Well... a bit of drama here in monkey coffin land...

One night we became aware of some odd tonal vibration stuff in the speak we are using on the right channel. I was able to find a piece of music that really highlighted the issue—and tracked it down to the Volt mid. Basically at certain frequencies—say long horn or string notes—there would be a mechanical vibration that I could "fix" by finger muting the outside of the dome. Definitely only on one of the mids—and VERY noticeable and even in a low res video I made. Matthias and 6L6 said it was the voicecoil rubbing...

Sent the vid to Volt and Solen, their NA distributor where I bought them (outside Montreal). Volt passed the issue to Solen—who were very responsive and within about a week I had a new voicecoil assembly in my hands—self-aligning no less. Fixed the issue. I was in major music withdrawal about all of this! No serious music was making me nuts!

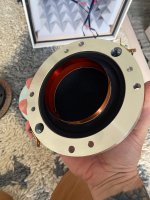

Everyone agreed that visually the "old" coil didn't look perfectly round. Not sure why we didn't notice it immediately—took the right music it seems at the right volume? You can see in the pics the tolerances.

One night we became aware of some odd tonal vibration stuff in the speak we are using on the right channel. I was able to find a piece of music that really highlighted the issue—and tracked it down to the Volt mid. Basically at certain frequencies—say long horn or string notes—there would be a mechanical vibration that I could "fix" by finger muting the outside of the dome. Definitely only on one of the mids—and VERY noticeable and even in a low res video I made. Matthias and 6L6 said it was the voicecoil rubbing...

Sent the vid to Volt and Solen, their NA distributor where I bought them (outside Montreal). Volt passed the issue to Solen—who were very responsive and within about a week I had a new voicecoil assembly in my hands—self-aligning no less. Fixed the issue. I was in major music withdrawal about all of this! No serious music was making me nuts!

Everyone agreed that visually the "old" coil didn't look perfectly round. Not sure why we didn't notice it immediately—took the right music it seems at the right volume? You can see in the pics the tolerances.

Attachments

Really glad to hear your good experience with Volt and Solen. Got my Volts via Solen as well.

@pfarrell - Thanks for all the good pics, particularly the Xovers.

I have all the parts. A couple of new hips has slowed me down. Hope to get back in the shop in the next couple of months and build a set.

@pfarrell - Thanks for all the good pics, particularly the Xovers.

I have all the parts. A couple of new hips has slowed me down. Hope to get back in the shop in the next couple of months and build a set.

I have all the parts. A couple of new hips has slowed me down. Hope to get back in the shop in the next couple of months and build a set.

I hope the "build a set" refers to the OSMCs, not the hips. I hope your hips are all set, so you can look forward to a substantial speed up of pretty much everything once they are "broken in" properly. 😀 Make sure you don't skimp on the physio and stuff!

YES!!! Another build! Love it. Xovers were almost a criminal amount of fun. And in the end—I'm really glad they are in separate boxes—lots of stuff to try over time with things like Pass ACN etc—add extra jacks to the speaks, IMO.

Happy healing.

Happy healing.

I’ve moved the posts regarding a flush in-wall Open Source Monkey Box design here:

https://www.diyaudio.com/forums/multi-way/363564-wall-monkey-box.html#post6138981

I think the OSMB could fulfill a need for high quality studio monitor type flush installation exceptionally well....

https://www.diyaudio.com/forums/multi-way/363564-wall-monkey-box.html#post6138981

I think the OSMB could fulfill a need for high quality studio monitor type flush installation exceptionally well....

Last edited:

how to

@pfarrell,

Your work is amazing, just curious what tool is needed to cut those large speaker holes and recesses. Thanks,

Don

YES!!! Another build! Love it. Xovers were almost a criminal amount of fun. And in the end—I'm really glad they are in separate boxes—lots of stuff to try over time with things like Pass ACN etc—add extra jacks to the speaks, IMO.

Happy healing.

@pfarrell,

Your work is amazing, just curious what tool is needed to cut those large speaker holes and recesses. Thanks,

Don

Thanks Don!

