Great stuff, thanks ! Remind me what software your using for the box calculations? 🙂T/S max flat = ~81.48 L net, ~52.7 Hz Fb, 20.32 cm/8" dia. x 25.9 cm/10.2" vent.

Classic BR = ~121.5 L net, 42 Hz (ideally actual Fs) Fb, 20.32 cm/8" dia. x 28.9 cm/11.38" (or empirically find length for actual Fs) vent.

Btw, I'm sure most know this but a full spec sheet with some useful measurements was shared in another post about a decade or so ago. Pretty handy https://www.diyaudio.com/community/threads/need-to-pad-down-paudio-tweeter.178749/post-2403560

I had some of these before the Unitys, and like every other large format coax I owned (many), I would never use them as a 2 way. They need an LF driver added below and xover at 200-300 to keep the LF out of the midrange.

You're welcome!Great stuff, thanks ! Remind me what software your using for the box calculations?

T/S math

Classic pg. 76

I use Hornresp to sim nowadays.

Ok, I'm now trying to have a more determined crack at modelling these BM15CX38 for a compact active PA speaker to run with sub(s). As has been stated many times they're not really the right driver for a novice speaker DIY-er like me but hey, part of the fun is making mistakes. Better to make them in software first of course!

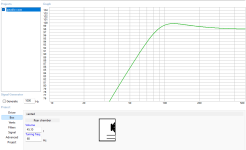

I really need to get out the DATS and measure them properly but is we assume that the Klang Und Ton spec sheet is close then I've modelled a box in WinISD using 4 ports similar to the bigger PA coaxials I've seen from LD Systems, Tannoy etc. I've roughly scaled up an 18sound 12 inch DIY coaxial design with a bit more bracing and with 19mm ply. Currently I'm at about 45L volume (any bigger and the weight becomes a problem), 4 poly pipe ports of 7.62cm inner diameter and just under 21 cm length. Tuning frequency is 68Hz as this seems the best compromise between the port length I can fit and a low end hump that's not too high.

Does this work in any way ? What stupid/invalid assumptions have I made here and will this even work well as a PA top crossed at around 1.2Khz or is the off-axis response too compromised by the 15" beaming by the time it crosses to the horn? Not too many rodeos under my belt here so I'm posting this with a fair bit of trepidation! 😆

I really need to get out the DATS and measure them properly but is we assume that the Klang Und Ton spec sheet is close then I've modelled a box in WinISD using 4 ports similar to the bigger PA coaxials I've seen from LD Systems, Tannoy etc. I've roughly scaled up an 18sound 12 inch DIY coaxial design with a bit more bracing and with 19mm ply. Currently I'm at about 45L volume (any bigger and the weight becomes a problem), 4 poly pipe ports of 7.62cm inner diameter and just under 21 cm length. Tuning frequency is 68Hz as this seems the best compromise between the port length I can fit and a low end hump that's not too high.

Does this work in any way ? What stupid/invalid assumptions have I made here and will this even work well as a PA top crossed at around 1.2Khz or is the off-axis response too compromised by the 15" beaming by the time it crosses to the horn? Not too many rodeos under my belt here so I'm posting this with a fair bit of trepidation! 😆

Attachments

Last edited:

We can barely hear +/- 3 dB in a quiet environment, so 2 dB is 'flat' to us humans. FWIW, historically PA cabs were (still are in some cases) intentionally undersized @ Vas/1.44, Fb = 1.56x Fs to somewhat ensure not bottoming out drivers.

Regardless @ 286.84/45 L = 6.374a sealed = sqrt(6.374+1)*0.22 = 0.6 Qtc, so not too small, but needs to be tuned ~2x Fs for good power handling, so need 4x vent area = 2x dia. for max vent eff = 6" dia = shortest vent if it will fit.

15" is ~100 deg/1.2 kHz, so you tell me......... 😉 I mean this is its factory XO spec, right?

Regardless @ 286.84/45 L = 6.374a sealed = sqrt(6.374+1)*0.22 = 0.6 Qtc, so not too small, but needs to be tuned ~2x Fs for good power handling, so need 4x vent area = 2x dia. for max vent eff = 6" dia = shortest vent if it will fit.

15" is ~100 deg/1.2 kHz, so you tell me......... 😉 I mean this is its factory XO spec, right?

Ok, thanks, this is super helpful! If you'll indulge my learning as I go, could I just unpack all this a little - So tuning closer to 85hz (Fs = 42.9) would be better for power handling? Have I understood you're also suggesting a port diameter of 6" ? Apologies if I'm misunderstanding (quite likely!) but I reckon that'll end up being too big for my current design. Very open to starting again, but I've done two different designs based on pvc pipe diameters I can easily source from my local hardware (82mm and 90mm OD). Both seem to model in WinISD with acceptable port velocity - even the 7.62mm ID ports has an air speed of 19 m/s at 400 watts using 4 port tubes. I plan to flare them somewhat also.so not too small, but needs to be tuned ~2x Fs for good power handling, so need 4x vent area = 2x dia. for max vent eff = 6" dia = shortest vent if it will fit.

