Do you have time to put together a 20,000 ft. block diagram of the overall direction and parts. What is the total price diy like for EVERTHING?😉

Total cost will likely be around $300 plus transformers and chassis. With a basic remote interface. I haven't done any block diagrams. I'll post some more up to date schematics once I figure out how much I can squeeze onto the DAC board. It's filling up quick.

Those look easy enough to work with. The LP2951s on the backplane and LP5907s right at the devices.

Now the only thing left is the 5V analogue supply. Should we do another Jung or just shunt what we have?

shunt what we have. that was the reason for the jungs .75a rating.

then the dac's analog ground can the the one and same as the line stage.

os

You are right, it is Jeff's pre-amp based on the fact he is doing the cad design.Should you change the title of the thread? I have been watching the two of you go back and forth and I'm seeing this as being more of a digital thread than as a pre-amp thread, am I missing something in what you two are creating?

And I am following along just for the fun of it, help out where I can. I have no intentions of making Jeff's h/w, as he is of making my design(s) but it is a good learning experience for everyone.

I guess I am looking in the rear view mirror in some senses.

I tried diptrace, it is not worth investing any $ into when I have something that does a much better job of it. So no eCAD sharing on this project = too bad

O/S has set his design requirements but for me they are too limited to make a good multi-functional pre-amp for my own use.

Like I want a tuner, media player, usb codec, phono and probably tone controls. I look at these designs with the intentions that they are functional and potentially marketable.

I still consider my stuff DIY however.

Investing $300+ in parts and cheaping out on a 100mm sq pcb does not make a whole lot of sense to me.

So some posts ago I put forth my design feature set.

If anyone is interested we can switch to a new thread to discuss my creations... but I doubt anyone is interested 🙂

For me the biggest problem is mechanical design. In the old days as a pro ee, mech design usually drove or worked in unison with pcb design, just like chip and s/w design all working in unison.

You are right, it is Jeff's pre-amp based on the fact he is doing the cad design.

And I am following along just for the fun of it, help out where I can. I have no intentions of making Jeff's h/w, as he is of making my design(s) but it is a good learning experience for everyone.

I guess I am looking in the rear view mirror in some senses.

I tried diptrace, it is not worth investing any $ into when I have something that does a much better job of it. So no eCAD sharing on this project = too bad

O/S has set his design requirements but for me they are too limited to make a good multi-functional pre-amp for my own use.

Like I want a tuner, media player, usb codec, phono and probably tone controls. I look at these designs with the intentions that they are functional and potentially marketable.

I still consider my stuff DIY however.

Investing $300+ in parts and cheaping out on a 100mm sq pcb does not make a whole lot of sense to me.

So some posts ago I put forth my design feature set.

If anyone is interested we can switch to a new thread to discuss my creations... but I doubt anyone is interested 🙂

For me the biggest problem is mechanical design. In the old days as a pro ee, mech design usually drove or worked in unison with pcb design, just like chip and s/w design all working in unison.

I'm trying to keep under 100mm square boards to keep the cost from jumping to $400. 101mm boards are $45. 100mm boards are $13. Adds up fast when prototyping. The other nice part about these smaller boards is the pin count is lower. I'm still running on the free version of Diptrace. If I need more space, I add some .100" headers and stack another board on. Another plus is if I screw up the design too badly, I can redesign a section and throw out $13 worth of boards and a few components as opposed to a complete project.

Another bonus with a modular design is the chassis isn't limited as much with single board design. The layout you are working on is going to make your chassis a predetermined depth being you have through panel connectors on the front and the rear of the board. I like the ability to make the chassis match the amplifier so mine will end up to be a 19" rack mount chassis like my amp.

You obviously like integrated amplifiers. I prefer component systems. I think OS does too. That's just a personal preference. To each their own. I'd rather have a big full sized tuner that could tune in a station far away accurately as opposed to a little mobile audio module. Radio stations are terrible in my area and they overpower anything 100 km away. CRTC rules require Canadian radio stations to limit their power at 100000 watts. There isn't a limit in the US. If I try to tune in a Toronto radio station I will get 20 easy listening stations from Detroit mixing the Bee Gees in with whatever I tune to. This is why I won't bother with a tuner in mine. Others can add whatever they like. That's why I'm taking the time to make mine adaptable and somewhat modular.

Hardware has always been the easy part for me. I'm sure I could learn to write software with some practice but right now I don't have the time to invest to learn it. I've been to the point where I've needed to learn it for a few years now but have gotten lucky so far and have always been able to run with Arduinos.

Last edited:

rsavas,

If you start your own thread I would gladly follow along, not that I could help in any way.

A question to whoever can answer this. rsavas has just said that he wanted to add tone controls to his preamp. With today's ever present cell phones carrying peoples music if you used that as the source how do you do tone controls, is that in the phone software or do you still have to do that in the following section if you are using the Bluetooth or even the headphone output to drive an external system?

