I believe that making beams similar to those burned in this unfortunate sinister can be done using the laminated system.

On one occasion in the shipyard we had to repair a Brazilian boat (Orione was called) that participated in the classic regatta Buenos Aires - Rio de Janeiro.

It was thrown by the storm (known here as sudestada, typical of the Rio de la Plata) on a breakwater and almost destroyed the entire port side (left side of the boat looking from stern to bow, for those who do not know the jargon maritime).

The frames, which give the shape and strength to the helmet, were made of thin sheets glued on a mold.

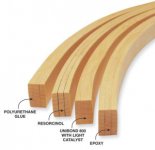

This construction system was different from the one we used here, (cutting a thick hardwood board with the desired shape) so we had to learn the system from them and put it into practice. A much higher resistance is achieved in this way than it would have a single piece, which has a tendency to break. The same construction system is the one used for the masts, they are four glued and entangled panels, hollow in the middle, it is not a solid piece. The aluminum came to partially replace this system in the masts, much more economical, but many customers refused to see their boat with an "ordinary" metal mast.

So I do not see the drawback of using this system to make new beams and rebuild the wooden structure of the roof of the cathedral, also today there are even paintings that mimic the grain of wood. (For those who are too demanding and would not want to apply a uniform color paint, I do not know if it was oak "natural" or with some treatment of that time, such as vegetable oils, etc. (think of "special" oil that Tannoy used in his cabinets )

On one occasion in the shipyard we had to repair a Brazilian boat (Orione was called) that participated in the classic regatta Buenos Aires - Rio de Janeiro.

It was thrown by the storm (known here as sudestada, typical of the Rio de la Plata) on a breakwater and almost destroyed the entire port side (left side of the boat looking from stern to bow, for those who do not know the jargon maritime).

The frames, which give the shape and strength to the helmet, were made of thin sheets glued on a mold.

This construction system was different from the one we used here, (cutting a thick hardwood board with the desired shape) so we had to learn the system from them and put it into practice. A much higher resistance is achieved in this way than it would have a single piece, which has a tendency to break. The same construction system is the one used for the masts, they are four glued and entangled panels, hollow in the middle, it is not a solid piece. The aluminum came to partially replace this system in the masts, much more economical, but many customers refused to see their boat with an "ordinary" metal mast.

So I do not see the drawback of using this system to make new beams and rebuild the wooden structure of the roof of the cathedral, also today there are even paintings that mimic the grain of wood. (For those who are too demanding and would not want to apply a uniform color paint, I do not know if it was oak "natural" or with some treatment of that time, such as vegetable oils, etc. (think of "special" oil that Tannoy used in his cabinets )

Attachments

Last edited:

we had to repair a Brazilian boat that participated in the classic regatta Buenos Aires - Rio de Janeiro.

Orion III

(German Frers design, 41' loa, 1976 build)

Attachments

Last edited:

Here in Norfolk where I am resident, they planted about 20 years ago a whole lot of oak trees that they called ‘cathedral oaks’ for the potential repair of Ely, Peterborough and Norwich cathedrals.

They will only be ready for use in 2300 . . . Now that’s forward planning.

I went on a tour of Ely cathedral (about 30 miles from here) with my wife about a year ago - fascinating place. My wife has a friend who is a stonemason and works exclusively on Peterborough cathedral - he’s offered to give us a private tour there as well.

(Interestingly, the tour guide at Ely was an American guy from Oregon who had a lifelong passion for cathedrals and being the guide at Ely was his dream job. A seriously knowledgeable individual).

They will only be ready for use in 2300 . . . Now that’s forward planning.

I went on a tour of Ely cathedral (about 30 miles from here) with my wife about a year ago - fascinating place. My wife has a friend who is a stonemason and works exclusively on Peterborough cathedral - he’s offered to give us a private tour there as well.

(Interestingly, the tour guide at Ely was an American guy from Oregon who had a lifelong passion for cathedrals and being the guide at Ely was his dream job. A seriously knowledgeable individual).

In places where wood is visible or even a main design feature, yes, they do spend extra for wood. In the case of Notre Dame, the visible surfaces were tiled ceiling and lead clad roof. Wood beams and rafters were in concealed area known as attic, only visible to maintenance personnel or a hunchback (if there is one).I believe that making beams similar to those burned in this unfortunate sinister can be done using the laminated system.

Jacco :

Wow !

Internet is incredible!

It was a few years before, it was the Orione II, now I remember it better, thank you!

I do not remember if it was also designed by Germán Frers ....

Wow !

Internet is incredible!

It was a few years before, it was the Orione II, now I remember it better, thank you!

I do not remember if it was also designed by Germán Frers ....

In places where wood is visible or even a main design feature, yes, they do spend extra for wood. In the case of Notre Dame, the visible surfaces were tiled ceiling and lead clad roof. Wood beams and rafters were in concealed area known as attic, only visible to maintenance personnel or a hunchback (if there is one).

I did not know Notre Dame, I thought the woods were in sight, thanks.

I suppose then that it will not be necessary to look for oak trees in the few remaining virgin forests ...

And if we do not reverse the climate change urgently, humanity will have no return. And if the Amazon rainforest, the lung of the world, continues to shrink, too.

I'm watching the series Our Planet, on Netflix, there are five chapters, I'm going for the second and I'm between amazed and scared ..

