It's a bought amp, I didn't build it.Did you build it or is it a bought amp?

I'm keen to get on the "modifying" path though..

I checked the o/p and it didn't say you had to have built your amp. Thought it was just a photo gallery....

Diabolical Artificer,

I am glad you are enjoying the music.

Some do not enjoy listening, for some, it is all about designing, building, and modifying (I like to do that too, but not exclusively).

You can not tell the difference when swapping tubes.

How many dB of negative feedback are wrapped around those tubes?

Thanks!

$0.04

Get ready for more inflation

I am glad you are enjoying the music.

Some do not enjoy listening, for some, it is all about designing, building, and modifying (I like to do that too, but not exclusively).

You can not tell the difference when swapping tubes.

How many dB of negative feedback are wrapped around those tubes?

Thanks!

$0.04

Get ready for more inflation

There are two different brand EL84 in there. One pair Sovtek (6P14) and one pair that looks like a western design.

I can't remember what they came with originality in the late 90's.

I'd put in a fresh quad for this nice amp.

I can't remember what they came with originality in the late 90's.

I'd put in a fresh quad for this nice amp.

Sorry for any offense caused, it was a question not an accusation. I did pre-apologise for being grumpy tooI checked the o/p and it didn't say you had to have built your amp. Thought it was just a photo gallery....

When I design & build an amp, I modify the circuit, so, not anti modification or experimentation. My point was that any valve substitution or tweaks might not be audible, but then a car does drive better after you've spent an hour cleaning it & polishing it.

I find it helps if you breath out, take a few deep breaths & center oneself : )Get ready for more inflation

Last edited:

Another major project completed, started planning this one 2.5 years ago. LCR phono stage using D3a and E55L tubes. Uses Dave Slagle's MC step up transformers, 1:1 coupling transformers, and LCR chokes.

Here's a basic schematic.

Two chassis design. In the power supply chassis, there are two raw B+ boards, one for each channel. There are four separate DC heater regulators, one for each tube, elevated some 30VDC above ground. Mains transformer is custom from Toroidy.

In the phono chassis are two Maida style regulators for the raw DC, one for each channel. Six transformers and four chokes makes for one heavy little box.

Chassis side-by-side with tubes installed.

Sounds amazing with my TD-125 MKII. Still need to check real world RIAA compliance, but it certainly sounds the part right away. I also need to make more distance between the two chassis however with a longer umbilical as the transformers are picking up some mains hum. I was overly optimistic to try them side-by-side.

Here's a basic schematic.

Two chassis design. In the power supply chassis, there are two raw B+ boards, one for each channel. There are four separate DC heater regulators, one for each tube, elevated some 30VDC above ground. Mains transformer is custom from Toroidy.

In the phono chassis are two Maida style regulators for the raw DC, one for each channel. Six transformers and four chokes makes for one heavy little box.

Chassis side-by-side with tubes installed.

Sounds amazing with my TD-125 MKII. Still need to check real world RIAA compliance, but it certainly sounds the part right away. I also need to make more distance between the two chassis however with a longer umbilical as the transformers are picking up some mains hum. I was overly optimistic to try them side-by-side.

Since it's winier here, we can use the tubes to add warmth to the house.

Yes, the power supply is separated chassis

View attachment 1231927View attachment 1231928View attachment 1231929

Oh, I think it's time to post some pictures again to maintain the competition... 😀😉

