Christer,

This seemingly random weaving of traces is most likely for prop. delays.

But, it may also be some twisted process to accomplish "thieving". Thieving is a process where large areas, void of copper, are prevented on a circuit board. The conductors next to a bare area can be plated excessively. By adding extra traces to "thieve" the excess, and ensuring an even distribution of copper on a board, more consistant plating thickness can be achieved.

Thieving is usually done in copper floods and it usually a checkerboard or something of similar copper desity to real traces on the board.

😉

This seemingly random weaving of traces is most likely for prop. delays.

But, it may also be some twisted process to accomplish "thieving". Thieving is a process where large areas, void of copper, are prevented on a circuit board. The conductors next to a bare area can be plated excessively. By adding extra traces to "thieve" the excess, and ensuring an even distribution of copper on a board, more consistant plating thickness can be achieved.

Thieving is usually done in copper floods and it usually a checkerboard or something of similar copper desity to real traces on the board.

😉

I think the t shirt printing stuff deposits the entire backing film onto the cloth when ironed on, I don't think it would transfer just the traces. I use the glossy paper toner transfer in a laser, and it works well for me.

pinkmouse said:If you're careful, you can even do a silkscreen:

I have been thinking about that, but haven't tried it. Waiting for somebody to start selling white toner. 🙂

Paper toner transfer

Hi

Since more than two years ago I'm using picture paper from

Staples #471861 with great success. After you copy your layout

on this paper on a laser jet printer (also at Staples, $.07 each

copy) you can iron it on the copper making sure the printing on

the copper is secure.

The only minor problem with this method is you have to be very careful taking the paper out under warm water not rubbing hard

and being patient. After your'e done taking the paper out the

traces show a garyish color, don't worry about it, it will stay on

the copper after the etching is done.

It's a great method that I'm using after a fellow who has a site

on the net showing how it's done (can't remember the URL).

I use to have this same problem as you guys but since then

it's just a matter of getting a good copy of a laser jet printer

on this particular paper.

I hope this helped someone, especially the ones that don't use

the photographic method.

Hi

Since more than two years ago I'm using picture paper from

Staples #471861 with great success. After you copy your layout

on this paper on a laser jet printer (also at Staples, $.07 each

copy) you can iron it on the copper making sure the printing on

the copper is secure.

The only minor problem with this method is you have to be very careful taking the paper out under warm water not rubbing hard

and being patient. After your'e done taking the paper out the

traces show a garyish color, don't worry about it, it will stay on

the copper after the etching is done.

It's a great method that I'm using after a fellow who has a site

on the net showing how it's done (can't remember the URL).

I use to have this same problem as you guys but since then

it's just a matter of getting a good copy of a laser jet printer

on this particular paper.

I hope this helped someone, especially the ones that don't use

the photographic method.

Jmateus,

Just to avoid confusion for people following your advice, maybe you should make clear if you mean a laser printer or an ink jet printer. I don't think there is any such thing as a laser jet printer (although there might be som brand that uses such a name on their printers to confuse people).

Just to avoid confusion for people following your advice, maybe you should make clear if you mean a laser printer or an ink jet printer. I don't think there is any such thing as a laser jet printer (although there might be som brand that uses such a name on their printers to confuse people).

Correction

Christer

Your'e perfectly right. A slip of the tongue of mine.

I meant to say Laser printer, jet printer doesn't work in this

process, not that I haven't tried, but doesn't work.

Thanks

Christer

Your'e perfectly right. A slip of the tongue of mine.

I meant to say Laser printer, jet printer doesn't work in this

process, not that I haven't tried, but doesn't work.

Thanks

The reason why it works with lasers only is, that toner contains a lot of granulated plastic, that's what sticks to the copper when heated.

I read some place, (and tried the tip with great result), that some of the papers we get with advertising, the real glossy ones, are fine too. I don't know what it's called in English, but where i live we get tons every week in the mailbox.

I read some place, (and tried the tip with great result), that some of the papers we get with advertising, the real glossy ones, are fine too. I don't know what it's called in English, but where i live we get tons every week in the mailbox.

Hi jmateus,

It's finally listed in our Staples up here. I looked for it earlier and they didn't know anything about it. So I'll try and pick some up - thanks!

Of course you know I'll print off a Symasym or more! 😉

-Chris

It's finally listed in our Staples up here. I looked for it earlier and they didn't know anything about it. So I'll try and pick some up - thanks!