Watch this thread instead.And if we do not reverse the climate change urgently, humanity will have no return. And if the Amazon rainforest, the lung of the world, continues to shrink, too.

I'm watching the series Our Planet, on Netflix, there are five chapters, I'm going for the second and I'm between amazed and scared ..

Well, not much new to see there after being closed over 5 months ago.

As was noted before, the forests of oak that were harvested starting over 800yr ago, and the construction techniques - including some of the earliest examples of such extensive use of flying buttresses for external stabilization of the very tall and relatively very thin stone walls thereby allowing the awe-inspiring internal spaces- were the embodiment of state of the art of the era. And those stained glass windows - mon Dieu.

Why should not any effort to rebuild the damage, in whatever form for which consensus can be found - particularly if motivated in part by a perhaps politically arbitrary dated of 2024 (hmmm, what’s on the agenda for Paris that year?) - use current state of the art design processes and proven materials/ construction methods?

As was noted before, the forests of oak that were harvested starting over 800yr ago, and the construction techniques - including some of the earliest examples of such extensive use of flying buttresses for external stabilization of the very tall and relatively very thin stone walls thereby allowing the awe-inspiring internal spaces- were the embodiment of state of the art of the era. And those stained glass windows - mon Dieu.

Why should not any effort to rebuild the damage, in whatever form for which consensus can be found - particularly if motivated in part by a perhaps politically arbitrary dated of 2024 (hmmm, what’s on the agenda for Paris that year?) - use current state of the art design processes and proven materials/ construction methods?

The thing that I keep coming back to in this tragedy is that it's likely to have been caused by a simple human error, maybe even that of a single human.

I work in churches all the time - my standard joke (with friends, not clients) is that I'm in church every day of the week except Sunday. None of my churches are within an order of magnitude of the significance of Notre Dame (or even 2), but still - I don't know how I would live with such a mistake.

I work in churches all the time - my standard joke (with friends, not clients) is that I'm in church every day of the week except Sunday. None of my churches are within an order of magnitude of the significance of Notre Dame (or even 2), but still - I don't know how I would live with such a mistake.

I could not find the firemen yet, I must explore more ...🙂

Attachments

How freeze is managed on winter in such cold old monuments ? Is it possible to put large diameter tubes running from the river to such roofs? .....

Fire pipes are often "dry". When fire happens, then you put water in the bottom and it comes out the top. Flowing water doesn't freeze. (Not in Maine, and surely not in Paris; probably different where the only water is barely above freezing.) We all-the-time pump 50 deg F (10C) ground water through fire-hoses in 10F/-10C weather.

When done with water, you drain the pipe.

In tall skyscrapers, any water to the top requires really heavy-wall pipes or intermediate pumps. The top of NYC is about 30 atmospheres of water-column, 450 psi, which is more than standard steel pipe is good for. Pumps at intermediate floors could reduce the load on the pipes, and this is done for drinking water, but pumps high in the building in a fire may fail. Ground level pumps for this pressure need more horsepower and bigger/more impeller wheels.

In that regard: fire pump engines are "special". An engine in an oil-field may run non-stop for a decade, 100,000 hours, and must have a low rating to last that long without major overhaul. Truck engines may be rated at a higher power for 10,000 hours because they need to be peppy and can usually drive to a repair facility. Fire pump engines have higher power ratings (on the same block) but rated 100 hours! If the fire is not out in 10 hours, it is probably a total loss, and you want a MAXIMUM of power and water in those few hours. (The other 90 hours because you need to run the engine monthly and if no fire happens that may be hundreds of short runs.)

I have been in data centers full of servers, they use Halon (I think) systems, instead of water to prevent destroying everything. I don't know if that could be applied here though?

Halon is only useable in enclosed spaced and then only after you get the people out first as it would kill them.

Jan

Jan

Well, not much new to see there after being closed over 5 months ago.

In effect, the authority decided that there can be no further discussion on that subject.

I have my position taken for a long time and it is indeclinable, so I will not bother reading the skeptics.... 🙄

Most fires that occur during repairs/restorations are directly due to oversights by workers. I am afraid this is one of those occasions.

I feel sorry for the poor schlum who made the mistake that set this in motion.

I feel sorry for the poor schlum who made the mistake that set this in motion.

In effect, the authority decided that there can be no further discussion on that subject.

I have my position taken for a long time and it is indeclinable, so I will not bother reading the skeptics.... 🙄

It being one of the types of subjects that have a pattern of devolving to the same nadir, it’s surprising it wasn’t shut down at the outset.

I did not know that. You are free to take the position you want, at least in free countries.In effect, the authority decided that there can be no further discussion on that subject.

I have my position taken for a long time and it is indeclinable, so I will not bother reading the skeptics.... 🙄

...they use Halon...

Halon production has been banned since the early 1990s. There's enough existing stock, at HIGH price, to do high-value server-rooms. It has to be a closed space, you have to get all the people out before you displace all the air in the room.... so good for a server room, very bad for a large and public space which is probably drafty.

My Dad used to work for Kidde, the fire extinguishing people. Back in the 70s, I think, Halon was the new great thing. They did some tests to see if sites could be evacuated fast enough to allow use of Halon. After a couple of broken limbs they gave up on the idea of using it in anything but unmanned locations or for the military....

- Home

- Member Areas

- The Lounge

- Notre Dame cathedral