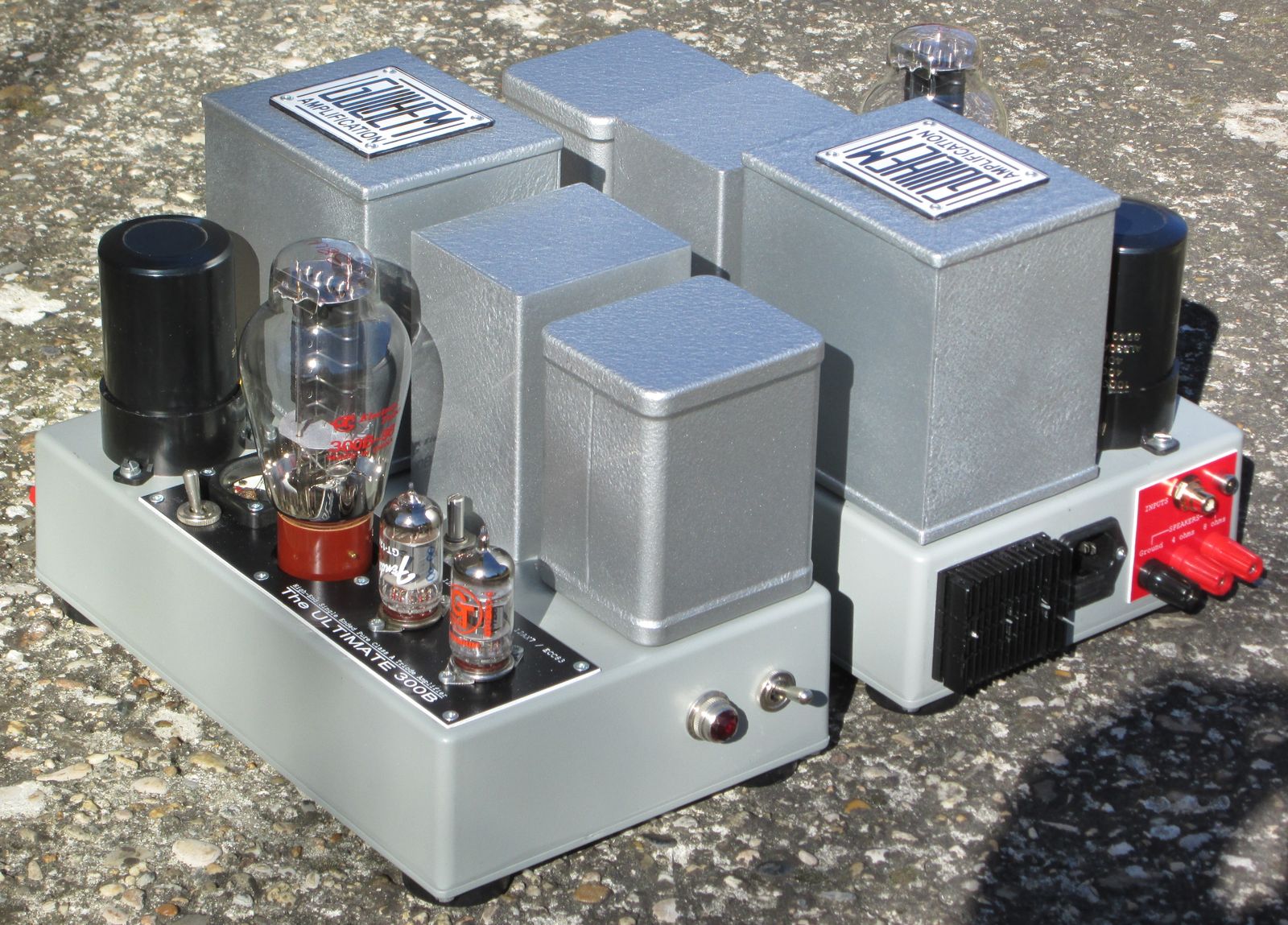