I have some serious routers at my disposal but here is what I actually used (I have a bunch of Makita batteries—and not having to deal with a powercord is very nice when cutting circles. Plus a battery powered router has a million uses):

https://www.amazon.com/gp/product/B074C31YML/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1&fpw=alm

Note the 2 handled base shown in the link above is required for this piece:

https://www.amazon.com/gp/product/B084X5QXZ5/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1&fpw=alm

The circle jig assumes a 1/4" bit. I used a solid carbide spiral flute plunging bit. Making 2-3 passes for 3/4" material (Russian multiply is VERY dense). It's very straight forward once you grasp the process—drill an 1/8" hole dead center of the circle you are about to cut—insert a stainless steel pin that comes with the jig. You need to make sure the bit is REALLY tight in the collett. You can youtube proper 2 wrench tightening/loosening techniques for router bits—there some good tricks, one handed, if you aren't aware. You have to cut the depth and circumference for the driver flange before you cut the hole all the way through the material, otherwise there's nothing for the jig pin to stick into. The hardest part is actually working up the "right" diameters and depths for your material and the actual measurements of the drivers—given that there's foam involved for sealing—I took measurements of the compressed foam thicknesses plus the thickness of the driver/waveguide flanges—and then backing off it all a hair to allow for the fact that the bolts will compress more than my calipers also knowing that I bought a bunch of different foam tapes in varying thicknesses to account for screwups and options. Whew... not so simple....but in the end everything is flush with the baffle surface—but if it's not—it's not the end of the world either.

What I did in reality was different from what Matthias has in his drawings where the driver circle cuts are noted—I made my own cuts based on the actual parts I had in hand—adhering to his center points of course.. I also used 3/4 material throughout and made sure my interior dimensions matched his drawings. To get the 20mm baffle depth for the Volt, I actually used a cork/foam sheet material between the driver and baffle—it's a bit over 1/8" thick, and not very compressible. Worked perfectly. Please excuse any "talking to" that might be coming across with all of this—I have no idea what you know and don't know—and I don't pretend to "know" anything. Ha!

More questions—ask away!

Oh, and I don't know what you have already purchased and from where—but I regret not ordering extra bass ports—they are pretty cheap—and easy to pop and in and out—and once cut—you can't go back...

I have some serious routers at my disposal but here is what I actually used (I have a bunch of Makita batteries—and not having to deal with a powercord is very nice when cutting circles. Plus a battery powered router has a million uses):

https://www.amazon.com/gp/product/B074C31YML/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1&fpw=alm

Note the 2 handled base shown in the link above is required for this piece:

https://www.amazon.com/gp/product/B084X5QXZ5/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1&fpw=alm

The circle jig assumes a 1/4" bit. I used a solid carbide spiral flute plunging bit. Making 2-3 passes for 3/4" material (Russian multiply is VERY dense). It's very straight forward once you grasp the process—drill an 1/8" hole dead center of the circle you are about to cut—insert a stainless steel pin that comes with the jig. You need to make sure the bit is REALLY tight in the collett. You can youtube proper 2 wrench tightening/loosening techniques for router bits—there some good tricks, one handed, if you aren't aware. You have to cut the depth and circumference for the driver flange before you cut the hole all the way through the material, otherwise there's nothing for the jig pin to stick into. The hardest part is actually working up the "right" diameters and depths for your material and the actual measurements of the drivers—given that there's foam involved for sealing—I took measurements of the compressed foam thicknesses plus the thickness of the driver/waveguide flanges—and then backing off it all a hair to allow for the fact that the bolts will compress more than my calipers also knowing that I bought a bunch of different foam tapes in varying thicknesses to account for screwups and options. Whew... not so simple....but in the end everything is flush with the baffle surface—but if it's not—it's not the end of the world either.

What I did in reality was different from what Matthias has in his drawings where the driver circle cuts are noted—I made my own cuts based on the actual parts I had in hand—adhering to his center points of course.. I also used 3/4 material throughout and made sure my interior dimensions matched his drawings. To get the 20mm baffle depth for the Volt, I actually used a cork/foam sheet material between the driver and baffle—it's a bit over 1/8" thick, and not very compressible. Worked perfectly. Please excuse any "talking to" that might be coming across with all of this—I have no idea what you know and don't know—and I don't pretend to "know" anything. Ha!

More questions—ask away!

Oh, and I don't know what you have already purchased and from where—but I regret not ordering extra bass ports—they are pretty cheap—and easy to pop and in and out—and once cut—you can't go back...

cabinet work

pfarrell,

Thank you so much. And the detail is greatly appreciated. There is a first time for everything and this is it for me on the woodworking side. You are so good with this stuff. The only thing better would be a utube video of it. 😀😀😀

Thanks again.

Best wishes,

Don

pfarrell,

Thank you so much. And the detail is greatly appreciated. There is a first time for everything and this is it for me on the woodworking side. You are so good with this stuff. The only thing better would be a utube video of it. 😀😀😀

Thanks again.

Best wishes,

Don

Ha! I hadn't really cut any circles either... Make lots of test cuts obviously... Youtube has all of it WAY covered. Not sure I could add much....Making the OSMCs was therapy—figuring out how to film it all would have added stress! OMG.