I've been thinking I have to add EQ to my speakers as I am going to intentionally make the enclosure smaller than optimum and will use the excess power of OS's amplifier section to push up the bottom end with eq and power. The driver will be mounted in a sealed enclosure so I'll be doing this as an air suspension design and extend the bottom with eq and power, I can tune the cone by adding mass to bring the bottom end back up or change some of the suspension parameters.

If you start your own thread I would gladly follow along, not that I could help in any way.

A question to whoever can answer this. rsavas has just said that he wanted to add tone controls to his preamp. With today's ever present cell phones carrying peoples music if you used that as the source how do you do tone controls, is that in the phone software or do you still have to do that in the following section if you are using the Bluetooth or even the headphone output to drive an external system?

I've been thinking I have to add EQ to my speakers as I am going to intentionally make the enclosure smaller than optimum and will use the excess power of OS's amplifier section to push up the bottom end with eq and power. The driver will be mounted in a sealed enclosure so I'll be doing this as an air suspension design and extend the bottom with eq and power, I can tune the cone by adding mass to bring the bottom end back up or change some of the suspension parameters.

There's no tone controls in Android phones. It's sounding like your speakers could use a DSP with all the toys you want to add.rsavas,

If you start your own thread I would gladly follow along, not that I could help in any way.

A question to whoever can answer this. rsavas has just said that he wanted to add tone controls to his preamp. With today's ever present cell phones carrying peoples music is you used that as the source how do you do tone controls, is that in the phone software or do you still have to do that in the following section if you are using the Bluetooth or even the headphone output to drive an external system?

I've been thinking I have to add EQ to my speakers as I am going to intentionally make the enclosure smaller than optimum and will use the excess power of OS's amplifier section to push up the bottom end with eq and power. The driver will be mounted in a sealed enclosure so I'll be doing this as an air suspension design and extend the bottom with eq and power, I can tune the cone by adding mass to bring the bottom end back up or change some of the suspension parameters.

JW,

Your right about using dsp, I just don't know anything really about how all that is implemented and done without getting really expensive at this point.

Your right about using dsp, I just don't know anything really about how all that is implemented and done without getting really expensive at this point.

JW,

Your right about using dsp, I just don't know anything really about how all that is implemented and done without getting really expensive at this point.

I don't think the hardware side of it is expensive. The software side is the bigger part of that. Time alignment has come a long way since my days playing with car audio.

JW,

I've been cursorily following the RePhase thread and what they are doing. I haven't jumped in far enough to see how they are doing some of the software manipulation. I'm not to worried about time alignment as much as simple phase coherency at the crossover point. If that was the case, and I have some ideas for later, I will create a truly time coherent coaxial design. I've been toying with the motor design needed to do that, it is not a simple problem.

I've been cursorily following the RePhase thread and what they are doing. I haven't jumped in far enough to see how they are doing some of the software manipulation. I'm not to worried about time alignment as much as simple phase coherency at the crossover point. If that was the case, and I have some ideas for later, I will create a truly time coherent coaxial design. I've been toying with the motor design needed to do that, it is not a simple problem.

Yes Jeff I understand your contraints and the modular approach does allow for more flexibility in the mech packaging. It is a more cautious approach which is fine too. Once you get your building blocks going, you can integrate more if you like too.

If you are using 19" EIA racking, that is a ton of room to work with.

For my stereo work, I found Bascom-avr, so much easier to use compared to ardunio/gcc. But I do agree you have to invest a lot of time to get up to speed. It is no different than learning ECAD.

I did offer you my complete stereo code/design/eCad s/w if you want it for free. I could teach you orcad and bascom-avr. Having a good teacher vs having to beat your head hard, are many stars apart.

Okay to answer your?

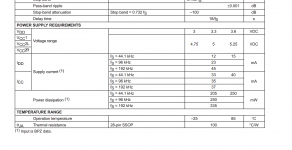

The current for pcm1794A Icc is total for all pins. If you multiply out (Vdd * Idd) + (Vcc * Icc) it works out to the 205mW as stated for the 44.1k bit rate.

If you are using 19" EIA racking, that is a ton of room to work with.

Me too, I worked as a h/w designer, had a team to do the rest, chip, s/w, m/e etc.Hardware has always been the easy part for me. I'm sure I could learn to write software with some practice but right now I don't have the time to invest to learn it. I've been to the point where I've needed to learn it for a few years now but have gotten lucky so far and have always been able to run with Arduinos.

For my stereo work, I found Bascom-avr, so much easier to use compared to ardunio/gcc. But I do agree you have to invest a lot of time to get up to speed. It is no different than learning ECAD.

I did offer you my complete stereo code/design/eCad s/w if you want it for free. I could teach you orcad and bascom-avr. Having a good teacher vs having to beat your head hard, are many stars apart.

