Going through WinISD they give you options for port dimensions, I am thinking of a rectangular port about a port 10.5" wide and .85" high. This makes the vent length fine, according to WinISD. I usually see round ports and have not seen a very narrow port, Does anyone KNOW this will work fine or know it WILL fail?

It'll be somewhere in between working and failing, some prototyping may be required.

Generally, for slot ports we don't want to make them too wide & skinny, as that significantly increases the total surface area of the inside walls of the port, increasing friction and IIRC increasing the risk of turbulence.

One rule of thumb I've seen is to keep the width:height ratio no higher than 9:1 to avoid the risk of this being a problem - your proposal is 12.3:1, so may not work as well as hoped. (Disclaimer, I haven't tested this myself, so I don't know how critical it is.)

If a slot port is built in against a wall of the cabinet, as many are, we also need to adjust the port length - this is because 3 of the 4 walls of the port are now much longer than the 4th - the good news is this means a shorter 4th wall is used, taking up less space in the box.

The bad news is that simple modelling programs like WinISD don't calculate this, we need to do a bit of number crunching ourselves.

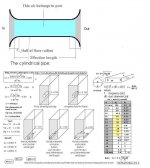

The attached graphic, provided by Bjorno, shows a couple of the manual formulae that can be used for this and provides the alternative "End Correction Factor" values to use to calculate the new, shorter port length.

HTH,

David.

Generally, for slot ports we don't want to make them too wide & skinny, as that significantly increases the total surface area of the inside walls of the port, increasing friction and IIRC increasing the risk of turbulence.

One rule of thumb I've seen is to keep the width:height ratio no higher than 9:1 to avoid the risk of this being a problem - your proposal is 12.3:1, so may not work as well as hoped. (Disclaimer, I haven't tested this myself, so I don't know how critical it is.)

If a slot port is built in against a wall of the cabinet, as many are, we also need to adjust the port length - this is because 3 of the 4 walls of the port are now much longer than the 4th - the good news is this means a shorter 4th wall is used, taking up less space in the box.

The bad news is that simple modelling programs like WinISD don't calculate this, we need to do a bit of number crunching ourselves.

The attached graphic, provided by Bjorno, shows a couple of the manual formulae that can be used for this and provides the alternative "End Correction Factor" values to use to calculate the new, shorter port length.

HTH,

David.

Attachments

I've build many and much more narrow ports than that, I think the narrowest one was 15" by 0.6" for a 6" driver. It could be coincidence but this one sounded better without a high pass filter.

The main point is to keep the port velocity below ~22 m/sec, simulated with the maximum power you intend to drive it with.

The main point is to keep the port velocity below ~22 m/sec, simulated with the maximum power you intend to drive it with.

Oh great to know! I’ll look for that in Win ISDI've build many and much more narrow ports than that, I think the narrowest one was 15" by 0.6" for a 6" driver. It could be coincidence but this one sounded better without a high pass filter.

The main point is to keep the port velocity below ~22 m/sec, simulated with the maximum power you intend to drive it with.

OK thanks I’ll check that out! The whole thing about this port designers that will be outside of the box because my boxes gonna be in a large enclosure!It'll be somewhere in between working and failing, some prototyping may be required.

Generally, for slot ports we don't want to make them too wide & skinny, as that significantly increases the total surface area of the inside walls of the port, increasing friction and IIRC increasing the risk of turbulence.

One rule of thumb I've seen is to keep the width:height ratio no higher than 9:1 to avoid the risk of this being a problem - your proposal is 12.3:1, so may not work as well as hoped. (Disclaimer, I haven't tested this myself, so I don't know how critical it is.)

If a slot port is built in against a wall of the cabinet, as many are, we also need to adjust the port length - this is because 3 of the 4 walls of the port are now much longer than the 4th - the good news is this means a shorter 4th wall is used, taking up less space in the box.

The bad news is that simple modelling programs like WinISD don't calculate this, we need to do a bit of number crunching ourselves.

The attached graphic, provided by Bjorno, shows a couple of the manual formulae that can be used for this and provides the alternative "End Correction Factor" values to use to calculate the new, shorter port length.

HTH,

David.

Anything other than a properly sized and flared round port remains a compromise in one way or another, or many! Slots and triangular ports are amongst the worst options - don't use them unless you are ok with reducing the output and increasing distortion in your build.

I would look at the attachment in post #2Going through WinISD they give you options for port dimensions, I am thinking of a rectangular port about a port 10.5" wide and .85" high. This makes the vent length fine, according to WinISD. I usually see round ports and have not seen a very narrow port, Does anyone KNOW this will work fine or know it WILL fail?

WinISD only has error correction up to .850 for 2 flanged ends

assuming your building a slot port that shares 3 wall of the cabinet you need a end correction of 2.22

which WinISD wont calculate.

Also the efficiency of a slot port is lower

So programs that actually calculate port length with entered Qp values

and also have adjustable end factor correction

So in a nutshell sharing walls, and low efficiency usually means a much shorter port.

WinISD number would make the port too long, unless it does not share walls

WinISD can calculate a proper square port, but it cannot share any walls.

As far as ratio have seen 1:8 recommended value

technically it can be anything as long as the Velocity is OK

As the ratio increases surface area can increase so technically

you would lower Qp value. And use a program which adjust port length

with Qp or Port Losses.

Ideal port has Qp of 100, with more surface area or extreme ratios

you would lower that to 60 to 80

Correction factor of 2.22 would shorten the port length

and a Qp of around 60 to 70 would also slightly shorten the length

Something i have explicitly explored and now much prefer.One rule of thumb I've seen is to keep the width:height ratio no higher than 9:1 to avoid the risk of this being a problem

A longish high aspect ratio slot vent adds R to the vent. Literally hundreds and hundreds have been built and people are happy with them.

The sims you do need to be extrapolated to estimate the end result, they will only go as low as they go, but the bottom tends toward nuanced and well defined, with a higher tolerance to dynamic changes in T/S parameters.

dave

...you are ok with reducing the output and increasing distortion in your build.

High ratio slot vents certainly decrease output, the box is pushed towards aperiodic, but increased distrotion is the opposite of the sonic result.

dave

Can you elaborate a little on this please - 'prefer' in what respects, audible and measured?Something i have explicitly explored and now much prefer.

Audiable. Measurements have confirmed the extention interpolation.

It comes from a cross bewteen the brillant side wall design of an Onken, and the vent tricks you do to make a typical, but poorly tuned, BR sound better.

Quality over quantity.

dave

It comes from a cross bewteen the brillant side wall design of an Onken, and the vent tricks you do to make a typical, but poorly tuned, BR sound better.

Quality over quantity.

dave

Subwoofer and fullrange / mid driver application have very different issues / requirements and one should consider what works for each. What works for the other most probably is not optimal for the other just because the other needs pristine midrange performance while the other does not.

Subwoofer and fullrange / mid driver application have very different issues / requirements and one should consider what works for each

Indeed. If i am building a sub i am looking for a woofer that works well sealed. With FRs it is almost always the case that you need to somehow add a helpful hole to the box to help extend the bottom downward.

dave

- Home

- Loudspeakers

- Subwoofers

- Oddly shaped port sound?