Hello Eric,

I know your Aleph-X-amps from the pics on your website.

Nice aluminum-monsters... 😉

Greets

Dirk

I know your Aleph-X-amps from the pics on your website.

Nice aluminum-monsters... 😉

Greets

Dirk

to MEPER #6140

Hello MEPER,

sorry for my late response. A lot of garden-work.... Leafs,leafs,...

To cut straight and long is difficult to do with a jigsaw. And you will have to file a lot. Too time-consuming.

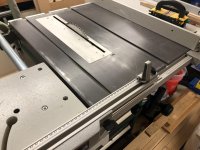

A tablesaw like that one from starcat is fantastic for such jobs. And a good blade

Electric tools from Festool are in the upper price range..If you don't need them often - too expensive.

Better to look for a machine shop - a few cuts will be pretty cheap.

Cheers

Dirk 😀

Hello MEPER,

sorry for my late response. A lot of garden-work.... Leafs,leafs,...

To cut straight and long is difficult to do with a jigsaw. And you will have to file a lot. Too time-consuming.

A tablesaw like that one from starcat is fantastic for such jobs. And a good blade

Electric tools from Festool are in the upper price range..If you don't need them often - too expensive.

Better to look for a machine shop - a few cuts will be pretty cheap.

Cheers

Dirk 😀

When building my OBL-15 speakers I used a hand hold circular saw (a Bosch) that came with rails and that went quite well for cutting wood. Don't know if that would work with aluminium with the right blade. Such a tool has only one speed and that it full power. I probably better get it pre-cut as I have no space for a table saw 🙂

I sometimes cut aluminium-stuff with my circular saw (it’s a small mafell, as good and pricey as festool), which has a special blade (made for resin etc.)… works perfectly, just take care not to push too hard/dive too deep into the material!

(BTW, the dealer who sold me the saw said that some even plane their aluminium … 😱 )

(BTW, the dealer who sold me the saw said that some even plane their aluminium … 😱 )

I have cut small pieces of aluminium with a jig-saw (like on picture which is an unfinished project). I have the smallest Bosch (PST 650) which is a model where blade can't "swing" forward/backwards for quicker sawing action. But it is ok for smaller tasks. I have a lot of the Green (amateur) Bosch electrical tools which works fine for my use.

I will look at what my large circular saw can do regarding cutting aluminium but have respect for these rotating tools.

I will look at what my large circular saw can do regarding cutting aluminium but have respect for these rotating tools.

Attachments

Thank you......some filing/sanding was necessary after jig-saw work.

It is the control panel for a burn-in tube tester for the double triode types like ECC83 etc. There are many types. Hope I can continue during the Christmas vacation 🙂

I don't need it but I just thought it could be fun and I could learn more about these tubes. It turned out to be more complicated to build that my initially impression.

It is the control panel for a burn-in tube tester for the double triode types like ECC83 etc. There are many types. Hope I can continue during the Christmas vacation 🙂

I don't need it but I just thought it could be fun and I could learn more about these tubes. It turned out to be more complicated to build that my initially impression.

I will look at what my large circular saw can do regarding cutting aluminium but have respect for these rotating tools.

Respect is never wrong!

take care that you have a suitable blade, that the piece you‘re cutting to pieces is safely attached (can’t move) and that the blade can’t bite into the alu!

Yes, safely attached is a must.

It is a 2HP+ machine that uses 190mm blades.

Also important when using table-drills with large diameter drill bits. It looks so "harmless" when just running but it can change very quickly......

It is a 2HP+ machine that uses 190mm blades.

Also important when using table-drills with large diameter drill bits. It looks so "harmless" when just running but it can change very quickly......

Wear protective glasses and make sure that the tools got adjustable speed as you shouldn't cut aluminium at full speed.

Then I need another tool. I have a Bosch PKS 66 AF and it runs full speed only. It can cut 66mm thickness (but not aluminium of course). Tools like this is meant for wood I think.

At this speed it will need a blade with very small teeth's.

At this speed it will need a blade with very small teeth's.

My saw also hasn’t a speed control. It’s working though, but make sure to work gently, with the appropriate blade, and eventually (if going through thick material) use some kühlmittel (cooling stuff?)

The professional gear also run at high speeds, but with lots of lubricant/cooler…

The professional gear also run at high speeds, but with lots of lubricant/cooler…

Last edited:

IXYS-Mosfet-amp

Good evening,

I hope everybody is fine out there!

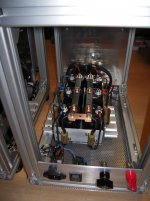

Some small progress - cap-banks are in....

Have to make some ground-loop-breakers.

Cheers

Dirk 😀

Good evening,

I hope everybody is fine out there!

Some small progress - cap-banks are in....

Have to make some ground-loop-breakers.

Cheers

Dirk 😀

Attachments

to MEPER #6159

Good morning, MEPER!

I wouldn't call it a XA25-Monoblock. Because we don't know the exact circuit

Nelson Pass has used in his XA25. This amp is still in production.

For me it is a kind of a test bed.

I am influenced by the

- F4-beast-builders-thread

- Babelfish XA252 from ZenMod

- perhaps a BA-3 on steroids.

I hope that I will not destroy the pretty nicely matched IXYS-Mosfets.

Cheers

Dirk 😀

Good morning, MEPER!

I wouldn't call it a XA25-Monoblock. Because we don't know the exact circuit

Nelson Pass has used in his XA25. This amp is still in production.

For me it is a kind of a test bed.

I am influenced by the

- F4-beast-builders-thread

- Babelfish XA252 from ZenMod

- perhaps a BA-3 on steroids.

I hope that I will not destroy the pretty nicely matched IXYS-Mosfets.

Cheers

Dirk 😀

- Home

- Amplifiers

- Pass Labs

- Pictures of your diy Pass amplifier