Okay to answer your?

The current for pcm1794A Icc is total for all pins. If you multiply out (Vdd * Idd) + (Vcc * Icc) it works out to the 205mW as stated for the 44.1k bit rate.

Not sure what you are comparing here.I'd rather have a big full sized tuner that could tune in a station far away accurately as opposed to a little mobile audio module.

I mean a analog tone control that can be switched in/out. It is placed after the PGA2320 volume control chip and before the line/headphone amp. I had already did the layout for the Doug Self variable freq tone control unit, so thought what the heck try that circuit out too. I even bought the pots too IIRC. I did ltspice on it at one time, it worked as published. Sure, if you have a dsp, tone control can be done there as well, much cheaper place to do it.A question to whoever can answer this. rsavas has just said that he wanted to add tone controls to his preamp. With today's ever present cell phones carrying peoples music if you used that as the source how do you do tone controls, is that in the phone software or do you still have to do that in the following section if you are using the Bluetooth or even the headphone output to drive an external system?

Maybe not design wise, but it is always nice to get someone else's opinion of feature sets, what looks appealing etc.not that I could help in any way.

Last edited:

rsavas,

I'll send you a pm with the picture of my speaker design if you haven't seen it on this thread. I think I posted it on this thread. I can use all the help I can get, I am much more comfortable on the speaker side of things, the electronics package has held up the entire process for me as I had to start from very little understanding on the electronics side of things.

If anyone needs any help on any mechanical design aspects of something I work in cad all the time.

I'll send you a pm with the picture of my speaker design if you haven't seen it on this thread. I think I posted it on this thread. I can use all the help I can get, I am much more comfortable on the speaker side of things, the electronics package has held up the entire process for me as I had to start from very little understanding on the electronics side of things.

If anyone needs any help on any mechanical design aspects of something I work in cad all the time.

? You mean analog, right ? Because i use a full digital 10 bands equalizer in mine.There's no tone controls in Android phones.

? You mean analog, right ? Because i use a full digital 10 bands equalizer in mine.

Is it an app? I've never seen one on any of my Samsung phones.

samsung does have that handy app that lets you equalize your attached headset (buds or phones) to apprx flat response based on hearing tone testing.

works very well on my S4.

some of the music apps have a multiband equalizer built in. i don't remember which ones.

mlloyd1

works very well on my S4.

some of the music apps have a multiband equalizer built in. i don't remember which ones.

mlloyd1

Yes.Is it an app? I've never seen one on any of my Samsung phones.

PlayerPro (free) : 5 band+ basses.

Power Amp (pay but worth the price) 10 band.

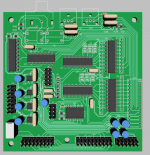

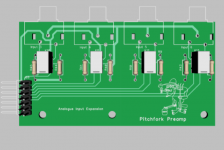

I'm making a little more headway. Just the display board and supplies to go. It's modular with up to 6 analogue inputs and 4 digital ins. The DAC also has a connector for a WaveIO USB board.

Attachments

I am going no where on my attempt, doing bodywork on my old 95 Chev 4x4 takes priority. I also have a few other projects ahead, LME49830 wire amp and TPA3116 weiner.

Post your schematics/gerbers and i will take a look, if you want someone to do some checking for you.

On your dual RCA conns, they spec a slot for the mounting tabs. I assume you are using the Kobicon (161-4219-E) or equiv from CUI. It can be non-plated since it has no connectivity. How do you plan to get your pcb (pcbway) fab to make them?

Post your schematics/gerbers and i will take a look, if you want someone to do some checking for you.

On your dual RCA conns, they spec a slot for the mounting tabs. I assume you are using the Kobicon (161-4219-E) or equiv from CUI. It can be non-plated since it has no connectivity. How do you plan to get your pcb (pcbway) fab to make them?

I am going no where on my attempt, doing bodywork on my old 95 Chev 4x4 takes priority. I also have a few other projects ahead, LME49830 wire amp and TPA3116 weiner.

Post your schematics/gerbers and i will take a look, if you want someone to do some checking for you.

On your dual RCA conns, they spec a slot for the mounting tabs. I assume you are using the Kobicon (161-4219-E) or equiv from CUI. It can be non-plated since it has no connectivity. How do you plan to get your pcb (pcbway) fab to make them?

I'm using CUI RCJ-2223 jacks. PCBway has no problem milling slots. They use a CNC router to cut he boards so slotting isn't a separate process.

I plan to post the schematics but I need to organize them better first. They became pretty scattered with some quick reworking on the fly while laying out boards. Hopefully I can get them up here by this evening. I would appreciate someone giving them a second look. They are all under 500 pins now. I can email you some files if you want to view them in DipTrace.

- Home

- Source & Line

- Analog Line Level

- Pitchfork pre-amplifier