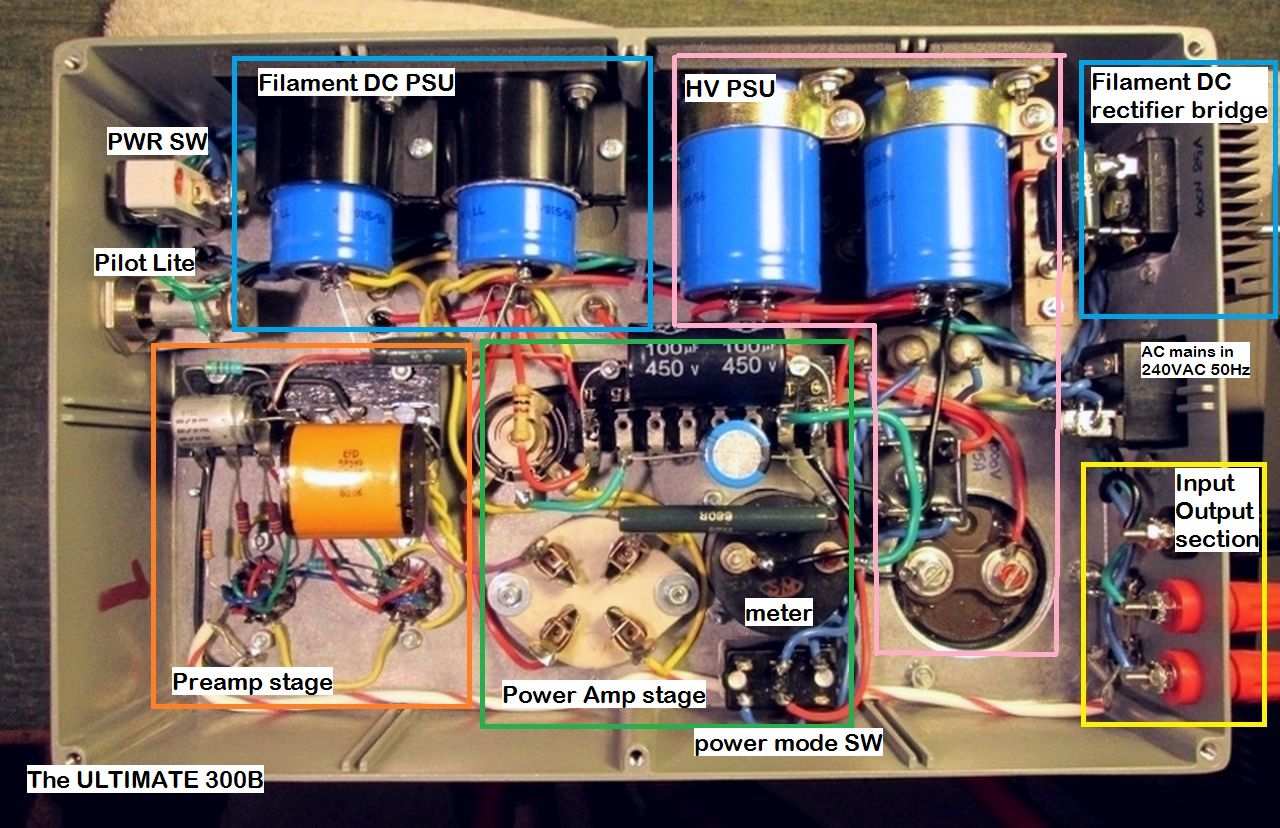

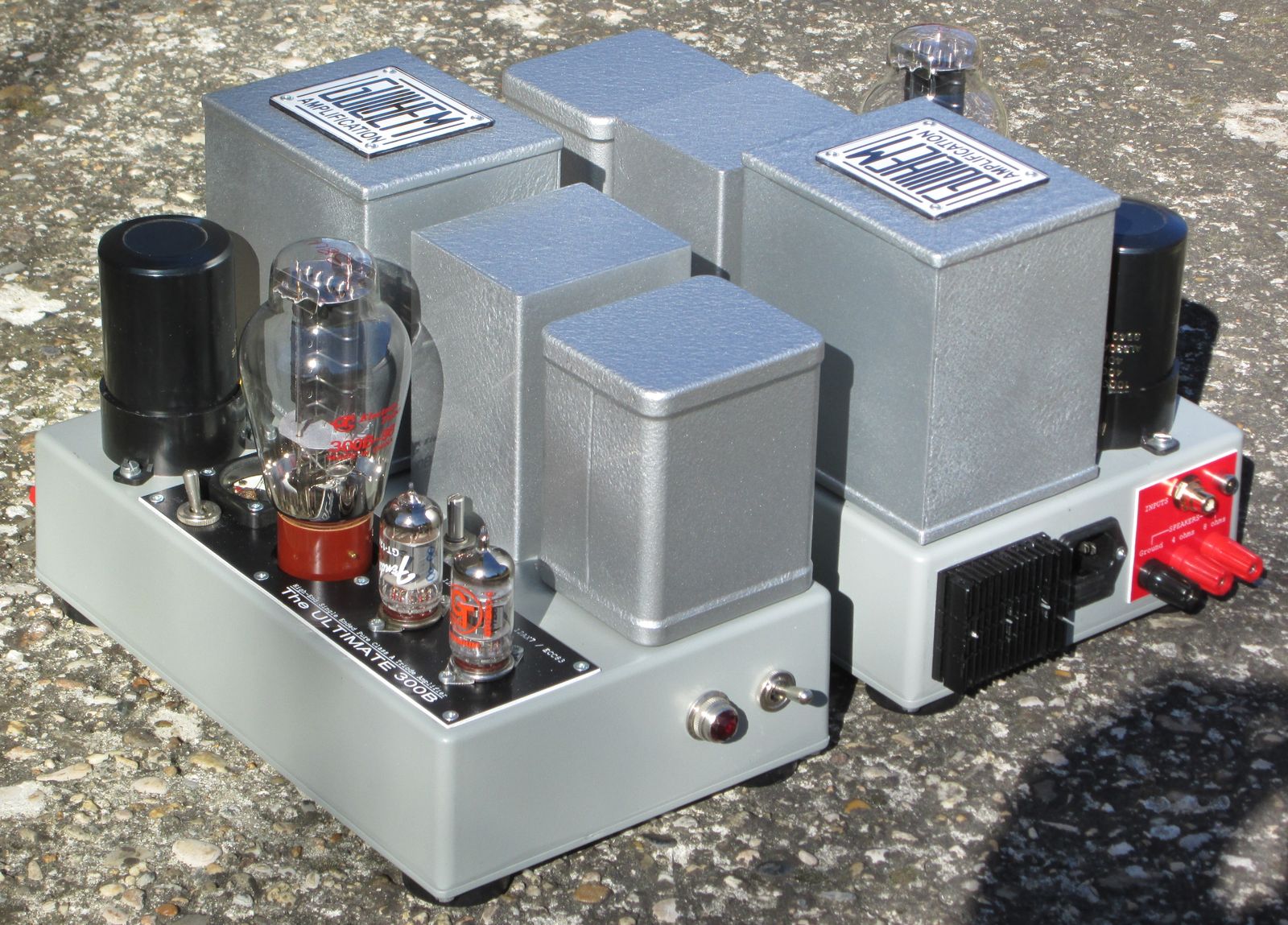