In this case yes, since you aren’t cutting in 1 pass. This: Amana Tool - 46321 Solid Carbide Spiral Plunge 1/4 Dia x 1-1/4 x 1/4" Shank Up-Cut

sketchup

Just curious if anyone has put the final cab version of the Monkey Coffin into Sketchup.

There is a speciality shop in Kansas that can send me a kit for less than I would spend for the parts. This is for the cap only. Thinking of doing this.

Thanks,

Don

Just curious if anyone has put the final cab version of the Monkey Coffin into Sketchup.

There is a speciality shop in Kansas that can send me a kit for less than I would spend for the parts. This is for the cap only. Thinking of doing this.

Thanks,

Don

I have not looked at Sketchup. Please go ahead and let us know how it goes! You may also share the Sketchup here if you like.

Don, do you mean just the baffle when you say “cap”? Or the whole box? I could probably generate a drawing pretty quickly... never occurred to me since we all have access to different materials, thicknesses etc.

Pfarrell,

My bad. The first time I said cab and the second time cap. Too much inspeak and a typo. My supplier uses cab - short for cabinet. The whole entire wooden box. Makes it out of 3/4in Baltic Birch. All done by computer. Amazingly efficient.

Did you use 3/4 inch? The business I am using just uses the interior dimensions and key features like is it a removable inset back face. They can do speak cutouts too but you had better give it to them right. Or.... My plunge router is ready to go, I just have to practice up.

The main reason I asked wasn't just for me but I thought it might be helpful to others who are interested as it simplifies the build for us. Kind of like a Gerber file.

Since you are on the line, I wanted to ask you why you think the sound is so good. My layman's opinion is that everything goes into making something really good. Crossovers, wiring, drivers, cabinet, etc. Any way, I would be delighted to hear what your thoughts are on the Monkey coffin end results and why it is.

I am really thinking of this as a reference project although the crossovers scare me. I need to move that over to "criminal amount of fun".

Thanks for you offer to help.

Regards,

Don

My bad. The first time I said cab and the second time cap. Too much inspeak and a typo. My supplier uses cab - short for cabinet. The whole entire wooden box. Makes it out of 3/4in Baltic Birch. All done by computer. Amazingly efficient.

Did you use 3/4 inch? The business I am using just uses the interior dimensions and key features like is it a removable inset back face. They can do speak cutouts too but you had better give it to them right. Or.... My plunge router is ready to go, I just have to practice up.

The main reason I asked wasn't just for me but I thought it might be helpful to others who are interested as it simplifies the build for us. Kind of like a Gerber file.

Since you are on the line, I wanted to ask you why you think the sound is so good. My layman's opinion is that everything goes into making something really good. Crossovers, wiring, drivers, cabinet, etc. Any way, I would be delighted to hear what your thoughts are on the Monkey coffin end results and why it is.

I am really thinking of this as a reference project although the crossovers scare me. I need to move that over to "criminal amount of fun".

Thanks for you offer to help.

Regards,

Don

I kept decent notes about overall dimensions—since yes—I worked with 3/4" (19mm) Russian ply—15plys—no voids. Just couldn't bring myself to play with the MDF. I did use MDF for the internal bracing—and circle cutting practice. I'm not sure I kept great notes about the exact cutout specs for the drivers. I measured them out from life and cut them in real time, adjusting depth and testing. For the baffle (and cabs) if CNC'd I'd expect to have to run it at least twice if I were going to go that route. I also dadoed all the joints—which adds further measurement fun. Perhaps If I made them again I'd consider box joints (been doing a ton of research on guitar amps—and am building two—perfect OSMC followup IMO).

So—OSMC sound. BTW—building the crossovers was my favorite part—If I was forced to choose. I suppose I could fret about all the smallest details—MDF vs ply vs Mundorf this vs that, but....I think I'd go insane (and I did fret them ALL haha.). I try to listen to the people around me that I think know more about whatever it is than I do—and even then—I still act like I don't know anything (to myself ;-)... that means, when Matthias says he didn't like the results with super fancy caps—I listened—clearly he knows a ton more about speakers than I do. I'm just making it my job to figure out what I like and don't like audio-wise since we all have different ideas about that—and more importantly we have different rooms—and I think a giant element here with speakers—is the room. It's all massively subjective.

For my audio education, I needed to give myself a baseline. For me that meant trying to listen to a system that someone I trust has already made (M2X to boot!) and vinyl based (instinct here). I accomplished that last January—and while listening to a totally awesome vinyl playback setup in a dedicated and tweaked room—I purchased records that I heard there that I liked—and they became my references for later when listening to my system as it evolves.

