Gilbert Briggs suggested a novel approach to the problem of panel resonance by using an expanded polystyrene sphere.

By mounting two drivers at opposite sides of the sphere with both cones facing outwards and the voice coils connected in phase to obtain push-pull, out of phase operation, little resonance was heard in spite of the fact that the vibration of the 'walls' of the sphere could be felt by finger touch.

Filling the interior of the sphere loosely with BAF reduced the main resonance peak.

Incidently, Briggs noted that the polystyrene sphere fitted with a single unit, or two units operating in phase, were unsatisfactory.

By mounting two drivers at opposite sides of the sphere with both cones facing outwards and the voice coils connected in phase to obtain push-pull, out of phase operation, little resonance was heard in spite of the fact that the vibration of the 'walls' of the sphere could be felt by finger touch.

Filling the interior of the sphere loosely with BAF reduced the main resonance peak.

Incidently, Briggs noted that the polystyrene sphere fitted with a single unit, or two units operating in phase, were unsatisfactory.

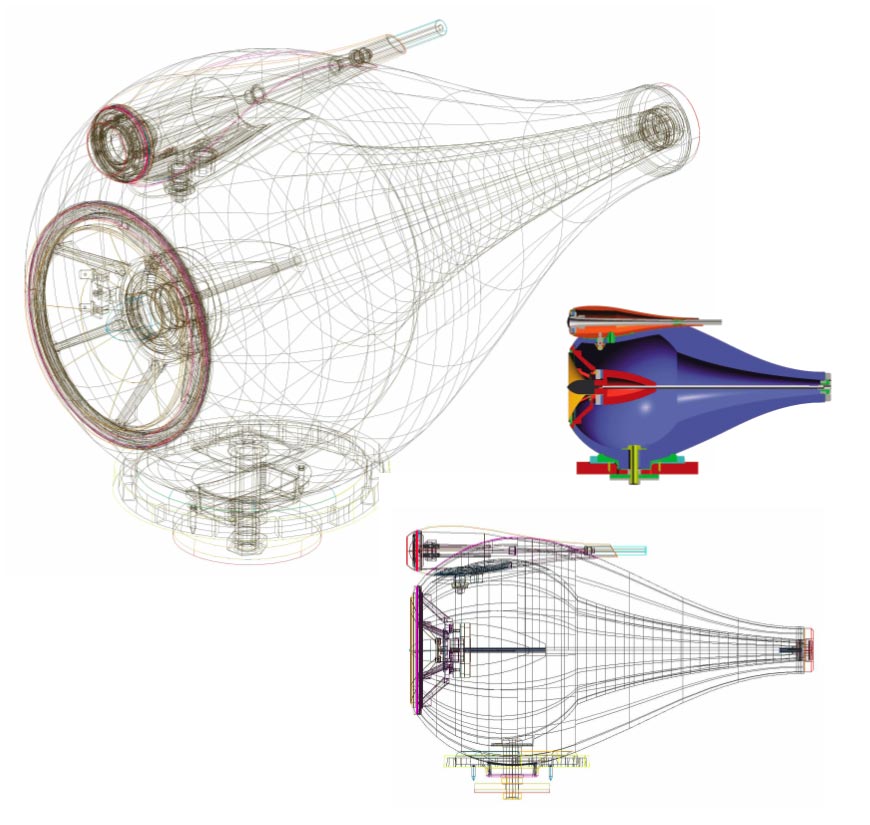

By coincidence, the Briggs polystyrene enclosure was 50 cm in diameter. The polystyrene walls were, understandably, 5 cm thick.The loudspeaker should get a spherical plastic housing (approx. 50cm diameter).

Here's an idea of a helix in a egg/sphere shape, the surface would have a double wall, the void in between filled with sand ( or possibly sand mixed with a rubber compound ), the helix would reduce internal echoes and also stiffen the structure. If you're going to 3d print something, you might as well let your imagination rip.

Here's a slightly better picture, if the driver used was a car coaxial, the tweeter could be removed, and the resulting hole through the pole piece/ magnet could be used to have a piece of studding going from a phase plug, through a cast iron weight ( that would be supported on foam for isolation ) and a hemispherical " nut " on the outside of the enclosure that would hold the assembly in place.

View attachment 988010

Here's an idea of a helix in a egg/sphere shape, the surface would have a double wall, the void in between filled with sand ( or possibly sand mixed with a rubber compound ), the helix would reduce internal echoes and also stiffen the structure. If you're going to 3d print something, you might as well let your imagination rip.