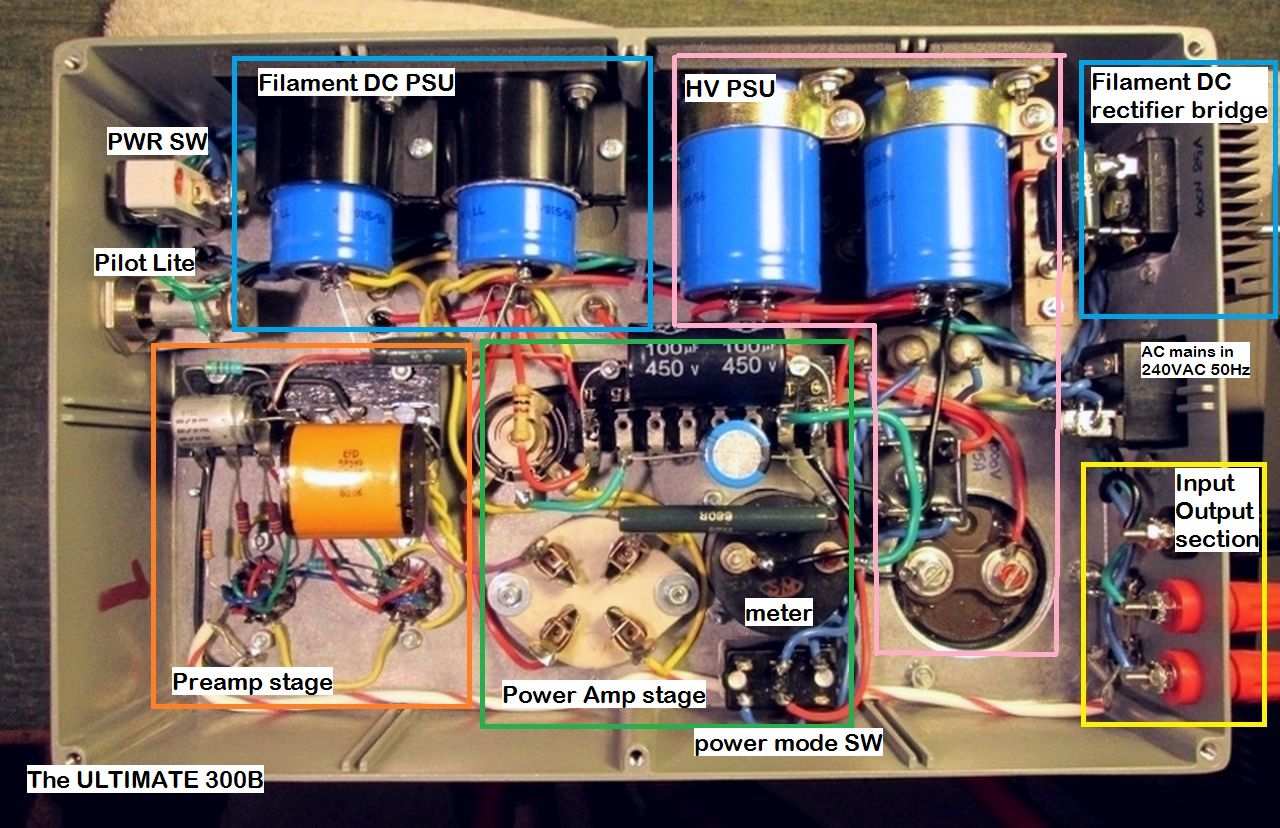

The U-300B :

