In vintage Japanese amps many resistors values may be completely out of factory value. Although your unit is not from Japan, it has a lot of gray cylinder caps possibly made by Suzuki, so I'm not sure about the rest of the parts.

Check my blog at

http://www.vacuum-tube.eu/wp/?p=268

Check my blog at

http://www.vacuum-tube.eu/wp/?p=268

Last edited:

@Eli: I don't want to be the guy that buys a mint vintage piece, proceeding to rip its guts out and replace it with whatever YouTube says is da bestest. I want to preserve it, and I want it to sound good. It will be my home office amp, connected to a DAC, and, somewhere down the line, a record changer and maybe a cassette player.

That's precisely why I suggested Soviet surplus K40 PIO caps. as replacements for the parts in the signal path. The OEM Suzuki parts are PIO, but they are notorious for becoming leaky. The Russian stuff is hermetically sealed and will last longer than old farts, like me.

Yes, I guess I wasn't clear. I will get some Russian caps -- I just got a knee-jerk reaction when what I hoped was a simple thing turned out to be Yet Another Project where I spend countless hours pouring over technical details of parts, and it takes forever before I can use the gear

Not sure if it's relevant, but all caps in this amp are Nichicon, not Suzuki.

Not sure if it's relevant, but all caps in this amp are Nichicon, not Suzuki.

Current production Nichicon electrolytic caps. are excellent. Another poster thought the signal caps. are Suzuki. The long term survival of the "iron" suggests replacing Japanese "oilers" with their Russian counterparts. While the Soviet regime crapped all over the citizenry, it did take pretty darned good care of its military.

All this blabber over capacitors!

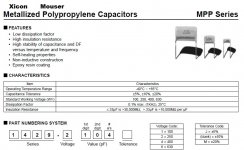

Listen, at the service shop, I've done hoardes of re-capping of customer's equipment over the decades, using Xicon's.

Never an issue with my servicing, never any complaints.

Gotten a Five Star Review rating as well.

Just get to Mouser's website, order the caps, fix that amp up and enjoy it for decades.

Listen, at the service shop, I've done hoardes of re-capping of customer's equipment over the decades, using Xicon's.

Never an issue with my servicing, never any complaints.

Gotten a Five Star Review rating as well.

Just get to Mouser's website, order the caps, fix that amp up and enjoy it for decades.

Attachments

I already ordered caps before I got the amp. So I'll have an assortment of MKP and C0G.

I don't feel knowledgeable enough to have a strong opinion on whether the capacitor type has anything to say, but I do want to listen to those with more experience than me. Aesthetics is also an important factor. The capacitors must look good where they are, and be of an appropriate color/style.

I don't feel knowledgeable enough to have a strong opinion on whether the capacitor type has anything to say, but I do want to listen to those with more experience than me. Aesthetics is also an important factor. The capacitors must look good where they are, and be of an appropriate color/style.

C0G (NP0) dielectric parts are the only ceramic stuff acceptable in the signal path.

MKP stuff is not bad, but it's also not very good. You may find what you receive has radial leads, instead of the axial leads on the OEM parts. Soviet surplus K40 PIOs have axial leads and a metal sleeve, which may or may not be painted. Look here for some possibilities. If the brown paint on the 400 WVDC parts is acceptable, get those. Otherwise, get the 630 WVDC stuff.

MKP stuff is not bad, but it's also not very good. You may find what you receive has radial leads, instead of the axial leads on the OEM parts. Soviet surplus K40 PIOs have axial leads and a metal sleeve, which may or may not be painted. Look here for some possibilities. If the brown paint on the 400 WVDC parts is acceptable, get those. Otherwise, get the 630 WVDC stuff.

Yes, I typically buy axial when I can (and it is needed). High ripple current for reservoir caps, extended lifetime etc. I typically use a couple of hours to pick suitable components, match specs, read datasheets etc. Which is why I was so bummed when you said "no MKP please"..😱

I already ordered caps before I got the amp. So I'll have an assortment of MKP and C0G.

I don't feel knowledgeable enough to have a strong opinion on whether the capacitor type has anything to say, but I do want to listen to those with more experience than me. Aesthetics is also an important factor. The capacitors must look good where they are, and be of an appropriate color/style.

Very well, then use the caps ordered.

The hype over how caps "sound" is overplayed IMO, particularly with a common thing like that Lafayette amp.

However, these parts are underchassis components, AND enclosed in a case, so concerning yourself with "aesthetics" and the color of them is a bit obsessive/OCD, since these components are never going to be seen, nor need to be admired.

It pays to be reasonable, in my view of things.

Sure. I wouldn't rather die than have nice caps. But just as I enjoy neat wiring and uniform solder joints, I also like my components to look the part. Vintage Hi-Fi is like food and wine, after all. Love is an important ingredient 🙂

I just don't get why a capacitor with an inferior dielectric like paper should »sound better« than one that involves one of the best known dielectrics - if a capacitor does sound at all. I severly suppose that those PIO capacitors should be named more precisely PISO - paper in snake oil.

Best regrds!

Best regrds!

