Nice!Here's my 13E1 single tube OTL amp prototype, all done up for Christmas.

Ho ho ho! 🙂

Just keep the tinsel away from the HT and yule be fine... 😀

I just wish the 13E1 was more available / affordable, but I doubt Santa can help with that either.

Here is my prototype EL84 Headphone amplifier together with the 80V stabilized power supply build with the 85A2.

On the left side I made also a RIAA equilizer but this time with transistors. The equilizer still has to be connected to the main amplifier input.

On the left side I made also a RIAA equilizer but this time with transistors. The equilizer still has to be connected to the main amplifier input.

Attachments

Wavebourn,

Thanks for your technical posts. I learned a lot from them. And I enjoyed the personal post about you getting the class working on a problem, leaving the room, and coming back after they were quiet!

I always wanted to try a powder coated chassis. Is that essentially what your Edelweiss-3 red chassis is? It looks great, and ideal to test output tubes.

I usually only go to the Tubes / Valves area. And I just re-"discovered" the photo gallery. I will be checking for your other posts.

Thanks for your technical posts. I learned a lot from them. And I enjoyed the personal post about you getting the class working on a problem, leaving the room, and coming back after they were quiet!

I always wanted to try a powder coated chassis. Is that essentially what your Edelweiss-3 red chassis is? It looks great, and ideal to test output tubes.

I usually only go to the Tubes / Valves area. And I just re-"discovered" the photo gallery. I will be checking for your other posts.

Last edited:

Broskie Aikido in DIY chassis. I plan to get larger silver knobs and have a proper front panel made eventually. This sounds much better than the 100K passive volume box I was using before. But I have too much gain so really only the first five positions of the stepped attenuator are useful right now.

I'm a little embarrassed by the off-center holes in the front panel. I used a Uni-bit and it wandered while drilling. Need a better solution.

Congrats for the quality work ! I have the exact same project in my queue, albeit with the octal board, as I have loads of octal tubes. Three questions:

Charles

- how did you attach the hex spacers of the LED board to the front panel ?

- how do you assemble the edges of the case ?

- with all dissipators and 4 tubes, is the heat evacuation ok ?

Charles

"how did you attach the hex spacers of the LED board to the front panel ?"

tapped in the thickness of the facade

tapped in the thickness of the facade

Congrats for the quality work ! I have the exact same project in my queue, albeit with the octal board, as I have loads of octal tubes. Three questions:

I like your construction, I would be interested to do something similar.

- how did you attach the hex spacers of the LED board to the front panel ?

- how do you assemble the edges of the case ?

- with all dissipators and 4 tubes, is the heat evacuation ok ?

Charles

Thanks very much. Here are some more pictures.

As you can see there is a front sub-panel where most of the fastener action happens. The decorative front panel is just attached by the four flat-head socket screws.

Everything but the center divider is held together by flat-head screws tapped into the 3/8" square stock. I also tapped threads (x8) in the ends of the bars attached to the front and rear panels. There are screws going through the side panels into those holes to secure the sides to the front/rear.

The whole thing runs pretty cool. I would prefer to put slots in the bottom panel but I have no good technology for making them. Same issue for the top panel so right now I'm just running it open. The circuit is pretty we'll protected in my rack so the only real downside is dust buildup.

Pardon the Christmas mess in the living room. It's pretty hilarious that I have, what, maybe $10k worth of equipment if purchasing the equivalent commercially, but $268/pair speakers, LOL.

Last edited:

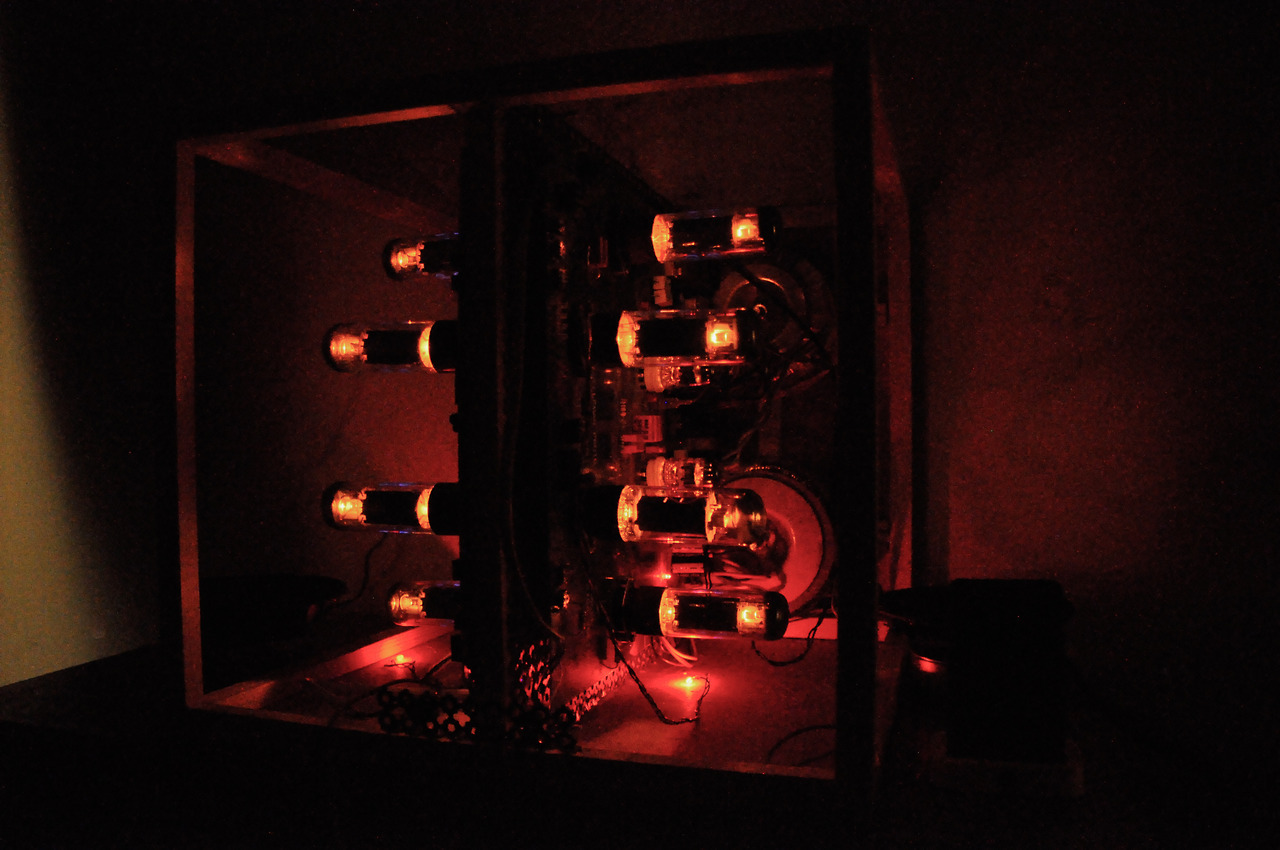

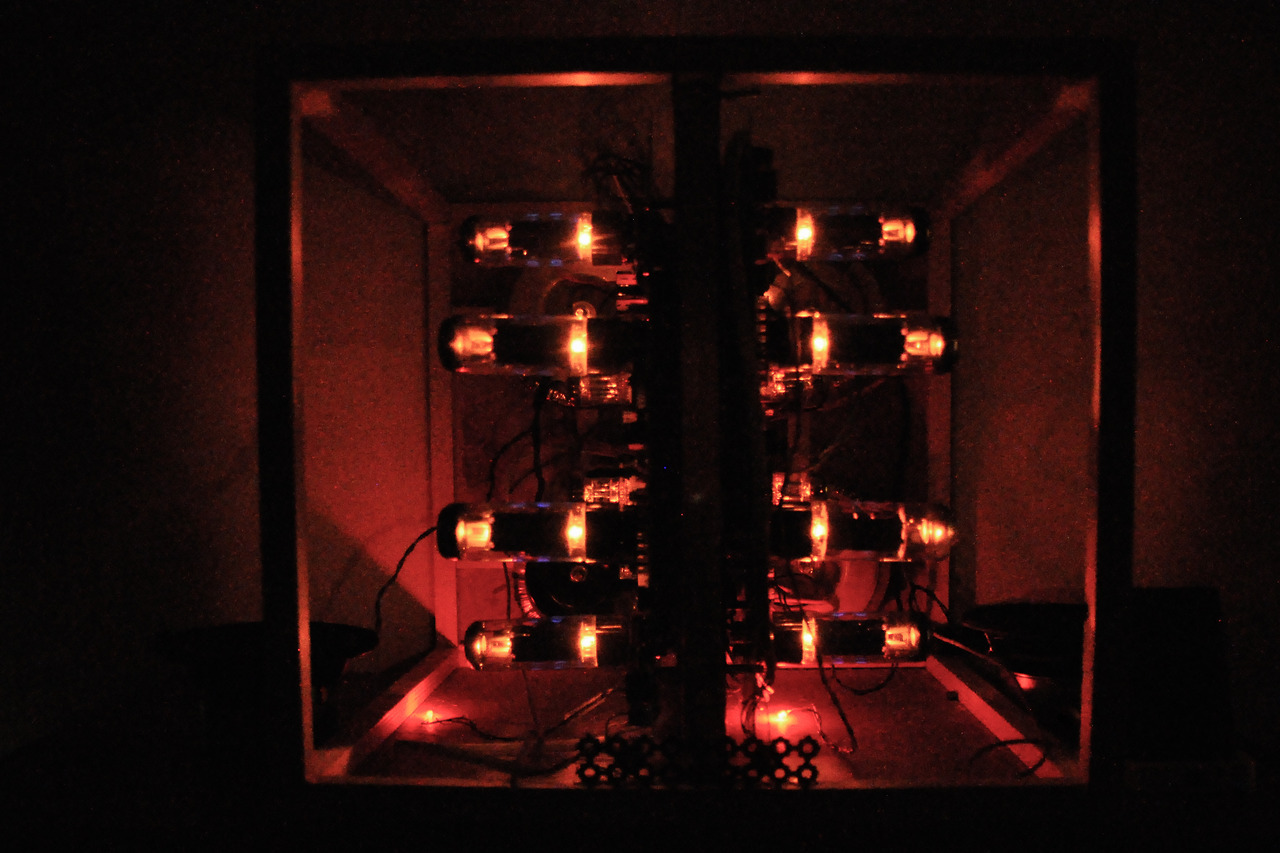

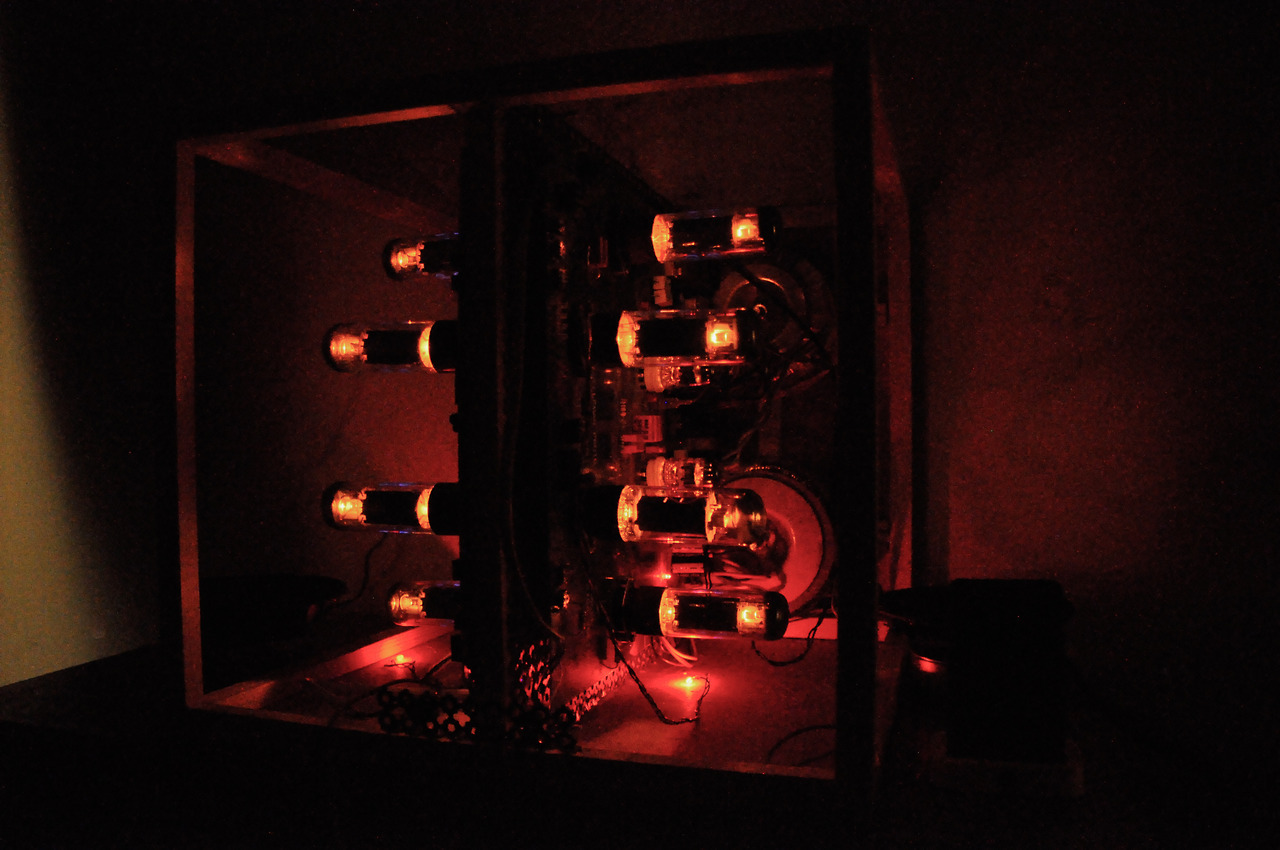

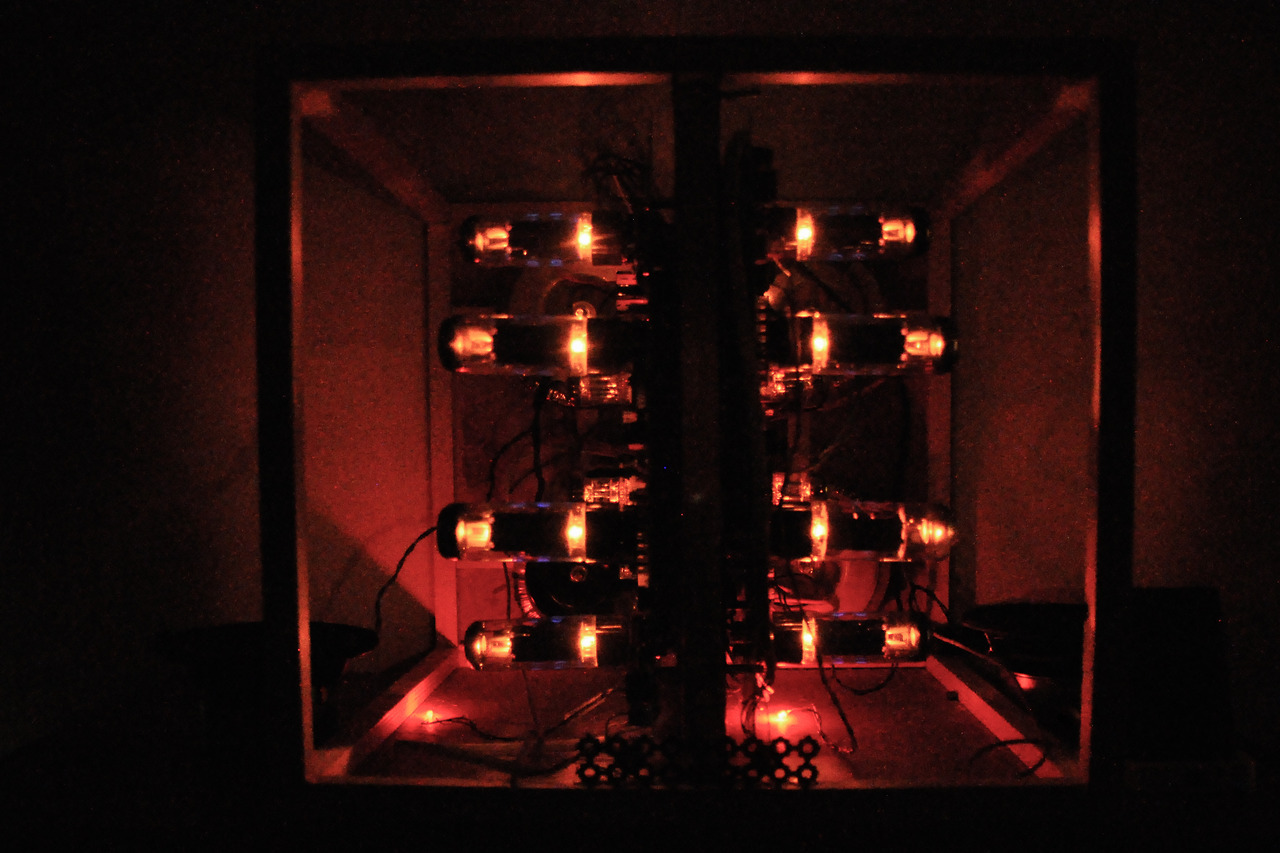

My Velleman twin P8011 mono-blocks in a custom metal/wood frame.

Based on EL34 output valves, ECC82, ECC83 preamp valves, PP configuration, solid state power supply, the only part to use transistors 🙂

It's currently out of service, needs an overhaul, currently in storage as I've just moved house.

Hope to replace all the valves, so they're a matched set, had to replace a blown cathode resistor which also took the tube with it, one hell of a flash and bang, put another EL34 in it and all was working, however like car tires, no point just replacing one, otherwise they will all have various numbers of hours on them.

Going to build a smaller SE amp based on EL34 valves and a 6N1P dual triode and a rectifier valve for the power supply, no transistors in this one. ;-)