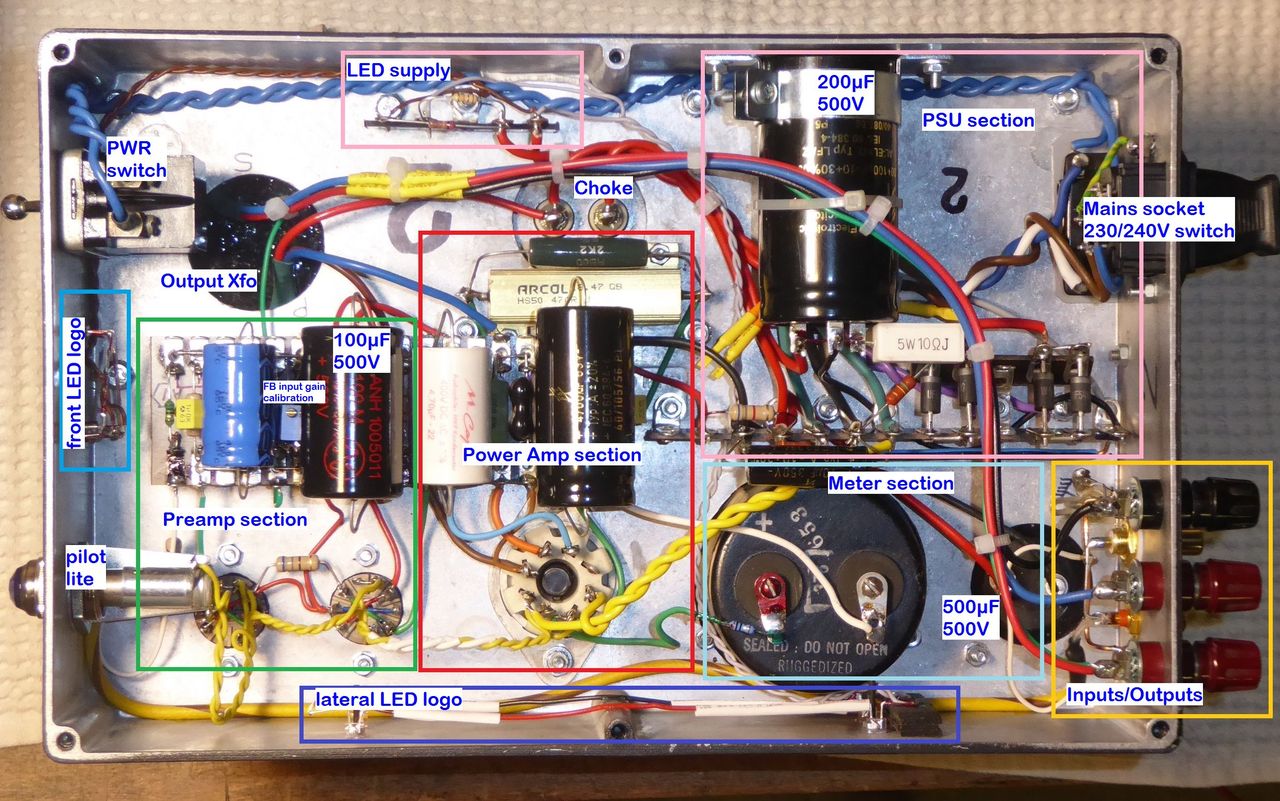

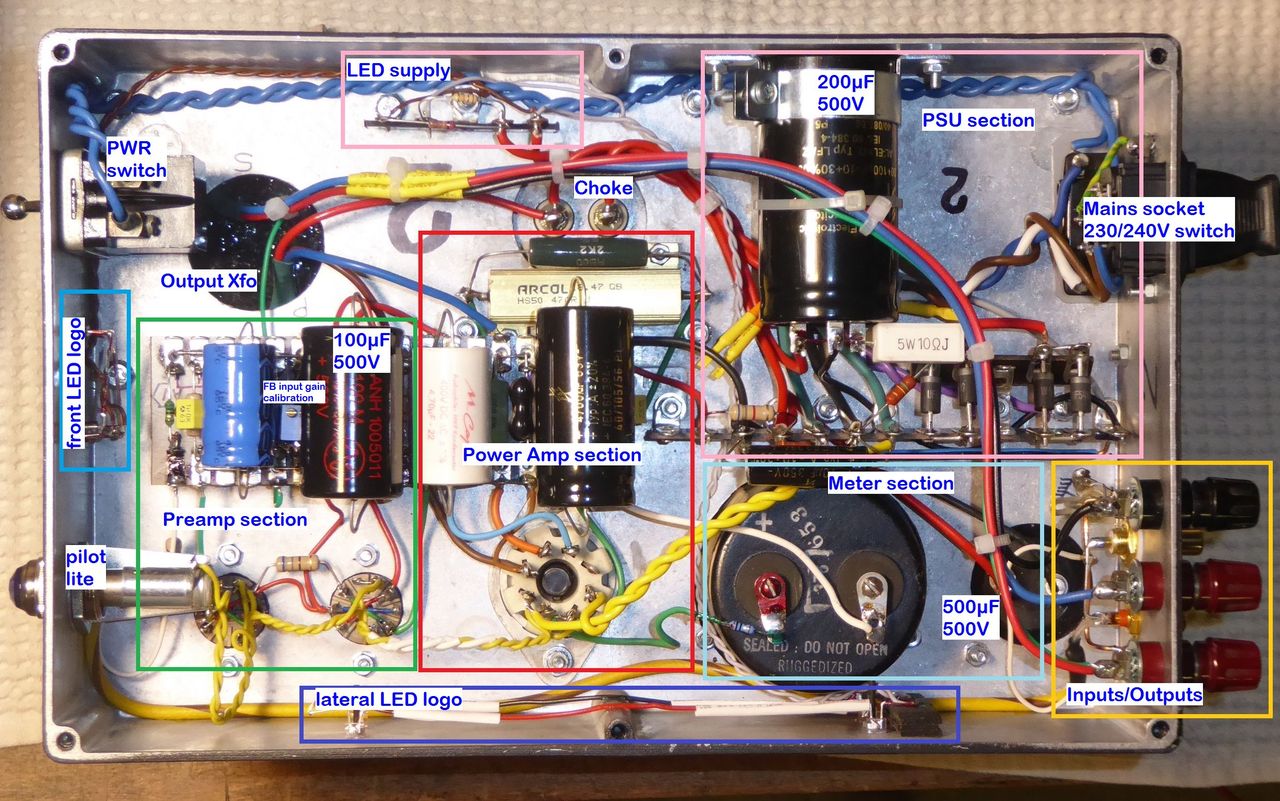

The U-KT120 :