The paper is a carrier for the oil, which is doing the "heavy lifting". FWIW, it's interesting that a number of folks claim that caps. containing PCBs "sound great". I'm not inclined to have anything to do with that sort of toxic hazard.

Going back to a previous question - these PIO caps, do they start leaking gradually, or suddenly? If grid voltage is within spec, is it risky to use the amp until I get parts and time?

I would really like to use it a bit to get to know the sound, and then do changes to see if I hear any difference.

I would really like to use it a bit to get to know the sound, and then do changes to see if I hear any difference.

They do need to be replaced.

The paper in oil capacitors that are in the amp sounded very good as paper in oil caps do when used in the correct places. The problem is, these caps are now about 60 years old so they usually develop leakage from moisture getting in because they are not hermetically sealed as paper in oil caps should be if you want unlimited life.When you have caps that develop leakage,they become a resistor because they are passing DC voltage from the prior stage to the grid of the output tubes.This causes the tubes so draw excessive current and can damage the output transformers if it goes on for extended periods of time along with the output tubes. Also change the caps in the preamp stage and there you can go with a film and foil like a 716p orange drop.

What you want to replace those caps with are the Russian K40Y-9 which are hermetically sealed paper in oil caps and they will also maintain the amp's signature sound which is very good. There aren't that many coupling caps in there to change from what I see. I have receiver that had these caps as well as several Sansui 1000a receivers. Go on Ebay or contact Jim McSHane and he will have what you need.

I picked up this absolutely pristine Lafayette LA-224B integrated amplifier. It's a 15W push pull from the mid-60s.

It's apparently in fully working order, but I assume the electrolytics need replacement. However, what about the non-polarized caps? They don't look like the old style paper caps -- can I leave them be?

I would prefer to disturb the innards as little as possible, but I don't want to blow my OT either..

Aw, just look at that interior! Isn't is beautiful? Even my wife loved it! 🙂

The paper in oil capacitors that are in the amp sounded very good as paper in oil caps do when used in the correct places. The problem is, these caps are now about 60 years old so they usually develop leakage from moisture getting in because they are not hermetically sealed as paper in oil caps should be if you want unlimited life.When you have caps that develop leakage,they become a resistor because they are passing DC voltage from the prior stage to the grid of the output tubes.This causes the tubes so draw excessive current and can damage the output transformers if it goes on for extended periods of time along with the output tubes. Also change the caps in the preamp stage and there you can go with a film and foil like a 716p orange drop.

What you want to replace those caps with are the Russian K40Y-9 which are hermetically sealed paper in oil caps and they will also maintain the amp's signature sound which is very good. There aren't that many coupling caps in there to change from what I see. I have receiver that had these caps as well as several Sansui 1000a receivers. Go on Ebay or contact Jim McSHane and he will have what you need.

Last edited:

Thanks, michaelsamra! If moisture creeping in is the main culprit here, then I assume the storage conditions has a lot to say? Is it possible to "dry it out" again? Would have made for a nice experiment, at least..

I'll order Russian caps, and luckily for me I'm awaiting a megger in the mail any time now (crossing fingers it didn't have to pass the Suez Canal). If they desolder easily, and if you're interested, I'll measure the leakage and post it here. I've done this before with electrolytics, and although it's tedious, it can be strangely rewarding. At least if someone else appreciates the numbers as well.. :0

I'll order Russian caps, and luckily for me I'm awaiting a megger in the mail any time now (crossing fingers it didn't have to pass the Suez Canal). If they desolder easily, and if you're interested, I'll measure the leakage and post it here. I've done this before with electrolytics, and although it's tedious, it can be strangely rewarding. At least if someone else appreciates the numbers as well.. :0

I just don't get why a capacitor with an inferior dielectric like paper should »sound better« than one that involves one of the best known dielectrics - if a capacitor does sound at all. I severly suppose that those PIO capacitors should be named more precisely PISO - paper in snake oil.

Best regrds!

In trying to teach myself how this stuff works, I've relied heavily on "Designing high fidelity tube preamps" by Merlin Blencowe. He has several graphs showing differences in distortion based on capacitor type/brand and voltage. There is an excerpt here: http://www.valvewizard.co.uk/DHFVP_sample.pdf

It's a good book that continues to help me a lot. I don't see any reason for him to be a quack. Granted, the differences in distortion levels are low, but they add up. He discussed several types of distortion in great detail, it's fascinating reading. I'm only a hobbyist, so I can't judge the book's merit, but it's the only authoritative source I have (internet excluded 🙂)

Didn't you notice that he's been talking about filters? We're talking about coupling capacitors in this discussion. Quite a different pair of shoes!

Best regards!

Best regards!

In that example, yes. But what is the difference? The capacitor passes a signal, and adds distortion. I'm not saying there isn't a difference, I just don't understand what it should be.

The difference is other than in filter applications and well above the LF roll off there's no significant AC voltage drop over a coupling capacitor.

Best regards!

Best regards!

- Home

- Amplifiers

- Tubes / Valves

- Old tube amp - do non-electrolytics need replacement?