Snarky Puppy, Binky, already blows me away with only one Speaker, The Snare hits you right in youre Face i am satisfied already with Passive Crossover Man!!!

Sounds already like one Chassis LOL, Nothing harsch, or Hard sounding. Timing is nice too.

Rigmor Gustafsson , I Will Wait For You, 04 Main' Whoopee and 05 Fire And Rain made my Day 😉 soft and smoth sounding Voices, damn.

Or Patricia Barber , Modern Cool, deep and soft Voices very nice.

But the best was Mike Mainieri and Man behind the Bars!!! That Xylophon hits youre Skin direktly to get Goose Flesh / Bombs, yeah!!!

Now i realy need to build an second Waveguide for Stereo listening LOL

Sounds already like one Chassis LOL, Nothing harsch, or Hard sounding. Timing is nice too.

Rigmor Gustafsson , I Will Wait For You, 04 Main' Whoopee and 05 Fire And Rain made my Day 😉 soft and smoth sounding Voices, damn.

Or Patricia Barber , Modern Cool, deep and soft Voices very nice.

But the best was Mike Mainieri and Man behind the Bars!!! That Xylophon hits youre Skin direktly to get Goose Flesh / Bombs, yeah!!!

Now i realy need to build an second Waveguide for Stereo listening LOL

Here my Refernce the Beyma TPL 200, looks not much different expect the very High Frequencies fall apart soon i guess because of the Length of the Beyma AMT \o/

And the Price isn't realy DIY friendly 😉

But this Speaker was Inspiering me to build my Waveguide!

https://audioxpress.com/article/tes...a-tpl200-h-pro-sound-air-velocity-transformer

And the Price isn't realy DIY friendly 😉

But this Speaker was Inspiering me to build my Waveguide!

https://audioxpress.com/article/tes...a-tpl200-h-pro-sound-air-velocity-transformer

Measurment With Waveguide and without on the Passive X-Over (2 uF, 3.3 Ohm in Series)

Blue Line is the AMT 25 on the Bottom @ my 2 Way Speaker so not exact the same Diaphragma and Enclousure Volume.

But i Print an second Waveguide right now so i will do the Measuring again in some days 😉

It isn't that easey to disasambler the Waveguide for that Test any more 😉

With Waveguide +9 dB @ 2 kHz but i guess with the same Enclousures on the Blue Line it would be a bit less

Yellow is now with the round eges Frame and without X-Over, Distance is around 50cm, 1,1m over Ground:

STL Files aplied!!!

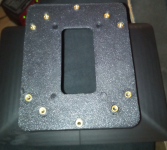

I used this, to screw it together with M4 Hex screws (Deburr the holes a bit, before inserting it with an soldering iron):

Blue Line is the AMT 25 on the Bottom @ my 2 Way Speaker so not exact the same Diaphragma and Enclousure Volume.

But i Print an second Waveguide right now so i will do the Measuring again in some days 😉

It isn't that easey to disasambler the Waveguide for that Test any more 😉

With Waveguide +9 dB @ 2 kHz but i guess with the same Enclousures on the Blue Line it would be a bit less

Yellow is now with the round eges Frame and without X-Over, Distance is around 50cm, 1,1m over Ground:

STL Files aplied!!!

I used this, to screw it together with M4 Hex screws (Deburr the holes a bit, before inserting it with an soldering iron):

Attachments

Last edited:

I like Measuring 😉

Here the 2 way Setup with 0 15 and 30 degree 1m distance 1,1m over the Ground:

Here the 2 way Setup with 0 15 and 30 degree 1m distance 1,1m over the Ground:

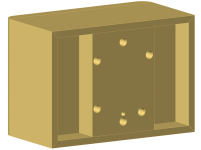

If anyone want to have an Drawing for that Woodenbox:

I will make an Technical Drawing with all required dimensions soon!

Its from 18 and 10mm MDF

I will make an Technical Drawing with all required dimensions soon!

Its from 18 and 10mm MDF

Attachments

Last edited:

Lots of information! You should probably start a build thread.

Your rear enclosure for the AMT is very close to the one I ended up. Mine is a little deeper I think (15mm), but also flat. I tried other shapes and depths but that was best overall. The second best was quite different, more house shaped. It was a square section about 1" deep, with an angled "roof" another 1" deep or so.

Your rear enclosure for the AMT is very close to the one I ended up. Mine is a little deeper I think (15mm), but also flat. I tried other shapes and depths but that was best overall. The second best was quite different, more house shaped. It was a square section about 1" deep, with an angled "roof" another 1" deep or so.

This enclousure isn't for my Project its for People that want to check that Waveguide.

How deep you want it its on you then, the most important Dimensions are for Waveguide and AM25 the rest you could change i guess 😉

Probably you are right i will start an build thread for my Speaker Projekt, i guess the Wavguide it's done 😉

Next is an Ripol Prototype but thats i cant Provide Drawings, Axel Ridthaler has the Patents of that and i payed for the Dimensions 😉 for my selected Woofer.

How deep you want it its on you then, the most important Dimensions are for Waveguide and AM25 the rest you could change i guess 😉

Probably you are right i will start an build thread for my Speaker Projekt, i guess the Wavguide it's done 😉

Next is an Ripol Prototype but thats i cant Provide Drawings, Axel Ridthaler has the Patents of that and i payed for the Dimensions 😉 for my selected Woofer.