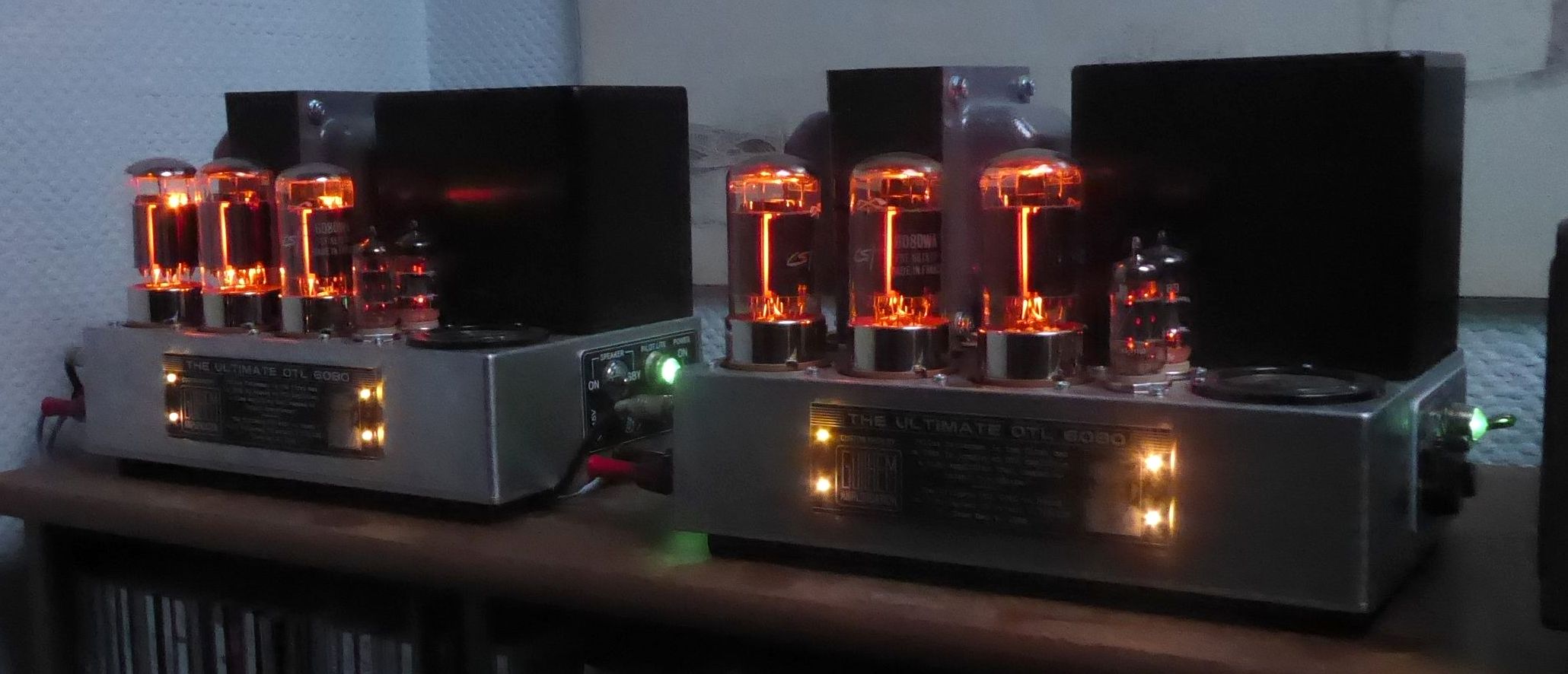

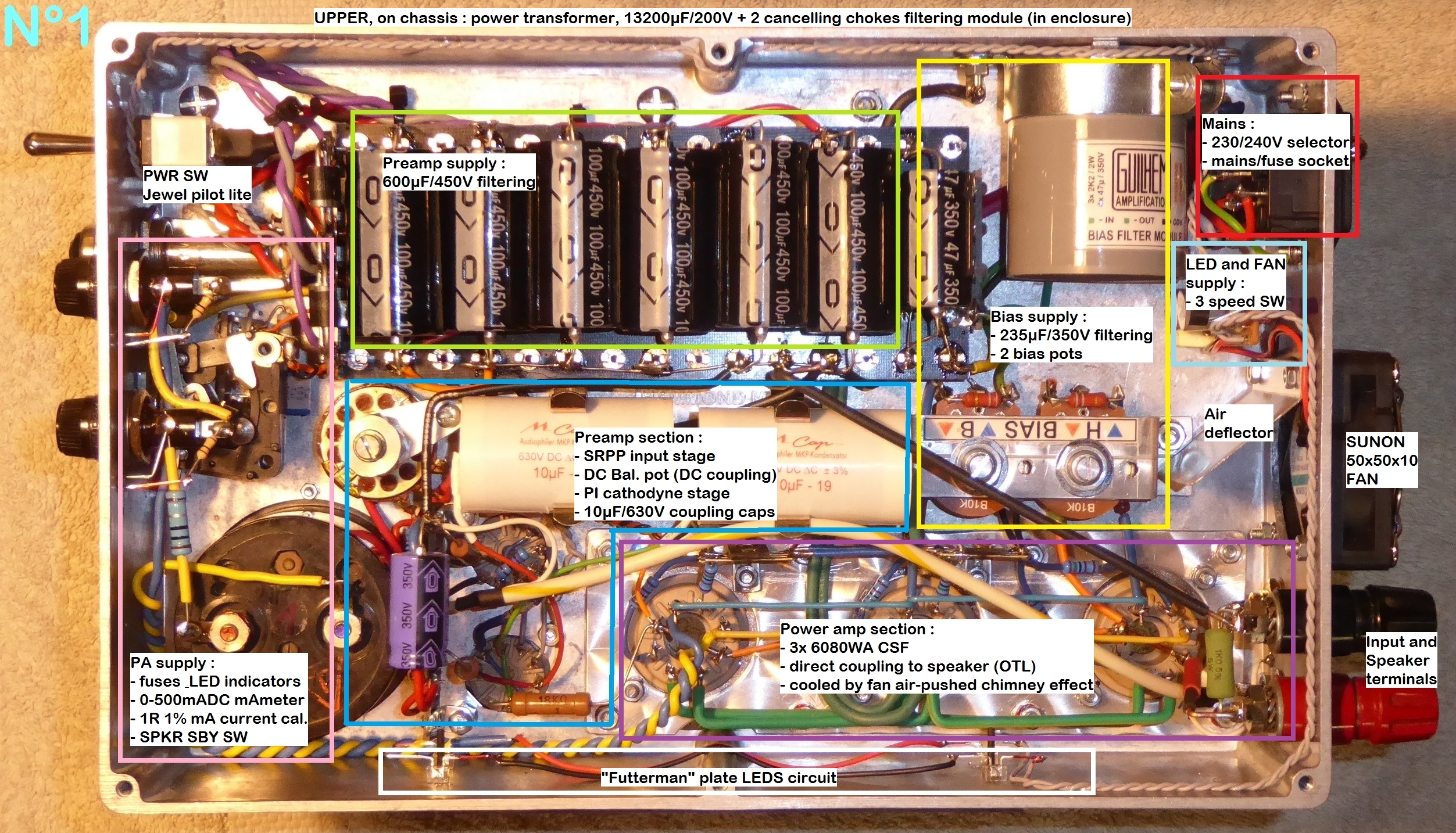

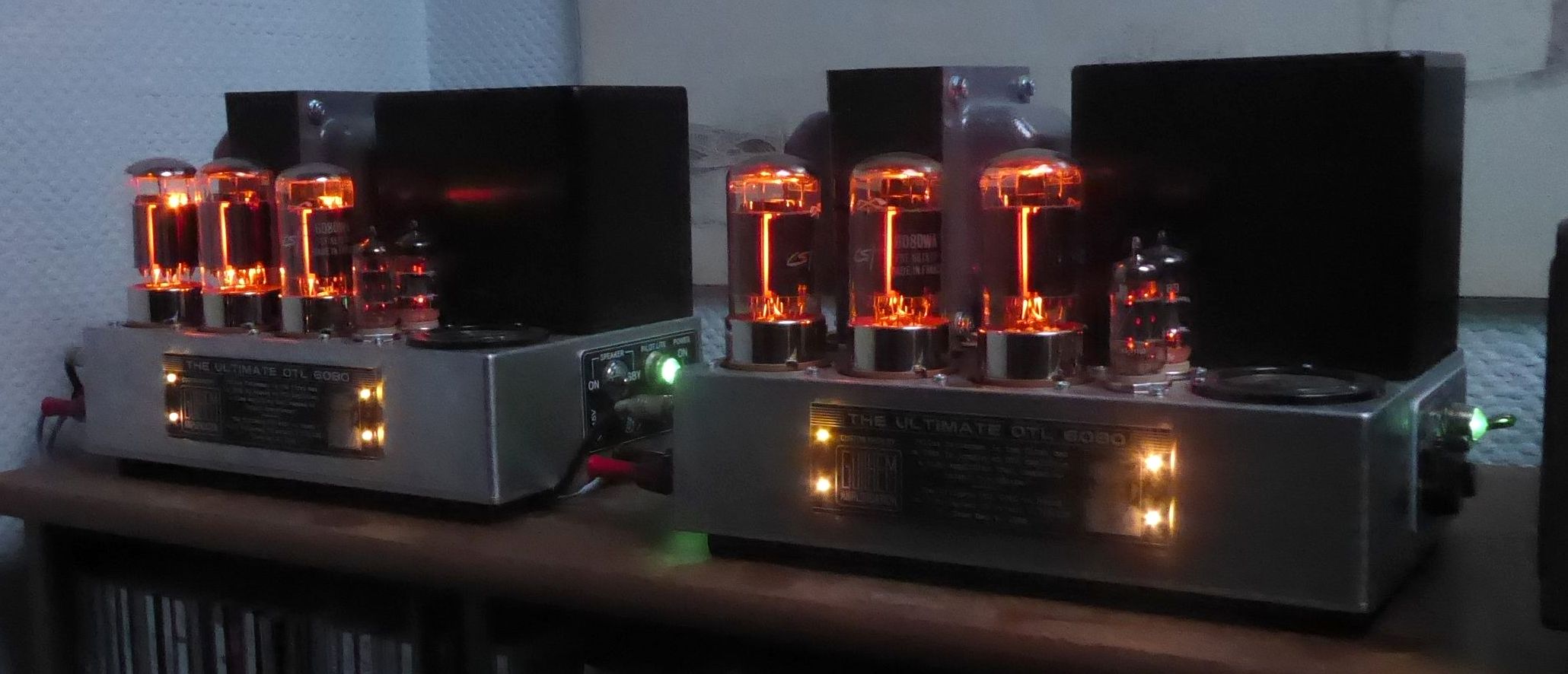

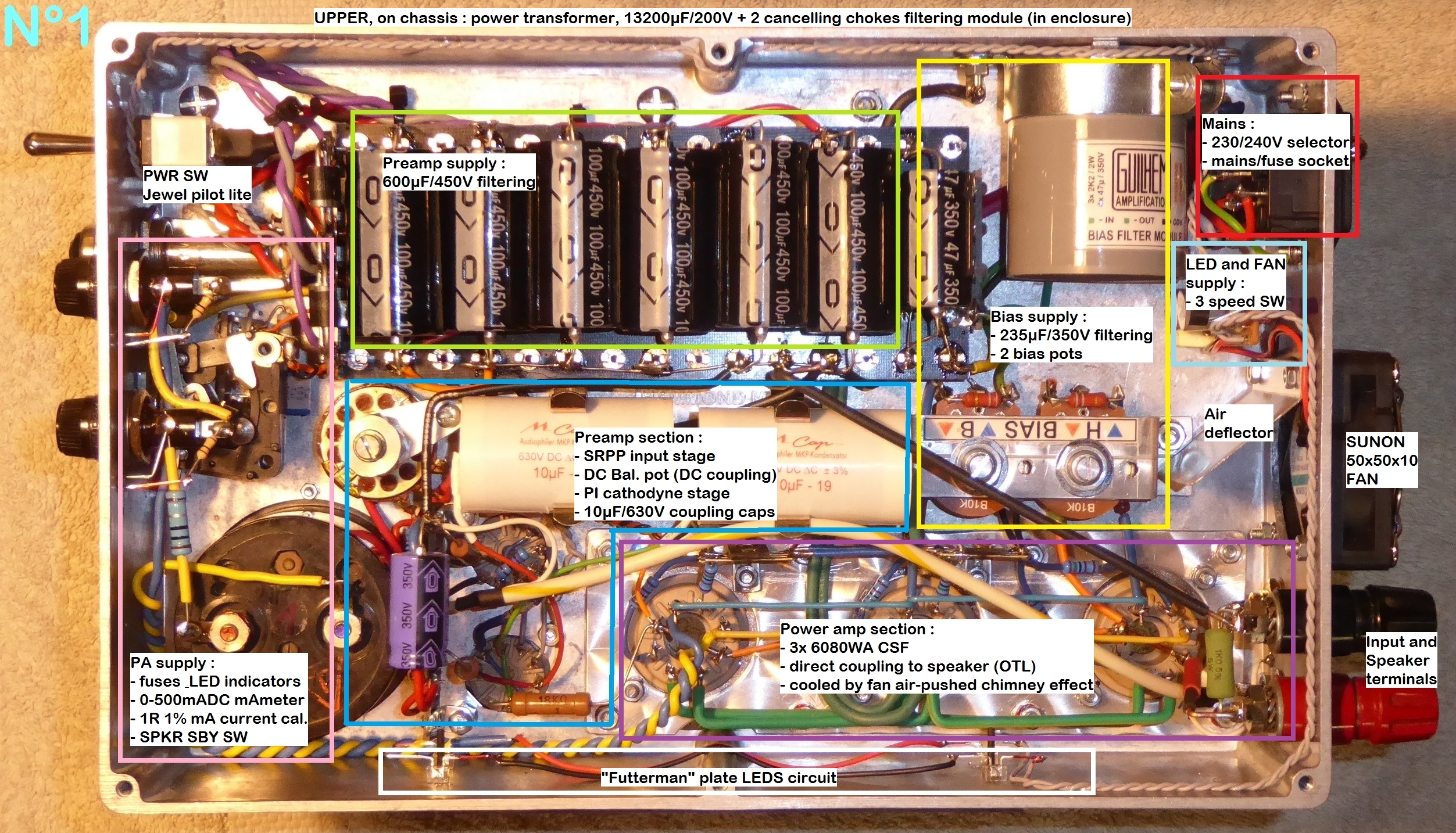

The U-OTL :

All those Mono blocks are built in the same compact aluminium chassis :

T

The U-300B :

The U-KT120 :

The U-OTL :

All those Mono blocks are built in the same compact aluminium chassis :

T

These are my M125 kits going into custom chassis with a few minor layout changes. These were finished and running a few years ago but since these were the first amps I had ever built they definitely had room for improvement. I had some pretty rough solder joints and messy wiring going on when they were first built.

Attachments

Chassis made of steel/iron? Have a steel/iron chassis that I had made a few years ago, but I was advised not to use it, as the magnetization from the transformers that are mounted causes a hum...Lovely amplifier you build!

@stenak the chassis are made from lasercut carbon steel. There's probably some truth to the effects of using magnetic materials in your chassis, but many tube amplifiers are made with carbon steel chassis and it doesn't seem to be a problem. The original M125 chassis were carbon steel before they switched to stainless, my Jeff Rowland model 1 has a steel chassis as well.

That's true. You can experience some hum issues due to magnetic inductions with steel chassis : I saw this several times... That said, it much depends on how you install the transformers on the chassis itself.

I take the occasion of the pictures posted by @brandon3212276 above, to note that the perpendicular (at left) position is usually better in terms of chassis induction than the horizontal (at right) position :