Of all the stuff I've made and tried—all made differences here and there—yes and no—but the two biggest changes that made me have to sit down, were trying an MC cart for the fist time—and plugging in the Monkey Coffins. I'm not sure I can wax poetic about the specifics since it's all hyperbole—but I just heard more—of everything—in every way—and finally got a taste of that thing I've read about where the speakers disappear in the room. And where your soul just moves since whatever it is you are listening too just makes you feel incredible. Also—the OSMC 100% closed the gap between my vinyl setup sounding "better" than my DAC setup. Vinyl is still "better" call it "more"—but it's a little less obvious now (and interestingly that gap closed even more with Salas's DCG3). It's also fun to move around the room and find the natural sweet spots. In one spot the bass is just so big that I frequently sit there just to get all wrapped up in it.

I also prepped the cabinets and crossover boxes/wiring for biamping—and also running a separate analog crossover network (like ACN) directly to the cabinets to mess around with twiddling in my own crossovers—not to try to improve upon Matthias's work—just to experiment myself. In terms of wiring crossover to cabs with speakon—I found the biggest "tray" cable I could that was 6 conductor and maxed out the speakOn connections—think it was ~14ga—and turned out to be Belden branded. Used similarly beefy gauges inside too.

Anyway—too much perhaps—or too little, I don't know—I can't imagine not being thrilled with having made them. Still look at them in disbelief in the room. Also—not one peep from the family about size etc. They know how good everything is sounding and I guess are willing to overlook some details... 😀

So—OSMC sound. BTW—building the crossovers was my favorite part—If I was forced to choose. I suppose I could fret about all the smallest details—MDF vs ply vs Mundorf this vs that, but....I think I'd go insane (and I did fret them ALL haha.). I try to listen to the people around me that I think know more about whatever it is than I do—and even then—I still act like I don't know anything (to myself ;-)... that means, when Matthias says he didn't like the results with super fancy caps—I listened—clearly he knows a ton more about speakers than I do. I'm just making it my job to figure out what I like and don't like audio-wise since we all have different ideas about that—and more importantly we have different rooms—and I think a giant element here with speakers—is the room. It's all massively subjective.

For my audio education, I needed to give myself a baseline. For me that meant trying to listen to a system that someone I trust has already made (M2X to boot!) and vinyl based (instinct here). I accomplished that last January—and while listening to a totally awesome vinyl playback setup in a dedicated and tweaked room—I purchased records that I heard there that I liked—and they became my references for later when listening to my system as it evolves.

Of all the stuff I've made and tried—all made differences here and there—yes and no—but the two biggest changes that made me have to sit down, were trying an MC cart for the fist time—and plugging in the Monkey Coffins. I'm not sure I can wax poetic about the specifics since it's all hyperbole—but I just heard more—of everything—in every way—and finally got a taste of that thing I've read about where the speakers disappear in the room. And where your soul just moves since whatever it is you are listening too just makes you feel incredible. Also—the OSMC 100% closed the gap between my vinyl setup sounding "better" than my DAC setup. Vinyl is still "better" call it "more"—but it's a little less obvious now (and interestingly that gap closed even more with Salas's DCG3). It's also fun to move around the room and find the natural sweet spots. In one spot the bass is just so big that I frequently sit there just to get all wrapped up in it.

I also prepped the cabinets and crossover boxes/wiring for biamping—and also running a separate analog crossover network (like ACN) directly to the cabinets to mess around with twiddling in my own crossovers—not to try to improve upon Matthias's work—just to experiment myself. In terms of wiring crossover to cabs with speakon—I found the biggest "tray" cable I could that was 6 conductor and maxed out the speakOn connections—think it was ~14ga—and turned out to be Belden branded. Used similarly beefy gauges inside too.

Anyway—too much perhaps—or too little, I don't know—I can't imagine not being thrilled with having made them. Still look at them in disbelief in the room. Also—not one peep from the family about size etc. They know how good everything is sounding and I guess are willing to overlook some details... 😀

Last edited by a moderator:

Matthias,

Before I dive off the deep end on this one would you please help me with two questions,

1. Is the doc dated June 24 and referenced in your post #890 still current, and

2. How do we currently get the Augerpro circular waveguide.

thanks,

Don

Before I dive off the deep end on this one would you please help me with two questions,

1. Is the doc dated June 24 and referenced in your post #890 still current, and

2. How do we currently get the Augerpro circular waveguide.

thanks,

Don

- Home

- Loudspeakers

- Multi-Way

- Open Source Monkey Box