So I've upped the box size a little (now 50L) to fit the bigger pvc tubes which if fusion360 is to be believed gets me to just under a 30kg loaded box. I'm currently at a tuning of 75hz with vents at about 18cm length although not factored in stuffing. Can I get away with that (85hz gives me a 4-5db hump) ? I know I'll have to play around with port lengths a bit. 🙂

Factory spec I'm not too sure - I think it was probably a bit higher than 1.2khz but while their site always promised it, p-audio never actually seemed to publish their DIY-115CX design which would have given some hints.

Last edited:

You're welcome!

Correct, 2x cutoff increase = 4x increased Xmax available

Right: (4) 3" dia. pipes = 3*sqrt(4) = 6" dia, which is most efficient, ergo in theory will be shorter than the 3"

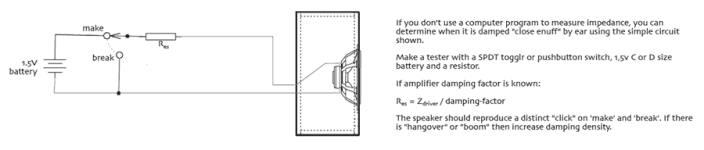

If you find the hump'd performance unacceptable, then critically damp the vents to 'taste'. 😉

Yeah, looks like 1.2 kHz to me based on a VC dia. cutoff = 34400/pi/7.214 = 1518 Hz, factory 1.2 kHz lower horn response spec.

Correct, 2x cutoff increase = 4x increased Xmax available

Right: (4) 3" dia. pipes = 3*sqrt(4) = 6" dia, which is most efficient, ergo in theory will be shorter than the 3"

If you find the hump'd performance unacceptable, then critically damp the vents to 'taste'. 😉

Yeah, looks like 1.2 kHz to me based on a VC dia. cutoff = 34400/pi/7.214 = 1518 Hz, factory 1.2 kHz lower horn response spec.

Attachments

Last edited:

I'm feeling a bit underdone here and there's a reasonable chance I'm misunderstanding the shorthand but basically you're saying the equivalent single 6 inch port is more efficient than four 3 inch ports? Certainly does end up shorter, by more than half! 🙂Right: (4) 3" dia. pipes = 3*sqrt(4) = 6" dia, which is most efficient, ergo in theory will be shorter than the 3"

Since they'll be DSP-ed I can always EQ out the bump after the port tuning so it's probably not a big deal at all. I suppose it more comes down to whether I'd ever need to cross them a bit lower. 75hz Fb gives me an F3 of about 85hz with WinISD which probably works Ok although I will need to also factor in damping.

Correct, much less internal friction + bigger end correction* = less length required.

* the air mass 'plug' that vibrates extends outside each end as it vibrates, so the bigger the pipe the more extends out, hence the shorter the pipe to compensate since it's this plug's length we're actually calculating based on its weight, not the pipe length per se

* the air mass 'plug' that vibrates extends outside each end as it vibrates, so the bigger the pipe the more extends out, hence the shorter the pipe to compensate since it's this plug's length we're actually calculating based on its weight, not the pipe length per se

Got it. 🙂 Wonder why so many of the 12" and 15" coaxial wedges/PA speakers out there now seem to be 4 port (18 sound, Tannoy, Rcf, LD Systems etc). I'm guessing so they can lower the port velocity and use smaller diameter tubes without risking audible turbulence?

Multiple ports to get desired any large sum total required are using them as an acoustic damping filter whereas I prefer the pioneer's max eff. venting and damp to 'taste' if required (rarely IME).

In prosound it's done to protect the driver at sustained high power by acoustically 'choking' it.

In prosound it's done to protect the driver at sustained high power by acoustically 'choking' it.

It certainly makes sense that accoustic damping due to frictional loss (heat I guess) gets bigger at higher power.. I think ive seen some papers about this non linear behaviour although not really understood the maths. More efficient ports are more linear presumably?In prosound it's done to protect the driver at sustained high power by acoustically 'choking' it.

Hmm, linear in that its 'stiction' is low enough to keep its vent mach low enough to keep acoustic efficiency high at high power, but at ~sustained high power the VC heats up exponentially, ergo so goes Qts to increasingly under-damped which in turn ideally needs an even larger vent, so sized for normal music power/'fast' transients and increasingly 'chokes'/damps the driver otherwise, limiting heat rise (for awhile anyway).

Higher math is literally 'Greek' to me, so ignore it and any higher math I post is either by others or I used this online software.

Higher math is literally 'Greek' to me, so ignore it and any higher math I post is either by others or I used this online software.

- Home

- Loudspeakers

- Multi-Way

- P-Audio BM15CX38 (What to do?)