I believe an automated shaker can be constructed using an old cd player door mechanism or a microwave motor and plate. Perhaps we should start such thread 😛 And a lamp above to keep the liquid warm.

Thanks all for this extensive information, I see I need to make something for it, I go make a etching tank from plastic glu it with chloroform of someting and do use a heater of a aquarium to warm it, and see what happens.

I do this outside, to prevent damages by corrosion.

regards

I do this outside, to prevent damages by corrosion.

regards

Use a plastic food container, tall thin type for spaghetti.

Use fish tank pump to create bubbles, no need to shake. Work in special area though as there will be small splashes from tank.

Use fish tank pump to create bubbles, no need to shake. Work in special area though as there will be small splashes from tank.

Ihave make some photo,s from the idea to make a tank from plexy glass.

I do glu it with MEK, it do well, unbelievable strong.

Do not breath the fumes, but it stinks like acetone, this stuff is used by painters to get fat off.

I do glu it with MEK, it do well, unbelievable strong.

Do not breath the fumes, but it stinks like acetone, this stuff is used by painters to get fat off.

Attachments

I just use a tray for etching, preheat the etchant, and (carefully) slosh it around. I try to keep the exposed copper to a minimum, so I use up less etchant (ferric chloride), and this has the nice feature of allowing me to see the copper etch away under a bright light. The copper etches into a brownish plume, which largely stops once the pattern has been etched. It's easy for me to then see when the etching is done, and control the amount of side etching (undercutting) done to partially compensate for the squished toner.

The toner transfer part is the tough part, and I suspect that my printer's toner is more of a PITA than others. But, what can you do… it's not practical for me to find or use an ancient LaserJet.

The toner transfer part is the tough part, and I suspect that my printer's toner is more of a PITA than others. But, what can you do… it's not practical for me to find or use an ancient LaserJet.

nice idea! 🙂Use a plastic food container, tall thin type for spaghetti.

nice idea! 🙂

Trouble is what and where, here we have not that spaghetty containers as far as I now..

Making the etching tank like I tell above is very easy and looks good, just big enough and small for the biggest I ever pcb I ever do.

regards

Last edited:

The best ones are these or the flat ones I already have but difficult for bubbling.

JÄMKA Dry food jar with lid, set of 2 - 3/4 qt - IKEA

These are still to small.

regards

JÄMKA Dry food jar with lid, set of 2 - 3/4 qt - IKEA

These are still to small.

regards

Something like this.

Must be easy to find in Holland?!! Most supermarkets here have this kind of container.

An externally hosted image should be here but it was not working when we last tested it.

Must be easy to find in Holland?!! Most supermarkets here have this kind of container.

Something like this.

An externally hosted image should be here but it was not working when we last tested it.

Must be easy to find in Holland?!! Most supermarkets here have this kind of container.

It do not fit, I make bigger pcb.

I do weld a own plastic container.

Same here, a Tupperware kind of box for big stuff, margarine cartons or even aerosol lids for the tiny stuff.I just use a tray for etching

Yep, warm to mildly hot keeps the etch time down to single figures.preheat the etchant,

Keep it swirling over the board and you can see the copper dissolve in real time.and (carefully) slosh it around.

Same here... it can make for really neat board design too if you use 'copper pour' on the layout to fill in large open areas.I try to keep the exposed copper to a minimum, so I use up less etchant (ferric chloride

.......and control the amount of side etching (undercutting) done to partially compensate for the squished toner.

The toner transfer part is the tough part, and I suspect that my printer's toner is more of a PITA than others. But, what can you do… it's not practical for me to find or use an ancient LaserJet.

That's where we part company, I use the UV and transparency method. A standard inkjet printer will do stuff as fine as anything you might see on a commercial product.

That's where we part company, I use the UV and transparency method. A standard inkjet printer will do stuff as fine as anything you might see on a commercial product.

I actually agree with you there too - my complaint is more with the imprecise nature of toner transfer, and not the quality of the laser printer images I get - they're crisp 600 DPI images, and I've tweaked the process so that the software doesn't mess me up with half-toning stuff or the like, which might be fine for documents, but disastrous for resist and etching!

With toner transfer, fine traces and features can get sabotaged by tiny flecks of toner that don't get transferred, and also sometimes by small features 'spreading out' during the lamination process. For example, I just can't seem to get an SOT883 footprint to work, but that's usually not a big deal - alternate packages are usually available. With care, I can do a DFN1212-3, so it's not hopelessly sloppy, but just not quite as good as the smallest packages require.

I've thought about using UV and transparencies, but at this point, I can get a cheap and 'good enough' single sided toner transfer board for a breadboard circuit, and I really need to start using commercial processes so I can use multilayer boards with solder mask and holes. For me, this would make more sense to spend effort on… 🙂

What is the best solution for copper oxide? 10 % 8 % more, because I do not think that every pcb needs different etchant, maybe copper is thicker on some boards but oke.

I go try the uv negative way.

regards

I go try the uv negative way.

regards

While I usually associate multilayer boards with more than two layers, double sided is of course also multilayer... ;-)

True multilayer is impossible to do in a kitchen lab.......and commercial proto boards are now quite cheap

Etchants for prototyping machines are usually ferric chloride, sodium persulphate or ammonium persulphate. For a hobby lab with occasinal use, I'd go with a Hydrochloric acid and hydrogen peroxide mix, on a throw away basis. Just make sure to have very good ventilation. All the other ones are mixes usually stored in etching machines, and ferric chloride, although very efficient, makes horrible stains on anything, that can be removed, but not always easily.....

Pre sensitized boards, both negative and positive resist, is fairly cheap, and with positive resist, there is no need for reversal, either in the printer or with reversal films..

True multilayer is impossible to do in a kitchen lab.......and commercial proto boards are now quite cheap

Etchants for prototyping machines are usually ferric chloride, sodium persulphate or ammonium persulphate. For a hobby lab with occasinal use, I'd go with a Hydrochloric acid and hydrogen peroxide mix, on a throw away basis. Just make sure to have very good ventilation. All the other ones are mixes usually stored in etching machines, and ferric chloride, although very efficient, makes horrible stains on anything, that can be removed, but not always easily.....

Pre sensitized boards, both negative and positive resist, is fairly cheap, and with positive resist, there is no need for reversal, either in the printer or with reversal films..

Last edited:

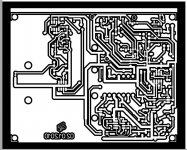

I did made a negative artwork with Gerbv but it give a black border because it is colour inverted to get what I want, I do not now if there are other ways so the black borders are not present, maybe here I get a answer. I get it from gerber output to postcript with gerbv.

thanks

thanks

Attachments

Usually, there is a setting in Gerber tools that lets you define the outline. I don't know Gerbv, so I can't say anything about it's settings. Any postscript tool that allows you to trim the outline ???

Usually, there is a setting in Gerber tools that lets you define the outline. I don't know Gerbv, so I can't say anything about it's settings. Any postscript tool that allows you to trim the outline ???

I did use ghostcript for printing and did not find that option.

can try gerber tools but that is a soft with a license I think.

But is not a problem, I can use it as it is, I go search for some tools who maybe can first.

thanks for thinking with me.

Last edited:

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- pcb etching