In your case, @brandon3212276, and considering the relative position of the two transformers, you certainly have good results in hum and induction speaking, moreover if the supply transformer is the vertical one.

When possible, I try to distance as best the power transformer from the others, notably in my guitar amplifiers where the gain is always higher than in an audio amp (output at left, power at right)...

... But also in compact audio amps, like my Micro-Amp (power at left, outputs at right) :

T

I take the occasion of the pictures posted by @brandon3212276 above, to note that the perpendicular (at left) position is usually better in terms of chassis induction than the horizontal (at right) position :

In your case, @brandon3212276, and considering the relative position of the two transformers, you certainly have good results in hum and induction speaking, moreover if the supply transformer is the vertical one.

When possible, I try to distance as best the power transformer from the others, notably in my guitar amplifiers where the gain is always higher than in an audio amp (output at left, power at right)...

... But also in compact audio amps, like my Micro-Amp (power at left, outputs at right) :

T

Just catching up on this thread.. No offence caused!Sorry for any offense caused,

This is very true!a car does drive better after you've spent an hour cleaning it & polishing it.

@tubelectron I appreciate the insight, I basically just took the existing chassis design from the original Tubes4hifi kit. I spaced things out a little more and moved the big can capacitor inside the chassis.

Is there something that can be easily done to isolate the transformer from the chassis?

Is there something that can be easily done to isolate the transformer from the chassis?

