored for a few years my NS1000,'s (standard XO), (as well as other speakers I've had) did seem to open up, seemingly in resolution. But maybe that is just my ears getting acclimated! I feel no need to engage in a "speaker cable" type back and fourth on this.

All said and done, thanks for an interesting thread.

https://hub.yamaha.com/audio/a-how-to/how-to-burn-in-speakers/

https://mynewmicrophone.com/do-speakers-need-to-be-broken-in-burned-in-fact-fiction/

But here is a good post (with some measurements) that seems to say otherwise.

https://www.audiosciencereview.com/forum/index.php?threads/do-audio-speakers-break-in.11898/

So now I'm more undecided, I would say that less than five hours is not a very long time. But I'm not so invested as to get tired checking, I would say that after being stored for a few years my NS1000,'s (standard XO), (as well as other speakers I've had) did seem to open up, seemingly in resolution. But maybe that is just my ears getting acclimated! I feel no need to engage in a "speaker cable" type back and fourth on this.

All said and done, thanks for an interesting thread.

I don't think anyone has argued that burn in of a driver does not happen, it does but it does not fix cancellations and phase issues as pointed out 🙂

A couple of things, the NS-1000 was produced for 20 years, there has been subtle changes to the drivers.

The damping material under the mid cavity might be in varying shape, Urethane ages, and often breaks down over time.

And the edge coating materials on the mid might be dried up or missing in some examples, depending on what they have been exposed to.

There is more then one factor, that can account for some of the differences.

Also the Electrolytic caps in 30-50 year old speakers can't be expected to be in original condition, if they have been changed, you will also get variations from stacking Lytics with loose tolerances, etc.🙂

A couple of things, the NS-1000 was produced for 20 years, there has been subtle changes to the drivers.

The damping material under the mid cavity might be in varying shape, Urethane ages, and often breaks down over time.

And the edge coating materials on the mid might be dried up or missing in some examples, depending on what they have been exposed to.

There is more then one factor, that can account for some of the differences.

Also the Electrolytic caps in 30-50 year old speakers can't be expected to be in original condition, if they have been changed, you will also get variations from stacking Lytics with loose tolerances, etc.🙂

Surprisngly, such cracks - I assume they are small, as they don't show on photos, - once glued and sealed, have little to no consequences in midrange, where the driver is used. Phenolic glues (apply, let dry, cook at 120-140 deg. C for 1-2 hour) are most suitable for metallic diaphragms. Can be substituted with epoxy if pheolic is unabtainable. Use thin aluminium foil as backing, preferably anodised/oxidized, but regular cooking foil works too.Thanks Arez and jkB77,

Finally found two mid driver is cracked not woofer problems. How can I fix this ?

It coil is already burn ?

Best regard

Vox.

I have not tried what you suggest but are other parts on the mid dome able to take that temperature for that time? Just another option (a room temp one) Could one use the thin smear of epoxy (as you suggested) over a carbon fibre tissue? Model shops sell it, and two or three layers could be built up with one thin coat of epoxy used to impregnate all of them at one time.

Maybe do a test first on an egg used as a mould (or some such thing) with some grease to act as a mould release agent.

PS.

They are available second hand.

https://www.ebay.co.uk/sch/i.html?_...a+NS-1000M+beryllium+midrange+driver&_sacat=0

I have not tried what you suggest but are other parts on the mid dome able to take that temperature for that time? Just another option (a room temp one) Could one use the thin smear of epoxy (as you suggested) over a carbon fibre tissue? Model shops sell it, and two or three layers could be built up with one thin coat of epoxy used to impregnate all of them at one time.

Maybe do a test first on an egg used as a mould (or some such thing) with some grease to act as a mould release agent.

PS.

They are available second hand.

https://www.ebay.co.uk/sch/i.html?_...a+NS-1000M+beryllium+midrange+driver&_sacat=0

PPS

Beryllium is a very very dangerous material if the dust is inhaled etc, read up on all precautions or leave alone.

Take care.

For instance..."Beryllium is toxic as both a skin irritant and an inhaled substance and can result in dermatitis, acute pneumonitis, and chronic pulmonary disease. The first signs of serious or life-threatening acute beryllium exposure may involve difficulty breathing, chest pain, or shortness of breath."

Beryllium is a very very dangerous material if the dust is inhaled etc, read up on all precautions or leave alone.

Take care.

For instance..."Beryllium is toxic as both a skin irritant and an inhaled substance and can result in dermatitis, acute pneumonitis, and chronic pulmonary disease. The first signs of serious or life-threatening acute beryllium exposure may involve difficulty breathing, chest pain, or shortness of breath."

Found problem is not only coil or beryllium. Magnet not stick with glue and coil is gap of .Everything was destroyed because the workers blamed it.

Now try to fix with epoxy glue .

Now try to fix with epoxy glue .

The only part of a driver which is somewhat heat sensitive is polyrethane damper inside the motor, and it takes 150 deg C easily - just tested with a digitally controlled heat gun to be extra sure. Support surround when baking - put something under it or place entire moving system on a suitably sized teacup so that it sits on a surround, not on VC or dome - otherwise surround may sag. Or suspend it on a string using binder clip.Vox.

I have not tried what you suggest but are other parts on the mid dome able to take that temperature for that time? Just another option (a room temp one) Could one use the thin smear of epoxy (as you suggested) over a carbon fibre tissue? Model shops sell it, and two or three layers could be built up with one thin coat of epoxy used to impregnate all of them at one time.

Maybe do a test first on an egg used as a mould (or some such thing) with some grease to act as a mould release agent.

PS.

They are available second hand.

https://www.ebay.co.uk/sch/i.html?_...a+NS-1000M+beryllium+midrange+driver&_sacat=0

Never tried carbon fibre in this application, but I guess it could work. Make sure epoxy resin penetrates the crack. Heating the dome to ~50 C helps, as does additg some (1..5%) acetone. Add acetone to the resin itself before mixing with hardener. Use regular non-thinned mix for second layer.

If repairs are made from inside the dome, original appearance of the driver can be completely preserved. Yamaha glue dissolves easily with acetone or methyletylketone or ethylacetate. Xylene should work too.

Beryllium toxicity is wastly overhyped for some reason. Metal or its oxide (beryllium ceramic) are completely safe; it's thin airborne particulates that are REALLY harmful, or dust which makes skin contact. So don't weld, grind or laser cut etc. berillium without due precautions; other methods are no more dangerous than handling aluminium.

Typical problem. Clean magnet and top plate thoroughly, remove corrosion and old glue residuals, prepare aluminium or bronze shims to ensure magnetic gap is really concentric, glue with phenolic glue or epoxy. Epoxy is harder to fix if mistakes are made, so take special care.Magnet not stick with glue and coil is gap of

- Home

- Loudspeakers

- Multi-Way

- Pls help Yamaha NS1000M