Of course you know I'll print off a Symasym or more! 😉

-Chris

Guys,

I wonder if... Kapton film could be used here in place of the ultimate paper?

Could it take the temp of the fuser?

Wondering because it is a noble material... the toner would probably not adhere well. Maybe this sheet of material could be reusable?

I also read somewhere that guys run their sheet through the printer twice to get an extra heavy build of toner. I tried with with just plain paper... you would be surprised to see how well the old HP registrates the paper.

I wonder if... Kapton film could be used here in place of the ultimate paper?

Could it take the temp of the fuser?

Wondering because it is a noble material... the toner would probably not adhere well. Maybe this sheet of material could be reusable?

I also read somewhere that guys run their sheet through the printer twice to get an extra heavy build of toner. I tried with with just plain paper... you would be surprised to see how well the old HP registrates the paper.

Hi poobah,

Running the sheet through twice may make a mess on the drum or fuser.

I was able to pick up the photo paper, picture paper from

Staples #471861. I may not get to play with it for a while. I'll try the T-shirt transfer stuff for faceplates or something. I bought an ink jet while I was there. HP Deskjet #3910 for $40 CDN. Darn thing is USB 😡 , I like parallel jobs. That's 'cause I use print servers to get them away from my desk.

-Chris

Running the sheet through twice may make a mess on the drum or fuser.

I was able to pick up the photo paper, picture paper from

Staples #471861. I may not get to play with it for a while. I'll try the T-shirt transfer stuff for faceplates or something. I bought an ink jet while I was there. HP Deskjet #3910 for $40 CDN. Darn thing is USB 😡 , I like parallel jobs. That's 'cause I use print servers to get them away from my desk.

-Chris

Yeah... same deal here with the print servers...

I made sure the test paper was good and cold before I ran it through the second time... drum was just fine.

Just some thoughts...

I made sure the test paper was good and cold before I ran it through the second time... drum was just fine.

Just some thoughts...

I've never had any need to run it through twice. Just make sure the image is 2 bit, and crank up the contrast.

There is a yahoo group dealing with toner transfer, Homebrew PCBs .

Their database lists various paper and the results

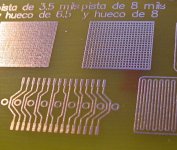

Attached is a pic of one of the groups results for TT.

Regards

James

Their database lists various paper and the results

Attached is a pic of one of the groups results for TT.

Regards

James

Attachments

Don't bother; it will not work. The entire sheet will transfer from the backing to the PCB, leaving the entire PCB coated. Some of it will be clear, some of it will be dyed black by the ink, but all of it will be useless.I think I'll buy an inkjet on sale for this to try.

As for toner transfer, I have had luck using ordinary overhead transparency sheets (the laser printer kind!). It is very easy and avoids the messing scrubbing step that is required with inket paper. You just iron on, let cool, and peel off. The toner sticks to the copper instead of the plastic sheet. YMMV.

macboy said:

As for toner transfer, I have had luck using ordinary overhead transparency sheets (the laser printer kind!). It is very easy and avoids the messing scrubbing step that is required with inket paper. You just iron on, let cool, and peel off. The toner sticks to the copper instead of the plastic sheet. YMMV.

I have thought about trying that but has been afraid it won't cope with the ironing since it is plastic. On the other hand, maybe it gets even hotter in the printer? Theay are after all made for laser printers.

I will test it the next time I make a board. It would be a lot simpler if not having to soak the board and remove the paper.

Hi macboy,

I tried using overhead transparency sheets for laser printers. I didn't get full dark patterns, so I gave up.

Since I now have both kinds, I can give them both a shot.

Now I just have to buy an iron. There is no way my wife will let me use hers! Can't say I blame her either.

-Chris

I tried using overhead transparency sheets for laser printers. I didn't get full dark patterns, so I gave up.

Since I now have both kinds, I can give them both a shot.

Now I just have to buy an iron. There is no way my wife will let me use hers! Can't say I blame her either.

-Chris

anatech said:

Now I just have to buy an iron. There is no way my wife will let me use hers! Can't say I blame her either.

-Chris

I found one in perfect condition at a second hand shop, at what would be same as 4 Canadian $. I really felt like a big spender 😀

- Status

- Not open for further replies.

- Home

- Design & Build

- Parts

- old pcb method, vintage pcb, fr4, bakelite