There is a commercial version of this idea: https://www.node-audio.com/docs/hylixa-technical-white-paper.pdf

The helix idea, but not quite as elabortae had a spate of builds and discussion a while back,

dave

dave

Hi very nice thread

If taming vibrations is the main aim i would look at the most critical application The subwoofers

I would look at how the subwoofers are built, the best ones i mean

They are almost all more or less a cube extremely rigid and heavy Ok someone is also spherical

I think that subwoofers design and construction is a very challenging task indeed

I have heard a shocking statement about the optimum ratio between the mass of the cabinet and the moving mass of the driver I can believe it

A ratio of thousands

If taming vibrations is the main aim i would look at the most critical application The subwoofers

I would look at how the subwoofers are built, the best ones i mean

They are almost all more or less a cube extremely rigid and heavy Ok someone is also spherical

I think that subwoofers design and construction is a very challenging task indeed

I have heard a shocking statement about the optimum ratio between the mass of the cabinet and the moving mass of the driver I can believe it

A ratio of thousands

Agreed, and Kevlar has higher internal damping than glass or carbon fibres so would be another step towards perfection! Also, epoxy resin can be used directly on expanded polystyrene without it dissolving.^^^^^^^ THIS will give you the strongest ball, way more than any printing.

They are almost all more or less a cube extremely rigid and heavy

Heavy is not an asset, stiff is critical in a woofer, one wants to push the (potential) resonances up above the speaker’s passband. A compact enclosure will tend to help in that respect, but some pretty good bass can be had from other shapes.

Active reaction force cancellation is a clver trick to dramatically reduce energy loaded into the enclosure from the woofers.

dave

Around that time I got a full US patent on a shape for enclosures made out of thin thermoplastic material, made dozens of enclosures based on those principles, quite some money too, and I respectfully submit that you have no clue.Speaker thickness plastic is a PITA.

You will need multiple layers, honeycombs, foam cores and so on.

Expensive, slow, unpredictable as it is a new process.

And a sphere, another new complication.

Been processing plastics since 1993...

Not sure why somebody processing plastics since 1993 (so for almost 30 years) finds it complicated/difficult/dazzling/whatever.

On the contrary I see people using plastic to build cabinets doing so to simplify their own life, increase production, reduce workforce, etc.

FWIW I make Guitar Amps and for the last two Months have been working to junk traditional Tolex covered MDF/chipboard cabinets and replace them with plastic thermoformed ones, go figure.

On the contrary I see people using plastic to build cabinets doing so to simplify their own life, increase production, reduce workforce, etc.

FWIW I make Guitar Amps and for the last two Months have been working to junk traditional Tolex covered MDF/chipboard cabinets and replace them with plastic thermoformed ones, go figure.

Agreed! When I commented about the need to mass load an already ~260 lb speaker due to its generally poor construction, most were skeptical at best, but one took it to task and here's the (temporary) results for both the cab and the separate HF horn perched on top, so ~2x heavier overall, a good rule-of-thumb (ROT) IME. Woofer mass = ~38.47 gr. less air load.A ratio of thousands

hi yes I agree I said a cube because there was a talk about spherical cabinetsHeavy is not an asset, stiff is critical in a woofer, one wants to push the (potential) resonances up above the speaker’s passband. A compact enclosure will tend to help in that respect, but some pretty good bass can be had from other shapes.

Active reaction force cancellation is a clver trick to dramatically reduce energy loaded into the enclosure from the woofers.

dave

a cube it's a much simpler shape

Moreover i see very few spherical subs around There must be a reason

And considering that the requirements for the lower woofer are quite different than for the remaining drivers i would look at a separate box for it

I see that almost no one like this and i really don't know why I mean the sat plus sub option They prefer to make a single huge and heavy cabinet

What shape will the yolk be in a square egg? It is important. Thinking about it is distracting and interferes with life.. 🙄 Is a tetrahedral or octahedral yolk better for a cubic egg?.. I wouldn´t be surprised at all them growing square eggs too.

Last edited:

they don't specify the frequency range for the PP version

it would be very interesting to see some distortion measurements

they just mention a very similar peak SPL but not at which Hz an distortion

the price difference is huge

they don't specify the frequency range for the PP version

it would be very interesting to see some distortion measurements

they just mention a very similar peak SPL but not at which Hz an distortion

the price difference is huge

The price difference mostly is due to DSP and Dante networking, not to the enclosure material.

- Home

- Loudspeakers

- Multi-Way

- Plastic Speaker Cabinet - How I calculate the thickness?