Based on EL34 output valves, ECC82, ECC83 preamp valves, PP configuration, solid state power supply, the only part to use transistors 🙂

It's currently out of service, needs an overhaul, currently in storage as I've just moved house.

Hope to replace all the valves, so they're a matched set, had to replace a blown cathode resistor which also took the tube with it, one hell of a flash and bang, put another EL34 in it and all was working, however like car tires, no point just replacing one, otherwise they will all have various numbers of hours on them.

Going to build a smaller SE amp based on EL34 valves and a 6N1P dual triode and a rectifier valve for the power supply, no transistors in this one. ;-)

Broskie Aikido in DIY chassis. I plan to get larger silver knobs and have a proper front panel made eventually. This sounds much better than the 100K passive volume box I was using before. But I have too much gain so really only the first five positions of the stepped attenuator are useful right now.

I'm a little embarrassed by the off-center holes in the front panel. I used a Uni-bit and it wandered while drilling. Need a better solution.

Nice lead dress, nice and clean assembly!

I feel you on those unibits- I like them for getting a hole close and then opening it up with a dremel, files, or similar. I find that miniature holesaws work well but they are a pain in the **** to use. I think the hole punches are the best but expensive investment... I do build enough amplifiers and gear to justify the expense, but that doesn't make them any cheaper 🙂

Nice lead dress, nice and clean assembly!

I feel you on those unibits- I like them for getting a hole close and then opening it up with a dremel, files, or similar. I find that miniature holesaws work well but they are a pain in the **** to use. I think the hole punches are the best but expensive investment... I do build enough amplifiers and gear to justify the expense, but that doesn't make them any cheaper 🙂

Thanks.

I tried a test with a 1.5" hole saw. It needed persuasion to go deeper than the depth of the teeth. The saw stayed centered but the hole didn't turn out very clean, and that's after some hand sanding.

An externally hosted image should be here but it was not working when we last tested it.

I don't think a Greenlee punch would go through 1/4" metal. Not without a hydraulic press, anyway.

I'll think of a solution eventually. No rush.

I don't think a Greenlee punch would go through 1/4" metal. Not without a hydraulic press, anyway.

Actually mine did, through 1/4" aluminium. Even with an 8" wrench it wasn't easy, though.

The punch itself survived just fine.

Actually mine did, through 1/4" aluminium. Even with an 8" wrench it wasn't easy, though.

The punch itself survived just fine.

Cool! I'll have to try. Thanks for the suggestion/info.

Cool! I'll have to try. Thanks for the suggestion/info.

Drill the pilot hole just large enough, and use a lot of machine oil.

- Home

- Amplifiers

- Tubes / Valves

- Photo Gallery