I don't agree at all that iron chassis would be worse than anything else. Just look at what meterial they used to have in chassis either it was wood or steel before 1945 but after WW2 then aluminum came. Take a look at Dynaco which is a big favorite of mine their chassis is just iron for the tube amplifiers if you do it right they are very quiet, my ST-35 is very quiet.Chassis made of steel/iron? Have a steel/iron chassis that I had made a few years ago, but I was advised not to use it, as the magnetization from the transformers that are mounted causes a hum...Lovely amplifier you build!

@tubelectron I appreciate the insight, I basically just took the existing chassis design from the original Tubes4hifi kit. I spaced things out a little more and moved the big can capacitor inside the chassis.

Is there something that can be easily done to isolate the transformer from the chassis?

Yes - sorry, I do not have pictures. I did this on a 1976 VOX AC 30 Top Boost.

Both the power and output transformers were installed flat, horizontally, at each end of the chassis, so distanced at best. Despite this, the amp significantly hummed (2x12" speakers...) no matter the setting of the controls.

In fact, the steel chassis acted as a supplementary lamination, common to both transformers, and so was transmitting the 50Hz induction flux from the power transformer to the output transformer.

I surelelvated the power transformers with 5mm rubber grommets, and 90% of the hum was over. The last 10% were eradicated when I did the same with the output transformer. All this isolated the chassis from direct magnetic coupling with the transformers laminations.

The gommets that I use are called in French clapet de robinet (faucet flap ?).

T

- Home

- Amplifiers

- Tubes / Valves

- Photo Gallery