Last edited:

Lots of information! You should probably start a build thread.

Your rear enclosure for the AMT is very close to the one I ended up. Mine is a little deeper I think (15mm), but also flat. I tried other shapes and depths but that was best overall. The second best was quite different, more house shaped. It was a square section about 1" deep, with an angled "roof" another 1" deep or so.

Did you try a rear enclosure shaped like an "M", with the AMT at the base of the M so the backwave is split in two? The house-shaped item would tend to have a rear surface more or less equidistant from the AMT center, and the flat one could have the usual front-to-back standing wave issues around 11 kHz (modulo lots of damping material, of course). The M shape might also alleviate side-to-side standing waves if the tip is close to the AMT.

I could Print one for Testing Purpose but my Enclousure is completle filled with Felt, but Testing is always an good idea 😉Did you try a rear enclosure shaped like an "M", with the AMT at the base of the M so the backwave is split in two? The house-shaped item would tend to have a rear surface more or less equidistant from the AMT center, and the flat one could have the usual front-to-back standing wave issues around 11 kHz (modulo lots of damping material, of course). The M shape might also alleviate side-to-side standing waves if the tip is close to the AMT.

Oh Misunderstanding you mean the back Enclousure for the AMT, right?Lots of information! You should probably start a build thread.

Your rear enclosure for the AMT is very close to the one I ended up. Mine is a little deeper I think (15mm), but also flat. I tried other shapes and depths but that was best overall. The second best was quite different, more house shaped. It was a square section about 1" deep, with an angled "roof" another 1" deep or so.

Neare the same shape and defth i have used on my 2 Way Speaker but had to fill it up with Cardboard till 3 mm left (filled with Felt) than i had an good Frequency Response and 6dB Filter around 3,5 kHz or so.

But now i can use the whole Volume on that Waveguide, not sure if more Volume will made it better, lower than 2 kHz the Distortion Level will rise!

Other shapes make it difficult to fil it up with Felt.

Did you try a rear enclosure shaped like an "M", with the AMT at the base of the M so the backwave is split in two? The house-shaped item would tend to have a rear surface more or less equidistant from the AMT center, and the flat one could have the usual front-to-back standing wave issues around 11 kHz (modulo lots of damping material, of course). The M shape might also alleviate side-to-side standing waves if the tip is close to the AMT.

My thinking was the same as yours: flat back, especially if shallow would be the worst performance. But it was the best overall. I used wool batting BTW. The triangle "roof" shape was good if it was on a square section first and had considerable depth. I also tried a circular back, but not a hemisphere since I did not want an equidistant reflection back the to the diaphragm. It was ok but not the best. I did not try an M shape. I considered doing a Kef-style Helmholtz array but in the end the the 15mm deep flat back was good enough performance.

You mean something like that ???Did you try a rear enclosure shaped like an "M", with the AMT at the base of the M so the backwave is split in two? The house-shaped item would tend to have a rear surface more or less equidistant from the AMT center, and the flat one could have the usual front-to-back standing wave issues around 11 kHz (modulo lots of damping material, of course). The M shape might also alleviate side-to-side standing waves if the tip is close to the AMT.

For the back Chamber, thats 4x 18300mm³ 😉 no Parallel Surfaces.

Top View:

Last edited:

Hi @augerpro is there any progress on the measurements and speaker designs? I'm still excitedly waiting for the Model 3 (entry level) design to start with as a beginnerMeasuring all 4 prototypes today. Verifying the baffle diffraction model and whether roundover or chamfer works best. I tried my best match the baffle diffraction to the native response of the drivers - mostly the woofer. Model 1 is Satori textreme and Be, Model 2 is SB "ceramic", Model 3 is SB's entry level drivers, and Model 5 is Scanspeak Discovery and either SB26STAC or CAT308. All tweeters on waveguides of course.

View attachment 1462533

Also would it be a good idea to CNC the waveguide directly onto the baffle like this? It could be cheaper than 3D printing separately, but im not sure if there's a need for sanding it down which might affect the waveguide's function. By doing this we could CNC the roundover/chamfer directly onto the baffle as well.

Custom MDF CNC service I found on TaoBao

Thanks

Last edited:

Importand information!!!!

This Noises comes from my 3D Printer running 24/7 Printing Waveguide Parts, so don't mess around with 😉

Got me realy a Headache finding the reason for that. LOL

This Noises comes from my 3D Printer running 24/7 Printing Waveguide Parts, so don't mess around with 😉

Got me realy a Headache finding the reason for that. LOL

Hi @augerpro is there any progress on the measurements and speaker designs? I'm still excitedly waiting for the Model 3 (entry level) design to start with as a beginner

Also would it be a good idea to CNC the waveguide directly onto the baffle like this? It could be cheaper than 3D printing separately, but im not sure if there's a need for sanding it down which might affect the waveguide's function. By doing this we could CNC the roundover/chamfer directly onto the baffle as well.

View attachment 1470021

Custom MDF CNC service I found on TaoBao

Thanks

I know of a couple people that have used the .step file to cnc the waveguide into a baffle. So yeah it could be done.

Measurements are done and I'm analyzing the results and prototyping crossovers. On the model you are specifically looking at I'm going to make a baffle modification and remeasure. Once I do that I'm going to build the actual speakers.

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!